May 12, ,282,708 T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE. Filed Sept. 26, Sheets-Sheet l. --No.zzzzzzzzzzae.

|

|

|

- Derrick Stanley

- 5 years ago

- Views:

Transcription

1 May 12, T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, ,282, Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2

2 May 12, T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, Sheets-Sheet 2 lose NS NR772SXSN S w A-1 A. e 22aaaaaaaaayaat ZA NSXSSSSSSSSSSN 26 s

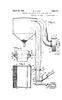

3 Patented May 12, ,708 UNITED STATES PATENT OFFICE 2,282,708 coffee ROASTING PRODUCT, METHOD, AND MACENE Tobias Dantzig, Hyattsville, Md. 13 Claims. This invention relates to coffee roasting and includes novel products resulting from novel methods and machines or devices for producing roasted Coffee. The roasting of coffee is a well developed art but the limitations of that art as practiced today require the roasting of the coffee bean in sub stantially centrally located roasting plants from which the roasted coffee is distributed to retail outlets. Handling coffee in this manner and roasting and distribution in this way gives rise to products which when stored over any substan tial period of time-even relatively short pe riods-result in the development of rancidity in the coffee. In more recent years there has been a demand for freshly roasted products and in fact daily roasting of coffee is carried out. Such methods, however, result in large losses where the coffee cannot be used because it has been on the shelf for more than a day or longer periods.... Other methods have sought to eliminate the development of rancidity in the roasted coffee, by removal of coffee oil at some stage of the coffee treatment process. While the removal of coffee oil tends to eliminate one of the principal reasons for development of rancidity, removal of the coffee oil entails loss of flavor and aroma which materially affects the quality of the roasted coffee.. Among the objects of the present invention are included coffee roasting methods in which the coffee can be roasted rapidly for use as desired. Other Óbjects include the production of novel. types of coffee products. Further objects include machines and devices for roasting coffee and producing such products. Still further objects and advantages of the present invention will appear from the more de tailed description given below, it being under-, stood, however, that this more detailed descrip tion is given by way of illustration and explana tion only, and not by way of limitation, since various changes therein may be made by those skilled in the art without departing from the Scope and spirit of the present invention. In connection with that more detailed descrip tion there is shown in the accompanying draw-. ings, in. Figure 1, a vertical sectional view through one form of roasting device that may be utilized in carrying out the present invention; and in pose Figure 2, another form of device for this pur e present invention is thus concerned with 55 Application September 26, 1940, serial No. 358, (C ) methods and devices or machines for rapidly roasting coffee and producing the finished prod uct from the green bean and operations which may be readily carried out treating larger or smaller quantities of coffee beans, the latter be ing in the green stage, so that the final roasted coffee product may be directly supplied to the consumer on demand of the consumer, freshly made from the green bean. These methods and devices and the resulting products require rapid production of roasted coffee without loss of aroma and flavor qualities : therefrom, in relatively simple and economical devices which are utiliz able either in retail stores, or in the home itself, 5 or may be used in enlarged conditions for roast ing if desired at central distributing roasting plants. - - N. In carrying out the present invention it has been found that if the green coffee bean is sub jected to a preheating Operation at a temperature insufficient to produce roasting, subsequent roast ing operations may be readily carried out with out loss of flavor and aroma qualities in the 25 coffee and further, such preheating operations enable the rapid roasting of the coffee to be readily carried out. Most desirably the roasting is carried out in two stages in which the pre heated coffee bean, while still in substantially, green condition, is subjected to a pre-roast oper 30 ation at a temperature and for a time insufficient to complete the roast of the bean but to convert it into a partially roasted condition, while the later stage involves a heat treatment for a time sufficient to roast the pre-roasted coffe bean: 3.s For rapid operation it has further been found desirable to subject coffee during the pre-roast treatment to a flattening operation so that dur ing the pre-roast treatment the coffee beans are desirably simultaneously flattened into elon gated disc-like wafers. In addition, such par tially roasted elongated flattened disc-like wafers produced in the pre-roast operation are sub jected to the final roasting treatment at the desired temperatures for the times necessary to complete the roast, while being subjected to pressure to convert them into a substantially, flaked form. By heat treatment carried out in. stages including a pre-heat treatment as set, forth above, the roasted product is obtained hav ing the fully developed flavor and aroma of the coffee bean without loss of oil or other ingre dients therefrom. r. The successive heat treat ment stages are particularly valuable in cond tioning the bean for the final roasting operation "..... and this is readily carried out particularly where

4 2 2,282,708 flattening and faking of the bean is simultane foil of roasted coffee are rapidly and readily ously effected during the pre-roasting and later powdered for use. roasting operations respectively. The final Figure of the drawings illustrates One form roasted and faked product retaining the full of device which may be utilized for carrying Out values of the coffee may be utilized directly, or the present invention. As there illustrated, a may be reduced to a shredded condition, or to. vertical elongated container has a hopper por a powdered condition. tion 2 for reception of the green coffee bean The treatments described above involve a cone shown at 3. The hopper portion 2 may desirably tinuity of operation on the coffee bean in which be provided with a cover 4. Means are provided the beans are carried through several stages of O to preheat the beans 3 in the hopper 2 and Such treatment at increasing temperatures. It will means may take the form of an electric heating also be noted that during such treatment, the coil 5 surrounding said hopper 2. Such heating beans are subjected to increasing pressures be coil desirably an electric heating coil, is not cause of the set of the rolls desirably employed. necessarily employed in connection with a closed The continuity of the process may be further ill 15 container since the heat from the heating rolls lustrated by treating the beans continuously in described below used for pre-roasting and roast Zones of treatment where the pressures increase ing operations, may be sufficient to preheat the from each zone to the successive One so that the beans to the desired temperature. From the beans during treatment in the pre-roast stages hopper 2 the beans 3 pass to a pair of pre-roast are subjected to relatively light pressures which 20 ing rolls 6 desirably positioned immediately be are increased until the highest pressures are low the outlet of the hopper 2 so that the beans reached in the later treatment zones. In such continuous processes where the beans are sub jected to increasing pressures in a multiplicity of ZOnes, the heat may be supplied to the beans in stages as set forth above so that there is a pre roast ZOne and a later final roasting zone, or the heat to which the beans are subjected may be substantially the same throughout the treatment with increments of pressure at successive stages, because the beans pass through the earlier stages so rapidly that they have not been subjected to the heat for a sufficient time to produce a com pletely roasted product, and such completely roasted product only emerges from the later stages. As illustrative of the methods that may be emi ployed for this purpose, the following is given. The green coffee bean may be preheated to a temperature of approximately 200 F. Such pre heat treatment conditions the bean for the roast ing operation or for a pre-roasting operation and also conditions the beans so that they may be readily flattened without Substantial rupture. The preheated green coffee beans thus obtained are then subjected desirably to a pre-roasting operation carried out for example, at tempera tures of about 400 F. Which are sufficient to partially roast the Coffee beans which have been subjected to the preheating operation. Further more, during such pre-roasting operation the coffee beans are desirably subjected to pressure as between rolls to flatten such preheated coffee during the pre-roasting operation into an elon gated disc-like wafer. The pre-roast coffee product thus obtained is then desirably subjected to a final roasting operation as for example, at temperatures of 500 F. and for rapidity of oper ation it is desirable to subject the beans during. Such final roasting step to pressure to convert them into a flaked condition so that flaking and roasting take place simultaneously. For this purpose a pair of rolls may desirably be en ployed which rolls are heated to the temperatures desired, such roasting rols taking the coffee from the pre-roast rolls and converting the pre roasted coffee into the final roasted form and faked condition. The simultaneously faked and roasted coffee product thus obtained may be: utilized as such for brewing operations or may if desired, be permitted to cool and subjected to a shredding operation, as for example, between rolls which may be partially heated, as for ex ample, at temperatures of 100 F. and which rotate at different speeds so that the flakes or falling upon the pre-roast rollers 6, 6 are gripped therebetween and carried between the pre-roast rolls and discharged downwardly therefrom. Such rolls may desirably be knurled or roughened to assist in the gripping of the bean 3 and the clearance between such rolls may be approxi mately as of an inch. Such pre-roast rolls are desirably provided with heating means which may take the form of electric heating coils or gas heating units placed within the rolls. From the pre-roast rolls the beans pass in a desirably flattened elongated disc-like form to the roasting rolls, 7 through a conduit 8. The roasting rolls, are desirably set quite close to gether and maintained at the roasting tempera ture, of for, example, about 500 F. by electric heating coils, gas elements or other heating ele ments (not shown) which may be utilized in any desirable way. In the roasting rolls or there between, the coffee is subjected to the final roast ing operation and where the rolls are set quite close together the Coffee emerges therefrom in the form of a roasted faked condition, the roast ing and faking being completed simultaneously between the rolls,. While the coffee in the flanked and roasted condition may be used as such, it may desirably be permitted to fall through the conduit 9 of sufficient length to partially cool the same down 50 to a point at which some of the plasticity of the faked product is lost and the faked material is available for a grinding or reducing operation. This may be desirably carried out between rolls D, O maintained at temperatures approximat ing room temperature and these rolls are desir ably operated at differential speeds in order to convert the foil or flaked form of coffee received therebetween to a shredded condition. The re duced product falls from the rolls,, and is collected in the receptacle if placed therebelow. The container may be provided with a hinged door 2 enabling ready access to the receiver and may desirably be provided with a valve out let 3 at its upper portion for removing vapors and gases as desired. A unitary device of the character illustrated and described above is par ticularly desirable because it retains all of the values of the coffee. during the operation, and a unitary device of this character may be readily employed for use in the home or in the treatment of small quantities of coffee on demand produced directly in the store from the green beans by the distributor on demand of the purchaser. On the other hand the device lends itself to construction

5 2,282, in large form for treatment of coffee by roasting The present invention thus readily permits the methods carried out on a large scale. In the form of device illustrated in Figure 2 of production of a roasted coffee by simple and eco nomical methods converting the green bean di the drawings, the coffee beans are subjected to continuous pressure while being heated and pass from the green condition at the receiving end to the ultimate roasted condition at the delivery. end. For this purpose there is illustrated the container 2 which may be provided with the hopper portion 22 for reception of the green coffee beans. From the hopper 22 the beans pass O to a pair of endless band conveyors 23, 24, these conveyors being spaced apart to form a converg ing channel 25 therebetween, which channel has its greatest width at 26 immediately adjacent the 1. delivery end of the hopper 22, the channel con-. verging to its lower end where the distance be tween the bands as at 27, is quite small. To maintain these bands in position, they operate Over pulleys, there being driving pulleys 2, 29 and end pulleys 30, 3. A series of idling pulleys 32, 33 are desirably employed between the driv ing pulleys 28, 29 and the end pulleys 30, 3, the idling pulleys cooperating with the other pulleys to maintain the desired positioning of the end less band conveyors 23, 24. Pulleys 34, 35 may be provided on the outer portions of the endless band conveyors for adjustment to permit tight ening or loosening of the band members (by con ventional means not shown). Scrapers 36, 37 are desirably provided acting against the endless band conveyors 23, and 24 respectively, for re moving any material which adheres to the con veyors, the treated coffee beans being received in the container 38.. The beans may be heated by any desired means during the passage through the device of Figure 2, such heating means, for example, may take the form of electrical heating elements 39 which may be placed between each successive pair of idling, pulleys 32, 33. The number of heating elements and the heat supplied will de pend on the particular treatment being carried out. Any of the elements which contact with the coffee bean should desirably be made of ma rectly to the final roasted condition without loss of value therefrom enabling the operation to be economically carried out in the treatment of green coffee beans of any desired blend, produced directly on demand of the consumer..... Treatment of the beans in accordance with the present invention preserves all of the values in the beans with very little if any, loss of aroma and flavor giving qualities. This is particularly true with the device shown in Figure 2. While oil is, of course, necessarily expressed to some extent during the pressure treatment" of the beans in accordance with the present invention, such oil and other products appear to be reab sorbed into the products before they pass from the last treatment zone. Furthermore, the treat ment of the beans in a continuous treatment zone or in zones placed successively one below. the other, results in the fresh beans being in a position to contact with vapors formed from beans in the later stages so that some absorption necessarily takes place. It may be noted in this connection that advantage is taken of the fact that the coffee bean is of substantially porous character. In any event, whatever the explana tion may be, treatment in accordance with the present invention results in a full flavored roasted coffee product from which substantially none of the values of the coffee bean have been lost. & Having thus set forth my invention, I claim: 1. The method of roasting coffee which com prises preheating the green coffee bean at a tem perature substantially below roasting, flattening the preheated bean while heating it to pre-roast temperature insufficient to complete the roast, and flaking; the partially roasted, flattened bean... while - heating it to la temperature sufficient to 45 complete the roast.. s. 2.The method of roasting coffee which com prises preheating the green coffee bean at a tem perature substantially below roasting, and simuli taneously flaking and roasting the preheated terial which is not affected by the coffee bean or oil so that desirably the endless band conveyors are made of stainless steel or Monel metal." green coffee bean. is... The operation of the device of Figure 2 will be 3. The method of roasting coffee which com apparent from the description thereof set forth prises preheating the green coffee bean at a 50 above. The green beans fed into the channel be temperature of substantially 200.F., flattening tween the endless conveyors 23, 24, from the hop the preheated bean while heating it to a pre per 22, pass down through the channel 2 where roasting, temperature of substantially 400 F. in they are subjected to gradually increasing pres sufficiently to complete the roast, and flaking the sures and continuously to a heat treatment so. 55 partially roasted, flattened bean while heating it that the treated beans emerge from the end of to a roasting temperature of about 500 F. to the channel in the desired roasted condition but complete the roast.. in reduced form. Generally the product will 4. In a method of roasting coffee, the steps of emerge in substantially a powdered condition preheating the green coffee bean at a tempera where it is collected in the receiver 38. Con tinuity of heat and pressure treatment is readily 60 ture substantially below roasting, and flattening the preheated bean while heating it to a pre secured in a device' of the character set forth in roast temperature insufficient to complete the Figure 2. and while the channel has been shown roast and to convert the coffee into a partially to be of gradually converging type, it is apparent. roasted, relatively thick, elongated, flattened, that the idlers may be set so that the channel 65 disc-like particle..... between the endless band conveyors is divided 5. In the method of roasting coffee, the steps into several successive zones where the pressures of flattening the green coffee bean rapidly at a increase from one zone to the next but where. the pressure in any particular zone is substan temperature sufficient to roast the bean partially tially the same. In other words, there can be, but not to complete the roast to convert the 70 for example, three or more zones, the pressure green coffee bean into a relatively thick, elon gated, disc-like, relatively thick particle in par in each zone being substantially the same but - the pressure from one zone to the next, increas tially roasted condition. ing substantially. Continuity of treatment, how 6. The method of roasting coffee which com ever, is more desirable. prises heating green coffee beans while subject 75 ing them to pressure of increasing amounts until

6 4 the beans are simultaneously roasted and com pressed into flattened particles. 7. The method of roasting coffee which com prises continuously heating green coffee beans while subjecting them to continuously increasing pressures until the beans are simultaneously roasted and compressed into flattened particles. 8. The method of roasting coffee which com prises continuously subjecting green coffee beans to increasing temperatures and pressures until the beans are simultaneously roasted and com-. pressed into flattened particles. 9. A coffee roasting device including means for preheating green coffee beans to a temperature substantially below roasting, means for flatten ing the preheated beans and heating them to a pre-roast temperature to partially roast the bean, and means for simultaneously flaking and roast ing the beans. 10. A coffee roasting device including means for preheating green coffee beans to a tempera ture substantially below roasting and means for simultaneously flaking and roasting the pre heated beans. 11. A coffee roasting device including means for preheating green coffee beans to a tempera ture substantially below roasting, heating rolls for flattening the preheated beans and heating them to a pre-roast temperature to partially roast the bean, and heating rolls for simultane 2,282,708 O ously faking and completing the roasting of the beans... w 12. A unitary coffee roasting device compris ing a closed container, a hopper at the upper portion of Said container for receiving green cof fee beans, heating means adjacent said hopper to preheat the beans therein, a pair of pre-roast rolls positioned in said container below said hop per to receive the beans therefrom and to flatten and pre-roast the pre-heated beans, means for heating said pre-roast rolls, a second pair of rolls positioned in said container below said pre-roast rolls to receive pre-roasted beans therefrom and to flake and roast the beans simultaneously, and means for heating said last named rolls. 13. A unitary coffee roasting device comprising a container, a hopper carried by said container for receiving green coffee beans, a pair of end less band conveyors positioned in said container adjacent said hopper to receive the green beans therefrom, the conveyors being spaced from each other to form a converging channel within which the beans are treated, said channel having its greatest width adjacent the receiving end where by beans in passing through said channel be tween the conveyors are subjected to increasing pressures, means for driving said conveyors, and means for heating the beans during the passage through the container. TOBAS OANZG,

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

III. United States Patent (19) Binacchi. Attorney, Agent, or Firm-Bucknam and Archer 57 ABSTRACT. 6 Claims, 3 Drawing Sheets

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

(*) Notice: Subject to any disclaimer, the term of this E. E. E. E. O.C.

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

Sept. 7, l.t. ward 2,092,596 SIPHON

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

---- ÆØerá Z3zzegzée. Vzerzega2ZY.Zazee. June 16, Zee/ErzezØrzs 2,286, Sheets-Sheet 2 D G O D D D OD

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

United States Patent (19)

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1. Hurley et al. (43) Pub. Date: Aug. 28, PROCESS Publication Classification

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

7 IANSNA. (12) Patent Application Publication (10) Pub. No.: US 2003/ A1. (19) United States 2//

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(2-12. Zazza72M4 Aarzanez. Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS. Zaza/adar. aeo/ae/ -- e

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

March 24, 1970 H. H. BRIDGFORD 3,502,488 COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER HUGH. BROGFORD / ATTORNEY

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

United States Patent (19) 11) 4,167,008 Blickenstaff 45) Sep. 4, 1979

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

United States Patent [11] 3,559,565

![United States Patent [11] 3,559,565 United States Patent [11] 3,559,565](/thumbs/93/114425987.jpg) United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

A33. AORNEY. March 22, G. C. HERZ, 1,850,719. APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC. Filed Dec, l6, l Sheets-Sheet l NVENTOR

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

ta-v, 9-1-N Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS EDWARD E ANDERSON ATORNEYS JACK D.

Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May 10, 1965 5 Sheets-Sheet INVENTORS EDWARD E ANDERSON JACK D. BROWN ta-v, 9-1-N-11-4. ATORNEYS Oct. 11,

Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May 10, 1965 5 Sheets-Sheet INVENTORS EDWARD E ANDERSON JACK D. BROWN ta-v, 9-1-N-11-4. ATORNEYS Oct. 11,

Center et al. (45. Date of Patent: Aug. 29, 1995

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

United States Patent (19) Ludder

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

1933,158 PROCESS FOR PRODUCING A CEREA, PRODUCT IN A NEW FORM Ralph M. Bohn, Evanston, and Carl S. Miner, No Drawing. Application August 6, 1930

Patented Oct. 31, 1933 UNITED STATES 1933,18 PATENT OFFICE 0. 3. po 1933,18 PROCESS FOR PRODUCING A CEREA, PRODUCT IN A NEW FORM Ralph M. Bohn, Evanston, and Carl S. Miner, Company, Glencoe, III Chicago,

Patented Oct. 31, 1933 UNITED STATES 1933,18 PATENT OFFICE 0. 3. po 1933,18 PROCESS FOR PRODUCING A CEREA, PRODUCT IN A NEW FORM Ralph M. Bohn, Evanston, and Carl S. Miner, Company, Glencoe, III Chicago,

W. A. HEYMAN 2,432,759. Dec. 16, PROCESS OF MAKING COFFEE CONCENTRATES. Filed Jan., l94l. it. Attorney

Dec. 16, 1947. W. A. HEYMAN 2,432,759 PRCESS F MAKING CFFEE CNCENTRATES Filed Jan., l94l S it. Attorney Patented Dec. 16, 1947 UNITED STATE s PATENT FFICE 2,432,759. PRCESS F MANG CFFEE concentrates 1

Dec. 16, 1947. W. A. HEYMAN 2,432,759 PRCESS F MAKING CFFEE CNCENTRATES Filed Jan., l94l S it. Attorney Patented Dec. 16, 1947 UNITED STATE s PATENT FFICE 2,432,759. PRCESS F MANG CFFEE concentrates 1

US A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

United States Patent It 3,593,647

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

(12) United States Patent

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

United States Patent (19) D'Alessandro

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent (19) Forino

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

3,702,608 11/1972 Tibbs. states by bying O st plunger T.

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080216664A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0216664 A1 K00n et al. (43) Pub. Date: Sep. 11, 2008 (54) ELECTRONICTEATHERMOMETER AND TIMER DEVICE (75) Inventors:

(19) United States US 20080216664A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0216664 A1 K00n et al. (43) Pub. Date: Sep. 11, 2008 (54) ELECTRONICTEATHERMOMETER AND TIMER DEVICE (75) Inventors:

Module 6: Overview of bakery machinery: mixers, forming machines and ovens.

Paper No. 09 Paper Title: Bakery and Confectionery Technology Module 6: Overview of bakery machinery: mixers, forming machines and ovens. Introduction Bakery units can be classified as manual, semi-automatic

Paper No. 09 Paper Title: Bakery and Confectionery Technology Module 6: Overview of bakery machinery: mixers, forming machines and ovens. Introduction Bakery units can be classified as manual, semi-automatic

(12) United States Patent (10) Patent No.: US 6,813,994 B2

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

United States Patent (19) Bowen et al.

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

III IIIHIII. United States Patent (19) Momiyama

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0187694 A1 Cai US 2004O187694A1 (43) Pub. Date: (54) (76) (21) (22) (63) HOLDER FOR PRESSURE-BREWING COFFEE DRINK Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0187694 A1 Cai US 2004O187694A1 (43) Pub. Date: (54) (76) (21) (22) (63) HOLDER FOR PRESSURE-BREWING COFFEE DRINK Inventor:

United States Patent (19)

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

TORTILLA-TORTILLA CHIPS

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

YEDENT AGRO GROUP OF COMPANIES PROCESSING OF SOY BASED PRODUCTS FOR HUMAN FOODS AND POULTRY FEEDS

YEDENT AGRO GROUP OF COMPANIES PROCESSING OF SOY BASED PRODUCTS FOR HUMAN FOODS AND POULTRY FEEDS 1. SOYA EXTRUSION AND PRESSING PROCESS EQUIPMENT 1. The Pre Cleaner 2. The Course Mill 3. The Extruder

YEDENT AGRO GROUP OF COMPANIES PROCESSING OF SOY BASED PRODUCTS FOR HUMAN FOODS AND POULTRY FEEDS 1. SOYA EXTRUSION AND PRESSING PROCESS EQUIPMENT 1. The Pre Cleaner 2. The Course Mill 3. The Extruder

JUICE EXTRACTION AND FILTRATION JUICE EXTRACTION METHOD AND EQUIPMENT

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

Ovens. A+: Energy efficiency class A+ helps to save up to 10% energy compared to class A. Maximum performance with minimum consumption is guaranteed.

Ovens A: Product drying performance, measured from A+++ to D / G depending on the product family B: Product energy rating, measured from A+++ to D / G depending on the product family. A+: Energy efficiency

Ovens A: Product drying performance, measured from A+++ to D / G depending on the product family B: Product energy rating, measured from A+++ to D / G depending on the product family. A+: Energy efficiency

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

SIGMA The results count

SIGMA The results count Designing the future since 1918 Operating efficiently producing quality SIGMA Purchasing a wine press is one of the most important decisions for your business to make. You are going

SIGMA The results count Designing the future since 1918 Operating efficiently producing quality SIGMA Purchasing a wine press is one of the most important decisions for your business to make. You are going

SF4604PMCNX New product Available soon

SF4604PMCNX New product Available soon ELECTRIC COMBINATION MICROWAVE OVEN, VAPOR CLEAN, COMPACT 45 CM, DOLCE STIL NOVO, BLACK GLASS EAN13: 8017709223632 Aesthetics Hidden handle Component finish: Stainless

SF4604PMCNX New product Available soon ELECTRIC COMBINATION MICROWAVE OVEN, VAPOR CLEAN, COMPACT 45 CM, DOLCE STIL NOVO, BLACK GLASS EAN13: 8017709223632 Aesthetics Hidden handle Component finish: Stainless

22 Filed: Jun. 6, 1995 (51) Int. Cl... A22C 9/ U.S. Cl /141; 426/56; 426/63 58) Field of Search /141, 142, Canner/Cutter

United States Patent (19) Teran IIII US0055120A 11 Patent Number: 45) Date of Patent: Apr., 1996 54 MEATTENDERIZATION PROCESS FOR A MICROWAVABLE MEAT PRODUCT 76 Inventor: James Teran, 932 E. Thames St.,

United States Patent (19) Teran IIII US0055120A 11 Patent Number: 45) Date of Patent: Apr., 1996 54 MEATTENDERIZATION PROCESS FOR A MICROWAVABLE MEAT PRODUCT 76 Inventor: James Teran, 932 E. Thames St.,

Dec. 9, M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

The Indirect Cooking Method

The Method Preparing Your Barbecue for It is indirect cooking method that distinguishes barbecue kettle from or barbecues. When roasting or baking, food is placed on upper grill between two fires, directly

The Method Preparing Your Barbecue for It is indirect cooking method that distinguishes barbecue kettle from or barbecues. When roasting or baking, food is placed on upper grill between two fires, directly

(63) Suation of set. No. 787,80s, Oct 16, 1985, aban 3,928,045 12/1975 Tsunoda et al /3

United States Patent 19 11 Patent Number: 4,886,674 Seward et al. (45) Date of Patent: Dec. 12, 1989 (54) BEVERAGE MAKING CARTRIDGE 3,352,226 11/1967 Nelsen... 426/79 75 Inventors: Barry Seward; Kevin

United States Patent 19 11 Patent Number: 4,886,674 Seward et al. (45) Date of Patent: Dec. 12, 1989 (54) BEVERAGE MAKING CARTRIDGE 3,352,226 11/1967 Nelsen... 426/79 75 Inventors: Barry Seward; Kevin

United States Patent (19) Kovacevich, Jr.

United States Patent (19) Kovacevich, Jr. 11 Patent Number: Date of Patent: Jun. 9, 1987 54) 76 21 22 63 (51) 52 58 56) WNE DISTRIBUTION METHOD Inventor: Appl. No.: Filed: Sam Kovacevich, Jr., R.R. 1,

United States Patent (19) Kovacevich, Jr. 11 Patent Number: Date of Patent: Jun. 9, 1987 54) 76 21 22 63 (51) 52 58 56) WNE DISTRIBUTION METHOD Inventor: Appl. No.: Filed: Sam Kovacevich, Jr., R.R. 1,

Eaton Filtration, LLC

Eaton Filtration, LLC 44 Apple Street, Tinton Falsl NJ 07724 Phone: 732-212-4700 Fax: 952-906-3706 E-Mail: filtration@eaton.com Web: www.eaton.com/filtration Installation, Operation & Service Manual Model

Eaton Filtration, LLC 44 Apple Street, Tinton Falsl NJ 07724 Phone: 732-212-4700 Fax: 952-906-3706 E-Mail: filtration@eaton.com Web: www.eaton.com/filtration Installation, Operation & Service Manual Model

Cyclotherm Ovens. Direct Gas Fired Ovens. Member of the

Cyclotherm Ovens Direct Gas Fired Ovens Member of the MCS Cyclotherm Ovens MCS Bakemaster Oven This oven is the result of 30 years of MCS experience in designing and manufacturing automatic baking systems

Cyclotherm Ovens Direct Gas Fired Ovens Member of the MCS Cyclotherm Ovens MCS Bakemaster Oven This oven is the result of 30 years of MCS experience in designing and manufacturing automatic baking systems

linda-lewis.co.uk Fimar Pizza Roller LLKFR30 Fimar Stick Blender LLKMX42/S Medium Duty Electric Slicer LLK250MDES Veg Prep LLKVPDISCS

LLKDM30 The LLK economy dough mixers are ideal for takeaways and small restaurants where pizzas are only part of the menu. There are 2 sizes available to suit the user s requirements: 20 Litres and 30

LLKDM30 The LLK economy dough mixers are ideal for takeaways and small restaurants where pizzas are only part of the menu. There are 2 sizes available to suit the user s requirements: 20 Litres and 30

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. Lange (43) Pub. Date: Nov. 22, 2012

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

United States Patent (19) Adams et al.

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

SFP9395X. Functions. Options. classic

SFP9395X 90cm "Classic" Pyrolytic Multifunction Oven,Finger Friendly Stainless Steel and Eclipse Glass Energy Efficiency Class B EAN13: 8017709212575 12 functions Inc. Circulaire with upper & lower element

SFP9395X 90cm "Classic" Pyrolytic Multifunction Oven,Finger Friendly Stainless Steel and Eclipse Glass Energy Efficiency Class B EAN13: 8017709212575 12 functions Inc. Circulaire with upper & lower element

Coffee Filter Chromatography

Here is a summary of what you will learn in this section: Solutions can be separated by filtration, paper chromatography, evaporation, or distillation. Mechanical mixtures can be separated by sorting,

Here is a summary of what you will learn in this section: Solutions can be separated by filtration, paper chromatography, evaporation, or distillation. Mechanical mixtures can be separated by sorting,

Ovens. Appointed dealers: Models with this symbol are available via appointed dealers. For details please see the website

Ovens Appointed dealers: Models with this symbol are available via appointed dealers. For details please see the website www.smeguk.com ECO: The combination of the grill, fan and lower element is particularly

Ovens Appointed dealers: Models with this symbol are available via appointed dealers. For details please see the website www.smeguk.com ECO: The combination of the grill, fan and lower element is particularly

BAKED GOODS VARIETY OF APPLICATIONS

APPLICATIONS BAKED GOODS BAKED GOODS VARIETY OF APPLICATIONS Process solutions and products. WITH HANDTMANN TO BAKED GOODS DIVERSITY First-class technology - expertise and experience - worldwide service.

APPLICATIONS BAKED GOODS BAKED GOODS VARIETY OF APPLICATIONS Process solutions and products. WITH HANDTMANN TO BAKED GOODS DIVERSITY First-class technology - expertise and experience - worldwide service.

TYPE AESTHETICS CONTROLS PROGRAMS / FUNCTIONS OPTIONS TECHNICAL FEATURES

EAN13: 8017709212230 Product Family: Oven Aesthetic: Classic Power supply: Electric Category: 70cm Cooking Method: Thermo-ventilated Colour: Fingerproof Stainless Steel Energy efficiency class: A TYPE

EAN13: 8017709212230 Product Family: Oven Aesthetic: Classic Power supply: Electric Category: 70cm Cooking Method: Thermo-ventilated Colour: Fingerproof Stainless Steel Energy efficiency class: A TYPE

The Premium Benefits of Steam Infusion UHT Treatment

EDITORIAL October 2012 The Premium Benefits of Steam Infusion UHT Treatment UHT, or Ultra High Temperature, treatment uses high temperature for a short time to kill micro-organisms in a food or beverage

EDITORIAL October 2012 The Premium Benefits of Steam Infusion UHT Treatment UHT, or Ultra High Temperature, treatment uses high temperature for a short time to kill micro-organisms in a food or beverage

Installation & Parts Manual 2" & 3" High Capacity Strainers For Class 1, Petroleum Applications

Installation & Parts Manual 2" & 3" High Capacity Strainers For Class 1, Petroleum Applications Installation: M200-20 www.lcmeter.com Table of Contents Description Page Number Introduction... 2 What LC

Installation & Parts Manual 2" & 3" High Capacity Strainers For Class 1, Petroleum Applications Installation: M200-20 www.lcmeter.com Table of Contents Description Page Number Introduction... 2 What LC

brewing device, and particularly an espresso machine. 4,871,555 10/1989 Schwartz et al /82

USOO5895672A United States Patent 19 11) Patent Number: Cooper ) Date of Patent: Apr. 20, 1999 54) PRODUCT AND PROCESS FOR PREPARING 5,072,661 12/1991 Kondo... 99/296 A TEA EXTRACT 5,104,666 4/1992 Sanvitale...

USOO5895672A United States Patent 19 11) Patent Number: Cooper ) Date of Patent: Apr. 20, 1999 54) PRODUCT AND PROCESS FOR PREPARING 5,072,661 12/1991 Kondo... 99/296 A TEA EXTRACT 5,104,666 4/1992 Sanvitale...

(12) United States Patent (10) Patent No.: US 8,601,937 B2

USOO8601937B2 (12) United States Patent () Patent No.: Campetella et al. (45) Date of Patent: Dec., 2013 (54) APPARATUS FOR MAKING COFFEE 5,605,091 A * 2/1997 Garber... 99,330 5,650,186 A * 7/1997 Annoni

USOO8601937B2 (12) United States Patent () Patent No.: Campetella et al. (45) Date of Patent: Dec., 2013 (54) APPARATUS FOR MAKING COFFEE 5,605,091 A * 2/1997 Garber... 99,330 5,650,186 A * 7/1997 Annoni

SmartCraft. Pure malt turns into precious drops. Innovations for a better world.

SmartCraft. Pure malt turns into precious drops. Innovations for a better world. Grain & Malt Handling Cleaning Grinding Transport Customer Service Grist 2 SmartCraft. Pure malt turns into precious drops.

SmartCraft. Pure malt turns into precious drops. Innovations for a better world. Grain & Malt Handling Cleaning Grinding Transport Customer Service Grist 2 SmartCraft. Pure malt turns into precious drops.

United States Patent (113,607,299

United States Patent (113,7,299 72 21 22 ) 73 54) (52) (51) Inventor Gregory L. Bolt Cincinnati, Ohio Appl. No. 8,364 Fied Sept. 4, 1969 Patented Sept. 21, 1971 Assignee The Procter & Gamble Company Cincinnati,

United States Patent (113,7,299 72 21 22 ) 73 54) (52) (51) Inventor Gregory L. Bolt Cincinnati, Ohio Appl. No. 8,364 Fied Sept. 4, 1969 Patented Sept. 21, 1971 Assignee The Procter & Gamble Company Cincinnati,

United States Patent (19) Morrison, Jr. et al. (54)

United States Patent (19) Morrison, Jr. et al. (54) (75) (73) 21 22 (51) 52) (58) (56) DESOLVENTIZNG PROCESS Inventors: Lowen R. Morrison, Jr., Hamilton; John H. Phillips, Fairfield, both of Ohio Assignee:

United States Patent (19) Morrison, Jr. et al. (54) (75) (73) 21 22 (51) 52) (58) (56) DESOLVENTIZNG PROCESS Inventors: Lowen R. Morrison, Jr., Hamilton; John H. Phillips, Fairfield, both of Ohio Assignee:

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

US 20070178190A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0178190 A1 Vatelot (43) Pub. Date: Aug. 2, 2007 (54) GRAPE TREATMENT METHOD FOR WINE (30) Foreign Application

US 20070178190A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0178190 A1 Vatelot (43) Pub. Date: Aug. 2, 2007 (54) GRAPE TREATMENT METHOD FOR WINE (30) Foreign Application

Baker Perkins Inc 3223 Kraft Ave SE Grand Rapids, MI USA. Baker Perkins Ltd Manor Drive Paston Parkway Peterborough PE4 7AP United Kingdom

Baker Perkins Ltd Manor Drive Paston Parkway Peterborough PE4 7AP United Kingdom T: +44 1733 283000 F: +44 1733 283004 E: bpltd@bakerperkinsgroup.com I: www.bakerperkinsgroup.com Baker Perkins Inc 3223

Baker Perkins Ltd Manor Drive Paston Parkway Peterborough PE4 7AP United Kingdom T: +44 1733 283000 F: +44 1733 283004 E: bpltd@bakerperkinsgroup.com I: www.bakerperkinsgroup.com Baker Perkins Inc 3223

ICE CREAM CONE MAKING

Profile No.: 46 NIC Code: 56103 ICE CREAM CONE MAKING 1. INTRODUCTION: Ice cream cones are a mass consumption item. An ice cream cone, poke or cornet is a dry, cone-shaped pastry, usually made of a wafer

Profile No.: 46 NIC Code: 56103 ICE CREAM CONE MAKING 1. INTRODUCTION: Ice cream cones are a mass consumption item. An ice cream cone, poke or cornet is a dry, cone-shaped pastry, usually made of a wafer

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

US 2007003 1551A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0031551A1 Samson et al. (43) Pub. Date: (54) METHOD FOR CONTINUOUSLY Publication Classification PROCESSING

US 2007003 1551A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0031551A1 Samson et al. (43) Pub. Date: (54) METHOD FOR CONTINUOUSLY Publication Classification PROCESSING

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

United States Patent (19)

United States Patent (19) Farkye et al. 4 (7) 73) 21) 22 1 (2) 8 6) CHEESE MAKING PROCESS Inventors: Nana Y. Farkye, Atascadero; B. Bhanu Prasad, San Luis Obispo, both of Calif. Assignee: California Polytechnic

United States Patent (19) Farkye et al. 4 (7) 73) 21) 22 1 (2) 8 6) CHEESE MAKING PROCESS Inventors: Nana Y. Farkye, Atascadero; B. Bhanu Prasad, San Luis Obispo, both of Calif. Assignee: California Polytechnic

52 U.S. Cl... 70s/ , 235,381 mitted from the automatic vending machine 1 to the center

US006021394A United States Patent (19) 11 Patent Number: 6,021,394 Takahashi (45) Date of Patent: Feb. 1, 2000 54) SALES MANAGEMENT METHOD IN 5,844,808 12/1998 Konsmo et al.... 364/479.14 AUTOMATIC VENDING

US006021394A United States Patent (19) 11 Patent Number: 6,021,394 Takahashi (45) Date of Patent: Feb. 1, 2000 54) SALES MANAGEMENT METHOD IN 5,844,808 12/1998 Konsmo et al.... 364/479.14 AUTOMATIC VENDING

United States Patent (19) Denier et al.

United States Patent (19) Denier et al. 11 Patent Number: 4,744,37 4 Date of Patent: May 17, 1988 (4) 7 73) (21) 22) 1 (2) (8) PROCESS FOR FORMING FLAVOR COMPOUNDS IN TOBACCO Inventors: Robert F. Denier;

United States Patent (19) Denier et al. 11 Patent Number: 4,744,37 4 Date of Patent: May 17, 1988 (4) 7 73) (21) 22) 1 (2) (8) PROCESS FOR FORMING FLAVOR COMPOUNDS IN TOBACCO Inventors: Robert F. Denier;

TYPE AESTHETICS CONTROLS PROGRAMS / FUNCTIONS OPTIONS TECHNICAL FEATURES

EAN13: 8017709191450 Product Family: Oven Aesthetic: Classic Power supply: Electric Category: Reduced height 90cm Cooking Method: Thermo-ventilated Colour: Fingerproof Stainless Steel Cleaning system:

EAN13: 8017709191450 Product Family: Oven Aesthetic: Classic Power supply: Electric Category: Reduced height 90cm Cooking Method: Thermo-ventilated Colour: Fingerproof Stainless Steel Cleaning system:

! MXING-LIQUID. United States Patent (19) Khalsa 2-"22 18 INSPECTION. 11 Patent Number: 5,298,274 45) Date of Patent: Mar.

United States Patent (19) Khalsa (54) METHODS FOR MAKING TORTILLACHIPS AND TORTELLA CHIPS PRODUCED THEREBY 76 Inventor: Nirbhao S. Khalsa, 3141 NW. Greenbriar Ter, Portland, Oreg. 97.210 21 22) (51) (52)

United States Patent (19) Khalsa (54) METHODS FOR MAKING TORTILLACHIPS AND TORTELLA CHIPS PRODUCED THEREBY 76 Inventor: Nirbhao S. Khalsa, 3141 NW. Greenbriar Ter, Portland, Oreg. 97.210 21 22) (51) (52)

(12) United States Patent

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

Hard sweet biscuit & crackers

Hard sweet biscuit & crackers The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given

Hard sweet biscuit & crackers The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given

Best Quality for the Best Wines

Best Quality for the Best Wines High-quality Raw Material Only exclusively selected healthy oak is used for supplied by longstanding partners that operate controlled, sustainable forestry. Computer-aided

Best Quality for the Best Wines High-quality Raw Material Only exclusively selected healthy oak is used for supplied by longstanding partners that operate controlled, sustainable forestry. Computer-aided

Retailing Frozen Foods

61 Retailing Frozen Foods G. B. Davis Agricultural Experiment Station Oregon State College Corvallis Circular of Information 562 September 1956 iling Frozen Foods in Portland, Oregon G. B. DAVIS, Associate

61 Retailing Frozen Foods G. B. Davis Agricultural Experiment Station Oregon State College Corvallis Circular of Information 562 September 1956 iling Frozen Foods in Portland, Oregon G. B. DAVIS, Associate

Buying Filberts On a Sample Basis

E 55 m ^7q Buying Filberts On a Sample Basis Special Report 279 September 1969 Cooperative Extension Service c, 789/0 ite IP") 0, i mi 1910 S R e, `g,,ttsoliktill:torvti EARs srin ITQ, E,6

E 55 m ^7q Buying Filberts On a Sample Basis Special Report 279 September 1969 Cooperative Extension Service c, 789/0 ite IP") 0, i mi 1910 S R e, `g,,ttsoliktill:torvti EARs srin ITQ, E,6

Product Consistency Comparison Study: Continuous Mixing & Batch Mixing

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

52 U.S. Cl... 99/295; 99/299; 99/305; 99/ / ) References Cited U.S. PATENT DOCUMENTS 1,778,792 10/1930 Cameron...

United States Patent (19) Glucksman (54) APPARATUS FOR BREWING COFFEE 76) Inventor: Dov Z. Glucksman, 137 Larch Row, Wenham, Mass. 01984 21 Appl. No.: 636,137 22 Filed: Dec. 31, 1990 51 Int. Cl.5......

United States Patent (19) Glucksman (54) APPARATUS FOR BREWING COFFEE 76) Inventor: Dov Z. Glucksman, 137 Larch Row, Wenham, Mass. 01984 21 Appl. No.: 636,137 22 Filed: Dec. 31, 1990 51 Int. Cl.5......

Product Presentation. Dough Dividers

Product Presentation Dough Dividers Dough Dividers for all types of dough In the Glimek Dough Divider range you will find the right machine for every bakery. Automatic suction-fed dough dividers with high

Product Presentation Dough Dividers Dough Dividers for all types of dough In the Glimek Dough Divider range you will find the right machine for every bakery. Automatic suction-fed dough dividers with high

ZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZ-->

Jan. 7, 1936. C. A. THOMAS ET AL METHOD OF ARTIFICIALLY AGING WHISKY Filed Sept. 12, 1934 27 E= autuavaaaaaaaaaaava V E22 V R 2 4 3 % [+] YA.!zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz!}}}}}}}####zzzz

Jan. 7, 1936. C. A. THOMAS ET AL METHOD OF ARTIFICIALLY AGING WHISKY Filed Sept. 12, 1934 27 E= autuavaaaaaaaaaaava V E22 V R 2 4 3 % [+] YA.!zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz!}}}}}}}####zzzz

Aaawaw A. M1axsom. - A 474/2/sr.przezz' SecY72/7. April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES.

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

Beer. in a Box. The future for draft beer distribution

Beer in a Box The future for draft beer distribution Carbonate Solutions Ltd is a UK Technology company specialising in carbonating drinks at the point of dispense. Incorporating 20 years research and

Beer in a Box The future for draft beer distribution Carbonate Solutions Ltd is a UK Technology company specialising in carbonating drinks at the point of dispense. Incorporating 20 years research and

Model GPX Precision Disc Style Coffee Grinder

Model GPX Precision Disc Style Coffee Grinder Modern Process Equipment, Inc. Chicago, Illinois OVERVIEW The Model GPX Disc Style Coffee Grinder utilizes precision cut "diamond hard" grinding plates to

Model GPX Precision Disc Style Coffee Grinder Modern Process Equipment, Inc. Chicago, Illinois OVERVIEW The Model GPX Disc Style Coffee Grinder utilizes precision cut "diamond hard" grinding plates to

(54) POPCORN BUTTER DISPENSER Publication Classi?cation

US 20140054316A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0054316 A1 Lehman et al. (43) Pub. Date: Feb. 27, 2014 (54) POPCORN BUTTER DISPENSER Publication Classi?cation

US 20140054316A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0054316 A1 Lehman et al. (43) Pub. Date: Feb. 27, 2014 (54) POPCORN BUTTER DISPENSER Publication Classi?cation

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120269946A1 (12) Patent Application Publication (10) Pub. No.: US 2012/026994.6 A1 Medaglia (43) Pub. Date: Oct. 25, 2012 (54) METHOD FOR THE PASTEURIZATION OF WINE ON A PRODUCTION

(19) United States US 20120269946A1 (12) Patent Application Publication (10) Pub. No.: US 2012/026994.6 A1 Medaglia (43) Pub. Date: Oct. 25, 2012 (54) METHOD FOR THE PASTEURIZATION OF WINE ON A PRODUCTION