---- ÆØerá Z3zzegzée. Vzerzega2ZY.Zazee. June 16, Zee/ErzezØrzs 2,286, Sheets-Sheet 2 D G O D D D OD

|

|

|

- Henry Bishop

- 5 years ago

- Views:

Transcription

1

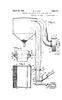

2 June 16, M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, Sheets-Sheet 2 D G O D D D OD C Q 0 ] O O G B C D E DO O D C D O G D G D D O DO OD O C O O. O O O O O O A 0 C ( ).g. --Zee/ErzezØrzs ÆØerá Z3zzegzée Vzerzega2ZY.Zazee ----

3 Patented June 16, 1942 M UNITED STATES PATENT OFFICE METHOD AND APPARATUS FOR PROCEss NG POTETAATTORES Mark Pringle, Amsterdam, and Herman F. Lamae, Albany, N. Y., assignors of thirty-three and one-thaird per cent to George A. Brace Application March 5, 1937, Seria No. 29,58 20 Claims. (C ) This invention relates to improvements in po- A further object of the invention is to provide tato processing apparatus, food products having an apparatus for a method of processing potat0e:s a primary potato base, and certain improved So that the entire edible portion is utilized. methods of manufacturing such products in a Other and further objects of the invention Will novel manner to be hereinafter more fully de- 5 become apparent from a consideration of the fol scribed. llowing detailed description thereof, and Of One A particularly desirable type of potato process- form of apparatus which may be employed to ing is One in which thin Slice.S of the raw product practice the invention as illustrated in the ac are dehydrated and cooked in a hot liquid both companying drawings in which: to produce a crisp chip which has many desir- 0 Figure li is a side elevational yiew, partly in able characteristics and uses as a food product. Section, of one form of apparatus for carrying However, potato chips as heretofore made have Out the objects Of the invention; possessedi Certain undesirable properties, and it Figure 2 is a Side elevational view, partly in is the object of this invention to overcome these section, on line 2-2 of Figure 3 showing the ap-. difficulties and to provide a highly superior prod- 5 paratus for further treating the potatoes after UCt. the initial cooking process; For example, potato chip products now avail- Figure 3 is a top plan View, partly in Section, able are markedly non-uniform in size, shape, on line 3-3 of Figure 1; and, Crispness and in other properties. Moreover, po- Figure 4 is a diagrammatic representation of tato chips made according to known methods 20 the various steps taken in processing the potatoes are exceedingly difficult to keep crisp and whole-, given in the preferred order of performing the some, for the period of time normally required S86. : for marketing. This is particularly true in warm A more complete understanding of the inven weather. This is ascribable to various causes tion and the manner in which the same isprac chief among which are the stated non-uniform- 25 ticed can be had from a detailed description of ity of the chips in size and shape rendering, prop- the drawings. In Figure 1, f 0 represents a suit er packaging impossible, and inferior methods of able container or cooking vat for the cooking processing the raw potato. fluid f i such as an oil or fat, a vegetable oil like One Of the objects of this invention is to pro- corn oil being preferable, while 2 indicates an vide an apparatus whereby potatoes, as they come 30 other container for a steeping fluid 13. Con from the field. may be passed through a continu- tinuous conveyor belts i 4, 5 and 6 are arranged ous process of novel character to produce a po- on a series of roller supports, as clearly shown in tato chip product having new and highly advan- Figure 1, which are so arranged and supported. tageous properties. that the same pass first through the steeping It is also an object of the invention to provide 35 fluid in container 2, and then through the cook potato chips in wafer form the individual wafers ing fluid in container 0. being uniform in size, shape, color, and in all One of the important features of the invention other characteristics. pertains to the novel arrangement of conveyor Another object of the invention is to provide belts i 4, 5 and 6, which may be of any suitable a wafer which is substantially fiat, and which 40 flexible material such as wire mesh, perforated Will retain Such shape until consumed. Sheet - metal or fabric. At least two belts are Another object of the invention is to make a i. essential, and as many more may be used as food product in wafer form which can be readily. is found practicable. For purposes of illüstra marked With indicia of any desired character tion, three are shown in the present drawings. such as the identifying mark of the manufac- 45 Belt i 6 is the shortest of the three and is directly tirer. Y supported by rollers f7, 8, 19 and 20. Roller Still another important object of the invention 9 is an idler roll which cooperates with roll 9 is to provide a food product in wafer form of to keep a portion of belt 6 emersed in the steep such uniformity in size, weight and shape that ing fluid 3, while the floating shoe 22 functions it can be economically packaged in a very com- 50 to keep another portion of the belt emersed in pact manner so as to exclude any appreciable º cooking fluid. (Llanfity of air, moisture or other agencies tend- A second belt 5 passes over rollers i 7, 8, 23, ing to affect the crispness, wholesomeness, fresh- i 24, 20, 25, 26 and 27, and a part thereof is in ness, or other qualities possessed by the newly direct contact with belt 6. The third belt 4, in manufactured product. addition to being supported by rollers 7, 8,

4

5 M Such manner that very little air remains in the package. The Wrapper may be of such material as to exclude light, though this is not of im portance. It is thought that the manner in which the apparatus herein shown operates has been so fully described in the foregoing that it is un necessary to say anything further at this point. It will, of course, be understood that the appara tus which has just been described is merely illus trative of a preferred arrangement of the more essential elements for practicing the invention, and that many variations and modifications, thereof may be resorted to by those skilled in the art without departing from the scope of this invention. Although no source of power, as well as other necessary parts of the apparatus have been described, it will be understood that the various conveyors and other moving parts may be driven in any suitable manner, and that the other parts necessary in an operable device cam be supplied by any skilled mechanic. One of the preferred modes of carrying out the process in accordance with this invention is as follows: The various steps of the process arranged in a preferred manner are diagrammatically illus trated in Fig. 4. From this chart it will be seen that the potatoes are initially weighed and in spected, at which time inferior potatoes, as well as foreign bodies, are removed. If desired, the potatoes may then be graded into various sizes, or if the potatoes are fairly uniform, it will Only be necessary for the inspectors to cast aside the Small specimens. The inspected potatoes are next pared, prefer ably by machinery, of which there are many forms available on the market.. After a tlhorough washing the pared potatoes pass into a shaping machine which forms the potatoes into uniformly shaped sections of the same cross-sectional area, though, of course, the sections may be of dif ferent lengths, depending upon the size of the in dividual potatoes. This step is sometimes known as coring. At this point, the potato sections are separated from the shawings and slabs removed in the shaping or coring operation, and are passed through another rinsing stage. The shavings and slabs just referred to can be shapedi into strings and a variety of novelty forms in prepara tion for the cooking and treating process which is of the same character as that to be described hereinafter in connection with the potato sec tions. It will, therefore, be seen that our in vention contemplates and provides for the use of the entire edible portion of the potato. The sections are now inspected and the oppo site. ends of each section are squared. The Sec tions are now ready to be sliced and cooked, and are conveyed into the slicing machine magazines 3. As the sections are sliced the slices fall into the steeping fluid and onto the conveyor belts. If desired, each slice can be marked at this point with any desired form of indicia as hereinabove described. M A After the slices have been steeped sufficiently long to remove any free starch, they are removed from the steeping bath, drained, and immediately passed into the hot cooking fluid. It has been found that a superior product results if the tem perature of the cooking bath varies in different stages of the cooking operation, and that a very good product can be obtained by conveying the slices, first, through hot cooking fluid at a low temperature, and then through at least one stage 3 at a higher temperature. Any desired number of cooking stages operating at different tempera tures can be used by simply inserting the neces Sary partitions across the cooking vat. It is not important that these partitions be fluid tight, since different temperatures can be easily main tained by any means which retards thermo Syphonic circulation of the fluid. It must be remembered, of course, that from () the time the potatoes are sliced until they are finally cooked into a crisp wafer, it is important that the slices be restrained against curling, Warping, blistering or losing the shape given to them by the slicing apparatus, it being under stood that by slicing is meant the operation by Which the potato sections are formed into thin Subdivisions of similar size and shape. As the wafers emerge from the cooking vat, the cooking fluid is allowed to drain off and re turn to the vat. Any desired seasoning, such as salt, may now be applied to the wafers, it having been found that liquid salt in a water or an oil solution imparts a very fine favor to the wafers. From the seasoning operation the wafers pass between the toasting and post-heating grids which serve Several purposes. Among other things, these grids can be controlled to give a rich brown color to the wafers, to vaporize any remaining liquid or fat, to facilitate the thorough penetration of the seasoning material, and to give. additional crispness to the wafers. It will also be evident that the wafers will emerge from the toasting and post-heating operation thoroughly Cooked and dehydrated. The final treatment stage is one in which the Wafers are subjected to irradiations from a Spe cially designed ultra-violet light apparatus now available on the market, and which, in itself, forms no part of this invention. These 688 tions not only serve to kill any bacteria or other Similar bodies in the wafers, but also to so act upom the constituents that certain vitamins are developed in a manner not as yet fully under stood. " The wafers are now ready for packaging and to this end may be passed through an assorting device to arrange the wafers in compact form and im Such manner that as much air as possible can be excluded from the package. The wrap ping may be any suitable material, such as air tight transparent or opaque sheets. In this way, the wafers can be kept for long periods in their original crisp and wholesome condition. Too much importance cannot be attached to the final treating stages of our invention, since it is at this point that a part of the superior flavor, the appealing color, the additional food value, and the excellent preservative qualities are im parted to the wafers. V X ; : * It Will be understood that the foregoing, de Scription of the method of practicing our inven tion can be carried out in various other ways, and by apparatus other than that shown and i de scribed without departing from the?pirit of the invention or the scope of the annexed claims. We claim: 1. The process of making an edible food prod uct comprising passing slices of raw potatoes through a cooking bath while restraining the lat eral side portions thereof, against displacement whereby the resultant product is a substantially flat wafer. M M 2. The method of making potato - chips com prising passing slices of the raw product through a cooking bath and preventing, at least one side

6 4 of the slices from becoming displaced from the plane of the slice.» 3. The process of making potato chips which comprises dehydrating and cooking slices of raw potato while maintaining the slices substantially flat. 4. The method of processing potatoes compris ing preparing uniformly shaped sections of raw potato, slicing said sections into thin wafers, pricking openings into each wafer, removing free starch from the wafers, and passing the wafers through a hot cooking fluid without allowing the same to become distorted. 5. The method of processing potatoes compris ing forming uniformly shaped sections of potato from cleaned specimens of the raw product, slic ing the sections into thin wafers, shaping the residue from the formation of the sections into small portions, removing the free starch from all the pieces, passing the wafers through a cooking fluid without allowing the same to become dis torted, seasoning the wafers, and tightly packag ing and sealing the wafers. 6. The method of processing slices of raw por tato so that the same may be tightly Wrapped and sealed in a moisture resisting package con taining a minimum of air, comprising passing slices of raw potato of uniform size and shape through a hot body of cooking fluid while retain ing the slices fdat, removing excess cooking fluid, applying a seasoning material to the slices, sub jecting the slices to heat to obtain a desired color, to vaporize retained liquids, and to insure a more uniform permeation of the seasoning, and exposing the slices, to ultra-violet irradiation for the purposes described. 7. The process of making an edible food prod uct comprising forming similar shaped, thin walled pieces i of raw i potato and passing said pieces -through a cooking process while restrain ing the lateral side portions thereof against dis placement. 8. The method of processing raw - potatoes which includes slicing sections of raw potato of uniform cross-section, marking at least certain of the slices with indicia, and cooking the slices so as to form a crisp, dehydrated, substantially un distorted wafer in which said indicia is clearly legible. 9. Apparatus for processing raw potatoes in a continuous operation which includes means for slicing prepared sections of the raw product, con veyor means, including means for pricking indicia into the slices, means for conveying the slices through a steeping fluid and then through a cooking fluid, while retaining the slices in their original shape, treating means for seasoning the cooked slices and for driving off excess liquid re maining thereon, and means for subjecting the 'slices to ultra-violet irradiations. 10. The method of treating raw potatoes which comprises forming the major portion of a potato into one or more sections of uniform cross section, reducing - the minor portion to pieces having at least one dimension relatively small in comparison to other dimensions, reducing said sections to similar shaped, thin-walled pieces, and passing the pieces of both portions through a cooking bath while restraining at least those pieces from said major portion against distortion. 11. An º apparatus for making potato chips' conveyor means arranged to conduct raw.slices of potato into cooking relation to said hot fluid whereby said "slices are processed by said hot fluid, said means being constructed and arranged to prevent said i slices from becoming distorted while being processed and while cooling after the cooking process. 12. That method of heat treating a food prod uct of the type tending to become warped and deformed during treatment, which comprises preforming the raw product into a thin-walled wafer-like blank, passing said preformed blank through a heated cooking zone, and then through an unheated zone, and preventing said blanks from becoming distorted in åny substantial amount while being heat treated and cooled. 13. A food product comprising a thin-walled, dehydrated, cooked piece of potato, the walls of which have substantially the same shape and contour as before being dehydrated and cooked. 14. In combination, a cooking vat for holding a cooking fluid, means dividing said vat into a plurality of independent cooking - chambers, means for heating the cooking fluid in- said chambers to different temperatures, a conveyor including a plurality of flexible belts, means sup porting said conveyor for movement through said chambers of said vat, means holding said belts in closely spaced relation as the same pass through said chambers, and means for feeding thin-walled pieces of an uncooked edible between said belts for transport through the heated cooking fluid in said vat whereby Said pieces are held against distortion as the same are cooked. 15. The combination set forth in claim 14, characterized by the provision of means for draining - cooking fluid from the cooked pieces as the conveyor emerg?s from the cooking fluid and of means for thereafter treating the pieces and the adhering cooking fluid with ultra-violet rays to retard the growth of bacteria and fungi bodies. 16. Apparatus for dehydrating raw potatoes comprising a vessel adapted to hold a cooking fluid, means to heat said fluid, means for hold ing a plurality of thin walled pieces of raw potato, against distortion, means'. for submerg ing said last named means in said cooking fluid while the pieces of potato are being dehydrated, means for removing said holding means from the cooking fluid while holding said pieces of potato against distortion, means for draining ex cess cooking fluid from the dehydrated pieces Of potato as the same are leaving said cooking ves sel, and means for thereafter treating the de hydrated pieces and the adhering cooking fluid with ultra-violet rays to retard the growth of bacteria and similar foreign bodies. 17. An apparatus for making potato chips endless conveyor, means having opposed Sub stantially fiat surfaces arranged to conduct raw slices of potato into cooking relation to Said hot fluid whereby said slices are processed by this hot fluid, said means being constructed and ar ranged to prevent said slices from becoming dis torted while being processed and while cooling after the cooking process, 18. An apparatus for making potato chips reticulated conveyor means including a plurality of endless webs having portions thereof passing in closely spaced relation and arranged to con duct raw slices of potato into cooking relation to said hot cooking fluid whereby said slices are processed by said hot fluid, said means being con structed and arranged to prevent said slices

7 from becoming distorted while being processed and while cooling after the cooking process. 19. An apparatus for making potato chips conveyor means including a plurality of endless webs arranged to provide substantially continu ous support to the opposite side of slices of potato and to conduct raw slices of potato into cooking relation to said hot fluid whereby said slices are processed by said hot fluid, said means being constructed and arranged to prevent said slices from becoming distorted while being processed and while cooling after the cooking process, and means for thereafter subjecting Said slices to a preservative process An apparatus for making potato chips means separating said container and the fluid therein into a plurality of bodies, means for heating said bodies of fluid to different tempera tures, conveyor means. arranged to conduct raw slices of potato into cooking relation to said hot bodies of fluid whereby said slices are processed by said hot fluid, said means being constructed and arranged to prevent said i slices from be coming distorted while being processed and while cooling after the cooking process. MARK PRINGE.

May 12, ,282,708 T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE. Filed Sept. 26, Sheets-Sheet l. --No.zzzzzzzzzzae.

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

III. United States Patent (19) Binacchi. Attorney, Agent, or Firm-Bucknam and Archer 57 ABSTRACT. 6 Claims, 3 Drawing Sheets

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19)

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(*) Notice: Subject to any disclaimer, the term of this E. E. E. E. O.C.

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

United States Patent (19) Forino

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. Lange (43) Pub. Date: Nov. 22, 2012

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

Sept. 7, l.t. ward 2,092,596 SIPHON

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

(2-12. Zazza72M4 Aarzanez. Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS. Zaza/adar. aeo/ae/ -- e

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1. Hurley et al. (43) Pub. Date: Aug. 28, PROCESS Publication Classification

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

United States Patent [11] 3,559,565

![United States Patent [11] 3,559,565 United States Patent [11] 3,559,565](/thumbs/93/114425987.jpg) United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

7 IANSNA. (12) Patent Application Publication (10) Pub. No.: US 2003/ A1. (19) United States 2//

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

Center et al. (45. Date of Patent: Aug. 29, 1995

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

A33. AORNEY. March 22, G. C. HERZ, 1,850,719. APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC. Filed Dec, l6, l Sheets-Sheet l NVENTOR

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

United States Patent (19) Adams et al.

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

US A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

HHHHH. United States Patent (19) Burrows et al. 5,084, Patent Number: (45) Date of Patent: Jan. 28, 1992

United States Patent (19) Burrows et al. 54 PRCESS FR PREPARING FRENCH FRIED PTAT STRIPS WITH SALT CNTENT 75) Inventors: Christopher B. Burrows, Kennewick; Janet. Wheeler; Jerry L. Sloan, both of Richland,

United States Patent (19) Burrows et al. 54 PRCESS FR PREPARING FRENCH FRIED PTAT STRIPS WITH SALT CNTENT 75) Inventors: Christopher B. Burrows, Kennewick; Janet. Wheeler; Jerry L. Sloan, both of Richland,

United States Patent (19)

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

22 Filed: Jun. 6, 1995 (51) Int. Cl... A22C 9/ U.S. Cl /141; 426/56; 426/63 58) Field of Search /141, 142, Canner/Cutter

United States Patent (19) Teran IIII US0055120A 11 Patent Number: 45) Date of Patent: Apr., 1996 54 MEATTENDERIZATION PROCESS FOR A MICROWAVABLE MEAT PRODUCT 76 Inventor: James Teran, 932 E. Thames St.,

United States Patent (19) Teran IIII US0055120A 11 Patent Number: 45) Date of Patent: Apr., 1996 54 MEATTENDERIZATION PROCESS FOR A MICROWAVABLE MEAT PRODUCT 76 Inventor: James Teran, 932 E. Thames St.,

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

Dec. 9, M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

JUICE EXTRACTION AND FILTRATION JUICE EXTRACTION METHOD AND EQUIPMENT

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

! MXING-LIQUID. United States Patent (19) Khalsa 2-"22 18 INSPECTION. 11 Patent Number: 5,298,274 45) Date of Patent: Mar.

United States Patent (19) Khalsa (54) METHODS FOR MAKING TORTILLACHIPS AND TORTELLA CHIPS PRODUCED THEREBY 76 Inventor: Nirbhao S. Khalsa, 3141 NW. Greenbriar Ter, Portland, Oreg. 97.210 21 22) (51) (52)

United States Patent (19) Khalsa (54) METHODS FOR MAKING TORTILLACHIPS AND TORTELLA CHIPS PRODUCED THEREBY 76 Inventor: Nirbhao S. Khalsa, 3141 NW. Greenbriar Ter, Portland, Oreg. 97.210 21 22) (51) (52)

(12) United States Patent (10) Patent No.: US 6,813,994 B2

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

TORTILLA-TORTILLA CHIPS

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

Improving the Quality of Ghanaian Parboiled Rice. Training Manual

Improving the Quality of Ghanaian Parboiled Rice Training Manual The Role of Parboilers This publication is an output from the Crop Post-harvest Research Programme of the UK Department for International

Improving the Quality of Ghanaian Parboiled Rice Training Manual The Role of Parboilers This publication is an output from the Crop Post-harvest Research Programme of the UK Department for International

3,702,608 11/1972 Tibbs. states by bying O st plunger T.

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

United States Patent (19)

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) 11) 4,167,008 Blickenstaff 45) Sep. 4, 1979

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

ISO 9852 INTERNATIONAL STANDARD

INTERNATIONAL STANDARD ISO 9852 Second edition 2007-05-01 Unplasticized poly(vinyl chloride) (PVC-U) pipes Dichloromethane resistance at specified temperature (DCMT) Test method Tubes en poly(chlorure

INTERNATIONAL STANDARD ISO 9852 Second edition 2007-05-01 Unplasticized poly(vinyl chloride) (PVC-U) pipes Dichloromethane resistance at specified temperature (DCMT) Test method Tubes en poly(chlorure

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(12) Patent Application Publication (10) Pub. No.: US 2015/ A1

(19) United States US 20150237893A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0237893 A1 Miyajima et al. (43) Pub. Date: (54) FROZEN COOKED NOODLE AND METHOD (30) Foreign Application Priority

(19) United States US 20150237893A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0237893 A1 Miyajima et al. (43) Pub. Date: (54) FROZEN COOKED NOODLE AND METHOD (30) Foreign Application Priority

INTRODUCTION TO CUSTOM FABRICATED STRAINERS

INTRODUCTION TO CUSTOM FABRICATED STRAINERS Nothing Too Big, Too Small or Too Special When unwanted solid material has to be removed from flowing fluids in order to protect equipment, a HAYWARD Strainer

INTRODUCTION TO CUSTOM FABRICATED STRAINERS Nothing Too Big, Too Small or Too Special When unwanted solid material has to be removed from flowing fluids in order to protect equipment, a HAYWARD Strainer

Product Consistency Comparison Study: Continuous Mixing & Batch Mixing

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

TO BE RESCINDED. 901: False or misleading labeling or practices generally: specific prohibitions and requirements for labels and containers.

ACTION: Final DATE: 10/17/2017 8:35 AM TO BE RESCINDED 901:3-31-03 False or misleading labeling or practices generally: specific prohibitions and requirements for labels and containers. (A) No product

ACTION: Final DATE: 10/17/2017 8:35 AM TO BE RESCINDED 901:3-31-03 False or misleading labeling or practices generally: specific prohibitions and requirements for labels and containers. (A) No product

United States Patent (19) Bowen et al.

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

EQUIPMENT FOR MAKING BABCOCK TEST FOR FAT IN MILK

}L~c ~ ~Babcock Test T HE for Fat in Mi~k By J. ~ JJ R Professor of Dairy Chemistry Research....,) ~ '( li: )..-djg's BABCOCK TEST is the most satisfactory and practical method for determining the percentage

}L~c ~ ~Babcock Test T HE for Fat in Mi~k By J. ~ JJ R Professor of Dairy Chemistry Research....,) ~ '( li: )..-djg's BABCOCK TEST is the most satisfactory and practical method for determining the percentage

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

United States Patent (19) D'Alessandro

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

Eaton Filtration, LLC

Eaton Filtration, LLC 44 Apple Street, Tinton Falsl NJ 07724 Phone: 732-212-4700 Fax: 952-906-3706 E-Mail: filtration@eaton.com Web: www.eaton.com/filtration Installation, Operation & Service Manual Model

Eaton Filtration, LLC 44 Apple Street, Tinton Falsl NJ 07724 Phone: 732-212-4700 Fax: 952-906-3706 E-Mail: filtration@eaton.com Web: www.eaton.com/filtration Installation, Operation & Service Manual Model

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

ISO INTERNATIONAL STANDARD. Infusion equipment for medical use Part 6: Freeze drying closures for infusion bottles

INTERNATIONAL STANDARD ISO 8536-6 Second edition 2009-11-15 Infusion equipment for medical use Part 6: Freeze drying closures for infusion bottles Matériel de perfusion à usage médical Partie 6: Bouchons

INTERNATIONAL STANDARD ISO 8536-6 Second edition 2009-11-15 Infusion equipment for medical use Part 6: Freeze drying closures for infusion bottles Matériel de perfusion à usage médical Partie 6: Bouchons

Kilned Versus Roasted: Do You Really Know Your Specialty Malt? DAVID RICHTER June 12, 2015 Briess Malting Company Chilton, Wisconsin

Kilned Versus Roasted: Do You Really Know Your Specialty Malt? DAVID RICHTER June 12, 2015 Briess Malting Company Chilton, Wisconsin Quick overview of discussion 1 - Malting 101 o Purpose of malting and

Kilned Versus Roasted: Do You Really Know Your Specialty Malt? DAVID RICHTER June 12, 2015 Briess Malting Company Chilton, Wisconsin Quick overview of discussion 1 - Malting 101 o Purpose of malting and

United States Standards for Grades of Italian Sprouting Broccoli

United States Department of Agriculture Agricultural Marketing Service Fruit and Vegetable Programs Fresh Products Branch United States Standards for Grades of Italian Sprouting Broccoli Effective November

United States Department of Agriculture Agricultural Marketing Service Fruit and Vegetable Programs Fresh Products Branch United States Standards for Grades of Italian Sprouting Broccoli Effective November

United States Patent It 3,593,647

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

CODEX STANDARD FOR RICE CODEX STAN

CODEX STAN 198 Page 1 of 10 CODEX STANDARD FOR RICE CODEX STAN 198-1995 The Annex to this standard contains provisions which are not intended to be applied within the meaning of the acceptance provisions

CODEX STAN 198 Page 1 of 10 CODEX STANDARD FOR RICE CODEX STAN 198-1995 The Annex to this standard contains provisions which are not intended to be applied within the meaning of the acceptance provisions

ta-v, 9-1-N Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS EDWARD E ANDERSON ATORNEYS JACK D.

Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May 10, 1965 5 Sheets-Sheet INVENTORS EDWARD E ANDERSON JACK D. BROWN ta-v, 9-1-N-11-4. ATORNEYS Oct. 11,

Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May 10, 1965 5 Sheets-Sheet INVENTORS EDWARD E ANDERSON JACK D. BROWN ta-v, 9-1-N-11-4. ATORNEYS Oct. 11,

United States Standards for Grades of Walnuts (Juglans regia) in the Shell

United States Department of Agriculture Agricultural Marketing Service Fruit and Vegetable Division Fresh Products Branch United States Standards for Grades of Walnuts (Juglans regia) in the Shell Effective

United States Department of Agriculture Agricultural Marketing Service Fruit and Vegetable Division Fresh Products Branch United States Standards for Grades of Walnuts (Juglans regia) in the Shell Effective

United States Patent (19) 11 4,094,997 Aishima et al. 45 June 13, 1978

United States Patent (19) 11 Aishima et al. 45 June 13, 1978 (54) BEEF FLAVORSUBSTANCE, PROCESS FOR 56) References Cited PRODUCING SAME AND BEEFFLAVORNGAGENT U.S. PATENT DOCUMENTS 3,394,0 7/1968 Giacino...

United States Patent (19) 11 Aishima et al. 45 June 13, 1978 (54) BEEF FLAVORSUBSTANCE, PROCESS FOR 56) References Cited PRODUCING SAME AND BEEFFLAVORNGAGENT U.S. PATENT DOCUMENTS 3,394,0 7/1968 Giacino...

Terrace Drying in Brazil: Facilities and Control of Quality and Safety during Drying

Terrace Drying in Brazil: Facilities and Control of Quality and Safety during Drying (Taken from Hygienic Coffee Drying prepared for this resource by Juarez de Sousa and Consuelo Domenici Roberto, University

Terrace Drying in Brazil: Facilities and Control of Quality and Safety during Drying (Taken from Hygienic Coffee Drying prepared for this resource by Juarez de Sousa and Consuelo Domenici Roberto, University

March 24, 1970 H. H. BRIDGFORD 3,502,488 COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER HUGH. BROGFORD / ATTORNEY

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

INF.3 Proposal for a new UNECE Standard: Inshell Pecans

Proposal for a new UNECE Standard: Inshell Pecans Contribution from the United States of America Note by the secretariat: This text is a revised proposal for a new UNECE Standard for Inshell Pecans reproduced

Proposal for a new UNECE Standard: Inshell Pecans Contribution from the United States of America Note by the secretariat: This text is a revised proposal for a new UNECE Standard for Inshell Pecans reproduced

United States Patent (19) Aldrich

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

industrial baking systems DIRECT FIRED TUNNEL OVEN Made in Italy

industrial baking systems DIRECT FIRED TUNNEL OVEN Made in Italy TURBOPIZZA OVEN Alitech produces and assembles in his own premises, which is fully equipped for all the manufacturing phases. The production

industrial baking systems DIRECT FIRED TUNNEL OVEN Made in Italy TURBOPIZZA OVEN Alitech produces and assembles in his own premises, which is fully equipped for all the manufacturing phases. The production

(12) United States Patent (10) Patent No.: US 7,325,807 B1. Eason (45) Date of Patent: Feb. 5, 2008

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

Fruits. Food Preservation. Important fruit canning pointers. Equipment. Canning jars. Syrup solutions WP

WP 375-09 wecan Fruits Food Preservation These processing recommendations are for West Virginia conditions (maximum altitude, 4,000 feet). For canning directions in other locations, consult your county

WP 375-09 wecan Fruits Food Preservation These processing recommendations are for West Virginia conditions (maximum altitude, 4,000 feet). For canning directions in other locations, consult your county

WHOLE MUSCLE JERKY. Weigh meat and use enclosed WHOLE MUSCLE recipe chart to portion out spice and cure. Mix spice and cure together.

WHOLE MUSCLE JERKY Pre-Prep Procedures: a. Assemble meat, spices, thermometers, aprons and assure cutting boards and knives are clean and sanitized. Use non-reactive containers, such as stainless steel

WHOLE MUSCLE JERKY Pre-Prep Procedures: a. Assemble meat, spices, thermometers, aprons and assure cutting boards and knives are clean and sanitized. Use non-reactive containers, such as stainless steel

(12) United States Patent

USOO82363.63B2 (12) United States Patent Miyazaki et al. (54) METHOD FOR PRODUCING INSTANT NOODLES (75) Inventors: Yoshifumi Miyazaki, Osaka (JP); Kunihiko Yoshida, Osaka (JP); Rintaro Takahashi, Osaka

USOO82363.63B2 (12) United States Patent Miyazaki et al. (54) METHOD FOR PRODUCING INSTANT NOODLES (75) Inventors: Yoshifumi Miyazaki, Osaka (JP); Kunihiko Yoshida, Osaka (JP); Rintaro Takahashi, Osaka

III IIIHIII. United States Patent (19) Momiyama

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

Grooving Tool: used to cut the soil in the liquid limit device cup and conforming to the critical dimensions shown in AASHTO T 89 Figure 1.

DETERMINING THE LIQUID LIMIT OF SOILS FOP FOR AASHTO T 89 Scope This procedure covers the determination of the liquid limit of a soil in accordance with AASHTO T 89-13. It is used in conjunction with the

DETERMINING THE LIQUID LIMIT OF SOILS FOP FOR AASHTO T 89 Scope This procedure covers the determination of the liquid limit of a soil in accordance with AASHTO T 89-13. It is used in conjunction with the

Antifog Masterbatch. For PP-Film

Antifog Masterbatch For PP-Film CONTENT Description of MAXITHEN PP 75770 AFAB Antifog Masterbatch Product Information Test Report Cold Fog Test Report Hot Fog Antifog Evaluation Tests Description of Test

Antifog Masterbatch For PP-Film CONTENT Description of MAXITHEN PP 75770 AFAB Antifog Masterbatch Product Information Test Report Cold Fog Test Report Hot Fog Antifog Evaluation Tests Description of Test

3. : 12- C) {X C> C) () {X -K) --KX-KX-KX-K)--C-2 --C)-- (12) Patent Application Publication (10) Pub. No.: US 2012/ A1 4 - (19) United States

(19) United States US 2012O138603A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0138603 A1 McGuinness et al. (43) Pub. Date: Jun. 7, 2012 (54) VARIABLE GEOMETRY TORTILLA COOKINGAPPARATUS

(19) United States US 2012O138603A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0138603 A1 McGuinness et al. (43) Pub. Date: Jun. 7, 2012 (54) VARIABLE GEOMETRY TORTILLA COOKINGAPPARATUS

brewing device, and particularly an espresso machine. 4,871,555 10/1989 Schwartz et al /82

USOO5895672A United States Patent 19 11) Patent Number: Cooper ) Date of Patent: Apr. 20, 1999 54) PRODUCT AND PROCESS FOR PREPARING 5,072,661 12/1991 Kondo... 99/296 A TEA EXTRACT 5,104,666 4/1992 Sanvitale...

USOO5895672A United States Patent 19 11) Patent Number: Cooper ) Date of Patent: Apr. 20, 1999 54) PRODUCT AND PROCESS FOR PREPARING 5,072,661 12/1991 Kondo... 99/296 A TEA EXTRACT 5,104,666 4/1992 Sanvitale...

The Premium Benefits of Steam Infusion UHT Treatment

EDITORIAL October 2012 The Premium Benefits of Steam Infusion UHT Treatment UHT, or Ultra High Temperature, treatment uses high temperature for a short time to kill micro-organisms in a food or beverage

EDITORIAL October 2012 The Premium Benefits of Steam Infusion UHT Treatment UHT, or Ultra High Temperature, treatment uses high temperature for a short time to kill micro-organisms in a food or beverage

Attention is drawn to the following places, which may be of interest for search:

CPC - A23N - 2017.08 A23N MACHINES OR APPARATUS FOR TREATING HARVESTED FRUIT, VEGETABLES OR FLOWER BULBS IN BULK, NOT OTHERWISE PROVIDED FOR; PEELING VEGETABLES OR FRUIT IN BULK; APPARATUS FOR PREPARING

CPC - A23N - 2017.08 A23N MACHINES OR APPARATUS FOR TREATING HARVESTED FRUIT, VEGETABLES OR FLOWER BULBS IN BULK, NOT OTHERWISE PROVIDED FOR; PEELING VEGETABLES OR FRUIT IN BULK; APPARATUS FOR PREPARING

(12) United States Patent

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

Tomato Product Cutting Tips

Tomato Product Cutting Tips Tomato Product Cutting Tips Know your customer and the application of the products being shown. Confirm the products will work for the application. Listen to the customer regarding

Tomato Product Cutting Tips Tomato Product Cutting Tips Know your customer and the application of the products being shown. Confirm the products will work for the application. Listen to the customer regarding

PHILIPPINE NATIONAL STANDARD Baby corn - Grading and classification

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 Foreword The Philippine National Standard (PNS) for Baby corn Grading and classification is a modified adoption of the CODEX STAN 188-1993 Standard for Baby

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 Foreword The Philippine National Standard (PNS) for Baby corn Grading and classification is a modified adoption of the CODEX STAN 188-1993 Standard for Baby

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

US 20020074337A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2002/0074337 A1 Melton (43) Pub. Date: Jun. 20, 2002 (54) PRINTED INSERTS FOR THERMOFORMED Related U.S. Application

US 20020074337A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2002/0074337 A1 Melton (43) Pub. Date: Jun. 20, 2002 (54) PRINTED INSERTS FOR THERMOFORMED Related U.S. Application

VIII. Claim Drafting Methodologies. Becky White

VIII. Claim Drafting Methodologies Becky White Claims A series of numbered statements in a patent specification, usually following the description, that define the invention and establish the scope of

VIII. Claim Drafting Methodologies Becky White Claims A series of numbered statements in a patent specification, usually following the description, that define the invention and establish the scope of

UNITED STATES STANDARDS FOR WHOLE DRY PEAS¹

UNITED STATES STANDARDS FOR WHOLE DRY PEAS¹ Terms Defined 401 Definition of whole dry peas. Threshed seeds of the garden type pea plant (Pisum sativum L. and Pisum sativum var. arvense (L.) Poir.), which

UNITED STATES STANDARDS FOR WHOLE DRY PEAS¹ Terms Defined 401 Definition of whole dry peas. Threshed seeds of the garden type pea plant (Pisum sativum L. and Pisum sativum var. arvense (L.) Poir.), which

GEORGIA DEPARTMENT OF CORRECTIONS Standard Operating Procedures

Policy Number: 409.04.31 Effective Date: 10/24/17 Page Number: 1 of 7 I. Introduction and Summary: It is the policy of the Food and Farm Services Subdivision to establish and outline standard operating

Policy Number: 409.04.31 Effective Date: 10/24/17 Page Number: 1 of 7 I. Introduction and Summary: It is the policy of the Food and Farm Services Subdivision to establish and outline standard operating

(12) United States Patent

(12) United States Patent US008778441B2 () Patent No.: Sky (45) Date of Patent: Jul. 15, 2014 (54) READY-TO-EAT OAT-BASED FOOD (56) References Cited PRODUCT U.S. PATENT DOCUMENTS (76) Inventor: Phillip

(12) United States Patent US008778441B2 () Patent No.: Sky (45) Date of Patent: Jul. 15, 2014 (54) READY-TO-EAT OAT-BASED FOOD (56) References Cited PRODUCT U.S. PATENT DOCUMENTS (76) Inventor: Phillip

United States Patent (19)

United States Patent (19) Farkye et al. 4 (7) 73) 21) 22 1 (2) 8 6) CHEESE MAKING PROCESS Inventors: Nana Y. Farkye, Atascadero; B. Bhanu Prasad, San Luis Obispo, both of Calif. Assignee: California Polytechnic

United States Patent (19) Farkye et al. 4 (7) 73) 21) 22 1 (2) 8 6) CHEESE MAKING PROCESS Inventors: Nana Y. Farkye, Atascadero; B. Bhanu Prasad, San Luis Obispo, both of Calif. Assignee: California Polytechnic

CODEX STANDARD FOR RAISINS CODEX STAN

CODEX STAN 67-1981 Page 1 of 5 CODEX STANDARD FOR RAISINS CODEX STAN 67-1981 1. SCOPE This standard applies to dried grapes of varieties conforming to the characteristics of Vitis vinifera L. which have

CODEX STAN 67-1981 Page 1 of 5 CODEX STANDARD FOR RAISINS CODEX STAN 67-1981 1. SCOPE This standard applies to dried grapes of varieties conforming to the characteristics of Vitis vinifera L. which have

TEMPERATURE CONDITIONS AND TOLERANCE OF AVOCADO FRUIT TISSUE

California Avocado Society 1961 Yearbook 45: 87-92 TEMPERATURE CONDITIONS AND TOLERANCE OF AVOCADO FRUIT TISSUE C. A. Schroeder and Ernest Kay Professor of Botany. University of California, Los Angeles;

California Avocado Society 1961 Yearbook 45: 87-92 TEMPERATURE CONDITIONS AND TOLERANCE OF AVOCADO FRUIT TISSUE C. A. Schroeder and Ernest Kay Professor of Botany. University of California, Los Angeles;

Obtaining protein compositions for foodstuffs A23J 1/00 Preparation of proteins C07K 1/00

CPC - A22C - 2017.08 A22C PROCESSING MEAT, POULTRY, OR FISH (preserving A23B; obtaining protein compositions for foodstuffs A23J 1/00; fish, meat or poultry preparations A23L; disintegrating, e.g. chopping

CPC - A22C - 2017.08 A22C PROCESSING MEAT, POULTRY, OR FISH (preserving A23B; obtaining protein compositions for foodstuffs A23J 1/00; fish, meat or poultry preparations A23L; disintegrating, e.g. chopping

THE EGG-CITING EGG-SPERIMENT!

1 of 5 11/1/2011 10:30 AM THE EGG-CITING EGG-SPERIMENT! Knight Foundation Summer Institute Arthurea Smith, Strawberry Mansion Middle School Liane D'Alessandro, Haverford College Introduction: Get ready

1 of 5 11/1/2011 10:30 AM THE EGG-CITING EGG-SPERIMENT! Knight Foundation Summer Institute Arthurea Smith, Strawberry Mansion Middle School Liane D'Alessandro, Haverford College Introduction: Get ready

W. A. HEYMAN 2,432,759. Dec. 16, PROCESS OF MAKING COFFEE CONCENTRATES. Filed Jan., l94l. it. Attorney

Dec. 16, 1947. W. A. HEYMAN 2,432,759 PRCESS F MAKING CFFEE CNCENTRATES Filed Jan., l94l S it. Attorney Patented Dec. 16, 1947 UNITED STATE s PATENT FFICE 2,432,759. PRCESS F MANG CFFEE concentrates 1

Dec. 16, 1947. W. A. HEYMAN 2,432,759 PRCESS F MAKING CFFEE CNCENTRATES Filed Jan., l94l S it. Attorney Patented Dec. 16, 1947 UNITED STATE s PATENT FFICE 2,432,759. PRCESS F MANG CFFEE concentrates 1

(12) United States Patent (10) Patent No.: US 8,601,937 B2

USOO8601937B2 (12) United States Patent () Patent No.: Campetella et al. (45) Date of Patent: Dec., 2013 (54) APPARATUS FOR MAKING COFFEE 5,605,091 A * 2/1997 Garber... 99,330 5,650,186 A * 7/1997 Annoni

USOO8601937B2 (12) United States Patent () Patent No.: Campetella et al. (45) Date of Patent: Dec., 2013 (54) APPARATUS FOR MAKING COFFEE 5,605,091 A * 2/1997 Garber... 99,330 5,650,186 A * 7/1997 Annoni

SIMPLEX STRAINER MODEL 90

The Eaton Model 90 Fabricated Simplex Strainer has been designed for manufacturing flexibility. It can be made for pipeline sizes from 1 to 48 in carbon steel or stainless steel although other materials

The Eaton Model 90 Fabricated Simplex Strainer has been designed for manufacturing flexibility. It can be made for pipeline sizes from 1 to 48 in carbon steel or stainless steel although other materials

S m a rtset Control for Convection Models

S m a rtset Control for Convection Models C O N T E N T S Features of your Oven Control.....................1 Setting the Clock...............................2 Setting the Minute Timer.........................2

S m a rtset Control for Convection Models C O N T E N T S Features of your Oven Control.....................1 Setting the Clock...............................2 Setting the Minute Timer.........................2

Flexible gear grinding machines

Flexible gear grinding machines In recent years some extremely innovative gear grinding machines have come onto the market both in terms of how they are constructed and of how they operate. It is a well-known

Flexible gear grinding machines In recent years some extremely innovative gear grinding machines have come onto the market both in terms of how they are constructed and of how they operate. It is a well-known

How to Build a Wine Cellar

How to Build a Wine Cellar Introduction This guide has been prepared as a general resource to help you build your own wine cellar. The information provided here has been gathered over the course of our

How to Build a Wine Cellar Introduction This guide has been prepared as a general resource to help you build your own wine cellar. The information provided here has been gathered over the course of our

United States Patent (19) Driessen et al.

United States Patent (19) Driessen et al. 54 CONTINUOUS PREPARATION OF FERMENTED MILK PRODUCTS 75 Inventors: Fransiscus M. Driessen, Ede; Jacobus J. Stadhouders, Bennekom; Jacob Ubbels, Ede, all of Netherlands

United States Patent (19) Driessen et al. 54 CONTINUOUS PREPARATION OF FERMENTED MILK PRODUCTS 75 Inventors: Fransiscus M. Driessen, Ede; Jacobus J. Stadhouders, Bennekom; Jacob Ubbels, Ede, all of Netherlands

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States US 20040096.559A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0096559 A1 Swanson et al. (43) Pub. Date: (54) METHOD FOR PRODUCTION OF FROZEN (21) Appl. No.: 10/298,873

(19) United States US 20040096.559A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0096559 A1 Swanson et al. (43) Pub. Date: (54) METHOD FOR PRODUCTION OF FROZEN (21) Appl. No.: 10/298,873