(12) (10) Patent No.: US 7,763,302 B2. Hairsine et al. (45) Date of Patent: Jul. 27, 2010

|

|

|

- Kelly Woods

- 5 years ago

- Views:

Transcription

1 United States Patent USOO B2 (12) (10) Patent No.: Hairsine et al. (45) Date of Patent: Jul. 27, 2010 (54) METHODS FOR AUTOMATICALLY MAKING 4,137,838 A * 2/1979 Warren LARGE QUANTITIES OF PRE-COOKED 4.321,864 A * 3/1982 Willsey EGGS HAVING ANATURAL APPEARANCE A 10/1983 Riley f ,962 A 12/1983 Siciliano (75) Inventors: Alan E. Hairsine, Gaylord, MN (US); 4.425,367 A 1/1984 Berkowitz et al. Jason W. Matthews, Gaylord, MN (US); A 12/1984 Bliss /510 Ted A. Kurpgeweit, Wayne, NE (US); Dale E. Weaver, Lenox, IA (US) (73) Assignee: Michael Foods of Delaware, Inc., (Continued) Minnetonka, MN (US) FOREIGN PATENT DOCUMENTS (*) Notice: Subject to any disclaimer, the term of this patent is extended or adjusted under 35 EP O , 1989 U.S.C. 154(b) by 955 days. (21) Appl. No.: No 10/741,793 9 (Continued) (22) Filed: Dec. 19, 2003 Primary Examiner Anthony Weier (74) Attorney, Agent, or Firm Fredrikson & Byron, PA (65) Prior Publication Data US 2005/O136172A1 Jun. 23, 2005 (57) ABSTRACT (51) (52) (58) (56) Int. C. A2.3L I/32 ( ) U.S. Cl /614; 426/515; 426/478 Field of Classification Search /614, 426/515,478 See application file for complete search history. References Cited U.S. PATENT DOCUMENTS 1494,602 A 5, 1924 Jenkins 1,727,493 A * 9, 1929 Tranin ,700 A * 9/ , ,280 A * 2/ ,55 2,722,173 A * 11/ ,168 3,640,732 A 2, /114 3,843,825 A 10, ,393 3,941,892 A 3, 1976 Glasser et al ,104 3,958,035 A 5, 1976 Stearns et al ,614 4,000,323 A 12/1976 Youngquist /93 4,046,922 A 9, 1977 Burkwall, Jr ,104 4,068,570 A 1, 1978 Lanoie The present invention includes methods and devices for mass producing cooked, cooled egg products having a grill fried egg appearance. One device includes a portion for positioning whole, intact, shelled eggs positioned laterally across and above a cooking mold conveyor, and a portion for cracking the eggshells and depositing the eggs into cooking molds on the conveyor. Some devices and methods include an egg yolk splitter for rupturing the egg yolk sac to deposit a whole egg having a ruptured egg yolk into each mold. Other devices and methods include irregularly shaped egg molds for providing a mass produced cooked egg having a natural, irregularly shaped outlines and/or surfaces. Devices and methods according to the present invention can be used to produce irregularly, outlined shaped cooked egg products including whole eggs, formulated eggs, or eggs made from scrambled egg mixes. The pre-cooked eggs can be delivered pathogen free to fast food establishments and reheated for consumers in less time than required to cook the egg. 37 Claims, 10 Drawing Sheets

2 Page 2 U.S. PATENT DOCUMENTS 5, A 5/1997 Kristensen 5,636,726 A 6/1997 Nield ,637 A 12/1984 Loeffler ,653 5,665,416 A 9, 1997 Manderfeld et al ,614 4, A 3, 1985 Thomas , A 1/1999 Thomas ,299 4,512,250 A * 4, 1985 Schindler et al ,425 5,932,276 A 8, 1999 Bhatia et al. 4,519,494 A 5/1985 McEvoy et al /448 6, A 2/2000 McEvoy et al ,519,505 A 5, 1985 Thomas ,513 6,056,341 A 5/2000 Bliss , 88 4,569,444 A 2/1986 McEvoy et al ,510 6,234,070 B1 5/2001 Hutchinson et al ,497 4,711,425 A 12/1987 Spiel et al ,117 6,237,978 B1 5/2001 Bliss , 88 4,750,316 A 6, 1988 Bliss , / A1 4/2002 Fernandez 4, A 8, 1988 Bliss , / A1 3/2003 Beale et al , , A 10/1988 McEvoy et al / / A1* 7/2003 Merkleet al ,614 4,889,741 A 12, 1989 Timmons et al , , A1 12/2003 Mathews 4,961,946 A * 10/1990 Shimizu ,299 5,069,119 A 12/1991 Idowu et al. FOREIGN PATENT DOCUMENTS 5,227,189 A 7, 1993 Vassiliou 5,293,021 A 3, 1994 Davis /728 JP A 9, ,427,016 A 6, 1995 Dunckel... 99/ , 1997 JP * 2/ ,872 A 1/1996 Nield JP A 6, 1998 D373,234 S 9, 1996 Manderfeld.... D1 (130 JP * 1, 2001 D376,251 S 12/1996 Manderfeld.... D1 (130 WO WO 87, , ,617,782 A 4, 1997 Thomas ,500 5,620,735 A 4, 1997 Manderfeld et al ,614 * cited by examiner

3 U.S. Patent Jul. 27, 2010 Sheet 1 of 10 s

4 U.S. Patent Jul. 27, 2010 Sheet 2 of 10

5 U.S. Patent Jul. 27, 2010 Sheet 3 of 10

6 U.S. Patent Jul. 27, 2010 Sheet 4 of 10 s N S. N S. nn. S. N ON s O N,N- Q) - N- - N o s N i : -1 3 &

7 U.S. Patent Jul. 27, 2010 Sheet 5 of 10 FIG. 10

8 U.S. Patent Jul. 27, 2010 Sheet 6 of 10 FIG. 11 FIG. 12

9 U.S. Patent

10 U.S. Patent Jul. 27, 2010 Sheet 8 of 10

11

12 U.S. Patent

13 1. METHODS FOR AUTOMATICALLY MAKING LARGE QUANTITIES OF PRE-COOKED EGGS HAVING ANATURAL APPEARANCE FIELD OF THE INVENTION The present invention is related generally to food process ing. More specifically, the present invention is related to egg cooking methods and devices for mass producing cooked egg products. BACKGROUND OF THE INVENTION Individuals increasingly eat food away from home, or at home, at work, or even in an automobile, where the food was at least partially prepared or precooked outside at the home. Grill fried eggs are well known and have been made for centuries. Consumers prepare grill fried eggs at home, and also eat grill fried eggs prepared in eating establishments. The grill fried eggs are aesthetically pleasing to consumers, per haps because grill fried eggs have the appearance of home cooked food and/or food prepared at well-established restau rants. Many consumers demand eggs prepared at ever-increas ingly short time intervals. Some consumers expect cooked eggs to be made available in the time between ordering a product at a speaker post, and the arrival of their automobile at a drive-up window in a fast food establishment. Other consumers expect eggs to be made available shortly after paying for the eggs at the counter of a fast food restaurant, expecting to receive the cooked eggs in less than the time required to cook the eggs, for example, within one minute. Some fast food restaurants grill fry eggs ahead of time, prior to their being ordered. One such fast food restaurant uses a three-inch ring, open at the bottom, in sets of six. These are put on the grill, the egg deposited in the ring, then covered and steamed. These restaurant prepared eggs, while nutri tious, do not closely resemble home, grill fried eggs. They are also made prior to being ordered, allowing for the possibility of wastage if they are not sold within an allotted time period. Another fast food establishment uses a three and one quarter inch ring, breaks the egg, puts the egg into the ring, breaks the yolk, and partially cooks the egg. The partially cooked egg is flipped over in the ring, and the ring removed. This allows the remainder of the egg to cook and flow out wardly somewhat. This method also requires the eggs to be made ahead of the short time demanded by Some consumers, with the cooked eggs being readily distinguishable from an irregular or randomly shaped, home grill fried egg. Such cooking methods suffer from drawbacks. Firstly, if the eggs are to be delivered to consumers in a time period less than the time required to break the eggs, cook the eggs, and package the cooked egg product, then the eggs must be cooked prior to the time of ordering. This allows for some wastage, as previously discussed. Secondly, while modern eggs are typically very safely delivered from almost all ven dors, the possibility exists for Some pathogens being carried with the eggs. While this occurrence is extremely rare, it has happened. Thirdly, the manual preparation of grill fried eggs is somewhat time and labor consuming. In some situations, the cooking grill would not otherwise be required but for the requirement for cooking the grill fried eggs. What would be desirable are methods and devices for mass producing pre-cooked, cooled eggs that resemble grill fried eggs. Such eggs could be mass produced in a controlled environment to Substantially reduce the chance of pathogen contamination. The mass produced, precooked, cooled eggs would preferably resemble home cooked grilled eggs. If mass produced, grill fried eggs were made available, fast food eating establishments could save on labor, and reduce wast age by reheating the previously cooked egg products. What would be most desirable are pre-cooked, cooled, egg products that resemble home, grill fried eggs that could be prepared at a fast food establishment inless than the time required to cook the eggs. SUMMARY OF THE INVENTION The present invention provides methods for mass produc ing cooked, cooled eggs having a grill fried egg appearance. One method includes depositing an egg product into a plural ity of mold depressions, wherein the molds have irregular shaped boundaries. Another method includes depositing an egg product into a plurality of mold depressions having an irregularly varying depth and bottom Surface. The methods can further include cooking the deposited egg products in the molds, removing the cooked egg products from the molds, and cooling the cooked egg products below room tempera ture. Some methods include depositing whole eggs with intact yolks, while other methods include depositing whole eggs having brokenyolks. The methods may include allowing the yolk to settle into a minor depression located within the major depression of the mold. In some methods, the yolks are broken by dropping the whole eggs through an egg yolk rupturing device having sharp edges. Still other methods include depositing scrambled egg products or formulated egg products. In some methods, the mold depressions arearranged side to side in a pan along a width dimension, and the pans arranged end to end along a length dimension, in which the depositing includes depositing a plurality of eggs along the width into the plurality of mold depressions at Substantially the same time. The depositing can occur when the mold pans are moving. In Some methods, the shelled eggs are located a first distance apart while the eggs are broken, and are diverted to a second distance apart, further apart than the first distance, to be deposited into mold depressions located approximately the second distance apart on center. The present invention provides a method for breaking egg yolks including dropping the egg yolks through a device for rupturing the egg yolk sacs. In some methods, the device includes an orifice having sharp edges, and the method includes dropping the egg yolks through the orifice having the sharp edges. Some devices include a plate having an orifice with sharp inwardly protruding edges, and the method can include dropping the egg yolks through the orifice having the sharp edges. In some methods, the device has a plurality of orifices, and can receive a plurality of egg yolks simulta neously. The plurality of orifices can be arranged in a side by side pattern. In some methods, the egg yolk sac rupturing device has a plurality of orifices each disposed in a down wardly extended or depressed plate portion. The present invention further provides an egg mold for producing eggs having irregular shaped peripheries, the mold including a planar Surface having a depression therein, wherein the depression has an irregularly shaped outline. In Some molds, the depression outline is asymmetric about any Vertical plane drawn through the planar Surface and the depression. The mold is preferable formed of a nonstick, food grade material, at least at the Surface. Some egg molds are formed as a plurality of depressions in the planar Surface of an egg mold pan. Some molds have a top Surface and include a first depres sion having a first bottom surface and a first depth relative to

14 3 the top Surface, and also include a second depression having a second bottom Surface and a second depth relative to the top surface. The first and/or second bottom surface depth can vary over the respective Surface. In some molds the second depres sion has a Surface area at least/10th or/6th the Surface area of the first depression. The second depression can have a mean depth of at least/4 or /3 greater than the mean depth of the first depression. The yolk, eitherintact, broken, or formulated, can be allowed to settle into the second depression, providing a cooked egg product having a prominent cooked yolk. A device for mass producing cooked, fried eggs is also provided by the present invention. One device includes an egg breaking device comprising a plurality of vertically oriented, side-by-side, egg carousels, where the egg carrying carousels each have a plurality of egg carrier cups rotatably disposed about a horizontal central axis, the egg carrier carousels trav eling along a closed loop partly lying within a vertical plane. The device can further comprise an eggshell breaking knife for breaking the eggshells while the eggs are disposed within the egg carrying cups. The device can also include a moving belt including a plurality of pans, with each pan having a plurality of egg cooking mold depressions disposed side-by side therein. The molds can be disposed to each receive a falling egg from the egg breaking device. In some devices, the molds are disposed directly under the egg carrying cups at the point at which the shells are broken. Other devices include chutes or deflectors to deflect the falling eggs from the egg carrying cups laterally outward to a distance furtherapart than the egg carrying cups are located from each other, to insure depositing the falling eggs into the molds. In still other devices, an egg yolk breaking device having an orifice for receiving a falling liquid whole egg and having sharp edges for rupturing the egg yolk sack of the falling egg yolk is disposed between the egg carrying cup and the cooking mold. In some devices, the molds have an irregular outline shape, as previously described. The present invention also provides a cooked, cooled egg product comprising a plurality of cooked egg products having a Substantially planar shape and having an irregular shaped outline, in which a substantial portion of the eggs have the same irregular shaped outline, in which the cooked egg prod ucts have a temperature of less than 30 centigrade. The cooked egg products are whole eggs having intact yolks in Some embodiments, are whole eggs having broken yolks in other embodiments, are scrambled eggs in still other embodi ments, and are formulated egg products in yet other embodi ments. Some egg products have an irregular shaped Surface having an irregularly varying height over the product. Other egg products are cooked formulated eggs having a formulated egg yolk portion and/or a formulated egg white portion, resembling a Sunny-side-up fried egg. This product can be made by depositing the formulated yolk into a secondary mold depression and depositing the formulated egg white into a primary mold depression having the secondary depression within. The present invention also includes methods for making cooked whole eggs including automatically conveying eggs to an egg breaking location, automatically breaking the egg shells of the whole eggs, allowing the contents of one egg shell to fall into one mold, automatically conveying each mold into a heated area, and cooking the egg contents in each mold in the heated area. Some automatic methods include methods for making cooked whole eggs by mechanically conveying a plurality of whole, shelled eggs, mechanically breaking the conveyed plurality of egg shells, allowing the egg contents to fall into a plurality of molds, mechanically conveying the molds con taining the egg contents into a heating area, and cooking the egg contents in the molds. Each mold receiving egg content preferably receives one and only one whole egg content. The mechanical methods can include mechanisms selected from the group consisting of purely mechanical, pneumatic, elec trical, magnetic, hydraulic, and electromechanical mecha nisms and combinations thereof. Some methods include mechanically carrying each egg in an egg carrier, mechani cally breaking the egg shell with a knife, and moving a belt or loop formed of linked articulated molds into the heating area. The molds used and the resulting cooked eggs can have round outlines, symmetrical outlines, irregular outlines, irregular surfaces, and/or two different and nested levels of surfaces. The present invention provides, generally, a device for mass producing cooked eggs having a grill fried egg appear ance. The device includes a first part for positioning eggs in a spaced apart relationship from each other and for breaking the eggshells, allowing the whole egg products within to fall. The device also includes a second part, including a belt having a plurality of egg cooking molds disposed to capture the falling, whole egg products within the molds. The molds can be disposed on a longitudinally moving belt, which can propel the deposited eggs in the cooking molds toward an oven. DESCRIPTION OF THE DRAWINGS FIG. 1 is a photograph of three natural whole eggs having broken yolks and an irregular outline or periphery; FIG. 2 is a photograph of three cooked eggs having irregu lar outlines made from scrambled egg mix: FIG. 3 is a photograph of three formulated eggs having irregular shaped outlines; FIG. 4 is a photograph of a mold having an irregular shaped outline that can be used to make some of the irregular shaped eggs in FIGS. 1-3: FIG. 5 is a photograph of another mold having an irregular shaped outline that can be used to make some of the irregular shaped eggs of FIGS. 1-3: FIG. 6 is a photograph of yet another mold having an irregular shaped outline or periphery that can be used to make some of the eggs of FIGS. 1-3: FIG. 7 is a perspective view of a pan having three molds each having a first depression and a second depression with the first depression; FIG. 8 is a top view photograph of a pan having a mold having a first depression and four more depressions within the first depression; FIG. 9 is a top view photograph of a pan having a mold having an irregular shaped outline, an irregular depth bottom Surface, a first depression, and four more depressions within the first depression; FIG. 10 is a top view of a cooked egg product made using the molds of FIGS. 8 and 9: FIG. 11 is a photograph of a whole egg having a broken yolk and a substantially regular outline; FIG. 12 is a photograph of a whole cooked egg having an unbroken yolk; FIG. 13 is a perspective view of a egg yolk breaking device that can be used to make the broken yolk cooked egg of FIG. 11, the breaking device shown partially retracted from an egg breaking machine; FIG. 14 is a perspective view of an egg breaking machine having several vertical egg carrying carousels disposed side by-side for breaking shelled eggs and dropping the liquid eggs through five deflectors or chutes into cooking molds disposed under the five chutes;

15 5 FIG. 15 is a perspective view of the five deflectors or chutes of FIG. 14, adapted to receive falling eggs from the narrowly spaced vertical egg carrying carousels and for depositing the liquid whole eggs into wider-spaced cooking molds; and FIG. 16 is a side view of the egg breaking carousel device of FIG. 14, where the shelled eggs could be broken and dropped at the left onto the rotating belt of cooking molds. DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS FIG. 1 is a photograph illustrating three cooked, whole, natural eggs having irregular outlines made by a method of the present invention, that resemble flat grill fried eggs. FIG. 1 includes a first egg 30 having a yolk 31 and an irregular outline or periphery32. The irregular outline 32 may be seen to be irregular, and is not round, square, rectangular, or oval. As may be seen from inspection of FIG. 1, there is no axis of symmetry that can be drawn through egg 30 that will result in a mirror image being formed on either side of the axis of symmetry. Irregular outline 32, in the embodiment illustrated, includes outward or convex protuberance 34 and inward or concave region 36. Convex protuberance 34 and concave protuberance 36 may be seen to be substantially rounded in appearance. Another outward vertex 38 may be seen, being formed between a first substantially straight region 40 and a second Substantially straight region 42. Yet another outward protuberance or convex region 48 may be seen formed between a first concave region 44 and a second concave region 46. A broken yolk 31 may be seen within egg 30. The present invention includes both eggs having broken and unbroken yolks. FIG. 1 also includes a second whole, cooked natural egg 50 having an irregular outline and a broken yolk 54. A third, whole, cooked natural egg 56 may be seen, also having an irregular outline 58. Eggs 30, 50, and 56 may all be seen to have different irregular outlines. FIG. 2 illustrates three cooked eggs product formed from a scrambled egg mix. A first scrambled egg 60 having an irregu lar outline or periphery 62 may be seen. A second scrambled egg 64 having an irregular outline 66 is also present in FIG. 2. A third Scrambled egg 68 may also be seen, having an irregu lar outline or periphery 70. FIG. 3 illustrates three formulated eggs made according to the present invention. A first formulated egg 72 having an irregular outline 74 may be seen. A second formulated egg 76 having an irregular outline or periphery 78 is also illustrated in FIG. 3. A third formulated egg 80 having irregular outline 82 may also be seen. Formulated eggs are well knownto those skilled in the art. Formulated eggs can be made by cracking whole eggs, separating or Substantially separating the yolk and the albumin, and recombining the yolk and the albumin components to form a cooked egg product resembling a natu ral, whole, grilled fried cooked egg. The formulated eggs can have the albumin and/or the yolk component modified by the addition of Substances, for example, gums. The albumin and/ or yolk may also be partially or totally replaced. In one Such example, the yolk may be replaced with a food product resem bling a natural yolk, but having a Substantially reduced cho lesterol component. FIG. 4 illustrates a first mold 90 having an irregular outline 92 that can be used to form and cook the cooked egg products, for example, eggs 30, 60, and 72 of FIGS. 1, 2, and 3, respec tively. Mold 90 can be made by punching a sheet metal material with an irregular outline stamp or punch, resulting in the irregular shaped outline 92 seen in FIG. 4. A vertically beveled or stepped periphery 96 may be seen in FIG. 4 as well. Mold 90 can include a substantially flat bottom surface 94. Mold 90 can further be coated with a food grade, non-stick material, for example, Teflon (PTFE). FIG. 5 illustrates a second mold 98 having an irregular outline 100 that can be used to make cooked eggs having an irregular outline, for example, eggs 50, 64, and 80 of FIGS. 1, 2, and 3, respectively. FIG. 6 illustrates a third mold 102 having an irregular outline 104 that can be used to make cooked egg products, for example, eggs 56, 68, and 76, of FIGS. 1, 2, and 3, respec tively. Referring again to FIGS. 1 through 6, the present invention includes methods to include a pre-cooked egg product with a shape that simulates that of a fresh egg product that has been cooked on a flat grill Surface. This method can utilize a pan with an irregular shaped mold in which the liquid egg product is deposited. The molds of FIGS. 4 through 6 have been designed from actual egg products cooked on a grill to pro vide a finished product that simulates this irregular shape. The liquid egg product can be deposited into pans having the irregular mold formed as part of the pan. This egg product can then be cooked in the pan to a minimum temperature of 170 degrees Fahrenheit. The cooked egg product can then be cooled. This method includes both frozen and refrigerated products, and includes, but is not limited to, the cooking of natural whole eggs, scrambled egg mixes, and formulated eggs. The irregular shaped cooked egg products of FIGS. 1 through 3 can provide a natural looking egg product that more closely resembles that of products cooked on a flat grill. The end user can rapidly reheat this product and provide a more natural looking product without having to cook a liquid egg product on a grill. The precooked, cooled eggs made accord ing to the present invention can be more easily delivered pathogen free to the end user. Wastage can be reduced as the individual eggs can be heated on an as-needed basis. Another aspect of the present invention includes methods for making cooked egg products having brokenyolks and the cooked egg products made according to these methods. The time required to fully cook the yolk portion of a fried egg with intact yolk exceeds the time required to fully cook the white portion due to the increased thickness of the yolk. This can result in overcooking of the white portion of the egg in order to fully cook the yolk. The present invention includes a method for breaking the yolk in order to minimize the differ ences in thickness associated with an egg with an unbroken yolk. This method also improves process efficiencies by reducing the total amount of time necessary to fully cook the egg to an internal temperature of 170 degrees Fahrenheit. The time required to cook an egg with an unbroken yolk can be between 25 percent and 75 percent longer than cooking an egg that has a broken yolk. The cooking of the egg with a brokenyolk also results in a more uniform cooking of the egg, which results in improved texture. FIG. 7 illustrates a pan 200 including a top planar surface 202 and three egg molds 204, 206, and 208 therein. Molds 204 and 206 are similar while mold 208 is somewhat different. Mold 204 includes a first downwardly extending or sloped region 210 followed by a first planar horizontal region 212. Planar region 212 is followed by a second downwardly sloped or extending region 214 followed in turn by a bottom cupped or rounded region 216. A first or primary depression is thus formed by first sloped region 210 and first planar region 212. A second or secondary depression is thus formed by second sloped region 214 and bottom cupped or rounded region 216. Mold 208 includes regions 210, 212, and 214, as discussed

16 7 with respect to mold 204. Mold 208 includes a bottom flat region 218, rather than a bottom rounded region 216 as in mold 204. Mold 208 includes a second or secondary depres sion formed from second sloped region 214 and bottom flat region 218. In Some embodiments, the second depression has a Surface area of at least about/io" or '/6" the surface area of the first or primary depression. As used herein, the term "surface area refers to the projection of the Surface area onto the top planar surface 202. Thus, the surface area refers to the surface area that is horizontal when top planar surface 202 is disposed horizontally. Thus, if first sloped region 210 were perfectly perpendicular to top planar surface 202, then first sloped region 210 would have no surface area. The surface area of the first depression, for the purposes of this application, includes the combined surface area of the first and the second depres sions. The first depression has a depth relative to top planar surface 202. In the example illustrated, the depth of the first depression is the distance between first planar region 212 and top Surface 202. The second or secondary depression also has a depth relative to top planar surface 202. This depth is the maximum distance within the second or secondary depres sion and the top planar Surface. In some embodiments, the depth of the second depression is at least 4" or even /3" greater than the depth of the first depression. The molds of the present invention have a major width dimension of less than 6 inches and 4 inches, and a maximum depth of less then 1/2 inches, 1 inch, and 34 inch, in various embodiments. In use, a yolk can be deposited into the second depression while an egg white is deposited into the first depression. The yolk may be a whole intact yolk, a whole egg broken yolk, or a formulated yolk, depending on the embodiment. In some methods, the yolk is deposited into the second depression first, followed by depositing the egg white, either natural, enhanced, or formulated. In other methods, the egg is depos ited at once, and the yolk allowed to settle into the second depression. In one Such method, the yolk is a formulated yolk, having a heavier density than the egg white. The heavier density formulated yolk thus settles into the second depres sion while the egg white is primarily located within the first depression. Pan 200 can then be subjected to heating, thus cooking the egg products within the molds. The pan can then be inverted and the cooked egg products dislodged. The resulting egg products will have the yolk portion prominently displayed, resembling a grill fried Sunny side up cooked egg. The resulting cooked egg can be a natural whole egg, or an egg having a formulated yolk and/or white portion. FIG. 8 illustrates another cooking pan 230 according to the present invention. Pan 230 includes a top planar surface 232 and a mold 233. Mold 233 includes generally a first depres sion 234 and four secondary depressions 236 formed within primary depression234. As may be seen from inspecting FIG. 8, both primary depression 234 and secondary depressions 236 have a substantially Smooth appearance. FIG. 9 illustrates another cooking pan 240 having a mold 241 therein. Mold 241 includes an irregular shaped outline 242 and a primary depression 244. Primary depression 244 includes four secondary depressions 246, 247, 248, and 249, each having an irregular Surface. The depth of the secondary depressions may be seen to vary over the area of the second ary depressions. In the examples illustrated in FIGS. 8 and 9. the four secondary depressions are each roughly disposed within one quadrant of the mold. FIG. 10 illustrates a cooked egg product produced using the molds of FIGS. 8 and 9. Cooked egg product 250 may be seen to have an irregular height surface 252 thereover, the result of being cooked using mold 233 of FIG. 8. Another cooked egg product 254 is also seen, having an irregularly varying height surface 256. Cooked egg product 254 is the result of an egg product being cooked in mold 241 of FIG Both cooked egg products 250 and 254 may be seen to have four raised regions, one in each quadrant, the result of being cooked in the secondary depressions of the molds of FIGS. 8 and 9. The irregular height of cooked egg product 250 is also the result of the raised ridge regions of the primary depression relative to the secondary depression in mold 233 of FIG. 8. The irregularly varying height of the cooked egg products in FIG. 10 more closely resemble home cooked egg products. In particular, some cooked egg products made using this method more closely resembled grill fried Scrambled eggs that have been disturbed or moved during the cooking pro cess, as with a spatula. The eggs may also resemble eggs having a lighter or fluffier consistency, relative to similar eggs having a planar, flat or regularly rounded Surface. Inspection of the egg products of FIG. 10 also show that in this embodi ment of the invention, that there exists no axis of symmetry about which the raised portions appear identical or mirror images of each other. FIG. 11 illustrates a cooked egg 110 having a brokenyolk. FIG. 11 may be contrasted with FIG. 12, illustrating an egg 114 having an intact yolk 116. As is discussed below, the present invention also includes methods and apparatus for breaking the yolks prior to depositing the eggs. The methods and apparatus used to break the yolks can accomplish this task rapidly, allowing for incorporation of the devices to mass produce cooked eggs having broken yolks. The present invention also includes devices for mass pro ducing eggs having a grill fried egg appearance. The mass produced, cooked, and cooled egg products can include the intact or broken egg yolk products, and/or the irregular shaped cooked egg products previously described. FIG. 13 illustrates an egg yolk splitting or rupturing device 130. Yolk rupturing device 130 includes a first depression 122, a second depression 124, a third depression 126, a fourth depression 128, and a fifth depression (not shown). Egg yolk breaking device 130 can be formed from a Teflon-coated pan having four inch round depressions stamped into the pan which can be about 0.65 inches in depth. These depressions can be positioned to align with mold depressions in the cook ing belt underneath. In the embodiment illustrated, the bottom of each depres sion was cut into eight equal segments 132 separated by openings 134 therebetween. The segments thus formed were then bent downward to form an opening for the liquid egg contents to pass through. As the liquid egg white and yolk fall through this opening, the pointed portion of each segment ruptures the membrane of the yolk sac, causing it to break. Varying degrees of yolk spread on the finished fried egg can be achieved by changing the size of the opening on the yolk breaker. After the egg passes through the egg yolk breaker, it can be deposited into the mold on the cooking oven to be cooled. The segments meet at a central aperture 136 formed at the vertices of the segments. The segments can have sharp edges, both along their sides and at their vertices, which can rupture the egg yolk sac. The present invention includes gen erally any device having an aperture with sharp edges, inter nal or external, for rupturing the egg yolk sac. FIG. 13 shows that egg yolk breaking device 130 can be used as part of an egg breaking machine 120. Egg breaking machine 120 may be seen to have a belt 157 carrying numer ous egg carriers 156. Belt 157 is driven by a first toothed wheel 154 and a second toothed wheel 152 (not illustrated in FIG. 13). A large gear 150 may be seen for driving wheels 152 and 154. In normal operation, belt 157 moves toward the right, indicated at arrow 159. Egg breaking machines and egg carriers are well known to those skilled in the art, with some being further described in U.S. Pat. Nos. 5,617,782 and 6,234, 070, both herein being incorporated by reference.

17 FIG. 14 illustrates egg breaking device 120, previously introduced in FIG. 13. First toothed wheel 154, second toothed wheel 152, and drive gear 150 may be noted, to orient device 120 with respect to the view previously shown in FIG. 13. The egg carriers of device 120 are carried by a closed loop chain or belt that carries egg carriers 162, 164, and 166, beneath first toothed wheel 154 and traveling toward the right in FIG. 14. Other egg carriers 168 and 170 (illustrated in FIG. 16) are disposed above first toothed wheel 154 and travel toward the left in FIG. 14. In normal operation, a whole shelled egg conveyor 172 delivers whole, shelled eggs to the egg carriers which each carry an egg downward in a Substan tially vertical fashion, then breaking the shells, and depositing the whole eggs onto the cooking pans of the equipment. The egg carriers may be seen to form 5 side-by-side col umns of egg carriers, for example, egg carriers 160 and 161, disposed alongside each other and traveling vertically down ward at one point. The egg breaking device of FIG. 14 may be considered to be, or include, a plurality of vertically disposed carousels disposed in a side-by-side fashion. The carousels could be considered to be circular or circular in at least a part of the belt or chain length, conveying the egg carriers about a closed loop path each lying Substantially within a vertical plane. The egg carriers at the position indicated at 174 are dis posed directly above five chutes or deflectors including a right-most chute or deflector 176 and a left-most chute or deflector 178. The illustrated embodiment utilizes a conven tional egg breaking machine, a Diamond W80 modified for the present use. A belt 180 having a plurality of pans, for example, pans 182 and 184 may be seen. Each of the pans includes a plurality of molds or depressions 186. Depressions 186 may be seen located a distance apart that is greater than the distance separating egg carriers 160 and 161. In order to deposit the falling eggs coming from egg carriers 160 and 161 into the more widely separated molds 186, chutes or deflec tors 176 through 178 may be used to laterally disperse the falling whole liquid eggs. In the example illustrated in FIG. 14, belt 180 is traveling toward the right, toward an oven. In Some embodiments, for producing cooked eggs having bro ken yolks, yolk breaking device 130 can be interposed between the egg carriers at 174 and chutes or deflectors 176 through 178. The falling, whole eggs can have the yolks ruptured prior to falling through the chutes, allowing eggs with broken yolks to fall into the cooking pans below. FIG. 15 illustrates the moving cooking belt having numer ous pans 180 and depressions or molds 186 described with respect to FIG. 14. Chutes or deflectors 176 and 178 may be seen in FIG. 15 as previously described. Left-most chute or deflector 178 may be seen to have a laterally outwardly sloped portion 195 and chute or deflector 176 may be seen to have an outwardly sloped portion 194. Portions of the middle three chutes or deflectors 190, 191, and 192 may also be seen in FIG. 15. FIG. 16 illustrates device 120 from the side. Egg carriers 168, 170, 162, 164, and 166 may be seen as previously described. Drive gear 150 and toothed wheels 154 and 152 may also be seen. Cooking pans 180 may be seen heading rightward toward the cooking oven. Device 120, in the embodiment illustrated, is based on a modified Diamond W80 egg breaker (Diamond Automation, Farmington Hills, Mich.). Modifications to the diamond W80 breaker can include shortening the in-feed conveyor, modi fying the frame, and electronic control changes to synchro nize the egg breaking equipment with the cooking oven. Eggs can be loaded manually onto the in-feed conveyor by means of a vacuum assist mechanism. The eggs can then be posi tioned into lanes by a series of guide rods. These eggs can then be transported via spool conveyor rollers to the egg loader where they are deposited into individual egg holders or egg carriers. The eggs can then be cracked with a knife attachment and the shell spread, allowing the egg contents to drop into the yolk breaking device. The empty egg shells can then be auto matically deposited into an auger, which conveys the shells to a holding hopper. The oven, which can be referred to as a mold oven, can be a 40-foot gas-fired forced convention oven, made for example by Wolverine-Proctor & Schwartz (Merri mac, Mass.). The cooked eggs can then be cooled in a spiral freezer and packaged. All of the modifications in this para graph are well within the abilities of those skilled in the art, provided the teachings of the present inventory. The detailed description above should be read with refer ence to the drawings, in which like elements in different drawings are numbered identically. The drawings, which are not necessarily to Scale, depict selected embodiments and are not intended to limit the scope of the invention. Several forms of invention have been shown and described, and other forms will now be apparent to those skilled in art. It will be under stood that embodiments shown in drawings and described above are merely for illustrative purposes, and are not intended to limit the scope of the invention as defined in the claims that follow. The invention claimed is: 1. A method for mass-producing cooked eggs, the method comprising: dropping an egg having a yolk and a white through a device to break the yolk sac, wherein the device comprises one or more depressions including a plurality of segments having sharp edges and/or pointed portions to rupture the yolk sac, the segments are separated therebetween to form an opening to allow the egg to pass through; depositing the egg into a mold, wherein the mold receives only one egg and has an irregularly shaped peripheral boundary; cooking the deposited egg in the mold; removing the cooked egg from the mold; and cooling the cooked egg below room temperature. 2. A method as in claim 1, in which the egg includes whole eggs, in which the depositing includes depositing the whole eggs. 3. A method as in claim 1, in which the egg product includes whole eggs having intact yolks, in which the depos iting includes depositing the whole eggs having intact yolks. 4. A method as in claim 1, in which the egg product includes whole eggs having essentially all intact yolks, in which the depositing includes depositing the whole eggs hav ing essentially all intact yolks. 5. A method as in claim 1, wherein dropping an egg com prises dropping a plurality of eggs and wherein the mold is arranged side to side along a width dimension and end to end along a length dimension with a plurality of other molds, and in which the depositing includes depositing the plurality of eggs along the width into the plurality of molds at Substan tially the same time. 6. A method as in claim 5, in which the depositing includes depositing the plurality of eggs along the width while the molds are moving along the length dimension. 7. A method as in claim 1, in which the method includes breaking the egg shells while the whole eggs are spaced a first distance apart from each other, followed by diverting the broken egg contents in the width dimension to a second distance apart from each other to drop into the molds. 8. A method as in claim 1, wherein the mold has a first depression and a second depression disposed within the first depression, wherein the depositing includes depositing the egg products into the first and second depressions. 9. A method as in claim8, wherein the egg product includes whole eggs having intact yolks, wherein the depositing

18 11 includes depositing the whole eggs and allowing the yolks to settle into the second depression. 10. A method as in claim 8, wherein the mold includes a bottom Surface having a depth that varies irregularly over the bottom surface. 11. A method for breaking egg yolks comprising: dropping an egg having a yolk and a white through a device for rupturing the egg yolk sac, wherein the device com prises one or more depressions including a plurality of segments having sharp edges and/or pointed portions to rupture the yolk sac, and wherein the segments are sepa rated therebetween to form an opening to allow the egg to pass through; and depositing the egg into a mold, wherein the mold receives only one egg. 12. A method as in claim 11, in which the device has a plurality of depressions and can receive a plurality of egg yolks simultaneously. 13. A method as in claim 11, in which the device has a plurality of depressions arranged in a side-by-side pattern. 14. A method as in claim 11, in which the device has a plurality of depressions, each disposed in a downwardly extending plate portion. 15. A method for making cooked whole eggs, the method comprising: mechanically conveying a plurality of whole eggs, the eggs having a shell and egg contents including an egg yolk and an egg white; mechanically breaking the conveyed plurality of egg shells; dropping the eggs through a device to break the yolk sac, wherein the device comprises a plurality of depressions including a plurality of segments having sharp edges and/or pointed portions to rupture the yolk sac, and wherein the segments are separated therebetween to form an opening to allow the egg to pass through; allowing the egg contents to fall into a plurality of molds wherein each mold receives only one egg: mechanically conveying the molds containing the egg con tents into a heating area; and cooking the egg contents in the molds. 16. A method as in claim 15, in which the egg conveying, egg breaking, and mold conveying include mechanisms selected from the group consisting of pneumatic, electrical, magnetic, hydraulic, purely mechanical, and electro-me chanical mechanisms and combinations thereof. 17. A method as in claim 15, in which the egg conveying includes mechanically carrying each egg in an egg carrier. 18. A method as in claim 15, in which the egg shell mechanical breaking includes breaking the egg shell with a knife. 19. A method as in claim 15, in which the molds are joined together into a closed loop of linked molds, and in which the mold conveying includes moving the loop of linked molds toward the heating area. 20. A method as in claim 15, in which the molds have an irregularly shaped outline, such that cooked eggs have a resulting irregularly shaped outline. 21. A method as in claim 15, in which the molds have an irregularly shaped bottom Surface. Such that the cooked eggs have a resulting irregularly shaped surface. 22. A method as in claim 15, in which the molds have a first depression and a second depression located within the first depression further comprising disposing the egg yolks in the second depression A method as in claim 15, in which the molds have a symmetrical outline. Such that the cooked eggs have a sym metrical outline. 24. A method as in claim 15, in which the molds have a rounded outline. Such that the cooked eggs have a rounded outline. 25. A method for making cooked whole eggs having an egg shell and egg contents including egg yolk and egg white, the method comprising: automatically conveying whole eggs to an egg-breaking location; automatically breaking the egg shells of the whole eggs; dropping the eggs through a device to break the yolk sac, wherein the device comprises a plurality of depressions including a plurality of segments having sharp edges and/or pointed portions to rupture the yolk sac, and wherein the segments are separated therebetween to form an opening to allow the egg to pass through; allowing the contents of only one whole egg to fall into one mold; automatically conveying each mold into a heating area; and cooking the egg contents in each mold in the heating area. 26. The method for mass-producing cooked eggs accord ing to claim 1 wherein the mold comprises a planar Surface having a depression therein and wherein the depression has an irregularly shaped outline. 27. The method for mass-producing cooked eggs accord ing to claim 26 wherein the depression outline is asymmetric about any vertical plane drawn through the planar Surface and the depression. 28. The method for mass-producing cooked eggs accord ing to claim 26 wherein the planar surface is formed of a non-stick, food grade material. 29. The method for mass-producing cooked eggs accord ing to claim 26 wherein the mold comprises a plurality of depressions in the planar Surface. 30. The method for mass-producing cooked eggs accord ing to claim 26 wherein the depression has a flat bottom. 31. The method for mass-producing cooked eggs accord ing to claim 26 wherein the depression has upwardly and outwardly beveled edges. 32. The method for mass-producing cooked eggs accord ing to claim 26 wherein the mold include a bottom surface having an irregularly varying depth over the bottom surface. 33. The method for mass-producing cooked eggs accord ing to claim 26 wherein the depression includes a first depres sion and a second depression disposed within the first depres S1O. 34. The method for mass-producing cooked eggs accord ing to claim 1 wherein the one or more depressions are cut at the bottom to form the plurality of segments and the segments are bent to form the opening. 35. The method for breaking egg yolks of claim 11 wherein the one or more depressions are cut at the bottom to form the plurality of segments and the segments are bent to form the opening. 36. The method for making cooked whole eggs of claim 15, wherein the one or more depressions are cut at the bottom to form the plurality of segments and the segments are bent to form the opening. 37. The method for making cooked whole eggs having an egg shell and egg contents including egg yolk and egg white of claim 25, wherein the one or more depressions are cut at the bottom to form the plurality of segments and the segments are bent to form the opening. k k k k k

III. United States Patent (19) Binacchi. Attorney, Agent, or Firm-Bucknam and Archer 57 ABSTRACT. 6 Claims, 3 Drawing Sheets

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

(*) Notice: Subject to any disclaimer, the term of this E. E. E. E. O.C.

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

United States Patent (19) 11) 4,167,008 Blickenstaff 45) Sep. 4, 1979

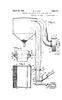

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(12) United States Patent (10) Patent No.: US 6,813,994 B2

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. Lange (43) Pub. Date: Nov. 22, 2012

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

US A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1. Hurley et al. (43) Pub. Date: Aug. 28, PROCESS Publication Classification

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

United States Patent [11] 3,559,565

![United States Patent [11] 3,559,565 United States Patent [11] 3,559,565](/thumbs/93/114425987.jpg) United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

7 IANSNA. (12) Patent Application Publication (10) Pub. No.: US 2003/ A1. (19) United States 2//

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

United States Patent (19) Ludder

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

March 24, 1970 H. H. BRIDGFORD 3,502,488 COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER HUGH. BROGFORD / ATTORNEY

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

(12) United States Patent (10) Patent No.: US 7,325,807 B1. Eason (45) Date of Patent: Feb. 5, 2008

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

(12) United States Patent

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

May 12, ,282,708 T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE. Filed Sept. 26, Sheets-Sheet l. --No.zzzzzzzzzzae.

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

(12) United States Patent

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

United States Patent (19)

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

III IIIHIII. United States Patent (19) Momiyama

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

United States Patent (19)

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

United States Patent (19) Bowen et al.

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

United States Patent (19) Adams et al.

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

Sept. 7, l.t. ward 2,092,596 SIPHON

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

III. United States Patent (19) 5,590,586 Jan. 7, % 4. Ulfig et al. (75) Inventors: Kimberly A. Ulfig, Glen Ellyn;

United States Patent (19) Ulfig et al. 54 KITCHEN LAYOUT, SYSTEM (75) Inventors: Kimberly A. Ulfig, Glen Ellyn; Patricia A. Venetucci, Hawthorn Woods, both of Ill. (73) Assignee: Restaurant Technology,

United States Patent (19) Ulfig et al. 54 KITCHEN LAYOUT, SYSTEM (75) Inventors: Kimberly A. Ulfig, Glen Ellyn; Patricia A. Venetucci, Hawthorn Woods, both of Ill. (73) Assignee: Restaurant Technology,

(12) United States Patent

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120279416A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0279416A1 Nishimura et al. (43) Pub. Date: Nov. 8, 2012 (54) RAILCAR BOGIE (52) U.S. Cl.... 105/218.1 (75)

(19) United States US 20120279416A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0279416A1 Nishimura et al. (43) Pub. Date: Nov. 8, 2012 (54) RAILCAR BOGIE (52) U.S. Cl.... 105/218.1 (75)

3,702,608 11/1972 Tibbs. states by bying O st plunger T.

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

Center et al. (45. Date of Patent: Aug. 29, 1995

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

United States Patent It 3,593,647

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

US A United States Patent 19 11) Patent Number: 5,620,735 Manderfeld et al. 45 Date of Patent: Apr. 15, 1997

IIII IIHIII III US00567A United States Patent 19 11) Patent Number: 5,6,7 Manderfeld et al. Date of Patent: Apr. 15, 1997 54 SIMULATED EGG PATTY FOREIGN PATENT DOCUMENTS 75 Inventors: Michelle M. Manderfeld;

IIII IIHIII III US00567A United States Patent 19 11) Patent Number: 5,6,7 Manderfeld et al. Date of Patent: Apr. 15, 1997 54 SIMULATED EGG PATTY FOREIGN PATENT DOCUMENTS 75 Inventors: Michelle M. Manderfeld;

United States Patent (19) Forino

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

Sugar maple tree named Legacy

( 1 of 1 ) United States Patent PP4,979 Wandell February 1, 1983 Sugar maple tree named Legacy Abstract This disclosure concerns a new and distinct variety of Acer saccharum (commonly known as sugar maple

( 1 of 1 ) United States Patent PP4,979 Wandell February 1, 1983 Sugar maple tree named Legacy Abstract This disclosure concerns a new and distinct variety of Acer saccharum (commonly known as sugar maple

United States Patent (19) D'Alessandro

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

Module 6: Overview of bakery machinery: mixers, forming machines and ovens.

Paper No. 09 Paper Title: Bakery and Confectionery Technology Module 6: Overview of bakery machinery: mixers, forming machines and ovens. Introduction Bakery units can be classified as manual, semi-automatic

Paper No. 09 Paper Title: Bakery and Confectionery Technology Module 6: Overview of bakery machinery: mixers, forming machines and ovens. Introduction Bakery units can be classified as manual, semi-automatic

3,000 POUND CAPACITY AUTO BODY ROTISSERIE UNIT

3,000 POUND CAPACITY AUTO BODY ROTISSERIE UNIT INSTALLATION / OWNERS MANUAL ROTISSERIE (R3000G) 1 IN50016 Rev. B 03/30/2009 TABLE OF CONTENTS IMPORTANT INFORMATION...pg 2 OWNER / EMPLOYER RESPONSIBILITIES...pg

3,000 POUND CAPACITY AUTO BODY ROTISSERIE UNIT INSTALLATION / OWNERS MANUAL ROTISSERIE (R3000G) 1 IN50016 Rev. B 03/30/2009 TABLE OF CONTENTS IMPORTANT INFORMATION...pg 2 OWNER / EMPLOYER RESPONSIBILITIES...pg

United States Patent (19)

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

Attention is drawn to the following places, which may be of interest for search:

CPC - A23N - 2017.08 A23N MACHINES OR APPARATUS FOR TREATING HARVESTED FRUIT, VEGETABLES OR FLOWER BULBS IN BULK, NOT OTHERWISE PROVIDED FOR; PEELING VEGETABLES OR FRUIT IN BULK; APPARATUS FOR PREPARING

CPC - A23N - 2017.08 A23N MACHINES OR APPARATUS FOR TREATING HARVESTED FRUIT, VEGETABLES OR FLOWER BULBS IN BULK, NOT OTHERWISE PROVIDED FOR; PEELING VEGETABLES OR FRUIT IN BULK; APPARATUS FOR PREPARING

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 2012O096823A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0096823 A1 M00re (43) Pub. Date: Apr. 26, 2012 (54) FRUIT TREE PRUNER AND HARVESTING AOID 46/00 (2006.01)

(19) United States US 2012O096823A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0096823 A1 M00re (43) Pub. Date: Apr. 26, 2012 (54) FRUIT TREE PRUNER AND HARVESTING AOID 46/00 (2006.01)

3. : 12- C) {X C> C) () {X -K) --KX-KX-KX-K)--C-2 --C)-- (12) Patent Application Publication (10) Pub. No.: US 2012/ A1 4 - (19) United States

(19) United States US 2012O138603A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0138603 A1 McGuinness et al. (43) Pub. Date: Jun. 7, 2012 (54) VARIABLE GEOMETRY TORTILLA COOKINGAPPARATUS

(19) United States US 2012O138603A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0138603 A1 McGuinness et al. (43) Pub. Date: Jun. 7, 2012 (54) VARIABLE GEOMETRY TORTILLA COOKINGAPPARATUS

United States Patent (19) Aldrich

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

(12) United States Patent (10) Patent No.: US 8,601,937 B2

USOO8601937B2 (12) United States Patent () Patent No.: Campetella et al. (45) Date of Patent: Dec., 2013 (54) APPARATUS FOR MAKING COFFEE 5,605,091 A * 2/1997 Garber... 99,330 5,650,186 A * 7/1997 Annoni

USOO8601937B2 (12) United States Patent () Patent No.: Campetella et al. (45) Date of Patent: Dec., 2013 (54) APPARATUS FOR MAKING COFFEE 5,605,091 A * 2/1997 Garber... 99,330 5,650,186 A * 7/1997 Annoni

(12) Plant Patent Application Publication

(19) United States (12) Plant Patent Application Publication Martin US 20100 199395P1 (10) Pub. No.: (43) Pub. Date: Aug. 5, 2010 (54) BRUGMANSIA ANGELS SUMMER DREAM (76) Inventor: Byron E. Martin, Danielson,

(19) United States (12) Plant Patent Application Publication Martin US 20100 199395P1 (10) Pub. No.: (43) Pub. Date: Aug. 5, 2010 (54) BRUGMANSIA ANGELS SUMMER DREAM (76) Inventor: Byron E. Martin, Danielson,

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

Dec. 9, M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080216664A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0216664 A1 K00n et al. (43) Pub. Date: Sep. 11, 2008 (54) ELECTRONICTEATHERMOMETER AND TIMER DEVICE (75) Inventors:

(19) United States US 20080216664A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0216664 A1 K00n et al. (43) Pub. Date: Sep. 11, 2008 (54) ELECTRONICTEATHERMOMETER AND TIMER DEVICE (75) Inventors:

Hard sweet biscuit & crackers

Hard sweet biscuit & crackers The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given

Hard sweet biscuit & crackers The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given

EDSGN 100 Project 1 Dumpling Roller Mark I

1 EDSGN 100 Project 1 Dumpling Roller Mark I Section 10 Team 8 Submitted by Nikhil Reddy, Steven Lee, and Mitchell Ross www.team8project1.weebly.com Submitted to: Xinli Wu Date of Submission: November

1 EDSGN 100 Project 1 Dumpling Roller Mark I Section 10 Team 8 Submitted by Nikhil Reddy, Steven Lee, and Mitchell Ross www.team8project1.weebly.com Submitted to: Xinli Wu Date of Submission: November

(12) United States Patent (10) Patent No.: US 6,419,120 B1

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States US 2004O238555A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0238555 A1 Parks (43) Pub. Date: Dec. 2, 2004 (54) VENDING MACHINE THAT DELIVERS Publication Classification

(19) United States US 2004O238555A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0238555 A1 Parks (43) Pub. Date: Dec. 2, 2004 (54) VENDING MACHINE THAT DELIVERS Publication Classification

A33. AORNEY. March 22, G. C. HERZ, 1,850,719. APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC. Filed Dec, l6, l Sheets-Sheet l NVENTOR

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.