ta-v, 9-1-N Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS EDWARD E ANDERSON ATORNEYS JACK D.

|

|

|

- Adele Newton

- 5 years ago

- Views:

Transcription

1 Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May 10, Sheets-Sheet INVENTORS EDWARD E ANDERSON JACK D. BROWN ta-v, 9-1-N ATORNEYS

2 Oct. 11, 1966 J. D. BROWN ETA 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May lo, Sheets-Sheet 2 t Sir Sir a se - INVENTORS EDWARD E ANDERSON JACK D. BROWN N- Pasa,?hort- ye 2.e.--& AT TORNEYS

3 Oct. 11, 1966 Filed May 10, 1965 J. D. BROWN ETA METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS 3,278,311 PROCESSED CORN KERNELS RNNSYSNNNNS SNN N N JACK D. BROWN EDWARD E ANDERSON 4-cy --- 2/4 -eza BYA a y. 1. AT TORNEYS

4 Oct. 11, 1966 J. D. BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May 10, l965 5 Sheets-Sheet 4 FIG. 4 NNYNNYSNYSNSYNYSNYSNYSSYNN YaYaNYaYaNYYY x 24% NYaNY NNNNNN ZY YC2Y --aam ZZZZ SYNNY35O 353 SYNNYS ZZZZZZZ 55O 352 ZZZZZZZZ --- ZZZZZZZ 353 ZZZZZZ NYYYYYYYY SYYYYYYYYYYYYYYYYYYYYYYYA-2 NYNY YNYNY F.G. 5 JACK D. BR6 VENTORS EDWARD E ANDERSON BY her--e. 9-y-4- X - a-- 2 ATTORNEYS

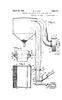

5 Oct. 11, 1966 J. D. BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May 10, Sheets-Sheet 5 COOked Corn Hopper 44 Weighing 8 Packaging INVENTORS JACK D. BROWN EDWARD E. ANDERSON '4.?ee ATTORNEYS

6 United States Patent Office 3,278,311 Patented Oct. 11, ,278,311 METHOD OF MANUEFACTURING CORN DOUGH AND CORN (CHPS Jack D. Browa, Dallas, Tex., and Edward E. Anderson, Lexington, Mass, assignors to Morton Foods, Inc., Dallas, Tex., a corporation of Texas Filed May 10, 1965, Ser. No. 459, Claims. (C ) The present application is a continuation-in-part of our United States patent applications Serial No. 184,037 filed April 2, 1962, entitled, "Method and Apparatus for the Manufacture of Corn Chips, now abandoned and Serial No. 184,442 filed April 2, 1962, entitled, "Method and Apparatus for Preparing Corn Dough, now aban doned. Our invention relates to an improved method for mak ing a snack item and more particularly for making such an item from corn. Snack items normally known as corn chips' are now Very widely Sold. It is customary in making such corn chips to cook the corn in the presence of lime, steep the processed corn and from this corn form a dough which is extruded as discrete pieces into hot fat to be cooked. It will be appreciated that by this method there are definite limitations on the size, shape and flavor char acteristics of the corn chip thus formed. The limita tions on size and shape associated with extruding the dough into the deep fat may be overcome by rolling and cutting the dough to form shapes. However, this is not easy to accomplish. U.S. Patent 2,905,559 discloses that it is possible to form sheets of dough and to cut this dough into predetermined shapes and fry them in deep fat provided the dough is perforated by docking before frying in. Such a way that the perforations thus formed remain throughout the corn chip after it is cooked. While the process disclosed in the above identified United States patent is useful with masa dough prepared by conventional processes (for example as in U.S. Patent 2,002,053) we have now found that by a unique combination of steps it is possible to provide an improved method of making corn chips and in particular a new method of dough formation which has a number of important advantages over the prior art. Among these advantages are the achievement of a continuous operation from the cooking of the corn kernels to the packaging of the finished chips, the ability to run this operation at high speed, the elimination of a washing step prior to grinding, the attainment of better quality control, the ability to make the final product in any desired shape and size, and the achievement of better flavor in the finished corn chips. By processing the corn kernels in the manner of our invention we may provide corn dough in thin sheets par ticularly well suited to the docking and cutting process described in U.S. Patent 2,905,559. The method of this invention involves the processing of the raw corn kernels, and the cutting and kneading and milling of the processed kernels in such a way as to form a dough which can be sheeted, docked, cut and cooked to form the corn chips. One of the major problems presented in providing a continuous process of corn chip manufacture is that of treating processed corn kernels, which have their hulls loosened or removed and which are penetrated with lime, to make a sheetable corn dough. Normally, doughs are formed from a number of components, for example a finely comminuted dry material (flour, meal or the like) to which are added liquids, shortenings and flavors. However, in the preparation of corn chips it is desirable for the attainment of the limed corn flavor to form the O O 2 dough from lime treated corn kernels alone without adding any other ingredients. Thus normal dough form ing methods are not useable in the conversion of the processed corn kernels to the dough needed for sheeting and Subsequent cutting. In the process of forming the dough from the corn kernels it is of course necessary to comminute the proc essed kernels which generally still retain essentially their original shape and size after cooking. We have found that the manner in which corn kernels are comminuted and the way in which the resulting comminuted material is further treated are critical aspects of making a corn dough from processed corn kernels. In the prior art of corn chip manufacture, the dough is formed by grinding the kernels between stone grinding Surfaces. The comminuted corn kernels are then formed into a loaf or similar shape termed a "masa. The masa dough is then extruded directly into hot cooking oil. Dough formed in this manner cannot, however, be sheeted Out, probably because this type of grinding achieves too fine a comminution which in turn brings about a break down of the corn kernels into a material which cannot be readily plasticized or kneaded for subsequent rolling into dough sheets. It is not entirely understood why this is true but it may be postulated that too fine com minution as achieved in stone grinding frees the oils and other constituents of the corn kernels to the extent that there remains no homogeneous mass for sheet formation. Moreover, stone grinding is not acceptable for a con tinuous commercial process for forming corn chips. The grinders possess an inherent low capacity and they are uneconomical to use inasmuch as the stones require frequent refacing. Moreover, stone grinding requires a preliminary washing of the processed corn kernels and the addition of water during grinding. These latter re quirements detract from the flavor of the finished corn chip. There are of course available other types of grinding devices Such as, for example, the well-known meat grinder which contains a rotating screw in an essentially cylin drical body having an end plate through which the ma terial is forced and cutting knives to remove the ma terial after grinding. In grinders of this type, reduction in size is primarily achieved by the process of attrition. However, these grinders alone are not suitable for han dling the processed corn. Although it is possible to grind processed corn kernels in such grinders, the tempera ture of the dough increases so rapidly that the resulting material becomes sufficiently sticky to materially slow down the grinder, and finally stop it. Accordingly cool ing of the grinder is required, which is not only difficult to achieve but uneconomical to operate. Moreover, ex ceedingly large capacity grinders are required to handle Sufficient quantities of kernels to achieve commercial pro duction. Finally, grinding the corn in this manner and bringing the dough to excessive temperatures detracts ma terially from the flavor of the finished corn chip. It may be seen from the foregoing description that it has not been possible heretofore to make a suitable corn dough in an economical and commercially feasible way. Although it is possible to grind corn kernels in a screw and plate type grinder, such as described, the difficulties encountered preclude the use of this type of grinder alone in the formation of suitable dough from processed corn kernels. Therefore, in order to make corn chips by sheet ing the dough and cutting it into desired configurations it is necessary to find a way to form a dough from processed corn kernels having physical characteristics which permit it to be roled and sheeted and which is also economical of operation.

7 3,278, It is an important object of our invention to provide Processing the raw material an improved method of making corn chips which includes the steps of sheeting out the dough and the cutting of it The first step in the forming of the corn chips is the into desired configurations. It is another object of our processing of the dried raw corn (preferably a mixture invention to provide a method of the character described of white and yellow corn in kernel form) with lime to put 5 which permits an essentially continuous production of corn the kernels in a condition where they may be further chips from raw kernels to finished product. It is yet an reduced in size and at the same time to impart the desired other object of our invention to provide a method which lime flavor. In the previous methods of processing corn is unique for the production of corn chips which exhibit to put it in condition for making dough for deep-fat fry improved flavor, texture and quality control. ing, the corn has been cooked for a period of time in a 10 Another object of our invention is to provide a method lime solution and then permitted to steep for an extended of readily converting processed corn kernels directly into period of time-sometimes as much as 24 hours. How a dough which can be readily sheeted out for cutting and ever, in order to make the process of this invention con further processing. It is a further object of our invention tinuous and to eliminate the necessity of steeping the corn to provide a method of the character described which for an extended period of time, it has been found that the results in the production of dough possessing a controlled corn kernels can be cooked under pressure provided a degree of plasticity and an improved flavor. Another sufficient quantity of lime, either alone or with other object is to provide a method of forming corn dough alkalies in combination, is employed. The actual cooking which is rapid and which lends itself particularly well to of the corn according to this improved process to put the incorporation in a continuous process of corn chip manu corn kernels in condition for particle size reduction and 20 facture. It is still another object of our invention to pro dough formation is more fully described in a United vide a corn dough from processed corn kernels which lends States Patent No. 3,083,103 issued to Edward E. Ander itself to rolling and sheeting. son et al. and dated March 26, 1963, and assigned to the assignee of the present application. Other objects of our invention will in part be obvious and will in part be apparent hereinafter. Due to the nature of corn and particularly to the fact Our invention accordingly comprises the several steps that the entire kernel (containing cellulose, starch, oil and and the relation of one or more of such steps with respect protein) is used in our process, the steps must be directed to each of the others, all as exemplified in the following to individually and collectively putting the corn and sub detailed disclosure, and the scope of the invention will sequently the dough in proper condition at all points in be indicated in the claims. the process. The desired conditions to be obtained will For a fuller understanding of the nature and objects of be defined for each step in the following description. In our invention, reference should be had to the following the figures, FIGS. 1a and 1b combined illustrate the entire detailed description taken in connection with the accom method of this invention in a preferred embodiment, panying drawings in which: In FIG. 1 a, it will be seen that the raw corn is treated FIG 1a is a schematic flow diagram illustrating the with the necessary amount of lime and water in a pres location, arrangement and types of apparatus and the or sure vessel 10 which has surrounding it a steam jacket der of steps utilized in the practice of the process of this 11 and which is equipped with an agitator 12 driven by invention up through the formation of the dough; motor 13, through gear box 13a. Appropriate conduits FIG. 1b is a continuation of the diagram of FIG. 1a are provided for introducing the materials into the pres showing the formation of the dough sheet, the docking, sure vessel 10, such as conduit 14 for the corn and lime cutting, cooking and final processing; and conduit 15 for water or steam or both. There is also FIG. 2 is a diagram of an alternative apparatus for provided a pressure relief line 16 to control the pressure use in connection with the apparatus of FIG. 1a in han within the vessel 10 and to release the pressure when the dling the processed corn to the point where it is cut and processing of the corn kernels has been completed. plasticized; The quantities of lime and water with relationship to FIG. 3 is a vertical sectional view of the apparatus of the amount of corn processed as well as the time and tem this invention used in converting processed corn kernels perature conditions of pressure cooking are described in to a plasticized corn dough; detail in the above-identified United States Patent No. FIG. 4 is a horizontal cross-section of the cutting mill 3,083,103. This application discloses that there are two taken along line 4-4 of FIG. 3; important aspects in the processing of the corn kernels, 50 FIG. 5 is a fragmentary vertical cross-section of a por namely the use of pressure and the use of lime in a tion of the cutting head taken along the line 5-5 of FIG. quantity equivalent to at least 1.5% by weight of the dry 2: corn. This pressure cooking produces a processed corn FIG. 6 is a diagram of apparatus for use in drying and which requires only a brief steeping, thus making a con storing the processed corn for later manufacture into a tinuous corn chip process possible if alternating cookers 55 corn chip product; and FIG. 7 is a diagram of an alternative apparatus for use in connection with the apparatus of FIG. 1b in trans ferring the cut dough chips to the cooking tank. We have found that the improved corn chips of this invention may be continuously made with excellent qual ity control if the corn and the resulting dough are handled as described below in detail. By cooking or processing the raw corn in a specific manner, by effecting a rapid but efficient steeping of the processed corn, and by cut ting the steeped corn to the desired particle size in a unique way and kneading and mixing the particles to form a dough which can be rolled into a thin sheet, the neces sary conditions can be established whereby the dough sheets can be subsequently docked, cut into shapes, deep fat fried and packaged. By the proper control of each of the steps described, it is possible to coordinate the method so that the dough may be handled in the desired manner. Each of the steps performed will be presented in detail with reference to the drawings are used. More important however, it produces a proc essed corn which does not have to be washed, as was re quired in the prior processes. After the corn has been processed under the desired conditions, pressure is released in the pressure vessel by means of the relief line 16, and by opening an air-operated valve 17, the processed corn, along with the liquid, is trans ferred through the conduit 18 into a pump hopper 19. At this point, the corn and associated liquid are at a tempera ture between about 210 and 220 F. Fresh cooling water is introduced through line 20 into the hot discharge from the pressure vessel to reduce the temperature to about 170 F. Subsequent to this cooling the processed corn and liquid are transferred through conduit 21, by means of pump 22 driven by motor 23, into a conduit 24 which leads into a corn-water separator 25 positioned in the upper part of a steeping tank 26. The corn-water Separator 25 Separates out a portion of the water and re turns it via conduit 27 into the pump hopper 19 to pro vide an additional quantity of liquid for ease of pumping the processed corn to the steeping tank 26.

8 5 Alternatively, the vessel 10 may be directly connected via a single conduit to the inlet to the steeping tank 26 (as shown for example in FIGURE 2). When the pres Sure cooking is completed, the valve 17 is opened and the pressure in the pressure vessel forces the liquid and corn through the conduit into the steeping tank 26. Here it must be immediately cooled since it has not had the cooling treatment provided in the pump hopper. To this end a conduit or pipe 33 is provided which is connected to a supply of cold, fresh water. When the cooked corn and liquid are introduced into the steeping tank by direct blow down as described above, cold fresh water is sup plied to rapidly drop the temperature to about 170 F. During a 60-minute steeping period, the temperature will further drop, reaching about 160 F. at the end of the period. Steeping is carried out for a relatively short period of time, preferably for about sixty minutes; however steep ing times of between minutes and two hours have been found satisfactory. Steeping is carried out in steeping tank 26 which is equipped with an agitator which in turn is driven by motor 32 through a gear box 32a. The agitator in the steeping tank 26 is not operated con tinuously but only periodically. The periodic stirring of the corn and liquid in the steeping tank is designed to disturb the interface between the corn kernel surface and liquid to get better lime penetration into the corn without wearing away the surface of the corn. In the process some husks from the corn kernels are, of course, removed, but it is preferred that the husk removal with in the steeping tank and during the stirring process be maintained at a minimum since it is desirable to have husks as well as the other parts of the kernels in the formation of a dough suitable for sheeting. Moreover, the use of all of the kernel contributes to the favor of the corn chip and to the attainment of high yield. In the agitation of the corn and liquid in the steeping tank 26, it is preferred that the stirring be carried out for a few seconds about every 10 minutes. At the end of the steeping period the corn kernels are in the proper condition for dough formation. This means that the kernel husks are loosened but substantially all yet at tached. In contrast to the prior art, no washing is re quired, in fact it is preferred to eliminate washing en tirely. We have also found that when the pressure cooked corn is transferred by direct blow-down from the pressure ves Sel as described above, the steeping time to achieve a given penetration of corn by the lime is materially re duced. For example, we have found that after direct blow-down the required time is reduced from the 60 minutes for conventionally transferred corn to about minutes. The corn, after steeping as noted above for about minutes to two hours with the described periodic stirring, is in condition for transferral to the next step in the process. Positioned at the bottom of steeping tank 26 is valve 35 which when open permits the steeped processed corn and liquid to be discharged into a discharge tank 36. Directly under the discharge valve 35 is located an endless for aminous belt 37 which picks up the corn kernels 38 and permits final draining of the liquid therefrom into discharge tank 36 and a draining pan 39. The liquid thus removed from the corn kernels is periodically discharged from discharge tank 36 by means of a drain line. Corn falling through the Small opening in the belt 38 and car ried out of the discharge tank 36 through the conduit may be recovered by a recovery system. Such a system might involve pumping the effluent through a screen for example. The recovered corn can be utilized in the re mainder of the process. The corn kernels conveyed by the foraminous belt are carried into a storage hopper 44 where they may be stored if desired before further processing. Although the proc essed corn can be stored at this stage of the process, 3,278, this is not required. On the other hand, it is preferable to use the kernels while still warm in dough formation. Formation of dough By the method of our invention processed corn kernels are converted to a sheetable dough by two distinct steps Which when performed in the order and in the manner described below result in a homogeneously kneaded or plasticized dough which can be passed through rollers and converted into a thin continuous sheet. The two steps of converting the processed corn kernels to dough include the cutting of the corn (as contrasted with grinding) in a cutting mill and the Subsequent plasticizing of the re Sulting comminuted material in a modified worm and plate grinder. Because the corn kernels are first cut rather than ground it is possible to control, through the control of particle size, the physical characteristics of the comminuted corn kernels. It is also possible to handle the processed corn kernels at an elevated temperature without cooling them since no great amount of heat is generated in their cut ting. Thus it is possible to form the dough from kernels Which, at the time they are introduced into the cutter, are at an elevated temperature, for example up to about 170 F. It appears that the wet starch in the corn kernels, When about 170 F. acts to lubricate the cutting knives in the cutting mill, thus permitting the cutting of the corn Without a Substantial temperature increase. Using warm kernels appears to be helpful also in achieving the plasticiz ing step. However, they may of course be introduced into the cutter at room temperature if they have been permitted to stand for a period of time after processing. It is not understood precisely why the combination of cutting and plasticizing makes it possible to form the sheet able corn dough, but it is believed that by controlling the size to which the kernels are comminuted, such compo nents of the kernels as oils, zein and other binder mate rials naturally occurring in the corn kernels are released only to the extent that they can be used to plasticize the comminuted material with the required amount of co hesion without producing an exceedingly sticky material as is produced in stone grinding for example. When cut and plasticized at somewhat above room temperature dough formation seens to be somewhat enhanced, due per haps to some activation of the naturally Occurring binder materials. By using the warm corn a very Satisfactory dough results; and, moreover, it is not necessary to cool each batch of processed kernels to room temperature be fore grinding. However, as noted above, it is possible to form dough from corn kernels which have reached room temperature. Cutting is carried out so that the resulting comminuted material has a maximum particle size ranging from about to inch. Comminuted material, the maximum particle size which is about 0.0, has been found to be Very Satisfactory in making a sheetable corn dough. It Will be appreciated that in cutting, at least a minor portion of the comminuted material may be somewhat smaller than these sizes specified. Plasticizing is carried out until a uniformly consistent and well kneaded dough is formed. From the storage hopper 44 in FIGURE1a the proc essed corn kernels are carried by means of an adjustable Screw feeder 45 into a cutting mill generally indicated at 46 and then by chute 47 into a plasticizer 48. The steps by which the kernels are reduced in size and then blended are critical to the formation of a corn dough which can be mechanically handled, that is rolled into a thin sheet, docked and cut. FIGURES 3-5 show in greater detail a typical cutting mill 46 and a plasticizer 44 which have been found to be particularly well adapted to making corn dough in ac cordance with this invention. The cutting mill as shown in FIGURE 3 is typified by cutting mills manufactured by Urschel Laboratories, Inc., of Valparaiso, Indiana, While the plasticizer is typified by screw grinders having

9 3,278, perforated end plates such as a meat grinder sold by flaky. At this point these particles exhibit only a small John E. Smith and Sons, Manufacturing Company of amount of cohesion and normally have a moisture con Buffalo, New York. In the following description and tent range from 45 to 60% by weight. claims the term cutting mill' is used to define any ap Turning again to FIG. 3 it will be seen that the cut paratus which is capable of comminuting the corn kernels 5 corn particles as they emerge from the cutting head 315 within the size range specified to give a more or less moist drop downwardly through housing 320, pass through and flaky material. The term plasticizer is used to indi joining number 47 and are introduced into the plasticizing cate any apparatus which is capable of kneading the device 48. The plasticizing means of FIGURE3 is shown comminuted corn kernels to form an essentially homoge to comprise a hopper 336 and a horizontally placed es neous cohesive plastic-like material which can be rolled IO Sentially cylindrical housing 337 which has rotating with to form a continuous thin sheet. in it a worm or screw 338 which is integrally formed on FIGURE 3 is a vertical cross-section of the entire a suitable rotating drive shaft 3. At the exit end of dough-forming apparatus while FIGURES 4 and 5 are de this screw type grinder is a perforated plate 342 having tailed cross-sections of a portion of the cutting head of a cutting mill. In FIGURE 3 the cutting mill is generally indicated at the numeral 46, the plasticizer by the numeral 48 and an element joining these two by the numeral 47. Turning first to the cutter 46 it will be seen to consist of a feed hopper 314 which introduces the processed corn kernels into the actual cutting device which comprises a stationary cutting head 315, an impeller 316 which rotates within the cutting head 315 and which has a series of impeller blades 317. The cutting head 315 is retained in its stationary position by being bolted to a top plate 318 and to a spindle housing 319. Surrounding the en tire cutting device and its driving means is a housing 320 which is affixed to the feed hopper 314 through suit able seals 321. Running upwardly through the spindle housing 319 is the impeller drive shaft 324 which is mechanically joined to the bottom plate 325 of the impeller as by a bolt 326 and dowel pins 326a (FIG. 4). The impeller drive shaft 324 is in turn attached to a spindle pulley 328 and is rotated by means of the drive belt 329 which is encased in a suitable belt housing 3. Finally a motor 332 is provided to drive belt 329 and in turn to rotate the im peller 316 within the cutting device. The cutting mill proper comprises the stationary circu lar cutting head 315 and the impeller 316 which revolves within the cutting head. The cutting head has, as shown in FIGURES 4 and 5, a number of tiers of shaped, spaced knives 352 around its periphery joined to spacers 350. The cutting head may be built up with two types of elements, the spacers 350 and knife elements 352. Both elements have the same thickness (typically about 0.020'). The knife elements 352 as seen in FIGURE 4 comprise two non-cutting portions 35a joined by a knife or "bridge' 352b which performs the actual cutting function. The spacers 350 have the same shape as the non-cutting portions 352a of the knife elements. In assembling the cutting head, a series of knife ele ments 352 are positioned around the periphery of the head So the portions 352a fall on each of the "columns' to be formed. As there are 20 "columns' as seen in FIGURE 4, 10 elements are used. Then additional elements are then placed on the first 10 to build up the column further but the elements of the second layer are placed in over lapping relation as shown in FIGURE 5, much as bricks are overlapped in building a wall. A spacer is placed in each column on top of this second layer knife element and the process is then repeated until a sufficient height is achieved. In this way the structure illustrated in FIG URE 5 is achieved. Typically, the openings 353 are there fore approximately 0.0' in height. The knife portions are staggered in adjacent openings around the periphery and the columns' are solid. In practice the elements 350 and 352 are stacked in sufficient numbers to provide a cutting head about 2 inches in height. As the impeller rotates within the cutting head, the corn kernels falling into the center of the impeller 316 are forced outwardly by centrifugal force against the in side surface of the cutting head. The kernels are then cut between the impeller blades and the knives and are forced out of the cutting head through spacings 353 in the form of finely divided particles which are moist and holes 343 formed therein. The grinder shaft is driven by motor 344 through reduction gearing generally in dicated at 345. The moist flaky comminuted cornas it passes through the grinder 48 is kneaded and mixed. It is possible that some further comminution takes place in the grinder 48 but the amount of comminution is small compared to that which has been achieved by the cutting mill. This is borne out by the fact that little if any heat is generated in the dough during plasticizing. Moreover, the fact that the size of the holes 343 in the end plate 342 is not critical indicates that there is little, if any cutting through attrition as the plasticized material is forced through these holes. The dough 346 which is delivered by the plasticizer is sufficiently cohesive to be transferred directly to rollers for sheet formation. As noted above the comminuted material as it is de livered from the cutting mill may have a maximum par ticle size ranging from about 0.02 to 0.05 inch which means that the spacing 353 (FIGURE 5) will be adjusted to fall within this range since this spacing controls the particle size. The blade thicknesses as shown in FIG URE 5 may range from about to 0.0 with about being preferred. For a cutting head having a 6' inside diameter, the speed of the impeller rotation may range from 1800 to 12,000 rp.m. with from 60 to 7000 r.p.m. being found quite satisfactory. The number of impeller blades and the impeller speed will in turn be determined by the rate at which the corn kernels are fed into the cutting mill. As a typical example of opera tion, when the corn is introduced at a rate of 3800 to 4500 lbs. per hour an impeller having 7 blades and rotat ing at 60 rp.m. produces the desired degree of com minution of the corn kernels. The number of blades is of course not critical so long as a sufficient number are provided. Corn feed rates and impeller speeds may of course be lower than those specified. Generally it will be desirable to introduce the corn into the cutter at an elevated temperature that is, up to about 170 F. There is very little increase in the tem perature of the corn during the cutting process due pri marily to the fact that it is cut rather than ground be tween two Surfaces, and to the fact that the cutting mill as illustrated in FIGURE 3 ingests a large quantity of air in its operation. Thus cutting and plasticizing may be carried out at temperatures up to about 170 F. It ap pears that the plasticizing of the dough at this tempera ture is advantageous and that a somewhat greater degree of cohesion is obtained. The plasticizer illustrated in FIG. 3 is preferably a screw grinder having a perforated end plate but without the usual cutting knives. As pointed out above, the size of the perforations in the end plate is not critical and may range any where from V8 to one inch in diameter. Generally these perforations will be from 3% to 5% inch in diameter, the larger hole size being used when the dough delivered is at its higher temperatures. The corn dough coming from the plasticizer is suitable for rolling and sheeting directly without any further treat ment. The thin sheet of dough formed can be readily cut and docked and although it possesses good cohesion it breaks easily from any surface which it contacts.

10 3,278,811 O AS So far described, the cut corn is deposited directly tains hot cooking fat 87 which is circulated by standard into the plasticizing apparatus to make a dough. We techniques such as by being pumped by a pump 88 through have also found as is described in greater detail below in the bottom portion where it is heated by out of contact connection with FIGURE 6 that the cut corn may be heat exchange with hot gases in coils 89. The gas burner dried before plasticizing and stored or shipped in its is shown diagrammatically at 90. The chips as they first dry condition. Thereafter, when it is desired to form enter the hot cooking fat drop to the bottom and then as a dough, moisture is added to the dried cut corn in the moisture is removed from them, they begin to float and proper amount, preferably until the total moisture is be are carried by rake-like fingers (not shown) onto another tween 50 and 53% by weight of the resultant dough, and endless belt 96 which removes them from the hot fat the reconstituted cut corn is placed in the plasticizing unit. By this process a corn dough which is substantially IO from which the cooked chips 97 are transferred to suc cessive conveyors such as belts 98, 99 and 100. While indistinguishable from the dough made from undried cut on belt 99 they receive a first coat of salt from a salter corn is obtained Then, as they are dropped to endless belt 100 they Processing of dough are turned over and Salted on the other side by another The description of the process and apparatus may now Salter 102. From endless belt 100 they are transferred to a vibrating conveyor 103 and then by suitable means such be continued with reference to FIG. 1b which is a con as conveyor 104 and belt 105 are taken into a weighing tinuation of FIGURE 1a. The plasticized and kneaded machine 106 where weighed quantities are dispensed into corn dough 49 as it comes from the plasticizer 48 is col Suitable bags such as 107. It is preferable to package lected in a hopper 50. From hopper 50 it is passed 20 the chips at a temperature somewhat above ambient tem through two rollers 51 and 52 to form a first thick sheet peratures; that is, between about 100 and 110 F. This 53. This thick sheet of dough 53 is picked up by an has the advantage of preventing any moisture condensa endless belt 70, or other suitable conveying means, and tion in the sealed bags or other containers. carried to the nip of rollers 71 and 72. The dough is then extruded through rollers 71 and 72. In order to handle this dough properly, the rollers must materially reduce the thickness of the dough sheet in such a manner that the thin sheet breaks clean from the rollers. This is done by rotating the rollers 71 and 72 (FIGURE 1b) at different peripheral speeds. In this case the lower roller 72 is moved somewhat faster than the upper roller 71. The actual distance between the rollers is main tained at from about.016 to.018 inch. It appears that after the dough sheet passes through the rollers onto sheeter belt 74, it expands since the thin sheet of dough 73 is about inch thick. In order to keep the dough moving along and to break it cleanly from the rollers, it is necessary that the surface speed of the sheeter belt 74 is maintained slightly greater than the peripheral speed of roller 72. This appears to have the effect of slightly stretching the dough and keeping it from piling up on the sheeter belt 74. Typical values for the relationship be tween the speeds of rollers 71 and 72 and the speed of the belt 74 are given in the following table: Speed of belt 74, ft.fmin. Speed of roiler 71 Speed of roller 72 R.P.M. Ft.fmin. R.P.M. Ft. Imin As the thin sheet of dough progresses forward on the sheeter belt 74, it is perforated by a suitable docker 75 and after perforation it is cut into desired shapes by a rotating cutter 76. The speed of the docker and cutter roll is synchronized with the speed of the sheeter belt 74 so that no additional stretch or wrinkling of the dough takes place. At this point in the process there are on the sheeter belt 74 the chips 77 cut into the desired configuration. If the chip configuration is such that a portion of the dough remains as scrap around the chips 77, (as if the chips are round, for example) then provision should be made for the recovery and reuse of the scrap dough. Normally the scrap will be present in the form of strips. These strips of scrap 78 are directed by means of a suitable roller 79 onto an endless belt 80 and are carried onto a collector 81 from which they are returned by means of belt 82 to the hopper 50 for reprocessing. The individual chips 77 are in the meantime carried to the end of sheeter belt 74 and from there dropped onto another endless belt 85 which carries them into the cooker 86. This cooker is of the conventional type and it con FIGURE 2 shows an alternative arrangement of ap paratus for handling the processed corn kernels to the point where they are introduced into the feed hopper 44. The alternative apparatus in FIGURE 2 embodies the use of a vacuum tank to cool the corn and liquid to the desired 170 F. immediately upon its transfer to the steeping tank rather than cold water as in FIGURE 1a. In this figure like numbers refer to like elements in FIG URE 1G. It will be seen in this arrangement that the pressure vessel 10 is provided with an additional line 110 for per mitting the entrance of air into the pressure tank to blow out the kernels and liquid subsequent to the pressure processing. As explained above, this is not required, since the pressure in the pressure vessel at the end of the cooking period is Sufficient to blow the corn to the steeping tank. The arrangement shows a conduit 111, connected to the bottom portion of the pressure vessel 10, which is designed to carry the corn kernels and liquid under pressure into the vacuum steeping tank 112 which is fitted with an agitator 113 and associated shaft 114 and motor 115, just as was the tank 26 in FIGURE 1a. There is also provided in this arrangement means for producing a vacuum within the tank 12. The tank itself is conven tional and may be of the type made of Groen Mfg. Co., of Elk Grove, Ellinois, for instance. A condensing pump 116 (such as Nash Hytor condensing pump) or a water jet condenser (Such as that made by the Schutte-Koerting Co., of Philadelphia, Pennsylvania), is provided to pro duce the vacuum in tank 112. Condensing pump 16 has leading into it a water line 117 and is joined to the vacuum tank 112 through a suitable conduit 118. The condensing pump 116 is also provided with a drain line 119. The vacuum tank 12 has associated with it at its bottom portion a valve 120 which permits the steeped corn kernels along with the accompanying liquid to be transferred by means of conduit 2 onto a screen 122 which extends over a catch basin 123, the latter being equipped with a drain 124 for removing the liquid at peri odic intervals. The corn kernels as they are removed from the liquid then may be conveniently conveyed to the feed hopper 44 by means of a suitable conveyor 125 which may be a jacketed conveyor either of a screw or vibrator type. In the operation of the apparatus shown in FIGURE 2, the steps for handling the processed corn kernels will be as follows: after the pressure cooking has been completed, the vent 16 to the atmosphere is opened and the corn and liquid are blown into the vacuum tank 12 with pres surized air introduced through line 110. Alternatively, as noted above, the internal pressure which has been built up in the pressure tank may also be used to blow the corn

11 3,278, and liquid into the vacuum tank. After the corn and der of the process followed to manufacture corn chips ac liquid have been transferred to the vacuum tank 112, a cording to our process. vacuum is pulled on it to cool the batch rapidly to about FIGURE 7 illustrates an alternative way of handling 170 F. or any desired temperature. Subsequent to the the corn chips once they have been cut from the dough. pulling of the vacuum on the vacuum tank 112, the corn In this figure like elements are given like numbers as in is permitted to steep in the liquid for about minutes to FIGURE 1b. The corn chips, after they have been cut by two hours and then a further vacuum is pulled on the tank the cutter 76, proceed along the sheeter belt 74 and are to cool it down to about 120 F. or the desired tempera then deposited into the cooking tank. Rather than pick ture. After cooling, the entire batch is transferred onto them up on another endless belt, such as belt 85 in FIG the screen 122 through valve 120 and conduit 121 and the 10 URE 1b, FIGURE 3 shows how they may be handled by water is removed and the processed corn kernels are trans means of a vacuum transfer system. This latter system ferred by means of the conveyor 125 into the hopper 44 permits the sheeter belt 74, which is formed of a material to be cut and plasticized as described above. which does not lend itself well to sharp bending, to be FIGURE 6 illustrates a process which may be used to designed for driving over a larger end roller thus permit dry the processed corn for storing or shipping after it has ting the belt to have a much longer life than in the arrange been formed into particles by the cutting mill but before ment shown in FIGURE 1b. it has been kneaded and formed into dough. In the arrangement shown in FIGURE 7, we provide a As shown therein, the corn hopper 44, conveyor 45 and Second endless belt 131 which is preferably of wire mesh cutting mill 46 are provided just as in FIGURE 1a. The cut corn from the cutting mill falls on an endless conveyor belt 200 which passes through a first series of drying units 202. It may be desirable to oscillate the feed to the con veyor belt 200 to obtain an even distribution of the cut corn across the conveyor. As the belt 200 carrying the wet cut corn passes through the dryer 202 heated air is forced downwardly through the bed of cut corn and the belt 200. The drying unit is of conventional construction and is of the type supplied, for example, by Surface Combustion, Inc. After passing through the drying unit 202, the corn bed is broken up by a cake breaker' generally indicated at 204. This unit comprises a motor driven shaft having a plurality of radially extending knives 206. Several sets of these knives are provided along the shaft, the shaft itself extending across the entire width of conveyor belt 200 at the location shown. A plurality of fixed knives 208 posi tioned to clear the rotating knives 206 are also provided. As the shaft on which the knives 206 are mounted ro tates, large pieces of dried cut corn from the bed are broken or cut into smaller pieces by passing between the fixed and rotating knives and fall into a screw conveyor 210 (shown in end view in FIGURE 3). The conveyor 210 carries the pieces to a unit which further reduces them in size. This is shown in FIGURE 3 as a pair of driven rolls 212 and 214; the dried chunks of corn passing through the nip of these rolls; a chopper or centrifugal cutter might also be used. Following this second reduction the reduced processed corn falls on the conveyor 216, which carries it in turn to a distributing conveyor 218. Conveyor 218 distributes the corn particles uniformly in a bed across the conveyor 220 associated with a drying unit 222, which is similar to drying unit 202. After passing through dryer 222 the corn is carried by conveyor 224 to a hopper 226 and is discharged therefrom, weighed and packaged, a weight controlled bagging machine 228 being provided for this purpose. This dried material produced by this process may be reconstituted by the addition of moisture and the recon stituted material made into a dough by inserting it into the kneading device 48 as shown in FIGURES 1 and 3. By using the remainder of the method and apparatus shown in FIGURE 1b the improved corn chips made by Our process and apparatus may be produced. The dried processed material may be conveniently stored and readily shipped. This is an important eco nomic consideration since it is desirable that the actual corn chips be made locally because of the perishable na ture of the product. Hence a single large plant, properly located with regard to corn supply and chip manufacturers can process corn through the cutting step according to our process for all chip makers. This processed corn may then be dried and stored or shipped to a number of smaller local plants where it may be reconstituted and the remain to carry the cut corn chips to the cooker 86. To transfer the cut corn chips from the sheeter belt 74 to belt 131 we provide a rotating steel drum 132 having formed in the sides thereof a plurality of openings 133. Within the drum we provide a fixed iron pipe 134 whose longitudinal axis is substantially the drum axis. A segment of the pipe 134 is removed along its entire length and a pair of plates 135 and 136 are secured to the pipe, as by welding, along the entire length of the opening. Each of the plates is also provided with an inturned flange 135a and 136a to define an opening extending across the entire conveyor and of a width somewhat greater than the largest chip which is to be transported. While there is a clearance between the lower surfaces of the flanges 135a and the inner surface of the drum 132; it is maintained as small as possible to avoid leakage as will be explained. One end of the pipe 134 is sealed and the other is connected via a vacuum line 137 to a vacuum pump 138 driven by a suitable motor 139. The plates are also sealed at both ends, as by end plates, to prevent the entrance of air. When the vacuum pump 138 is operating it will establish an area of reduced pressure within the pipe 134 and be tween the plates 135 and 136. The rotating perforated drum, will attract the cut corn chips to its periphery as a portion of the drum rotates into the space between the flanges 135a and 136a. The cut corn chip will adhere to the drum as it rotates and will be stripped off the drum as the portion to which the cut chip adheres rotates in front of the flange 136a. However, during its adherence, the chip will have been removed from the sheeter belt 74 and deposited on the wire mesh belt 131 for transporta tion to the cooker 86. From this point, the chips proceed as illustrated and described in connection with FIGURE 1b. It will be seen from the above detailed description of this invention that there is provided a unique method for continuously making improved corn chips improved in the sense that they can be formed in any desired size and shape and that they have an enhanced flavor, the quality of which can be uniformly controlled. The method comprises a series of steps unique to corn chip manufacture. These steps include pressure-cooking, short steeping with cooling if desired, reduction of the processed kernels and formation of dough by the com bination of cutting, kneading and mixing, rolling of the resulting dough into a thin sheet, cutting the thin sheet into the desired shapes and cooking the shaped material to form the final chips. It will thus be seen that the objects set forth above, among those made apparent from the preceding descrip tion, are efficiently attained and, since certain changes my be made in carrying out the above method without departing from the Scope of the invention, it is intended that all matter contained in the above description or shown in the accompanying drawings shall be interpreted as illustrative and not in a limiting sense.

12 3. Having thus described our invention, we claim: 1. The method of making corn chips comprising, in combination, the steps of pressure cooking corn kernels with lime and water in a first vessel, said lime being present in a quantity equivalent to at least 1.5% by weight of dry corn, cooling the cooked corn and Water lime solution, steeping the cooked corn in said water lime solution in a second vessel, draining the water-lime solution from the corn kernels, cutting the cooked corn to form a comminuted material having a moisture con tent of between and 60 percent by weight, the major portion of said material having a particle size in the range of between to inch, kneading and mix ing said communited material to form a dough, forming said dough into a thin sheet, docking said sheet, cutting said sheet to form a plurality of corn chips and deep fat frying said cut corn chips. 2. The method defined in claim 1 in which said corn is steeped in said second vessel for a period not greater than two hours. 3. The method defined in claim 1 in which said corn and water-lime solution is cooled to about 170 F. follow ing pressure cooking. 4. The method defined in claim 1 in which the cooked corn and the water-lime solution are transferred from said first to said second vessel by using the pressure in said first vessel to blow the corn and liquid into said second vessel when cooking is completed. 5. The method defined in claim 4 in which said corn is steeped in said second vessel for about minutes. 6. The method defined in claim 1 in which said dough is formed into a sheet by passing it through the nip of a pair of rotating rollers, said rollers rotating at different speeds. 7. The method of making corn chips comprising, in combination, the steps of pressure cooking corn kernels in a water-lime solution in a first vessel, the lime being at least 1.5% by weight of the corn kernels, cooling the cooked corn and water-lime solution to about 170 F. steeping the cooked corn kernels in said water-lime solu tion for not more than about two hours in a second vessel, draining said steeped corn kernels, cutting said corn kernels to form a comminuted material having a moisture content of between and 60 percent by weight, the major portion of said material having a particle size in the range of between and inch, kneading and mixing said comminuted material to form a dough, passing said dough through the nip of a set of rotating rollers to form a dough sheet, said rollers rotat ing at different speeds, perforating said dough sheet, cutting said dough sheet to form a plurality of corn 3,278, chips, deep fat frying said chips, and draining said dried chips to remove excess fat therefrom. 8. The method defined in claim 7 in which said cool ing after cooking is accomplished by adding cold water to the corn and water-lime solution after pressure cooking. 9. The method defined in claim 7 in which said sec Ond vessel is a vacuum tank, and in which cooling is accomplished by reducing the pressure within said second vessel after said corn and water-lime solution has been deposited therein. 10. The method defined in claim 7 in which the cooked corn and the water-lime solution are transferred from said first to said second vessel by causing the pressure in said first vessel to blow said corn and liquid into said second vessel, and in which said corn is steeped in said second vessel for about minutes. 11. The method defined in claim 7 which includes the steps of drying the cut corn kernels after cutting and before kneading and mixing, and reconstituting the dried corn kernels by adding moisture thereto before kneading and mixing. 12. A method of forming a sheetable-dough from corn kernels which have been cooked with lime compris ing, in combination, the steps of cutting the corn kernels to thereby form a comminuted flaky material the major portion of said material having a particle size in the range of between to inch and kneading and mixing said comminuted material to form a dough. 13. The method in accordance with claim 12 wherein Said cutting is carried out at elevated temperatures up to about 170 F. 14. The method defined in claim 12 in which said comminuted corn is dried after cutting and reconstituted by the addition of moisture before kneading and mixing to form said dough. References Cited by the Examiner UNITED STATES PATENTS 1,203,175 10/1916 Blacklock ,002,053 5/1935 Doolin ,060,8 11/1936 Wood ,905,559 9/1959 Anderson et al ,916,378 12/1959 Kunce et al ,020,162 2/1962 Cunningham et al ,083,103 3/1963 Anderson et al A. LOUIS MONACELL, Primary Examiner. ROSCOE. S. AULL, Assistant Examiner.

III. United States Patent (19) Binacchi. Attorney, Agent, or Firm-Bucknam and Archer 57 ABSTRACT. 6 Claims, 3 Drawing Sheets

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

May 12, ,282,708 T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE. Filed Sept. 26, Sheets-Sheet l. --No.zzzzzzzzzzae.

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(*) Notice: Subject to any disclaimer, the term of this E. E. E. E. O.C.

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

JUICE EXTRACTION AND FILTRATION JUICE EXTRACTION METHOD AND EQUIPMENT

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

TORTILLA-TORTILLA CHIPS

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

United States Patent (19) 11) 4,167,008 Blickenstaff 45) Sep. 4, 1979

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

United States Patent [11] 3,559,565

![United States Patent [11] 3,559,565 United States Patent [11] 3,559,565](/thumbs/93/114425987.jpg) United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

7 IANSNA. (12) Patent Application Publication (10) Pub. No.: US 2003/ A1. (19) United States 2//

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

United States Patent (19) Forino

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1. Hurley et al. (43) Pub. Date: Aug. 28, PROCESS Publication Classification

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

US A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

Sept. 7, l.t. ward 2,092,596 SIPHON

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

United States Patent (19) D'Alessandro

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent It 3,593,647

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

Module 6: Overview of bakery machinery: mixers, forming machines and ovens.

Paper No. 09 Paper Title: Bakery and Confectionery Technology Module 6: Overview of bakery machinery: mixers, forming machines and ovens. Introduction Bakery units can be classified as manual, semi-automatic

Paper No. 09 Paper Title: Bakery and Confectionery Technology Module 6: Overview of bakery machinery: mixers, forming machines and ovens. Introduction Bakery units can be classified as manual, semi-automatic

INTRODUCTION TO CUSTOM FABRICATED STRAINERS

INTRODUCTION TO CUSTOM FABRICATED STRAINERS Nothing Too Big, Too Small or Too Special When unwanted solid material has to be removed from flowing fluids in order to protect equipment, a HAYWARD Strainer

INTRODUCTION TO CUSTOM FABRICATED STRAINERS Nothing Too Big, Too Small or Too Special When unwanted solid material has to be removed from flowing fluids in order to protect equipment, a HAYWARD Strainer

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

Product Consistency Comparison Study: Continuous Mixing & Batch Mixing

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. Lange (43) Pub. Date: Nov. 22, 2012

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

SIMPLEX STRAINER MODEL 90

The Eaton Model 90 Fabricated Simplex Strainer has been designed for manufacturing flexibility. It can be made for pipeline sizes from 1 to 48 in carbon steel or stainless steel although other materials

The Eaton Model 90 Fabricated Simplex Strainer has been designed for manufacturing flexibility. It can be made for pipeline sizes from 1 to 48 in carbon steel or stainless steel although other materials

(12) United States Patent

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

YEDENT AGRO GROUP OF COMPANIES PROCESSING OF SOY BASED PRODUCTS FOR HUMAN FOODS AND POULTRY FEEDS

YEDENT AGRO GROUP OF COMPANIES PROCESSING OF SOY BASED PRODUCTS FOR HUMAN FOODS AND POULTRY FEEDS 1. SOYA EXTRUSION AND PRESSING PROCESS EQUIPMENT 1. The Pre Cleaner 2. The Course Mill 3. The Extruder

YEDENT AGRO GROUP OF COMPANIES PROCESSING OF SOY BASED PRODUCTS FOR HUMAN FOODS AND POULTRY FEEDS 1. SOYA EXTRUSION AND PRESSING PROCESS EQUIPMENT 1. The Pre Cleaner 2. The Course Mill 3. The Extruder

HHHHH. United States Patent (19) Burrows et al. 5,084, Patent Number: (45) Date of Patent: Jan. 28, 1992

United States Patent (19) Burrows et al. 54 PRCESS FR PREPARING FRENCH FRIED PTAT STRIPS WITH SALT CNTENT 75) Inventors: Christopher B. Burrows, Kennewick; Janet. Wheeler; Jerry L. Sloan, both of Richland,

United States Patent (19) Burrows et al. 54 PRCESS FR PREPARING FRENCH FRIED PTAT STRIPS WITH SALT CNTENT 75) Inventors: Christopher B. Burrows, Kennewick; Janet. Wheeler; Jerry L. Sloan, both of Richland,

United States Patent (19)

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

ZPM Mixer. Continuous mixing system

Mixer Continuous mixing system MIXER Continuous mixing system The continuous mixing system consists of several elements: Basic frame, drive support and pull-out frame with levelling legs for fastening

Mixer Continuous mixing system MIXER Continuous mixing system The continuous mixing system consists of several elements: Basic frame, drive support and pull-out frame with levelling legs for fastening

Beer Hardware, Systems and Delivery

Beer Hardware, Systems and Delivery An Industry Standard Beer is the number one dispensed beverage in the foodservice industry. Commonly, draft beer is preferred by a wide margin for taste and product

Beer Hardware, Systems and Delivery An Industry Standard Beer is the number one dispensed beverage in the foodservice industry. Commonly, draft beer is preferred by a wide margin for taste and product

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

SOFTDOUGH & COOKIES cat_softdough_rev12gea.indd 1 22/07/

SOFTDOUGH & COOKIES The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given them our

SOFTDOUGH & COOKIES The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given them our

BAKING SCIENCE AND TECHNOLOGY

BAKING SCIENCE AND TECHNOLOGY Learning Objectives Describe the purpose of mixing List common types of bread mixers Explain what mixing does to the dough and flour components Explain delayed mixing method

BAKING SCIENCE AND TECHNOLOGY Learning Objectives Describe the purpose of mixing List common types of bread mixers Explain what mixing does to the dough and flour components Explain delayed mixing method

Introduction. 12 CO H 2 O = C 12 H 22 O O 2 carbon dioxide + water = sucrose + oxygen

Sugar cane Introduction What we call sugar, the chemist knows as 'sucrose', one of the family of sugars otherwise known as saccharides in the grouping called carbohydrates Sucrose, C 12 H 22 O 11, is a

Sugar cane Introduction What we call sugar, the chemist knows as 'sucrose', one of the family of sugars otherwise known as saccharides in the grouping called carbohydrates Sucrose, C 12 H 22 O 11, is a

United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

Dec. 9, M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

A33. AORNEY. March 22, G. C. HERZ, 1,850,719. APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC. Filed Dec, l6, l Sheets-Sheet l NVENTOR

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

ACME Fluid Systems. Strainer Selection Guidelines Web:

ACME Fluid Systems Strainer Selection Guidelines E-mail: info@strainersindia.com Web: www.strainersindia.com Introduction This document provides a general introduction to the parameters to be kept in mind

ACME Fluid Systems Strainer Selection Guidelines E-mail: info@strainersindia.com Web: www.strainersindia.com Introduction This document provides a general introduction to the parameters to be kept in mind

(12) United States Patent

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

SEMOLINA TECHNOLOGY ENLIGHTENED

SEMOLINA TECHNOLOGY ENLIGHTENED THE EVOLVING PERFORMANCES Semolina, the new line of purification machines by Golfetto Sangati, is the result of 20 years of technological evolution and improvements that

SEMOLINA TECHNOLOGY ENLIGHTENED THE EVOLVING PERFORMANCES Semolina, the new line of purification machines by Golfetto Sangati, is the result of 20 years of technological evolution and improvements that

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

OPERATING MANUAL. Sample PRO 100 Series. Electric Heating. Applies to Versions: SPE1*, SPE2, SPE4, SPE6

OPERATING MANUAL Sample PRO 100 Series Electric Heating Applies to Versions: SPE1*, SPE2, SPE4, SPE6 NOTE: All electrically heated roasters in the Sample PRO 100 Series are modular and this manual applies

OPERATING MANUAL Sample PRO 100 Series Electric Heating Applies to Versions: SPE1*, SPE2, SPE4, SPE6 NOTE: All electrically heated roasters in the Sample PRO 100 Series are modular and this manual applies

United States Patent (19) Ludder

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

(2-12. Zazza72M4 Aarzanez. Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS. Zaza/adar. aeo/ae/ -- e

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

Attention is drawn to the following places, which may be of interest for search:

CPC - A23N - 2017.08 A23N MACHINES OR APPARATUS FOR TREATING HARVESTED FRUIT, VEGETABLES OR FLOWER BULBS IN BULK, NOT OTHERWISE PROVIDED FOR; PEELING VEGETABLES OR FRUIT IN BULK; APPARATUS FOR PREPARING

CPC - A23N - 2017.08 A23N MACHINES OR APPARATUS FOR TREATING HARVESTED FRUIT, VEGETABLES OR FLOWER BULBS IN BULK, NOT OTHERWISE PROVIDED FOR; PEELING VEGETABLES OR FRUIT IN BULK; APPARATUS FOR PREPARING

March 24, 1970 H. H. BRIDGFORD 3,502,488 COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER HUGH. BROGFORD / ATTORNEY

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

MCS Ovens. Member of the

MCS Ovens Member of the MCS Cyclotherm Ovens MCS Bakemaster Oven The MCS Bakemaster oven is the result of more than 40 years of experience in designing and manufacturing automatic baking systems and incorporates

MCS Ovens Member of the MCS Cyclotherm Ovens MCS Bakemaster Oven The MCS Bakemaster oven is the result of more than 40 years of experience in designing and manufacturing automatic baking systems and incorporates

TILT-HEAD STAND MIXER FEATURES

ENGLISH TILT-HEAD STAND MIXER FEATURES Speed Control Knob Motor Head Attachment Hub Attachment Knob Motor Head Locking Lever (not shown) Beater Shaft Flat Beater Beater Height Adjustment Screw Wire Whip

ENGLISH TILT-HEAD STAND MIXER FEATURES Speed Control Knob Motor Head Attachment Hub Attachment Knob Motor Head Locking Lever (not shown) Beater Shaft Flat Beater Beater Height Adjustment Screw Wire Whip

CASHEW PROCESS PLANT. On Turnkey basis. Sesha Sai, Best Engineering