United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994

|

|

|

- Charlene Wilkins

- 5 years ago

- Views:

Transcription

1 III US A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974 3,847,068 11/ ) Inventors: James C. Collard, Two Rivers; Larry 3,908,534 9/1975 W. Schiffer, Manitowoc, both of Wis. 3,988,975 11/ Assignee: Anchor Hocking Corporation, 5,078,050 l/1992 Freeport, Ill. FOREIGN PATENT DOCUMENTS 21) Appl. No.: 36, /1959 Australia... 99/425 (22 Filed: Mr. 25, /1987 European Pat. Off /425 s is are/ Primary Examiner-Stephen F. Gerrity 51 int. Cl'... A47J 37/10 Assistant Examiner-Reginald L. Alexander 52 U.S.C /425; g Attorney, Agent, or Firm-Baker & McKenzie 58) Field of Search... 99/425,422, 375, 400, 57 ABSTRACT 99/445, 415, 418, 126/390 An improved cooking device is provided for fat-free or (56) References Cited low-fat frying of foods. A combination frying pan and removable insert allows the drainage of excess fat with U.S. PATENT DOCUMENTS out interruption of the cooking operation. Fat is col 175,067 7/1875 Gates. lected on the convex cooking surface of the insert and 403,407 5/1889 Armour... 99/425 drains radially outward toward apertures disposed 717,655 1/1903 Astle. above a grease reservoir located in the outer bottom 1356,432 10/1020 Eidt periphery of the frying pan. The insert overlies the 1,733,450 10/1929 Detwiler. reservoir and may be easily removed and replaced dur 2,042,773 6/1936 Feldman... 99/425 2,229,518 1/1941 Parker /425 ing the cooking operation. The pan fits over standard 2,321,676 6/1943 Hennessy... 99/25 size electric burners. 3,332,113 5/1967 Simjian /390 3,427,957 2/1969 O'Reilly... 99/446 5 Claims, 3 Drawing Sheets azz-z-z-z-z-al-ysea YAGaleavia N a Zator-Herth-ang

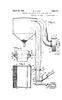

2 U.S. Patent June 28, 1994 Sheet 1 of 3 5,323,693

3 U.S. Patent June 28, 1994 Sheet 2 of 3 5,323,693

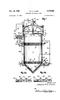

4 U.S. Patent June 28, 1994 Sheet 3 of 3 5,323, F G8. -F g / 4/ t CO a / 122

5 1. COMBINATION FRYING PAN INSERT AND FRYING PAN FIELD OF THE INVENTION This invention relates generally to a frying pan insert for use in combination with a specially designed frying pan to provide a cooking surface which effectively drains grease away from the frying food. More particu larly, the invention relates to an insert with a convex cooking surface that fits over an upraised bottom sur face of a frying pan. Grease drains away from the food along drainage channels and is deposited in a grease reservoir disposed in the outer periphery of the pan. BACKGROUND OF THE INVENTION In wake of the public awareness over the dangers of cholesterol and high fat diets, there has been a trend to lowering the amount of fat in one's diet. However, despite this trend, people of all cultures and all ethnic groups enjoy and will continue to enjoy numerous vari eties of pan-fried foods. The specific problem addressed by the present invention, and not satisfactorily ad dressed by the prior art, is a means for cooking low-fat or non-fat fried foods. More particularly, no current commercially available frying device allows the cook to simultaneously fry the food and drain the grease away from the food that is being cooked. Several attempts have been made at designing a low fat or fat-free frying pan. These designs normally consti tute a single piece of cookware. The frying pan may include an upraised central portion with a grease reser voir surrounding the upraised central portion and dis posed between the upraised central portion and the outer wall of the pan. Grooves, channels or grids may be provided to drain the grease from the upraised por tion into the grease reservoir. The above design scheme suffers from two common problems. First, the grease reservoir is not sufficiently isolated from the food. The pan is normally intended to be placed on top of an electric burner, the electric burner being disposed below the upraised central por tion and the reservoir being disposed around the elec tric burner. Because of the close proximity between the reservoir and the burner, the grease becomes hot as it is collected in the reservoir and has a tendency to splatter upward on both the food and the cook. Second, there is no way to drain excess grease from the reservoir as it accumulates without interrupting the cooking opera tion. If the cook tilts the pan to pour the grease out of the reservoir while the food remains disposed on top of the upraised central portion, the cook risks losing some of the food or the cook may damage the food by at tempting to firmly hold it in place with a spatula as the pan is tilted to pour out the excess grease. Another approach to providing a low-fat frying de vice is to provide an insert for placement inside a con ventional frying pan. The food is cooked on the insert and the grease drains off the insert or through the insert and is collected in the frying pan disposed below. Two problems are associated with this design scheme. First, the inserts are not removable and therefore the cook cannot easily lift the insert out of the pan during the cooking operation to drain excess grease from the pan. Second, the inserts do not effectively isolate the food from the grease and the hot grease disposed immedi ately below the insert splatters upward through the insert and on to the food. Most of the inserts are not 5,323, designed to isolate the food from the splattering grease but merely serve as a means to facilitate the drainage of excess grease after the cooking operation is completed. This process is not considered to be a low-fat cooking scheme because the food remains coated with grease during the entire cooking operation. Thus, there is a need for an improved frying pan insert and also for an improved combination frying pan/frying pan insert that allows for low-fat or even fat-free cooking. The insert should have an improved means for draining grease away from the food during the cooking operation and further an improved means for isolating the accumulated grease from the food. The insert should also be easily removed from the frying pan during cooking so that excess grease can be removed from the grease reservoir or reservoir without signifi cantly interrupting the cooking operation. Finally, there is a need for a frying pan insert/frying pan combi nation that provides a safe and effective means for low fat frying whereby the grease is separated and isolated from the frying food and further is not permitted to splatter upward back onto the food or toward the cook. BRIEF DESCRIPTION OF THE INVENTION The present invention makes a significant contribu tion to the low-fat cookware art by providing an im proved insert for use with a specially designed frying pan. The insert acts to effectively drain grease away from the food as it cooks. The insert and pan are de signed together so that the grease is drained away from the food and the insert and pan act to isolate the grease from the food and prevent upward splatter toward the food and/or the cook. Further, the cook may safely remove excess grease from the pan without interrupting the cooking operation. The pan of the present invention includes an upraised bottom surface with a grease reservoir disposed around the upraised bottom surface between the upraised bot tom surface and the upwardly protruding outer wall of the pan. The bottom surface of the grease reservoir is disposed vertically below the upraised bottom surface. The undersurface of the upraised bottom surface pro vides a round detent in the bottom of the pan and, in the preferred embodiment, this round detent fits over a standard-sized electric burner for effective heat trans fer. An insert is provided with a convex upper surface for cooking the food. The underside of the insert is config ured to fit snugly over the upraised bottom surface of the pan. The convex upper surface includes a plurality of drain channels that effectively drain the grease away from the food in radially outward directions. The drain channels terminate in a series of apertures disposed toward the outer periphery of the insert. The apertures provide fluid communication between the drain chan nels and the grease reservoir of the pan disposed there below. The insert extends radially outward beyond the up raised portion of the pan to substantially cover the res ervoir disposed therebelow. Therefore, with the excep tion of the apertures, the insert covers the reservoir and substantially precludes any upward splattering of the hot grease during the cooking operation. To assist in this regard, the preferred embodiment of the insert includes an inner peripheral leg disposed around the upraised bottom surface of the pan and an outer periph eral leg disposed around the outer periphery of the

6 3 insert and adjacent to the upwardly protruding outer wall of the pan. The two legs act to further contain any splattered grease within the reservoir and to provide a mateable engagement between the insert and pan. The insert also includes a slot for accommodating a handle so that the insert is easily grasped and lifted out of the pan during the cooking operation. After the insert is grasped and lifted, the cook may easily pour excess grease out of the reservoir and thereafter replace the insert and pan over the burner to resume cooking. The insert handle may then be easily removed from the insert so that it does not get in the way of the cook during the cooking operation. It is therefore and object of the present invention to provide an improved frying pan insert/frying pan com bination for low-fat or fat-free cooking of food. It is also an object of the present invention to provide an improved insert for use with a frying pan, the insert providing effective drainage of grease from the food during cooking. Yet another object of the present invention is to pro vide a frying pan insert and frying pan combination that effectively isolates the drained grease from the food during cooking and further prevents any upward splat ter of the grease during cooking. Yet another object of the present invention is to pro vide an improved frying pan insert that may be easily removed from the frying pan during cooking so that the cook may drain excess grease from the pan without substantially interrupting the cooking operation. BRIEF DESCRIPTION OF THE DRAWINGS This invention is illustrated more or less diagrammati cally in the accompanying drawings, wherein: FIG. 1 is a partial top plan view of a frying pan and a partial top plan view of a frying pan insert made in accordance with the present invention; FIG. 2 is a side sectional view of the frying pan in sert/frying pan combination shown in FIG. 1; FIG. 3 is a partial side sectional view of the frying pan insert/frying pan combination shown in FIG. 1; FIG. 4 is a top plan view of the frying pan insert shown in FIG. 1; FIG. 5 is a sectional view taken substantially along line 5-5 shown in FIG. 4; FIG. 6 is a partial top plan view of the frying pan insert shown in FIG. 4, particularly illustrating the apertures and drainage channels; FIG. 7 is a sectional view taken substantially along line 7-7 shown in FIG. 6; FIG. 8 is a partial side sectional view of the insert shown in FIG. 4, particularly illustrating the recessed middle portion and the inner end of a drainage channel; FIG.9 is an enlarged side sectional view of the outer periphery of the insert as shown in FIG. 5; FIG. 10 is a bottom plan view of the insert shown in FIG. 4; and FIG. 11 is an enlarged side sectional view of the insert shown in FIG. 10, particularly illustrating the grooves disposed in the underside of the insert. DETAILED DESCRIPTION OF THE INVENTION Like reference numerals will be used to refer to like or similar parts from figure to figure in the following description of the drawings. The dramatic improvement contributed by the pres ent invention is best understood after consideration of 5,323, how conventional low-fat or fat-free frying pans work. Normally, food is cooked on an upraised cooking sur face and grease drains down through channels and is deposited into a reservoir disposed in the outer periph ery of the pan. Hot grease collected in the reservoir is further heated and is free to splatter upward toward the cooking food and toward the cook. Inserts have previ ously been used but the inserts known in the art do not adequately isolate the food from the grease or are not easily removable during the cooking operation so that the cook may remove excess grease from the pan. The present invention overcomes these problems and pro vides an improved insert for effectively draining and isolating grease away from food as it cooks, collecting the grease in a reservoir disposed in the under periphery of the pan and further covering the reservoir so that grease may not splatter upward toward the cook or the food. The insertis easily removable from the pan during cooking so that excess grease may be removed without substantially interrupting the cooking operation. As seen in FIGS. 1 and 2, the combination frying pan/ insert 10 includes a frying pan insert 11 and a frying pan 12. Both the insert 11 and the pan 12 are equipped with handles 13, 14. The handle 13 is attached to the insert 11 by inserting a tongue (not shown) into the slot 15. The handle may also be easily removed from the insert 11 by lifting the handle 13 and the tongue (not shown) out of the slot 15. By equipping the insert 11 with an easy-to-remove/easy-to-insert handle 13, the insert 11 may be grasped and lifted out of the pan 12 during the cooking operation so that the cook can easily remove excess grease from the pan 12. Turning to FIG. 2, the pan 12 includes an upraised bottom surface 16 which extends radially outward to a downwardly sloping inner wall 20. The wall 20 con nects the upraised bottom surface 16 to the grease reser voir 21. The reservoir 21 extends radially outward to the upwardly protruding outer wall 22 which termi nates at an outwardly protruding lip 23. The grooves indicated at 24 are ornamental in nature. The handle 14 is attached to the pan 12 via a screw 25 and a mounting bracket 26 which is welded or otherwise fixedly at tached to the outer wall 22. Referring to FIGS. 1, 2 and 3 collectively, the insert 11 includes an undersurface 30 for engaging the up raised bottom surface 16 of the pan. The insert 11 also includes a convex cooking surface 31 (also shown in FIG. 5) which facilitates the draining of grease away from food as it cooks on top of the convex cooking surface 31. A plurality of drain channels, indicated gen erally at 32, provide a path for the grease to drain radi ally outward toward the apertures 35 disposed in the outer periphery 37 of the insert 11. As seen in FIG. 3, the apertures 35 provide fluid communication between the drain channels 32 and the reservoir 21. As food is cooked on the convex cooking surface 31, grease travels down the drain channels 32 and through the apertures 35 and is isolated from the food in the reservoir 21. Hot grease is maintained in the reservoir 21 and is prevented from splattering upward back onto the food or towards the cook by the inner peripheral leg 36 and outer pe ripheral leg 40. As seen in FIGS. 1 and 3, the outer periphery 37 of the insert 11, which includes the inner leg 36 and the outer leg 40, acts as a circular lid for the reservoir 21. Turning to FIG. 4, the insert 11 includes two basic types of drain channels 32a, 32b, The drain channels 32a extend radially outward from a central portion 41 of the

7 5 insert 11 and terminate at an aperture 35. The drain channels 32b extend radially outward from a middle portion of the insert 11 and terminate at an aperture 35. The apertures 35 provide fluid communication between the convex cooking surface 31 and the reservoir 21. The aperture or slot 15 also provides a means of com munication between a drain channel 32b and the reser voir 21 (see FIG. 2) and it also serves as a means for attaching the handle 13 to the insert 11 so that the insert 11 can be removed from the pan 12 while the food is cooking. With the insert 11 temporarily removed from the pan 12, the cook may remove excess grease from the reservoir 21 and the pan 12 during cooking and quickly replace the food and insert 11 back into the pan 12 to resume the cooking operation. Referring to FIG. 5, the convex cooking surface 31 includes a recessed middle portion 41 which communi cates with the inner ends 42 of the drain channels 32a. Melted grease and juices flow from the central portion 41 radially outward through the drainage channels 32a and then finally down through the apertures 35 and into the reservoir 21 disposed therebelow (see FIG. 3). The inner peripheral leg 36 extends around and is disposed adjacent to the inner wall 20 of the pan 12. The close physical contact between the undersurface 30 of the insert 11 and the upraised bottom surface 16 of the pan 12 allows for efficient heat transfer between the up raised bottom surface 16 and the insert 11. The outer peripheral leg 40 extends around and maintains close contact with the upwardly protruding outer wall 22 of the pan 12. The close fit of the insert 11 into the bottom of the pan 12 provides efficient heat transfer between the burner (not shown) and the upraised undersurface 43 of the pan 12 (see FIG. 2) which accommodates the burner. The upraised undersurface 43 is specifically sized to accommodate standard sized electric burners. The concentric grooves, indicated generally at 44, dis posed in the underside 30 of the insert 11 aid in the transfer of heat between the underside 30 of the insert 11 and the upraised bottom surface 16 of the pan 12. Turning to FIGS. 6 and 7, the drain channels 32a, 32b terminate in the apertures 35 and molten grease easily flows from the drain channels 32a, 32b down through the apertures 35 to the reservoir 21 (see FIG. 3) dis posed therebelow. The depth of the channels 32 should be deep enough to accommodate substantial flow of grease, which would result during the cooking of high fat foods, such as bacon. Turning to FIG. 8, the fluid communication between the central portion 41, the inner end 42 of a drain chan nel 32a and a drain channel 32a is illustrated. Turning to FIG. 9, the angle of the outer peripheral edge 46 should coincide with the lower angle of the upwardly protrud ing wall 22 of the pan 12. The outer peripheral surface 45 connects the outer peripheral leg 40 to the outer peripheral edge 46 of the insert 11. The inner peripheral surface 50, which connects the inner peripheral leg 36 to the undersurface 30, should coincide approximately with the inner wall 20 of the pan 12 (see FIG. 2). FIG. 10 is an illustration of the underside 30 of the insert 11. A key feature of the underside 30 is the series of concentric grooves indicated generally at 44. As noted above, the grooves 44 aid in the transfer of heat between the upraised bottom surface 16 of the pan 12 and the undersurface 30 of the insert 11. An example concentric groove 44 is illustrated in FIG. 11. In operation, the handle 13 is inserted into the slot 15 so that the insert 11 may be placed over the upraised 5,323,693 O bottom surface 16 of the pan 12. Heat is applied via an electric burner disposed within the upraised undersur face 43 of the pan 12 and the food is placed on the convex cooking surface 31 of the insert 11. As the food cooks, melted grease will flow into the central portion 41 and into the drain channels 32a and 32b of the insert 11. Because the cooking surface 31 is convex, the grease will flow, under the force of gravity, radially outward towards the apertures 35. The grease flows down through the apertures 35 and is deposited and retained within the reservoir 21. If excess grease is accumulated in the reservoir 21 during the cooking operation, the cook has the option of inserting the handle 13 into the slot 15 and raising the food and the insert 11 above the pan 12. Then, the cook may pour the grease out of the pan 12 and the reservoir 21, place the pan 12 back over the burner and replace the insert 11 and food over the upraised bottom surface 16 of the pan 12. The cooking operation will then be resumed without risking spillage or damage to the food. Although only one preferred embodiment of the present invention has been illustrated and described, it will at once be apparent to those skilled in the art that variations may be made within the spirit and scope of the present invention. Accordingly, it is intended that the scope of the invention be limited solely by the scope of the hereafter appended claims and not by any specific wording in the foregoing description. We claim: 1. Cookware for frying food and draining grease from the food during frying while eliminating grease splatter and optimizing heat transference from a heat source to the food during frying, the cookware comprising: a pan, said pan having a solid bottom structure which blends into an upstanding enclosing wall, said bottom structure having a peripheral channel forward between a main, center portion of said bottom structure and said enclosing wall, said main, central portion of said bottom structure being elevated with respect to said peripheral chan nel and extending radially outwardly from the center of said cookware to nearly a side wall, said peripheral channel being located in a radial dis tance between an outer edge portion of said main central portion and said enclosing wall, said bottom structure, including said peripheral chan nel, and said enclosing wall being integrally con structed so as to form a fluid tight container, an insert, said insert disposed on an elevated upper surface of said main central portion of said bottom structure of pan and extending radially outwardly so as to at least substantially overlie said peripheral channel, said insert having an upper, food contacting surface, substantially the entire bottom surface of said insert being in abutting, maximum heat transference contact with the upper surface of said main central portion of said bottom structure, said insert having a plurality of upwardly open drain channels extending outwardly from an internal region thereof, said drain channels directly communicating, via aper tures which extend through said insert, with said peripheral channel in said bottom structure, that portion of said insert overlying said peripheral channel forming a barrier which substantially en tirely prevents drained grease and fat in said pe ripheral channel from splattering upwardly.

8 5,323, The device of claim 1, maximum heat transference contact with a heat wherein said drain channels are formed in said upper, source such as an electric burner. food contacting surface only of said insert. 3. The device of claim 1, 5. The device of claim 1, wherein said upper food contacting surface of said wherein said elevated upper surface of main central 5 s portion of said bottom structure is flat. insert is convex whereby said drain channels slope 4. The device of claim 1 radially downwardly to said apertures so as to wherein said bottom surface of said main central direct grease and fluids generated during the cook portion of said bottom surface is flat and has a ing process to, and through, said apertures and into diameter large enough to enable said main central 10 said peripheral channel. portion of said bottom structure to make abutting,

(*) Notice: Subject to any disclaimer, the term of this E. E. E. E. O.C.

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

III. United States Patent (19) Binacchi. Attorney, Agent, or Firm-Bucknam and Archer 57 ABSTRACT. 6 Claims, 3 Drawing Sheets

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

(12) United States Patent (10) Patent No.: US 6,813,994 B2

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

US A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

United States Patent (19) 11) 4,167,008 Blickenstaff 45) Sep. 4, 1979

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

Sept. 7, l.t. ward 2,092,596 SIPHON

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

March 24, 1970 H. H. BRIDGFORD 3,502,488 COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER HUGH. BROGFORD / ATTORNEY

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. Lange (43) Pub. Date: Nov. 22, 2012

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

United States Patent (19) Forino

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(12) United States Patent (10) Patent No.: US 7,325,807 B1. Eason (45) Date of Patent: Feb. 5, 2008

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

7 IANSNA. (12) Patent Application Publication (10) Pub. No.: US 2003/ A1. (19) United States 2//

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

United States Patent It 3,593,647

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

United States Patent [11] 3,559,565

![United States Patent [11] 3,559,565 United States Patent [11] 3,559,565](/thumbs/93/114425987.jpg) United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

United States Patent (19)

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) D'Alessandro

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

United States Patent (19)

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

United States Patent (19) Bowen et al.

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

Dec. 9, M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

(12) United States Patent

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

May 12, ,282,708 T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE. Filed Sept. 26, Sheets-Sheet l. --No.zzzzzzzzzzae.

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1. Hurley et al. (43) Pub. Date: Aug. 28, PROCESS Publication Classification

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

3. : 12- C) {X C> C) () {X -K) --KX-KX-KX-K)--C-2 --C)-- (12) Patent Application Publication (10) Pub. No.: US 2012/ A1 4 - (19) United States

(19) United States US 2012O138603A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0138603 A1 McGuinness et al. (43) Pub. Date: Jun. 7, 2012 (54) VARIABLE GEOMETRY TORTILLA COOKINGAPPARATUS

(19) United States US 2012O138603A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0138603 A1 McGuinness et al. (43) Pub. Date: Jun. 7, 2012 (54) VARIABLE GEOMETRY TORTILLA COOKINGAPPARATUS

3,702,608 11/1972 Tibbs. states by bying O st plunger T.

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

United States Patent (19) Ludder

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

United States Patent (19)

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

PATENT ATTORNEYS EXAMINATION

2014 PATENT ATTORNEYS EXAMINATION PAPER E The New Zealand Law and Practice relating to Interpretation and Criticism of Patent Specifications Regulation 158 (1) (e) Duration: 4 hours (plus 10 minutes for

2014 PATENT ATTORNEYS EXAMINATION PAPER E The New Zealand Law and Practice relating to Interpretation and Criticism of Patent Specifications Regulation 158 (1) (e) Duration: 4 hours (plus 10 minutes for

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0187694 A1 Cai US 2004O187694A1 (43) Pub. Date: (54) (76) (21) (22) (63) HOLDER FOR PRESSURE-BREWING COFFEE DRINK Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0187694 A1 Cai US 2004O187694A1 (43) Pub. Date: (54) (76) (21) (22) (63) HOLDER FOR PRESSURE-BREWING COFFEE DRINK Inventor:

III. United States Patent (19) 5,590,586 Jan. 7, % 4. Ulfig et al. (75) Inventors: Kimberly A. Ulfig, Glen Ellyn;

United States Patent (19) Ulfig et al. 54 KITCHEN LAYOUT, SYSTEM (75) Inventors: Kimberly A. Ulfig, Glen Ellyn; Patricia A. Venetucci, Hawthorn Woods, both of Ill. (73) Assignee: Restaurant Technology,

United States Patent (19) Ulfig et al. 54 KITCHEN LAYOUT, SYSTEM (75) Inventors: Kimberly A. Ulfig, Glen Ellyn; Patricia A. Venetucci, Hawthorn Woods, both of Ill. (73) Assignee: Restaurant Technology,

Center et al. (45. Date of Patent: Aug. 29, 1995

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

US 20070178190A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0178190 A1 Vatelot (43) Pub. Date: Aug. 2, 2007 (54) GRAPE TREATMENT METHOD FOR WINE (30) Foreign Application

US 20070178190A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0178190 A1 Vatelot (43) Pub. Date: Aug. 2, 2007 (54) GRAPE TREATMENT METHOD FOR WINE (30) Foreign Application

(12) Patent Application Publication (10) Pub. No.: US 2010/ A1

(19) United States US 2010.0005979A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0005979 A1 Baccetti (43) Pub. Date: Jan. 14, 2010 (54) DISPOSABLE BEVERAGE PRESS Publication Classification

(19) United States US 2010.0005979A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0005979 A1 Baccetti (43) Pub. Date: Jan. 14, 2010 (54) DISPOSABLE BEVERAGE PRESS Publication Classification

United States Patent (19) Aldrich

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

Coffeemaker. Coffeemaker Safety... 2 Parts and Features... 3 Using Your Coffeemaker... 4 Cleaning Your Coffeemaker... 4 Customer Service...

Coffeemaker Coffeemaker Safety... 2 Parts and Features... 3 Using Your Coffeemaker... 4 Cleaning Your Coffeemaker... 4 Customer Service... 6 In USA: 1-800-851-8900 In Canada: 1-800-267-2826 840069400 Coffeemaker

Coffeemaker Coffeemaker Safety... 2 Parts and Features... 3 Using Your Coffeemaker... 4 Cleaning Your Coffeemaker... 4 Customer Service... 6 In USA: 1-800-851-8900 In Canada: 1-800-267-2826 840069400 Coffeemaker

(12) United States Patent

(12) United States Patent Chapman et al. USOO6539842B1 (10) Patent No.: (45) Date of Patent: US 6,539,842 B1 Apr. 1, 2003 (54) (75) (73) (21) (22) (51) (52) (58) (56) ROTISSERIE SYSTEM HAVING AREMOTE TEMPERATURE

(12) United States Patent Chapman et al. USOO6539842B1 (10) Patent No.: (45) Date of Patent: US 6,539,842 B1 Apr. 1, 2003 (54) (75) (73) (21) (22) (51) (52) (58) (56) ROTISSERIE SYSTEM HAVING AREMOTE TEMPERATURE

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

US 20020074337A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2002/0074337 A1 Melton (43) Pub. Date: Jun. 20, 2002 (54) PRINTED INSERTS FOR THERMOFORMED Related U.S. Application

US 20020074337A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2002/0074337 A1 Melton (43) Pub. Date: Jun. 20, 2002 (54) PRINTED INSERTS FOR THERMOFORMED Related U.S. Application

Sugar maple tree named Legacy

( 1 of 1 ) United States Patent PP4,979 Wandell February 1, 1983 Sugar maple tree named Legacy Abstract This disclosure concerns a new and distinct variety of Acer saccharum (commonly known as sugar maple

( 1 of 1 ) United States Patent PP4,979 Wandell February 1, 1983 Sugar maple tree named Legacy Abstract This disclosure concerns a new and distinct variety of Acer saccharum (commonly known as sugar maple

JUICE EXTRACTION AND FILTRATION JUICE EXTRACTION METHOD AND EQUIPMENT

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120279416A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0279416A1 Nishimura et al. (43) Pub. Date: Nov. 8, 2012 (54) RAILCAR BOGIE (52) U.S. Cl.... 105/218.1 (75)

(19) United States US 20120279416A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0279416A1 Nishimura et al. (43) Pub. Date: Nov. 8, 2012 (54) RAILCAR BOGIE (52) U.S. Cl.... 105/218.1 (75)

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

Aroma Fresh. Instructions for use Includes recipes. Model BCM120

Aroma Fresh Instructions for use Includes recipes Model BCM120 Contents Page Breville recommends safety first 4 Know your Breville Aroma Fresh Coffee Maker 5 Operating your Breville Aroma Fresh Coffee

Aroma Fresh Instructions for use Includes recipes Model BCM120 Contents Page Breville recommends safety first 4 Know your Breville Aroma Fresh Coffee Maker 5 Operating your Breville Aroma Fresh Coffee

(12) United States Patent

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

Grooving Tool: used to cut the soil in the liquid limit device cup and conforming to the critical dimensions shown in AASHTO T 89 Figure 1.

DETERMINING THE LIQUID LIMIT OF SOILS FOP FOR AASHTO T 89 Scope This procedure covers the determination of the liquid limit of a soil in accordance with AASHTO T 89-13. It is used in conjunction with the

DETERMINING THE LIQUID LIMIT OF SOILS FOP FOR AASHTO T 89 Scope This procedure covers the determination of the liquid limit of a soil in accordance with AASHTO T 89-13. It is used in conjunction with the

United States Patent (19) Best

United States Patent (19) Best 54 INFRARED GAS GRILL 76 Inventor: Willie H. Best, 18C The Heritage, Columbia, S.C. 29201 (21) Appl. No.: 138,854 22 Filed: Apr. 8, 1980 51) Int. C.... A47J 37/04 52 U.S.C....

United States Patent (19) Best 54 INFRARED GAS GRILL 76 Inventor: Willie H. Best, 18C The Heritage, Columbia, S.C. 29201 (21) Appl. No.: 138,854 22 Filed: Apr. 8, 1980 51) Int. C.... A47J 37/04 52 U.S.C....

Shotmeister Owner s Manual. The Sleekest Design, Pouring the Coldest Shots

Shotmeister Owner s Manual The Sleekest Design, Pouring the Coldest Shots Thank you for purchasing a Jägermeister Shotmeister! REGISTRATION INFORMATION Register your Jägermeister Shotmeister Online: at

Shotmeister Owner s Manual The Sleekest Design, Pouring the Coldest Shots Thank you for purchasing a Jägermeister Shotmeister! REGISTRATION INFORMATION Register your Jägermeister Shotmeister Online: at

(12) United States Patent (10) Patent No.: US 7,780,033 B2

USOO7780033B2 (12) United States Patent (10) Patent No.: Mansfield et al. (45) Date of Patent: Aug. 24, 2010 (54) PLURAL CHAMBER DRINKING CUP (56) References Cited U.S. PATENT DOCUMENTS (75) Inventors:

USOO7780033B2 (12) United States Patent (10) Patent No.: Mansfield et al. (45) Date of Patent: Aug. 24, 2010 (54) PLURAL CHAMBER DRINKING CUP (56) References Cited U.S. PATENT DOCUMENTS (75) Inventors:

1. IMPORTANT SAFEGUARDS When using electrical appliances, basic safety precautions should always be followed to reduce the risk of fire, electric

1. IMPORTANT SAFEGUARDS When using electrical appliances, basic safety precautions should always be followed to reduce the risk of fire, electric shock, and/pr injury to persons including the following:

1. IMPORTANT SAFEGUARDS When using electrical appliances, basic safety precautions should always be followed to reduce the risk of fire, electric shock, and/pr injury to persons including the following:

Aaawaw A. M1axsom. - A 474/2/sr.przezz' SecY72/7. April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES.

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

A33. AORNEY. March 22, G. C. HERZ, 1,850,719. APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC. Filed Dec, l6, l Sheets-Sheet l NVENTOR

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

III IIIHIII. United States Patent (19) Momiyama

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

VCS325SSBI Series and VCS525SSBI Series Assembly Procedures

VCS325SSBI Series and VCS525SSBI Series Assembly Procedures Model VCS525SSBI Shown Tools Required: Knife or scissors, Phillips or Robertson (square head) screwdriver. WARNING: Some parts may have sharp

VCS325SSBI Series and VCS525SSBI Series Assembly Procedures Model VCS525SSBI Shown Tools Required: Knife or scissors, Phillips or Robertson (square head) screwdriver. WARNING: Some parts may have sharp

(12) United States Patent

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

5KEK1322 W A_v08.indd 1 5/13/16 2:25 PM

5KEK1322 W10878653A_v08.indd 1 PARTS AND FEATURES PARTS AND ACCESSORIES Tea steeper lid (center section of lid with handle) Kettle lid (outer section) Stainless steel lime scale filter Removable stainless

5KEK1322 W10878653A_v08.indd 1 PARTS AND FEATURES PARTS AND ACCESSORIES Tea steeper lid (center section of lid with handle) Kettle lid (outer section) Stainless steel lime scale filter Removable stainless

United States Patent (19) Weller et al.

United States Patent (19) Weller et al. 54 BEVERAGE BREWING MACHINE 75 Inventors: Albrecht Weller, Steinbach; Georges Driesen, Niederhöchstadt, Andreas Peter, Kronberg; Peter Herber; Gerhard Schäfer, both

United States Patent (19) Weller et al. 54 BEVERAGE BREWING MACHINE 75 Inventors: Albrecht Weller, Steinbach; Georges Driesen, Niederhöchstadt, Andreas Peter, Kronberg; Peter Herber; Gerhard Schäfer, both

assembly guide ELECTRIC Model Numbers: Estimated time required for assembly: 1 Hour (English) /05/09

assembly guide Model Numbers: 08601559 10601578 10601585 10601514 Estimated time required for assembly: 1 Hour ELECTRIC (English) 42804372 11/05/09 2 ASSEMBLY GUIDE A, B, C, Assembly: CAUTION: For your

assembly guide Model Numbers: 08601559 10601578 10601585 10601514 Estimated time required for assembly: 1 Hour ELECTRIC (English) 42804372 11/05/09 2 ASSEMBLY GUIDE A, B, C, Assembly: CAUTION: For your

Notes on pressure fermentation

Notes on pressure fermentation Geoff Dye During World War II the fermenting room at Coopers Brewery, Southampton, received a direct hit which put it completely out of action, but left the brewhouse (wort

Notes on pressure fermentation Geoff Dye During World War II the fermenting room at Coopers Brewery, Southampton, received a direct hit which put it completely out of action, but left the brewhouse (wort

(12) Patent Application Publication (10) Pub. No.: US 2017/ A1

US 201700 13866A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2017/0013866A1 Tanaka et al. (43) Pub. Date: (54) EXTRUDED NOODLE AND DIE PIECE FOR (30) Foreign Application Priority

US 201700 13866A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2017/0013866A1 Tanaka et al. (43) Pub. Date: (54) EXTRUDED NOODLE AND DIE PIECE FOR (30) Foreign Application Priority

52 U.S. Cl... 99/295; 99/299; 99/305; 99/ / ) References Cited U.S. PATENT DOCUMENTS 1,778,792 10/1930 Cameron...

United States Patent (19) Glucksman (54) APPARATUS FOR BREWING COFFEE 76) Inventor: Dov Z. Glucksman, 137 Larch Row, Wenham, Mass. 01984 21 Appl. No.: 636,137 22 Filed: Dec. 31, 1990 51 Int. Cl.5......

United States Patent (19) Glucksman (54) APPARATUS FOR BREWING COFFEE 76) Inventor: Dov Z. Glucksman, 137 Larch Row, Wenham, Mass. 01984 21 Appl. No.: 636,137 22 Filed: Dec. 31, 1990 51 Int. Cl.5......

(12) Plant Patent Application Publication

(19) United States (12) Plant Patent Application Publication Pate US 201001.38965P1 (10) Pub. No.: US 2010/0138965 P1 (43) Pub. Date: Jun. 3, 2010 (54) BLUEBERRY VARIETY NAMED BLUE MOON (75) Inventor:

(19) United States (12) Plant Patent Application Publication Pate US 201001.38965P1 (10) Pub. No.: US 2010/0138965 P1 (43) Pub. Date: Jun. 3, 2010 (54) BLUEBERRY VARIETY NAMED BLUE MOON (75) Inventor:

Charcoal Grill WARNING: Kay Home Products TM

Kay ome Products T 30052 Charcoal rill WARNN: Your grill is intended for residential outdoor use only. Do not use for commercial cooking. Do not use in or on boats or recreational vehicles. Do not use

Kay ome Products T 30052 Charcoal rill WARNN: Your grill is intended for residential outdoor use only. Do not use for commercial cooking. Do not use in or on boats or recreational vehicles. Do not use

TECHNOLOGIES DEMONSTRATED AT ECHO: BRIQUETTE PRESSES FOR ALTERNATE FUEL USE

Copyright 2001 TECHNOLOGIES DEMONSTRATED AT ECHO: BRIQUETTE PRESSES FOR ALTERNATE FUEL USE BY JASON DAHLMAN WITH CHARLIE FORST Published 2001 AN ECHO TECHNICAL NOTE INTRODUCTION Briquettes made from materials

Copyright 2001 TECHNOLOGIES DEMONSTRATED AT ECHO: BRIQUETTE PRESSES FOR ALTERNATE FUEL USE BY JASON DAHLMAN WITH CHARLIE FORST Published 2001 AN ECHO TECHNICAL NOTE INTRODUCTION Briquettes made from materials

(12) Patent Application Publication (10) Pub. No.: US 2017/ A1

(19) United States US 2017.0089590A1 (12) Patent Application Publication (10) Pub. No.: US 2017/0089590 A1 Bruin-Slot et al. (43) Pub. Date: Mar. 30, 2017 (54) OVEN CAVITY CONNECTOR FOR (52) U.S. Cl. OPERATING

(19) United States US 2017.0089590A1 (12) Patent Application Publication (10) Pub. No.: US 2017/0089590 A1 Bruin-Slot et al. (43) Pub. Date: Mar. 30, 2017 (54) OVEN CAVITY CONNECTOR FOR (52) U.S. Cl. OPERATING

United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993

USOO5230281A United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993 (54) APPARATUS FOR ROASTING COFFEE 4,924.765 5/1990 Pera... 99/470 BEANS OR THE LIKE

USOO5230281A United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993 (54) APPARATUS FOR ROASTING COFFEE 4,924.765 5/1990 Pera... 99/470 BEANS OR THE LIKE

INFRARED BURNER KIT INSTRUCTIONS

3 INFRARED BURNER KIT INSTRUCTIONS (HOT SURFACE IGNITION) 5 1 4 NOTE: This unit has been retrofi tted with an infrared burner. Model # 3050 # 3060 Included parts 2 6* PARTS INCLUDED 1. Infrared burner

3 INFRARED BURNER KIT INSTRUCTIONS (HOT SURFACE IGNITION) 5 1 4 NOTE: This unit has been retrofi tted with an infrared burner. Model # 3050 # 3060 Included parts 2 6* PARTS INCLUDED 1. Infrared burner

Smart Plunger TM by PCS

Smart Plunger TM by PCS What they are Highly accurate downhole pressure & temperature gauges Contained inside a variety of high quality plunger styles Utilized in a traveling mode or stationary position

Smart Plunger TM by PCS What they are Highly accurate downhole pressure & temperature gauges Contained inside a variety of high quality plunger styles Utilized in a traveling mode or stationary position

(12) United States Patent (10) Patent No.: US 6,419,120 B1

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

US 20140123859A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0123859 A1 Verbeek (43) Pub. Date: May 8, 2014 (54) PREPARATION OF AN ARABIC COFFEE (52) U.S. Cl. BEVERAGE

US 20140123859A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0123859 A1 Verbeek (43) Pub. Date: May 8, 2014 (54) PREPARATION OF AN ARABIC COFFEE (52) U.S. Cl. BEVERAGE

SIMPLEX STRAINER MODEL 90

The Eaton Model 90 Fabricated Simplex Strainer has been designed for manufacturing flexibility. It can be made for pipeline sizes from 1 to 48 in carbon steel or stainless steel although other materials

The Eaton Model 90 Fabricated Simplex Strainer has been designed for manufacturing flexibility. It can be made for pipeline sizes from 1 to 48 in carbon steel or stainless steel although other materials

3,000 POUND CAPACITY AUTO BODY ROTISSERIE UNIT

3,000 POUND CAPACITY AUTO BODY ROTISSERIE UNIT INSTALLATION / OWNERS MANUAL ROTISSERIE (R3000G) 1 IN50016 Rev. B 03/30/2009 TABLE OF CONTENTS IMPORTANT INFORMATION...pg 2 OWNER / EMPLOYER RESPONSIBILITIES...pg

3,000 POUND CAPACITY AUTO BODY ROTISSERIE UNIT INSTALLATION / OWNERS MANUAL ROTISSERIE (R3000G) 1 IN50016 Rev. B 03/30/2009 TABLE OF CONTENTS IMPORTANT INFORMATION...pg 2 OWNER / EMPLOYER RESPONSIBILITIES...pg

(22 Filed: Feb. 8, 1988 s (51l Int. Cl."... A015/ U.S. C... Plt./88

United States Patent (19) Brown (54) AGLAONEMAQUEEN OF SIAM 75 Inventor: B. Frank Brown, Palm Bay, Fla. 73) Assignee: Weyerhaeuser Company, Tacoma, Wash. 21 Appl. No.: 153,735 (22 Filed: Feb. 8, 1988 s

United States Patent (19) Brown (54) AGLAONEMAQUEEN OF SIAM 75 Inventor: B. Frank Brown, Palm Bay, Fla. 73) Assignee: Weyerhaeuser Company, Tacoma, Wash. 21 Appl. No.: 153,735 (22 Filed: Feb. 8, 1988 s

Cucina HD2423, HD2422, HD2421, HD2420

Cucina HD2423, HD2422, HD2421, HD2420 2 2 3 2 3 4 ENGLISH 6 16 24 33 HD2423, 2422, 2421, 2420 6 ENGLISH Important Always follow basic safety precautions when using electrical appliances. Read these directions

Cucina HD2423, HD2422, HD2421, HD2420 2 2 3 2 3 4 ENGLISH 6 16 24 33 HD2423, 2422, 2421, 2420 6 ENGLISH Important Always follow basic safety precautions when using electrical appliances. Read these directions

Assembly Procedures VCS322SSBI Series / VCS522SSBI Series

Assembly Procedures VCS322SSBI Series / VCS522SSBI Series Tools Required: Knife or scissors, Phillips or Robertson (square head) screwdriver. Model VCS522SSBI Shown CAUTION: This grill is intended ONLY

Assembly Procedures VCS322SSBI Series / VCS522SSBI Series Tools Required: Knife or scissors, Phillips or Robertson (square head) screwdriver. Model VCS522SSBI Shown CAUTION: This grill is intended ONLY

(12) United States Patent

US007582325B2 (12) United States Patent Giori () Patent No.: (45) Date of Patent: Sep. 1, 2009 (54) PROCESS FOR THE PREPARATION OF TOMATO EXTRACTS WITH HIGH CONTENT IN LYCOPENE (75) Inventor: Andrea Giori,

US007582325B2 (12) United States Patent Giori () Patent No.: (45) Date of Patent: Sep. 1, 2009 (54) PROCESS FOR THE PREPARATION OF TOMATO EXTRACTS WITH HIGH CONTENT IN LYCOPENE (75) Inventor: Andrea Giori,

(12) United States Patent

(12) United States Patent USOO8469225B2 () Patent No.: US 8,469.225 B2 Fredland (45) Date of Patent: Jun. 25, 2013 (54) SEMI-RIGID BEVERAGE RECEPTACLE (56) References Cited (75) Inventor: Richard Fredland,

(12) United States Patent USOO8469225B2 () Patent No.: US 8,469.225 B2 Fredland (45) Date of Patent: Jun. 25, 2013 (54) SEMI-RIGID BEVERAGE RECEPTACLE (56) References Cited (75) Inventor: Richard Fredland,

(51) Int Cl.: A47J 31/18 ( ) A47J 31/46 ( )

(19) TEPZZ 7_ 95B_T (11) EP 2 712 295 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention of the grant of the patent: 31.08.16 Bulletin 16/35 (21) Application number: 12712780.1

(19) TEPZZ 7_ 95B_T (11) EP 2 712 295 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention of the grant of the patent: 31.08.16 Bulletin 16/35 (21) Application number: 12712780.1

INTRODUCTION TO CUSTOM FABRICATED STRAINERS

INTRODUCTION TO CUSTOM FABRICATED STRAINERS Nothing Too Big, Too Small or Too Special When unwanted solid material has to be removed from flowing fluids in order to protect equipment, a HAYWARD Strainer

INTRODUCTION TO CUSTOM FABRICATED STRAINERS Nothing Too Big, Too Small or Too Special When unwanted solid material has to be removed from flowing fluids in order to protect equipment, a HAYWARD Strainer

R. 36. azzo 1/2-Za-Yas. Nov. 18, 1969 J. P. H. LANES 3,478,669 APPARATUS FOR MAKING WINE Z2/27/7212. E. y N AA A. as SS f.

Nov. 18, 1969 J. P. H. LANES APPARATUS FOR MAKING WINE Filed Sept. 16, 1966 2. Sheets-Sheet l R. 36. re-war Nanuma - measuresheat s, a. AA A. E. y N as SS f M Z2/27/7212 azzo 1/2-Za-Yas Nov. 18, 1969 J.

Nov. 18, 1969 J. P. H. LANES APPARATUS FOR MAKING WINE Filed Sept. 16, 1966 2. Sheets-Sheet l R. 36. re-war Nanuma - measuresheat s, a. AA A. E. y N as SS f M Z2/27/7212 azzo 1/2-Za-Yas Nov. 18, 1969 J.

INTRODUCTION. Your new smoker comes almost completely assembled. You will need to complete the assembly which includes:

INTRODUCTION Congratulations on your purchase of this Smith & Wesson SMOKER, Model SWS032. With proper set-up, operation and maintenance, this smoker will provide you with years of cooking enjoyment. Your

INTRODUCTION Congratulations on your purchase of this Smith & Wesson SMOKER, Model SWS032. With proper set-up, operation and maintenance, this smoker will provide you with years of cooking enjoyment. Your

Wi-Fi Coffee Maker. Model# GCMW-4750 USER MANUAL

Wi-Fi Coffee Maker Model# GCMW-4750 USER MANUAL Read this manual thoroughly before using and save it for future reference Model: GCMW-4750 2018 Gourmia www.gourmia.com The Steelstone Group Brooklyn, NY

Wi-Fi Coffee Maker Model# GCMW-4750 USER MANUAL Read this manual thoroughly before using and save it for future reference Model: GCMW-4750 2018 Gourmia www.gourmia.com The Steelstone Group Brooklyn, NY

Coffeemaker User's manual

Coffeemaker User's manual EN Prior to using this appliance, please read the user's manual thoroughly, even in cases where you have previously familiarised yourself with the operation of similar types of

Coffeemaker User's manual EN Prior to using this appliance, please read the user's manual thoroughly, even in cases where you have previously familiarised yourself with the operation of similar types of

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080216664A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0216664 A1 K00n et al. (43) Pub. Date: Sep. 11, 2008 (54) ELECTRONICTEATHERMOMETER AND TIMER DEVICE (75) Inventors:

(19) United States US 20080216664A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0216664 A1 K00n et al. (43) Pub. Date: Sep. 11, 2008 (54) ELECTRONICTEATHERMOMETER AND TIMER DEVICE (75) Inventors:

HOT SPOTS COOKING SAFETY

Many families gather in the kitchen to spend time together, but it can be one of the most hazardous rooms in the house if you don't practice safe cooking behaviors. Cooking equipment, most often a range

Many families gather in the kitchen to spend time together, but it can be one of the most hazardous rooms in the house if you don't practice safe cooking behaviors. Cooking equipment, most often a range

CODEX STANDARD FOR QUICK FROZEN STRAWBERRIES 1 CODEX STAN

CODEX STAN 52 Page 1 of 6 CODEX STANDARD FOR QUICK FROZEN STRAWBERRIES 1 CODEX STAN 52-1981 1. SCOPE This standard shall apply to quick frozen strawberries (excluding quick frozen strawberry puree) of

CODEX STAN 52 Page 1 of 6 CODEX STANDARD FOR QUICK FROZEN STRAWBERRIES 1 CODEX STAN 52-1981 1. SCOPE This standard shall apply to quick frozen strawberries (excluding quick frozen strawberry puree) of

---- ÆØerá Z3zzegzée. Vzerzega2ZY.Zazee. June 16, Zee/ErzezØrzs 2,286, Sheets-Sheet 2 D G O D D D OD

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

APPLICATION PACK FOR TRADE, CRAFT, FOOD AND CHARITY STALLS WITH TERMS AND CONDITIONS

RANNOCH HIGHLAND GATHERING 2017 Saturday 19 th August 2017 STALL / PITCH APPLICATION APPLICATION PACK FOR TRADE, CRAFT, FOOD AND CHARITY STALLS WITH TERMS AND CONDITIONS CONTACT DETAILS NAME TELEPHONE

RANNOCH HIGHLAND GATHERING 2017 Saturday 19 th August 2017 STALL / PITCH APPLICATION APPLICATION PACK FOR TRADE, CRAFT, FOOD AND CHARITY STALLS WITH TERMS AND CONDITIONS CONTACT DETAILS NAME TELEPHONE

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

(19) United States US 201101 17255A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0117255A1 BrOWn et al. (43) Pub. Date: (54) ALCOHOLIC BEVERAGE FORMULATION (52) U.S. Cl.... 426/330.4; 426/592

(19) United States US 201101 17255A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0117255A1 BrOWn et al. (43) Pub. Date: (54) ALCOHOLIC BEVERAGE FORMULATION (52) U.S. Cl.... 426/330.4; 426/592

Coffee Grinder Instruction Manual

Coffee Grinder Instruction Manual CoffeeGrinder Manual-English Only.indd 1 07/01/2016 14:14:39 Savisto Home Coffee Grinder Voltage Supply: 220-240V~ 50/60Hz Power Consumption: 150W Eng Please read through

Coffee Grinder Instruction Manual CoffeeGrinder Manual-English Only.indd 1 07/01/2016 14:14:39 Savisto Home Coffee Grinder Voltage Supply: 220-240V~ 50/60Hz Power Consumption: 150W Eng Please read through

COOL TOUCH. Place your Order Today! (Toll Free) LID HANDLE COVERS. Bringing another Great Product to Your Home

Great Product to Your Home Stop reaching for that potholder! COOL TOUCH LID HANDLE COVERS Protects against burns Conveniently remains on lids between uses. Provides a secure, comfortable grip. Dishwasher

Great Product to Your Home Stop reaching for that potholder! COOL TOUCH LID HANDLE COVERS Protects against burns Conveniently remains on lids between uses. Provides a secure, comfortable grip. Dishwasher