Center et al. (45. Date of Patent: Aug. 29, 1995

|

|

|

- Amos Hubbard

- 5 years ago

- Views:

Transcription

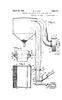

1 United States Patent (19) 11 USOO A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING 5,199,598 4/1993 Sampson. MACHINE 5,207,784 5/1993 Schwartzendruber. (75) Inventors: John L. Center; James W. Stalder, OTHER PUBLICATIONS both of Dallas, Tex. "Health Gards' advertisement from Vending Times, 73 Assignee: Recot, Inc., Wilmington, Del. Jul. 1987, p Appl. No.: 289,537 Primary Examiner-William E. Terrell Assistant Examiner-Dean A. Reichard 22 Filed: Aug. 12, 1994 Attorney, Agent, or Firm-Rothwell, Figg, Ernst & Kurz 51) Int. Cl... B65G 59/00 57 ABSTRACT 52 U.S.C /1; 221/150 R; X 221/199 A process for co-dispensing beverages and snack food 58 Field of Search /1, 133, 150 R, 199 products from a single vending machine. Filled bever - age containers and filled snack food containers are 56 References Cited stored in the vending machine and a buyer, upon pay U.S. PATENT DOCUMENTS ment, product selection, etc., can obtain both a bever /1959 Johnson. age, e.g., a soft drink, and a snack food, e.g., corn chips, 3.810,561 5/1974 Merk. from a single machine. The beverage and snack food 4,235,351 11/1980 Kölblet al.. containers preferably are of substantially the same size 4.483,459 11/1984 Taylor et al.. so that a vending machine of the type which dispenses 4.591,070 5/1986 Wirstlin. containers having a uniform size may be used to carry 2:7; 2. E. a a as a a '/'* out the present invention. A process for packaging 4920,764 5/1990 E. rey. 221/150 R X Snack food product in cylindrical containers also is 4,991,740 2/1991 Levasseur. disclosed. 4,997,106 3/1991 Rockola. 5,147,068 9/1992 Wright. 7 Claims, 3 Drawing Sheets 00 O

2 U.S. Patent Aug. 29, 1995 Sheet 1 of 3 5,445,287 C.

3 U.S. Patent Aug. 29, 1995 Sheet 2 of 3 5,445,287

4 U.S. Patent Aug. 29, 1995 Sheet 3 of 3 5,445,287

5 1 CO-DESPENSING SNACK FOOD PRODUCTS AND BEVERAGES FROM A VENDING MACHINE BACKGROUND OF THE INVENTION 1. Field of the Invention The present invention relates generally to processes for dispensing containers from vending machines or the like and, more particularly, to processes for dispensing both snack food products and beverages from a single vending machine. The present invention also relates to a novel process for packaging snack food products in cylindrical containers, including containers suitable for being dispensed by a vending machine. 2. Description of Relevant Art It is well known in the prior art to dispense bever ages, e.g., cans of soft drinks, from a coin-operated vending machine. Coin-operated vending machines also are used to dispense packages of food products, e.g., candy, snack foods such as potato chips or pretzels, or sandwiches. In the snack food art, salty snack food products, e.g. corn chips, cheese snacks, pretzels, etc., typically are packaged in bags formed of flexible packaging films, or canisters formed of paperboard material. These packag ing films typically are complex laminated structures that provide moisture and oxygen barrier layers to prevent premature staling or loss of product freshness. In addi tion, it is known to package food products such as pea nuts in a metal can having a resealable lid for maintain ing product freshness. In the prior art, a plurality of vending machines often are disposed or located together in a common area, e.g., a travel rest area or a snack bar. The machines contain and dispense various beverages, snack foods, candy, etc. However, in arrangements of the above-described type, the separate vending machines respectively dispense separate types of products. That is, a machine typically dispenses either beverages or food products, but not both. For example, a machine which dispenses cans of soft drinks does not dispense food products. Conse quently, a purchaser cannot obtain a beverage and a snack food product from prior art soft drink vending machines. The cost of a vending machine often prohibits its placement in certain locations where "turns,' or pur chases of the vended products, are not of sufficient frequency (relative to the product's shelf life) to pro vide an adequate return on investment. For this reason, it is not uncommon to find beverage vending machines standing alone without a snack food vending machine. Also, as beverage vending machines are refrigerated while snack food vending machines are not, there are many outdoor vending locations that are hostile to the placement of snack food vending machines due to tem perature and moisture extremes. Snack-food or rest-area vending arrangements often include an oven for cooking food products purchased from the machines. It is known in the prior art to com bine a microwave oven with a food-vending machine to permit the products to be cooked and then dispensed to the purchaser. See e.g., U.S. Pat. No. 5,147,068, which teaches that the food products may be dispensed by a conventional soft drink vending machine. The U.S. Pat. No. 5,147,068, however, does not teach or suggest dis pensing both a beverage product and a food product from a single vending machine but, rather, teaches only 5,445, the conventional usage of a machine to dispense only one product or the other. U.S. Pat. No. 2,901,964 discloses a vending machine with means for heating refrigerated sandwiches. The purchaser selects a type of sandwich which is then heated and dispensed by the machine. U.S. Pat. No. 5,207,784 discloses a monitoring system for monitoring the inventory status of vending machines from a remote location. U.S. Pat. No. 3,810,561 discloses a vending machine for dispensing containers having a circular cross-section through a discharge port. The U.S. Pat. No. 3,810,561 teaches that although the containers typi cally will be cans of soda, other items also can be dis pensed in the circular containers. However, as with the patents mentioned above, the U.S. Pat. No. 3,810,561 does not teach or suggest dispensing both a beverage and food product from a single soft drink vending ma chine. It is apparent that prior art product vending or dis pensing apparatus, such as those discussed above, dis pense either a beverage or a food product and, there fore, do not permit a purchaser to obtain both a bever age, e.g. a soft drink, and a snack food product, e.g. corn chips, from a single soft drink vending machine. Ac cordingly, there is a need in the art for improved dis pensing of such products. SUMMARY OF THE INVENTION The present invention provides a process for co-dis pensing beverages and snack food products from a sin gle vending machine, i.e., dispensing both filled bever age containers and filled food product containers from the same vending machine. Although not absolutely necessary to carry out the process of the present inven tion, the food product containers preferably have a size and shape substantially the same as the size and shape of the beverage containers. For example, both containers can be aluminum cans with a removable opening. This permits a conventional, refrigerated soft drink vending machine to be used to dispense both beverages and food products according to the present invention. Thus, the present invention provides a highly economical and efficient system for dispensing both refrigerated bever ages and snack foods via pre-existing soft drink vending machines. BRIEF DESCRIPTION OF THE DRAWINGS Other objects, features and advantages of the present invention will become more apparent from the follow ing detailed description of a preferred embodiment thereof taken in conjunction with the accompanying drawing figures, wherein: FIGS. 1A and 1B, respectively, are elevation views of a filled beverage container and a filled food product container which may be dispensed from a single vend ing machine according to the process of the present invention; FIGS. 2A and 2B, respectively, are plan views of the containers depicted in FIGS. 1A and 1B: FIG. 3 is a perspective schematic view of a vending machine that may be used in carrying out the process of the present invention; and FIG. 4 is a schematic diagram of a process for pack aging snack foods in a cylindrical container.

6 3 DETAILED DESCRIPTION OF PREFERRED EMBODIMENTS As stated above, the present invention provides a process for co-dispensing beverages and food products from a single vending machine. For the sake of simplic ity, apparatus which may be utilized to carry out the process of the present invention will be referred to collectively as vending machines. Such apparatus in clude, but are not limited to, conventional coin operated soft drink vending machines known in the art. FIG. 1 depicts a filled beverage container 10 and a filled snack food product container 30. The beverage container 10 preferably is aluminum and has a shape and size such that the container can be dispensed by a con ventional soft drink vending machine. Beverage con tainer 10 can be in the form of a conventional recyclable aluminum soft drink can including a body 12 with suit able advertising indicia as seen in FIG. 1A, and a pop top or like easy opening closure indicated generally at 14 (FIG. 2A). Closure 14 is conventional and includes a pull ring 16 which when lifted upward punches section 18 from upper surface 20 to provide an outlet, all as known in the art. Snack food product container 30 likewise can be in the form of a recyclable aluminum can having a body 32 with advertising indicia and an easy-opening closure indicated generally at 34 (FIG. 2B). As will be ex plained below, utilizing a snack food container that has the same or substantially the same size and shape as a conventional soft drink can permits a conventional soft drink vending machine to be used in practicing the present invention. Closure 34 differs from the closure 14 of beverage container 10 in that the entire upper surface 40 of container 30 preferably is removed to gain access to the contents thereof, i.e., the snack food product which, in FIG. 1B, is a snack food marketed by Frito Lay, Inc. under the trademark CHEE TOS (R) brand cheese flavored snacks. Pull ring 36 is grasped and lifted upward to depress portion 38 of surface 40 so as to permit easy removal thereof. This type of closure is known in the art and, therefore, is not discussed in fur ther detail. It will be recognized that containers 10 and 30 may be of any size. For example, the containers may have a 12 or 16 fluid ounce capacity, or any other fluid capacity. Fluid capacity, of course, refers to both containers 10 and 30 although only container 10 contains a beverage. In a preferred embodiment, both container 10 and con tainer 30 have a 12 fluid ounce capacity, and, therefore, may be dispensed by a conventional soft drink vending machine. FIG. 3 shows a perspective schematic view of a vending machine for dispensing both food and drink containers according to the present invention. The vending machine 100 includes an outer housing 102, a payment mechanism 104, a selector panel mechanism 106, and a dispensing outlet 108. The vending machine 100 further includes a front door 110 which is pivotally connected to housing 102 and can be opened to provide access to the interior of the machine to, e.g., refill the product supply and collect the money deposited in the machine. The front door 110 of vending machine 100 can have a suitable advertising display or indicia 112 which, in FIG. 1, depicts a beverage item and a snack food item contained therein. The operation of vending machine 100 is well known to and appreciated by those skilled in the art and thus 5,445,287 O will not be explained in any great detail herein. As mentioned above, the process of the present invention can be carried out utilizing conventional soft drink vending apparatus, i.e., the present invention does not require a specifically designed vending machine. Thus, the operation of such apparatus in response to the inser tion of money therein will not be described in detail. The process of the present invention can be practiced with a vending machine having sufficient internal space for storage of filled beverage and snackfood containers, and means for permitting a user to select a specific beverage or food item which item is dispensed upon the insertion of sufficient money in the machine. Accord ingly, it is possible to employ a conventional soft drink vending machine by using a portion of the soft drink container storage area for food product containers. Thus, the structure (e.g. tracks) used to convey or di rect soft drink containers to the outlet from the stacks in that portion of the storage area, according to the pres ent invention, instead direct snack food containers to the outlet from the stacks in that storage portion. Although those skilled in the art will appreciate the use of a conventional vending machine to carry out the present invention (as described above), a brief discus sion of such a machine will be made for the sake of clarity. Conventional soft drink vending machines typically have a plurality of holding stacks of a certain width and depth for holding a supply of soft drink containers. A dispenser mechanism typically is disposed at a lower portion of each holding stack and is operable by a drive mechanism. The drive mechanisms, in response to pur chaser selection, operate the respective dispenser mech anisms to dispense a soft drink container via the vending machine outlet. For example, U.S. Pat. No. 4,991,740 discloses a known type of vending machine that may be used in carrying out the process of the present inven tion. The U.S. Pat. No. 4,991,740 discloses a vending machine including horizontally-spaced container stacks with respective release mechanisms and a single ma chine outlet, as disclosed in FIGS. 1-5 and columns 4-8 of the U.S. Pat. No. 4,991,740, which disclosure is ex pressly incorporated by reference into the present appli cation. However, those skilled in the art, of course, will appreciate that other vending machine structures and apparatus may be used as well. Other known vending machines, e.g., those which include vertically-spaced container stacks, may also be used to carry out the present invention. U.S. Pat. No. 4,483,459 discloses a machine having vertically-spaced container stacks, as seen in FIGS. 2 and 3 therein. The operation of the vending machine in the U.S. Pat. No. 4,483,459 patent is disclosed in FIGS. 2-5 and columns 2-5, which disclosure also is expressly incorporated by reference in the present application. In a preferred embodiment of the present invention, the snack food container 30 is pressurized at about 5-15 psi (pounds per square inch) to give it added strength so as to prevent the container (aned snack food product) from being crushed or damaged during transportation, Storage, etc. - With reference to FIG. 4, a process for packaging snack foods in cylindrical containers 300 will now be described. The empty containers 300, which are open at the top thereof, preferably are flushed with nitrogen gas at a flushing station 310 to remove any oxygen present therein. The containers then are fed or directed to a filling station 320 equipped with a device or assembly

7 5,445,287 5 that includes a filling head for dispensing precise me tered amounts of the snack food product, e.g. corn chips, pretzels, cheese snacks, etc., from a supply 330 into the empty containers 300. The filling equipment can be in the form of a rotary table, conveyor belt or system, etc. The containers 300 should be positively captured or controlled during the filling process so that the amount of product placed therein can be controlled very accurately. It may be desirable to also flush the product itself 10 with nitrogen gas so as to substantially remove the oxygen captured or trapped therein to provide longer shelf life for the product. This can be done before the product is placed in the containers or, alternatively, may be accomplished after filling (but before sealing) of 15 the containers by passing the filled containers through area 340 (shown in phantom). Area 340 may be in the form of a tunnel, chamber, etc., that contains a nitrogen rich environment to remove oxygen from the product as the containers pass therethrough. It is desirable to reduce the oxygen content of the product to about 2% or less in order to provide long shelf life and product freshness. The containers are then sealed with a lid at a sealing station 350. The sealing of the containers may take place while the containers still are within the nitrogen envi ronment, i.e., area 340 in FIG. 4.). The lids used to seal the containers, as described above with respect to FIG. 2B, are designed for easy removal. In a preferred em bodiment, a small amount of liquid nitrogen is placed in the filled containers before the containers are sealed, as indicated by reference numeral 345 in FIG. 4. The liq uid nitrogen evaporates after the containers are sealed to provide additional internal pressurization of the con tainer, which in turn provides increased columnar and overall strength against crushing or deformation. In addition, the pressurization of the snack food container causes an audible noise upon opening which indicates the fresh and untampered condition of the product. As described above with respect to filled snack food con tainer 30 shown in FIGS. 1B and 2B, the purchaser simply pulls up the ring 36 and completely removes cover 40 to gain access to the product. As mentioned above, a significant benefit of packag ing the snack foods in a container having substantially the same size and shape as a soft drink can is that con ventional soft drink vending machines may be used to carry out the present invention. Therefore, while it is not necessary to utilize such similarly sized cans for packaging or containing the snack food products, a preferred embodiment of the present invention employs the same size can for both the beverage and snack food containers. Another benefit of utilizing the soft drink vending machine in carrying out the process of the present in vention is that the refrigerated environment present in the machine will maintain freshness of the snack food product for a longer period of time compared with storing such products at ambient temperatures. The lower storage temperature retards the oxidation of oil within the snack food, which in turn preserves the snack food's flavor for a longer period of time. It is apparent that the present invention provides an improved process for dispensing both beverages and snack food products from a vending machine, as well as a process for packaging snack foods in cylindrical con tainers suitable for being dispensed from a vending machine. 6 Although the present invention has been described with reference to particular embodiments, it is to be understood that the embodiments are merely illustrative of the application of the principles of the invention. Numerous configurations may be made therewith and other arrangements may be devised without departing from the spirit and scope of the invention. We claim: 1. A process for dispensing beverages and snack food products from a single vending machine, the process comprising steps of: providing a vending machine having a storage por tion for storing containers which have a predeter mined size and shape so as to be receivable in the storage portion of said vending machine; placing a plurality of containers filled with a bever age in the storage portion of said vending machine, each of the filled beverage containers having sub stantially the same size and shape; and 20 placing a plurality of containers filled with a snack food product in the storage portion of said vending machine, each of the filled snack food containers having a size and shape that are substantially the same as the size and shape of the filled beverage 25 containers; whereby said vending machine is capable of dispens ing both a filled beverage container and a filled snack food container when operated by a user. 2. A process according to claim 1, wherein the plural 30 ity of beverage containers and the plurality of snack food containers comprise an aluminum can with a re movable access opening. 3. A process according to claim 1, wherein the bever age containers and the snack food containers comprise a cylindrically-shaped can which has about a 12 fluid ounce capacity. 4. A process according to claim 1, wherein the stor age portion of said vending machine is refrigerated. 5. A process for dispensing both filled beverage con tainers and filled snack food containers from a vending machine configured to dispense soft drink containers, the process comprising steps of: providing a vending machine having at least first and second refrigerated storage portions, both of said refrigerated storage portions configured to receive stacks of containers, the containers having a uni form size such that when filled the machine con tains a plurality of containers all having a uniform size, the vending machine further including means for selecting either a beverage or snack food con tainer and means, responsive to the selecting means, for dispensing the selected container through an outlet of the machine; placing a plurality of containers filled with a bever age in the first refrigerated storage portion of said vending machine; and placing a plurality of containers filled with a snack food product in the second refrigerated storage portion of said vending maehine, the plurality of snack food containers and the plurality of beverage containers having a uniform size; whereby a customer may obtain both a snack food product and a beverage from said vending ma chine. 6. A single vending machine for dispensing both filled beverage containers and filled snack food containers, the vending machine configured to dispense uniform size containers, the machine comprising:

8 5,445, at least first and second refrigerated storage portions a plurality of containers filled with a snack food prod ge p s uct being disposed in the second refrigerated stor both of said refrigerated storage portions being age portion of said vending machine; configured to receive stacks of containers, the wherein the plurality of snack food containers and w 5 the plurality of beverage containers have a substan vending machine further including means for se- tially uniform size so that the first and second stor lecting either a beverage or snack food container age portions of said machine can receive either the and means, responsive to the selecting means, for snack food containers or the beverage containers; whereby a customer may obtain both a snack food dispensing the selected container through an outlet 10 E. and a beverage from said single vending acie, of the machine; 7. A vending machine according to claim 6, wherein a plurality of containers filled with a beverage being the beverage containers and the snack food containers disposed in the first refrigerated storage portion of 15 comprise a cylindrically-shaped can which has about a 12 fluid ounce capacity. - said vending machine; and ck k k :k

III. United States Patent (19) Binacchi. Attorney, Agent, or Firm-Bucknam and Archer 57 ABSTRACT. 6 Claims, 3 Drawing Sheets

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

(*) Notice: Subject to any disclaimer, the term of this E. E. E. E. O.C.

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

US A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

United States Patent (19)

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

United States Patent (19) 11) 4,167,008 Blickenstaff 45) Sep. 4, 1979

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

United States Patent (19) Forino

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

7 IANSNA. (12) Patent Application Publication (10) Pub. No.: US 2003/ A1. (19) United States 2//

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. Lange (43) Pub. Date: Nov. 22, 2012

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

(12) United States Patent (10) Patent No.: US 6,813,994 B2

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

March 24, 1970 H. H. BRIDGFORD 3,502,488 COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER HUGH. BROGFORD / ATTORNEY

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

May 12, ,282,708 T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE. Filed Sept. 26, Sheets-Sheet l. --No.zzzzzzzzzzae.

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

United States Patent (19) Kovacevich, Jr.

United States Patent (19) Kovacevich, Jr. 11 Patent Number: Date of Patent: Jun. 9, 1987 54) 76 21 22 63 (51) 52 58 56) WNE DISTRIBUTION METHOD Inventor: Appl. No.: Filed: Sam Kovacevich, Jr., R.R. 1,

United States Patent (19) Kovacevich, Jr. 11 Patent Number: Date of Patent: Jun. 9, 1987 54) 76 21 22 63 (51) 52 58 56) WNE DISTRIBUTION METHOD Inventor: Appl. No.: Filed: Sam Kovacevich, Jr., R.R. 1,

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

United States Patent (19)

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

United States Patent (19) D'Alessandro

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

Sept. 7, l.t. ward 2,092,596 SIPHON

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

(12) United States Patent

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

(12) United States Patent (10) Patent No.: US 6,419,120 B1

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1. Hurley et al. (43) Pub. Date: Aug. 28, PROCESS Publication Classification

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

brewing device, and particularly an espresso machine. 4,871,555 10/1989 Schwartz et al /82

USOO5895672A United States Patent 19 11) Patent Number: Cooper ) Date of Patent: Apr. 20, 1999 54) PRODUCT AND PROCESS FOR PREPARING 5,072,661 12/1991 Kondo... 99/296 A TEA EXTRACT 5,104,666 4/1992 Sanvitale...

USOO5895672A United States Patent 19 11) Patent Number: Cooper ) Date of Patent: Apr. 20, 1999 54) PRODUCT AND PROCESS FOR PREPARING 5,072,661 12/1991 Kondo... 99/296 A TEA EXTRACT 5,104,666 4/1992 Sanvitale...

(12) United States Patent (10) Patent No.: US 7,325,807 B1. Eason (45) Date of Patent: Feb. 5, 2008

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

United States Patent It 3,593,647

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States US 2004O238555A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0238555 A1 Parks (43) Pub. Date: Dec. 2, 2004 (54) VENDING MACHINE THAT DELIVERS Publication Classification

(19) United States US 2004O238555A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0238555 A1 Parks (43) Pub. Date: Dec. 2, 2004 (54) VENDING MACHINE THAT DELIVERS Publication Classification

United States Patent [11] 3,559,565

![United States Patent [11] 3,559,565 United States Patent [11] 3,559,565](/thumbs/93/114425987.jpg) United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

3,702,608 11/1972 Tibbs. states by bying O st plunger T.

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

(12) United States Patent

(12) United States Patent USOO8469225B2 () Patent No.: US 8,469.225 B2 Fredland (45) Date of Patent: Jun. 25, 2013 (54) SEMI-RIGID BEVERAGE RECEPTACLE (56) References Cited (75) Inventor: Richard Fredland,

(12) United States Patent USOO8469225B2 () Patent No.: US 8,469.225 B2 Fredland (45) Date of Patent: Jun. 25, 2013 (54) SEMI-RIGID BEVERAGE RECEPTACLE (56) References Cited (75) Inventor: Richard Fredland,

United States Patent (19) Ludder

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

(2-12. Zazza72M4 Aarzanez. Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS. Zaza/adar. aeo/ae/ -- e

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

United States Patent (19) Adams et al.

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

(12) United States Patent

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

United States Patent (19) Aldrich

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070184157A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0184157 A1 Stegmaier (43) Pub. Date: (54) HOT FILL AND QUICK CHILL PROCESS FOR PREMIUM QUALITY JUICE (75)

(19) United States US 20070184157A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0184157 A1 Stegmaier (43) Pub. Date: (54) HOT FILL AND QUICK CHILL PROCESS FOR PREMIUM QUALITY JUICE (75)

III IIIHIII. United States Patent (19) Momiyama

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

(12) United States Patent

(12) United States Patent Chapman et al. USOO6539842B1 (10) Patent No.: (45) Date of Patent: US 6,539,842 B1 Apr. 1, 2003 (54) (75) (73) (21) (22) (51) (52) (58) (56) ROTISSERIE SYSTEM HAVING AREMOTE TEMPERATURE

(12) United States Patent Chapman et al. USOO6539842B1 (10) Patent No.: (45) Date of Patent: US 6,539,842 B1 Apr. 1, 2003 (54) (75) (73) (21) (22) (51) (52) (58) (56) ROTISSERIE SYSTEM HAVING AREMOTE TEMPERATURE

52 U.S. Cl... 70s/ , 235,381 mitted from the automatic vending machine 1 to the center

US006021394A United States Patent (19) 11 Patent Number: 6,021,394 Takahashi (45) Date of Patent: Feb. 1, 2000 54) SALES MANAGEMENT METHOD IN 5,844,808 12/1998 Konsmo et al.... 364/479.14 AUTOMATIC VENDING

US006021394A United States Patent (19) 11 Patent Number: 6,021,394 Takahashi (45) Date of Patent: Feb. 1, 2000 54) SALES MANAGEMENT METHOD IN 5,844,808 12/1998 Konsmo et al.... 364/479.14 AUTOMATIC VENDING

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

III. United States Patent (19) 5,590,586 Jan. 7, % 4. Ulfig et al. (75) Inventors: Kimberly A. Ulfig, Glen Ellyn;

United States Patent (19) Ulfig et al. 54 KITCHEN LAYOUT, SYSTEM (75) Inventors: Kimberly A. Ulfig, Glen Ellyn; Patricia A. Venetucci, Hawthorn Woods, both of Ill. (73) Assignee: Restaurant Technology,

United States Patent (19) Ulfig et al. 54 KITCHEN LAYOUT, SYSTEM (75) Inventors: Kimberly A. Ulfig, Glen Ellyn; Patricia A. Venetucci, Hawthorn Woods, both of Ill. (73) Assignee: Restaurant Technology,

---- ÆØerá Z3zzegzée. Vzerzega2ZY.Zazee. June 16, Zee/ErzezØrzs 2,286, Sheets-Sheet 2 D G O D D D OD

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

Product Consistency Comparison Study: Continuous Mixing & Batch Mixing

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

(12) United States Patent (10) Patent No.: US 8,601,937 B2

USOO8601937B2 (12) United States Patent () Patent No.: Campetella et al. (45) Date of Patent: Dec., 2013 (54) APPARATUS FOR MAKING COFFEE 5,605,091 A * 2/1997 Garber... 99,330 5,650,186 A * 7/1997 Annoni

USOO8601937B2 (12) United States Patent () Patent No.: Campetella et al. (45) Date of Patent: Dec., 2013 (54) APPARATUS FOR MAKING COFFEE 5,605,091 A * 2/1997 Garber... 99,330 5,650,186 A * 7/1997 Annoni

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080216664A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0216664 A1 K00n et al. (43) Pub. Date: Sep. 11, 2008 (54) ELECTRONICTEATHERMOMETER AND TIMER DEVICE (75) Inventors:

(19) United States US 20080216664A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0216664 A1 K00n et al. (43) Pub. Date: Sep. 11, 2008 (54) ELECTRONICTEATHERMOMETER AND TIMER DEVICE (75) Inventors:

(12) United States Patent (10) Patent No.: US 6,514,552 B1

USOO6514552B1 (12) United States Patent (10) Patent No.: Sivetz (45) Date of Patent: Feb. 4, 2003 (54) METHOD FOR KEEPING ROAST COFFEE JP 8-OOO175 9/1996 BEAN FRESHINESS WO WO985.7862 * 12/1998 (76) Inventor:

USOO6514552B1 (12) United States Patent (10) Patent No.: Sivetz (45) Date of Patent: Feb. 4, 2003 (54) METHOD FOR KEEPING ROAST COFFEE JP 8-OOO175 9/1996 BEAN FRESHINESS WO WO985.7862 * 12/1998 (76) Inventor:

JUICE EXTRACTION AND FILTRATION JUICE EXTRACTION METHOD AND EQUIPMENT

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

HHHHH. United States Patent (19) Burrows et al. 5,084, Patent Number: (45) Date of Patent: Jan. 28, 1992

United States Patent (19) Burrows et al. 54 PRCESS FR PREPARING FRENCH FRIED PTAT STRIPS WITH SALT CNTENT 75) Inventors: Christopher B. Burrows, Kennewick; Janet. Wheeler; Jerry L. Sloan, both of Richland,

United States Patent (19) Burrows et al. 54 PRCESS FR PREPARING FRENCH FRIED PTAT STRIPS WITH SALT CNTENT 75) Inventors: Christopher B. Burrows, Kennewick; Janet. Wheeler; Jerry L. Sloan, both of Richland,

22 Filed: Jun. 6, 1995 (51) Int. Cl... A22C 9/ U.S. Cl /141; 426/56; 426/63 58) Field of Search /141, 142, Canner/Cutter

United States Patent (19) Teran IIII US0055120A 11 Patent Number: 45) Date of Patent: Apr., 1996 54 MEATTENDERIZATION PROCESS FOR A MICROWAVABLE MEAT PRODUCT 76 Inventor: James Teran, 932 E. Thames St.,

United States Patent (19) Teran IIII US0055120A 11 Patent Number: 45) Date of Patent: Apr., 1996 54 MEATTENDERIZATION PROCESS FOR A MICROWAVABLE MEAT PRODUCT 76 Inventor: James Teran, 932 E. Thames St.,

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120279416A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0279416A1 Nishimura et al. (43) Pub. Date: Nov. 8, 2012 (54) RAILCAR BOGIE (52) U.S. Cl.... 105/218.1 (75)

(19) United States US 20120279416A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0279416A1 Nishimura et al. (43) Pub. Date: Nov. 8, 2012 (54) RAILCAR BOGIE (52) U.S. Cl.... 105/218.1 (75)

USOO A United States Patent (19) 11 Patent Number: 5,956,151 Zajac et al. (45) Date of Patent: Sep. 21, 1999

USOO59.56151A United States Patent (19) 11 Patent Number: 5,956,151 Zajac et al. (45) Date of Patent: Sep. 21, 1999 54) BEVERAGE FRESHNESS MONITOR 3,606,829 9/1971 Alwood... 99/285 3,974,758 8/1976 Stone,

USOO59.56151A United States Patent (19) 11 Patent Number: 5,956,151 Zajac et al. (45) Date of Patent: Sep. 21, 1999 54) BEVERAGE FRESHNESS MONITOR 3,606,829 9/1971 Alwood... 99/285 3,974,758 8/1976 Stone,

United States Patent (19) Bowen et al.

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

Grooving Tool: used to cut the soil in the liquid limit device cup and conforming to the critical dimensions shown in AASHTO T 89 Figure 1.

DETERMINING THE LIQUID LIMIT OF SOILS FOP FOR AASHTO T 89 Scope This procedure covers the determination of the liquid limit of a soil in accordance with AASHTO T 89-13. It is used in conjunction with the

DETERMINING THE LIQUID LIMIT OF SOILS FOP FOR AASHTO T 89 Scope This procedure covers the determination of the liquid limit of a soil in accordance with AASHTO T 89-13. It is used in conjunction with the

(12) Patent Application Publication (10) Pub. No.: US 2010/ A1

(19) United States US 2010.0005979A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0005979 A1 Baccetti (43) Pub. Date: Jan. 14, 2010 (54) DISPOSABLE BEVERAGE PRESS Publication Classification

(19) United States US 2010.0005979A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0005979 A1 Baccetti (43) Pub. Date: Jan. 14, 2010 (54) DISPOSABLE BEVERAGE PRESS Publication Classification

(54) POPCORN BUTTER DISPENSER Publication Classi?cation

US 20140054316A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0054316 A1 Lehman et al. (43) Pub. Date: Feb. 27, 2014 (54) POPCORN BUTTER DISPENSER Publication Classi?cation

US 20140054316A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0054316 A1 Lehman et al. (43) Pub. Date: Feb. 27, 2014 (54) POPCORN BUTTER DISPENSER Publication Classi?cation

PATENT AGENT EXAMINATION PAPER A 2016

Page 1 of 25 PATENT AGENT EXAMINATION PAPER A 2016 Dear Candidate, Paper A is a patent drafting exercise in which you are being requested to prepare a full patent specification, with significant weight

Page 1 of 25 PATENT AGENT EXAMINATION PAPER A 2016 Dear Candidate, Paper A is a patent drafting exercise in which you are being requested to prepare a full patent specification, with significant weight

(12) United States Patent

US007582325B2 (12) United States Patent Giori () Patent No.: (45) Date of Patent: Sep. 1, 2009 (54) PROCESS FOR THE PREPARATION OF TOMATO EXTRACTS WITH HIGH CONTENT IN LYCOPENE (75) Inventor: Andrea Giori,

US007582325B2 (12) United States Patent Giori () Patent No.: (45) Date of Patent: Sep. 1, 2009 (54) PROCESS FOR THE PREPARATION OF TOMATO EXTRACTS WITH HIGH CONTENT IN LYCOPENE (75) Inventor: Andrea Giori,

3,000 POUND CAPACITY AUTO BODY ROTISSERIE UNIT

3,000 POUND CAPACITY AUTO BODY ROTISSERIE UNIT INSTALLATION / OWNERS MANUAL ROTISSERIE (R3000G) 1 IN50016 Rev. B 03/30/2009 TABLE OF CONTENTS IMPORTANT INFORMATION...pg 2 OWNER / EMPLOYER RESPONSIBILITIES...pg

3,000 POUND CAPACITY AUTO BODY ROTISSERIE UNIT INSTALLATION / OWNERS MANUAL ROTISSERIE (R3000G) 1 IN50016 Rev. B 03/30/2009 TABLE OF CONTENTS IMPORTANT INFORMATION...pg 2 OWNER / EMPLOYER RESPONSIBILITIES...pg

SOFTDOUGH & COOKIES cat_softdough_rev12gea.indd 1 22/07/

SOFTDOUGH & COOKIES The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given them our

SOFTDOUGH & COOKIES The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given them our

! MXING-LIQUID. United States Patent (19) Khalsa 2-"22 18 INSPECTION. 11 Patent Number: 5,298,274 45) Date of Patent: Mar.

United States Patent (19) Khalsa (54) METHODS FOR MAKING TORTILLACHIPS AND TORTELLA CHIPS PRODUCED THEREBY 76 Inventor: Nirbhao S. Khalsa, 3141 NW. Greenbriar Ter, Portland, Oreg. 97.210 21 22) (51) (52)

United States Patent (19) Khalsa (54) METHODS FOR MAKING TORTILLACHIPS AND TORTELLA CHIPS PRODUCED THEREBY 76 Inventor: Nirbhao S. Khalsa, 3141 NW. Greenbriar Ter, Portland, Oreg. 97.210 21 22) (51) (52)

Interpretation Guide. Yeast and Mold Count Plate

Interpretation Guide The 3M Petrifilm Yeast and Mold Count Plate is a sample-ready culture medium system which contains nutrients supplemented with antibiotics, a cold-water-soluble gelling agent, and

Interpretation Guide The 3M Petrifilm Yeast and Mold Count Plate is a sample-ready culture medium system which contains nutrients supplemented with antibiotics, a cold-water-soluble gelling agent, and

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004O1371.15A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0137115 A1 Leshik et al. (43) Pub. Date: (54) STABLE, MULTI-TEXTURE, READY-TO-EAT (22) Filed: Jan. 15, 2003

US 2004O1371.15A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0137115 A1 Leshik et al. (43) Pub. Date: (54) STABLE, MULTI-TEXTURE, READY-TO-EAT (22) Filed: Jan. 15, 2003

Beer Hardware, Systems and Delivery

Beer Hardware, Systems and Delivery An Industry Standard Beer is the number one dispensed beverage in the foodservice industry. Commonly, draft beer is preferred by a wide margin for taste and product

Beer Hardware, Systems and Delivery An Industry Standard Beer is the number one dispensed beverage in the foodservice industry. Commonly, draft beer is preferred by a wide margin for taste and product

PATENT ATTORNEYS EXAMINATION

2014 PATENT ATTORNEYS EXAMINATION PAPER E The New Zealand Law and Practice relating to Interpretation and Criticism of Patent Specifications Regulation 158 (1) (e) Duration: 4 hours (plus 10 minutes for

2014 PATENT ATTORNEYS EXAMINATION PAPER E The New Zealand Law and Practice relating to Interpretation and Criticism of Patent Specifications Regulation 158 (1) (e) Duration: 4 hours (plus 10 minutes for

VACUUM PACKAGING EVERYTHING YOU NEED TO KNOW ABOUT T : / F :

EVERYTHING YOU NEED TO KNOW ABOUT VACUUM PACKAGING 2555 Alfred Nobel, Drummondville (QC) Canada J2A 0L5 T : 819.395.5151 / 1.855.395.5252 F : 819.395.5343 www.sipromac.com TYPICAL SHELF LIVES OF VACUUM

EVERYTHING YOU NEED TO KNOW ABOUT VACUUM PACKAGING 2555 Alfred Nobel, Drummondville (QC) Canada J2A 0L5 T : 819.395.5151 / 1.855.395.5252 F : 819.395.5343 www.sipromac.com TYPICAL SHELF LIVES OF VACUUM

(12) United States Patent

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

Aaawaw A. M1axsom. - A 474/2/sr.przezz' SecY72/7. April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES.

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0276415 A1 Florine US 20110276415A1 (43) Pub. Date: Nov. 10, 2011 (54) (76) (21) (22) (60) (51) WNE MARKETING METHOD FOR SPORTING

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0276415 A1 Florine US 20110276415A1 (43) Pub. Date: Nov. 10, 2011 (54) (76) (21) (22) (60) (51) WNE MARKETING METHOD FOR SPORTING

United States Patent (19)

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

(51) Int Cl.: A47J 31/18 ( ) A47J 31/46 ( )

(19) TEPZZ 7_ 95B_T (11) EP 2 712 295 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention of the grant of the patent: 31.08.16 Bulletin 16/35 (21) Application number: 12712780.1

(19) TEPZZ 7_ 95B_T (11) EP 2 712 295 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention of the grant of the patent: 31.08.16 Bulletin 16/35 (21) Application number: 12712780.1

3. : 12- C) {X C> C) () {X -K) --KX-KX-KX-K)--C-2 --C)-- (12) Patent Application Publication (10) Pub. No.: US 2012/ A1 4 - (19) United States

(19) United States US 2012O138603A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0138603 A1 McGuinness et al. (43) Pub. Date: Jun. 7, 2012 (54) VARIABLE GEOMETRY TORTILLA COOKINGAPPARATUS

(19) United States US 2012O138603A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0138603 A1 McGuinness et al. (43) Pub. Date: Jun. 7, 2012 (54) VARIABLE GEOMETRY TORTILLA COOKINGAPPARATUS

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States US 20040O866O1A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0086601A1 ROSS et al. (43) Pub. Date: (54) SCORED SAVORY DOUGH WITH TOPPINGS OR FILLINGS (76) Inventors: Robert

(19) United States US 20040O866O1A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0086601A1 ROSS et al. (43) Pub. Date: (54) SCORED SAVORY DOUGH WITH TOPPINGS OR FILLINGS (76) Inventors: Robert

enjoy the experience

The enjoy the experience The The Sienna by DarenthMJS presents a futuristic approach to machine design and features exclusive styling with fine lines to perfectly compliment the high quality of beverages

The enjoy the experience The The Sienna by DarenthMJS presents a futuristic approach to machine design and features exclusive styling with fine lines to perfectly compliment the high quality of beverages

(12) Patent Application Publication (10) Pub. No.: US 2017/ A1

(19) United States US 2017.0089590A1 (12) Patent Application Publication (10) Pub. No.: US 2017/0089590 A1 Bruin-Slot et al. (43) Pub. Date: Mar. 30, 2017 (54) OVEN CAVITY CONNECTOR FOR (52) U.S. Cl. OPERATING

(19) United States US 2017.0089590A1 (12) Patent Application Publication (10) Pub. No.: US 2017/0089590 A1 Bruin-Slot et al. (43) Pub. Date: Mar. 30, 2017 (54) OVEN CAVITY CONNECTOR FOR (52) U.S. Cl. OPERATING

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0187694 A1 Cai US 2004O187694A1 (43) Pub. Date: (54) (76) (21) (22) (63) HOLDER FOR PRESSURE-BREWING COFFEE DRINK Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0187694 A1 Cai US 2004O187694A1 (43) Pub. Date: (54) (76) (21) (22) (63) HOLDER FOR PRESSURE-BREWING COFFEE DRINK Inventor:

(12) United States Patent (10) Patent No.: US 6,182,555 B1

USOO6182555B1 (12) United States Patent (10) Patent No.: Scheer et al. (45) Date of Patent: Feb. 6, 2001 (54) APPARATUS AND METHODS FOR 5,245,914 9/1993 Vitous... 99/28O BREWING AND DISPENSING BEVERAGES

USOO6182555B1 (12) United States Patent (10) Patent No.: Scheer et al. (45) Date of Patent: Feb. 6, 2001 (54) APPARATUS AND METHODS FOR 5,245,914 9/1993 Vitous... 99/28O BREWING AND DISPENSING BEVERAGES

52 U.S. Cl... 99/295; 99/299; 99/305; 99/ / ) References Cited U.S. PATENT DOCUMENTS 1,778,792 10/1930 Cameron...

United States Patent (19) Glucksman (54) APPARATUS FOR BREWING COFFEE 76) Inventor: Dov Z. Glucksman, 137 Larch Row, Wenham, Mass. 01984 21 Appl. No.: 636,137 22 Filed: Dec. 31, 1990 51 Int. Cl.5......

United States Patent (19) Glucksman (54) APPARATUS FOR BREWING COFFEE 76) Inventor: Dov Z. Glucksman, 137 Larch Row, Wenham, Mass. 01984 21 Appl. No.: 636,137 22 Filed: Dec. 31, 1990 51 Int. Cl.5......

(12) United States Patent

(12) United States Patent US008778441B2 () Patent No.: Sky (45) Date of Patent: Jul. 15, 2014 (54) READY-TO-EAT OAT-BASED FOOD (56) References Cited PRODUCT U.S. PATENT DOCUMENTS (76) Inventor: Phillip

(12) United States Patent US008778441B2 () Patent No.: Sky (45) Date of Patent: Jul. 15, 2014 (54) READY-TO-EAT OAT-BASED FOOD (56) References Cited PRODUCT U.S. PATENT DOCUMENTS (76) Inventor: Phillip

A33. AORNEY. March 22, G. C. HERZ, 1,850,719. APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC. Filed Dec, l6, l Sheets-Sheet l NVENTOR

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

US 20020074337A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2002/0074337 A1 Melton (43) Pub. Date: Jun. 20, 2002 (54) PRINTED INSERTS FOR THERMOFORMED Related U.S. Application

US 20020074337A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2002/0074337 A1 Melton (43) Pub. Date: Jun. 20, 2002 (54) PRINTED INSERTS FOR THERMOFORMED Related U.S. Application

Appendices. Section. Food Buying Guide for Child Nu tri tion Pro grams A P P E N D I C E S

Section 6 Food Buying Guide for Child Nu tri tion Pro grams Appendices A P P E N D I C E S Appendix A: Recipe Analysis Appendix B: Using Column 6 for Recipe Analysis Appendix C: The USDA Child Nutrition

Section 6 Food Buying Guide for Child Nu tri tion Pro grams Appendices A P P E N D I C E S Appendix A: Recipe Analysis Appendix B: Using Column 6 for Recipe Analysis Appendix C: The USDA Child Nutrition

Automatic proofers. Member of the

Automatic proofers Member of the MCS Automatic proofers Automatic proofers Over the last 30 years MCS has developed a unique and specific competence in designing and manufacturing automatic industrial

Automatic proofers Member of the MCS Automatic proofers Automatic proofers Over the last 30 years MCS has developed a unique and specific competence in designing and manufacturing automatic industrial

Your products, our technology. Kaak Benier DrieM Daub MCS LhotellierR2A Multiparts

Your products, our technology Kaak Benier DrieM Daub MCS LhotellierR2A Multiparts Kaak Group Total concept from Silo to Truck Based on more than 100 years of experience, the Kaak Group offers bakery companies

Your products, our technology Kaak Benier DrieM Daub MCS LhotellierR2A Multiparts Kaak Group Total concept from Silo to Truck Based on more than 100 years of experience, the Kaak Group offers bakery companies

Sugar maple tree named Legacy

( 1 of 1 ) United States Patent PP4,979 Wandell February 1, 1983 Sugar maple tree named Legacy Abstract This disclosure concerns a new and distinct variety of Acer saccharum (commonly known as sugar maple

( 1 of 1 ) United States Patent PP4,979 Wandell February 1, 1983 Sugar maple tree named Legacy Abstract This disclosure concerns a new and distinct variety of Acer saccharum (commonly known as sugar maple

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

Downloaded from Quick Start Guide D512. Smart Decanter

Quick Start Guide D52 Smart Decanter Contents Safety Precaution Cleaning Technical Data Correct Disposal of This Product Connecting Power Rechargeable Battery Installation Your isommelier 0 04 05 isommelier

Quick Start Guide D52 Smart Decanter Contents Safety Precaution Cleaning Technical Data Correct Disposal of This Product Connecting Power Rechargeable Battery Installation Your isommelier 0 04 05 isommelier

United States Patent (19) (11) 4,211,342. Jamgochian et al. 45) Jul. 8, MACHINE 3,976,222 8/1976 Spagnolo /144.5 X

United States Patent (19) (11) 4,211,342 Jamgochian et al. 45) Jul. 8, 1980 54 COMBINATION HOT AND COLD DRINK 3,830,405 8/1974 Jaeger... 222/129.3 MACHINE 3,976,222 8/1976 Spagnolo...... 222/144.5 X 4,068,781

United States Patent (19) (11) 4,211,342 Jamgochian et al. 45) Jul. 8, 1980 54 COMBINATION HOT AND COLD DRINK 3,830,405 8/1974 Jaeger... 222/129.3 MACHINE 3,976,222 8/1976 Spagnolo...... 222/144.5 X 4,068,781