United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993

|

|

|

- Logan Owen

- 5 years ago

- Views:

Transcription

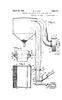

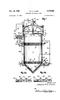

1 USOO A United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993 (54) APPARATUS FOR ROASTING COFFEE 4, /1990 Pera... 99/470 BEANS OR THE LIKE Y 4,949,632 8/1990 Porzi /468 5,068,979 12/1991 Wireman et al /483 (75) Inventors: Jack Wireman; Daniel R. Wireman, both of Fallbrook, Calif. FOREIGN PATENT DOCUMENTS o : ical /1983 Fed. Rep. of Germany. 73 Assignee E. ES /1989 U.S.S.R /58 p ey /1986 United Kingdom... 99/286 (21) Appl. No.: 727,899 Primary Examiner-Timothy F. Simone 22 Filed: Jul. 10, 1991 Attorney, Agent, or Firm-Bacon & Thomas 5) Int. Cl.... A23N 12/00; A23N 12/08; 57 ABSTRACT F26B 17/00, F26B 17/24 w 52 U.S. Cl... 99/483: 34/57 E. An apparatus for roasting coffee beans or the like in " " "3/896286, /58 cludes a controlled spinning bed or fluid bed roaster in 58) Field of Search....99/483,357,352,355, combination with a cyclone separator for removing 99/473,474, 475, 484,516, 286, 366/165; chaff from the heating medium. The cyclone separator 34/58,57R, 57 C, 57 B, 57 E, 184, 60,426/467, is disposed above and in coaxial and abutting relation 311,519, 520; 432/58; 406/173 ship with the roaster. The separator has a generally cylindrical shape with a plate having a plurality of lou (56) References Cited vers in the base thereof. The louvers impart rotational U.S. PATENT DOCUMENTS movement as the heating medium passes therethrough 2,857,683 10/1958 Schytil... 34/57 A so that the chaff can be removed therefrom. In a pre 3, /1965 Jager... 34/58 ferred embodiment of the invention, a second centrifu 3,964, 175 6/1976 Sivetz... 34/57 A gal separator which is relatively small with respect to 9:, 3. Sick al /355 the first separator is disposed adjacent the first separator a-- / ryant, 4, /1987 Gaget... 34/58 East t paration and returning the heated 4.785,726 11/1988 Wear et al /485 neal OaSc. 4,860,461 8/1989 Tamaki et al /286 4,875,904 10/1989 Munk... 34/62 13 Claims, 5 Drawing Sheets O

2 U.S. Patent July 27, 1993 Sheet 1 of 5 5,230,281 O

3 U.S. Patent July 27, 1993 Sheet 2 of 5 5,230,281

4 U.S. Patent July 27, 1993 Sheet 3 of 5 5,230,281

5 U.S. Patent July 27, 1993 Sheet 4 of 5 5,230,281

6 U.S. Patent July 27, 1993 Sheet 5 of 5 5,230,281

7 1 APPARATUS FOR ROASTING COFFEE BEANS OR THE LIKE This invention relates to an apparatus for roasting particulate vegetable material and, more particularly, to an apparatus for roasting coffee beans which includes a generally vertical roasting chamber; means for intro ducing a flow of heated fluid into the chamber for swirl ing or levitating the beans by means of the heated fluid and roasting the coffee beans therein; and an axially aligned and abutting centrifugal separator for removing chaff or residue from the heated fluid as the fluid is removed from the apparatus. The invention also relates to an improved cyclone separator for use with a con trolled spinning bed roaster or with a fluid bed roaster. BACKGROUND OF THE INVENTION In its simplest form, coffee roasting comprises heating a single bean to a prescribed temperature at which point chemical reactions occur that transform the bean into the desired state of pyrolysis. These reactions occur in the last part of the heating cycle. Thus, the residence time at the terminal temperature is crucial because difference in a few seconds in heat-history can have a significant effect on the taste of the coffee. The problem is that it is difficult to design a roaster that will roast several hundred pounds of beans at one time and to roast every bean evenly. Whether the pro cess for heat transfer is from convection, conduction, radiation, or some combination thereof, the heat is ab sorbed in the first few layers of a bean bed. Therefore, it is desirable to establish some means for equalizing bean temperature throughout the heating cycle so that when the final roasting temperatures are approached, all of the beans will be close to the same temperature during the pyrolysis process. The prior art is replete with attempts to obtain roast ing uniformity. For example, various approaches for roasting coffee are set forth in the United States patent of Schytil, U.S. Pat. No. 2,857,683. In the aforementioned prior art processes, the heating time to reach critical temperatures were considered to be relatively unimportant. For example, prior art pro cesses typically roasted coffee beans for periods of six to twenty minutes. However, in recent years, it has been found that coffee beans expand more and result in lower roast bean density if the heating process is speeded up to where the total heating cycle is accomplished in as short a time period as possible consistent with acceptable product characteristics, preferably within sec onds. Further, it has been found that these light density beans, when ground, have increased extractable solids and wettability, thus yielding an increase in extractable solids. The result of fast roasting is that coffee proces sors can fill the traditional 16 ounce container with a much reduced weight of coffee that still results in an equivalent number of cups as 16 ounces resulting from a longer roasting process. One approach to the more rapid roasting of coffee beans is disclosed in the U.S. patent of Brandlein et al., U.S. Pat. No. 4,737,376. As disclosed therein, the beans have a residence time within the roaster for a period of much less than three minutes and perhaps less than 1.5 minutes. During roasting, the beans are subjected to flow of heated gas which passes upwardly through a first foraminated container at a mass flow rate of at least ten pounds of gas per pound of beans. In that process, 5,230, the depth of the expanded bed is less than 50% of the diameter of the container. Further apparatus for the fluidized bed roasting of coffee is disclosed in the U.S. patent of Sivetz, U.S. Pat. No. 3,964,175. The Sivetz disclosure also contains a survey of prior art fluid bed roasters. A more recent approach for obtaining a rapid uni form roast is disclosed in our copending U.S. patent application, Ser. No. 07/463,557, which was filed on Jan. 11, 1990, now U.S. Pat. No. 5,068,979 entitled "Ap paratus and Process for Conditioning Particulate Mate rial" and which is incorporated herein in its entirety by reference. In essence, our earlier invention comprises a chamber for receiving a charge of coffee beans. The chamber has a generally circular base and an upwardly extending divergent wall defining a segment of a cone with a central axis and closed bottom. The divergent chamber wall preferably forms an included angle with respect to a horizontal plane of between 40 to 85 and also defines a plurality of openings in a lower portion thereof. Means are provided for inducing a mass of heated fluid generally tangentially into the chamber to rotate the coffee beans about the central axis of the chamber and for maintaining the rotating material in a relatively densely packed or controlled state during the heating thereof. During the rotation of the coffee beans, the chamber is stationary, i.e., it does not rotate about its central axis, so that there is relative movement between the rotating material and the stationary chamber. In addition, there is also vertical and radial movement of the coffee beans with respect to the chamber. There is also horizontal shearing within the spinning bed caused by beans near the bottom of the chamber moving faster relative to the beans near the top of the chamber. Coffee roasters in accordance with our earlier inven tion uniformly roast batches of coffee very rapidly with an efficient use of energy. They also provide condition ing, cooling, heating and roasting apparatus which are relatively flexible, competitively priced, relatively sim ple in operation, free of complexity and easy to operate and maintain. In addition, such roasters occupy a rela tively small area and can be rapidly converted to oper ate under different conditions in a job shop type of operation while fulfilling most of the requirements for food processing. Such roasters are referred to hereinaf ter as controlled spinning bed roasters or spinning bed roasters and are distinguished from fluid bed roasters even though both use a heated fluid such as air for transferring heat to the beans. The commercial roasting of coffee beans generates a relatively large amount of chaff and other debris during the roasting process. This chaff and other debris be comes entrained in the heating medium, i.e., hot gas, and is typically carried downstream from the roaster to a separate cyclone separator. There are several prob lems associated with this approach. For example, the mixture of hot gas and chaff is flammable and, as the chaff is further reduced in size as it is transferred to the separator, may form an explosive mixture. In addition, because the separator is located downstream from the roaster, ducting and fittings are required to connect the two. This ducting increases the internal surface area that is exposed to the hot gas and chaff and subsequently becomes fouled with condensed smoke and chaff parti cles. If this fouling is allowed to build up, a fire hazard is created. Hence, periodic removal is required and is typically accomplished by burning out the roaster, i.e.,

8 3 bringing the entire loop up to a high temperature (per haps 750 F) and holding until all deposits are reduced to ash. The larger surfaces, such as the roaster to separa tor ducting and separate cyclone surfaces, require more energy to overcome losses to the environment, both during roasting and burnout, even though the ducts are insulated. Further, a torturous path through elbows tends to amplify local deposits. Associated with the increased ducting is also an increased internal volume of the roaster loop. As smoke is generated during the roasting process, the greater the volume of smoke re tained in the loop, the greater the destructive energy should the smoke ignite and cause an explosion. It has now been found that an improved apparatus in accordance with the present invention overcomes many of the problems associated with the prior art devices. For example, it is now believed that the improved appa ratus disclosed and claimed herein minimizes the likeli hood of fire and/or explosion by reducing surface area for fouling and decreasing internal volume, lowers en ergy requirements by minimizing surface area exposed to the ambient environment, facilitates the handling and removal of chaff from the hot gas, reduces space re quirements because roaster and separator are now inte grated, results in a simpler design, saves floor space and lowers machine cost because a separate cyclone with its attendant support structure, extra duct work, extra insu lation and thermal expansion joints between it and the roaster are eliminated. SUMMARY OF THE INVENTION In essence, the present invention contemplates an apparatus for roasting coffee or the like which includes a chamber for receiving a charge of coffee beans. The apparatus also includes means for generating a flow of heated fluid and introducing the flow of heated fluid into the chamber for roasting the coffee beans within the chamber and with relative movement of the beans with respect to the chamber. In other words, the coffee beans are subjected to the heated fluid flow which form either a fluid bed or a controlled spinning bed of beans and roasting the same. Means are also provided for removing the roasted beans from the chamber. The invention also contemplates the addition of a centrifugal separator having a generally vertical axis disposed above and abutting the chamber and means for rotating the heated fluid as it moves upwardly out of the cham ber and into and through the separator. Finally, the invention contemplates means for separately removing a major portion of the heated fluid which is relatively free of chaff and other debris and a smaller portion of the heated fluid with the chaff and other debris concen trated therein. A preferred embodiment of the invention includes the combination of a controlled spinning bed roaster having a generally vertical axis and a centrifugal separator 5,230,281 disposed above and abutting said chamber. The separa tor, which includes a conical wall and a base with an opening adjacent to and abutting the top of the spinning bed roaster, is axially aligned with the roaster. Thus, the 60 separator receives the heated fluid mass and any chaff entrained therein as it is exhausted from the roaster. Means communicating with the opening in the base of the separator rotate the heated fluid mass as it moves upwardly into and through the separator. The separator also includes exit means in an upper portion thereof for separately removing a major portion of the fluid mass which is relatively free of chaff and a smaller portion of the fluid mass with essentially all of the chaff entrained therein from the separator. The combination also in cludes means for removing the roasted beans from the spinning bed roaster. A further embodiment of the invention is directed to a centrifugal or cyclone separator for use with fluid bed coffee roasters and controlled spinning bed roasters. The separator comprises a generally cylindrical body having an inner wall and an annular opening at the top and bottom thereof. Means communicating with and preferably within the opening at the bottom of the cy lindrical body are adapted to receive an upward flow of heated gas and entrained debris and for imparting suffi cient rotational movement to the flow so that the cylin drical forces imparted on the debris will move the de bris outwardly against the inner wall and upwardly toward the top of the cylindrical body. The cyclone separator also includes first exhaust means, i.e., the opening in the top of the cylindrical body for exhaust ing a major portion of the flow of gas which is relatively free of debris. A second exhaust means is also included in an upper portion of the cylindrical body next to or adjacent the inner wall for removing a minor portion of the gas and essentially all of the chaff and other debris. The chaff and gas are then separated by means of a standard cyclone, settling chamber or filter and the gas is returned to a point of lower pressure in the systems to be recycled. BRIEF DESCRIPTION OF THE DRAWINGS The invention will now be described in connection with the accompanying drawings, in which: FIG. 1 is a partially broken away perspective view of a roasting chamber having a controlled spinning bed of particulate material therein and an axially aligned abut ting separator as an integral part thereof. FIG. 2 is a cross-sectional view of a coffee roaster having an integral separator for chaff removal in accor dance with a presently preferred embodiment of the invention; FIG. 3 is a partially broken away perspective view of a roaster-separator in accordance with a preferred em bodiment of the invention; FIG. 4 is a side elevational view of a further embodi ment of an invention which includes a radial flame burner above the separator; and FIG. 5 is a partially broken away perspective illus trating another embodiment of the invention. DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS OF THE INVENTION An apparatus for roasting coffee beans or the like, according to the invention, will now be described in connection with the accompanying drawings wherein like reference numerals have been used to designate like parts. In accordance with a first embodiment of the inven tion, a coffee roaster 2 comprises a generally upright chamber 3 (FIGS. 1 and 2) which is adapted to receive a charge of coffee beans. The chamber 3 has a generally circular base 4 and an upwardly extending divergent wall 5 which defines a segment of a cone with a central axis (not shown). The circular base 4 may, as illustrated, define a relatively shallow cone which extends up wardly into the chamber so that any coffee beans falling thereon will flow outwardly toward the upwardly ex tending wall 5 of chamber 3.

9 5 A lower portion of chamber 3 also defines a plurality of openings 6 or preferably louvers 6' which are adapted to receive a mass of air. For example, heated air is induced tangentially into the chamber 3 through the opening 6 to form and maintain a spinning controlled bed of beans 8 as illustrated in FIG. 1. The chamber 3 also includes an upper portion 10 which is coaxial with the lower portion and which includes an upwardly extending wall 12. This upwardly extending wall 12 may define a right circular cylinder or a conical section wherein the slope of wall 12 is greater than the slope of wall 5. The purpose of the upper portion 10 is to stop the upward climb of the beans along the wall 5. The beans in the bed will preferably move spirally upwardly along the wall 5 because of the centrifugal force component on the bed. For example, the forces working on a single bean in the bed 8 is rotated about the central axis of the chamber 3 by means of tangentially induced air and is subjected to a centrifugal force component which forces the bean outwardly toward the wall 5. The weight of the bean produces a vertical component. Thus, there is a resultant force, which is due to the gravity and centrifugal acceleration. This resultant force should be approximately normal to the wall 5 or have a slightly upward component which will force the bean within the spinning bed to climb upwardly along a spiral path along wall 5. Thus, the forces acting on the beans in bed 8 cause the beans to climb the cone-shaped chamber and form a free surface which is approximately parallel to the wall 5. Thus, the purpose of the air is two-fold. First, the air imparts sufficient velocity to the beans to maintain the spinning bed; and, second, provides heat transfer to the beans. In practice, the air spins the beans about the central axis fast enough so that the centrifugal force component is several times that of gravity. This appar ent weight increase is important for heat transfer and permits a substantial amount of air to pass through the bed without levitating the beans. In fact, the result is a relatively stable spinning bed in which the beans follow a relatively defined path, remain in a relatively dense bed with a flow of gas through the bed and with con trolled mixing which provides a uniform roast so that each of the beans in the bed experience essentially the same heat history. The high velocity heated air enters the chamber 3 generally tangentially through the opening 6, past lou ver 6' and passes through the bed 8. For example, air which is preheated to 550 to 650 F. (287 to 343 C.) enters the chamber 3 through opening 6 at, for example, approximately 100 to 125 feet per second while the beans are travelling at approximately 10 feet (3.05 me ters) per second. As a result, there is a high relative scrubbing in the layer of beans next to the chamber and a very high film coefficient of heat transfer. Also, as the air transfers its momentum to the beans, it slows and follows a generally curved path through the bed and exits in a direction which is approximately normal to the inner surface of the bed 8. At that point, its velocity has decreased to about 10 feet (3.05 meters) per second which is insufficient to uplift or levitate the beans. Suit able means such as a plurality of nozzles (not shown) direct the air toward the louvers 6' or openings 6 so that the air enters the chamber in a mostly tangential direc tion. Once established, the bed will remain in essentially dynamic equilibrium with a minimal amount of recircu 5,230, lation as the beans in the outer portion of the bed spiral upwardly and those on the inner portion spiral down wardly. Thus, a stable spinning bed as described above can be established and maintained by selecting the slope of the chamber wall, diameter of the chamber and air velocity. For example, with a larger load of coffee beans, the beans in the inner free surface will be sub jected to the effects of gravity more so than those at the outer edge of the bed, i.e., closest to the chamber wall. To accommodate different loads and obtain uniform roasting during a relatively short roasting cycle, it is desirable to increase the mixing of the beans within the bed. For this reason, it is desirable to add separate mix ing means to mechanically turn and mix the bed. A bean spill 20 which is partially broken away in FIG. 1 illus trates the movement of the beans within bed 8. The bean spill 20 is formed of a curved metallic plate which curves downwardly and preferably inwardly to define a surface which is characteristic of a two-dimensional sheet which has been twisted. A centrifugal cyclone separator 30 comprises agen erally cylindrical wall 12' which may be an extension of wall 12. In a preferred embodiment of the invention, the separator 30 is axially aligned with roaster 2. The sepa rator 30 also includes a conically shaped plate 32 at the bottom thereof, i.e., between the roaster 2 and separator 30. The separator 30 would preferably be conical to aid in moving the chaff to the top (or bottom) take out point. The cylindrical chamber, as illustrated, requires more air velocity than a conical chamber to move all of the chaff to the top. An inverted cone with bottom chaff take out point could also be used as will be described hereinafter. The conically shaped plate 32 includes a plurality of relatively large elongated openings 33 and louvers 34 for redirecting the upwardly flowing hot gasses and imparting rotational movement thereto as illustrated by the arrow in FIG. 3. The cross sectional area of openings 33 should be at least equal to and preferably greater than the combined area of openings 6 in order to maintain a relatively small pressure drop in the heating medium or hot gas and entrained chaff as they enter the separator. Also the gas is cooled and its velocity reduced as it passes through the packed bed which leads to a reduced pressure drop. It is desirable to maintain a small pressure drop because the chaff is relatively light and the centrifugal force required to move the chaff outwardly against wall 12' and upwardly therealong is relatively small. The pres sure drop should also be maintained at a low level since it is advantageous to handle the chaff gently, i.e., to move the chaff with a minimal velocity in order to avoid breaking the relatively fragile chaff into smaller particles. Smaller particles are more difficult to collect and could contribute to a potentially explosive mixture. The separator 30 also includes a partial cover 36 extending around the top of wall 12' and defining a central aperture or opening 37 so that a major portion of the heated fluid medium or hot gas which is relatively free of chaff can be exhausted therethrough. The partial cover 36 also includes second exhaust means such as an opening 38 and pipe 40 adjacent to wall 12" for exhaust ing a relatively small portion of hot gas with a majority of the chaff entrained therein. There are a number of advantages in locating the separator 30 immediately above the roaster 2 or as an integral part thereof. Since the separator 30 captures the chaff almost immediately upon discharge through lou vers 34, piping, elbows and other transitions are elimi

10 5,230,281 7 nated. Elimination of these elements reduces chaff parti cle degradation and thus improves the efficiency of the chaff collection process. Elimination of piping, turns, lengthy runs and free standing components also reduces the cost of the overall system and improves the thermal 5 efficiency of the roaster by eliminating heat loss in ex posed pipe surface areas. The compact design of this embodiment of the inven tion also reduces the enclosed volume of the recircula tion loop and thus reduces the total amount of smoke 10 which is available to fuel an explosion. For this reason, it is presently believed that the potential for an explo sion will be reduced. Combining the roaster and separa tor or collector in accordance with the present inven tion also reduces the total amount of pressure loss in the system which is beneficial in fan or blower sizing as well as the horse power requirements for the system. The use of a compact design in the present embodi ment of the invention reduces the surface area of pipes and elbows and thus minimizes the internal available areas for fouling and/or chaff accumulation. In particu lar, elimination of elbows reduces chaff deposits since eddy currents are generally present on the downstream side of elbows. It is within these low velocity eddys that chaff slugs normally build up. These slugs of chaff can be the source of a smoldering ember during operation of a roasting system. In addition, the close coupling of roaster 2 and separator 30 reduces thermal expansion stresses in the recirculation loop and the elimination of 3 expensive thermal expansion joints. The compact de sign also reduces the amount of steel which is heated and cooled in each cycle and, therefore, contributes to a more efficient operation. A cylindrical hopper 42 for holding a charge of green is coffee beans 44 is disposed above separator 30 and is preferably axially aligned therewith. The hopper 42 may be supported by braces 43 or other suitable means and is connected to the roaster 2 by means of a central pipe 46 which passes through the separator 30 and the 40 conical plate 32. A valve 42 is opened to drop the charge of green beans into the roaster and then closed so that the hopper 42 can be refilled during the roasting process. It is presently believed that the central pipe passing 45 through the center of the separator will have no adverse effect on the separator since the rotational direction of the hot gasses moves the chaff outwardly toward wall 12". The operation of the apparatus according to the pres- 50 ently preferred embodiment of the invention will be described in more detail in connection with FIG. 2. For example, approximately 50 pounds (22.7 kilos) of green coffee beans are loaded into a cylindrical hopper 42. This hopper 42 may be approximately 16 inches ( cm) in diameter with a height of about 12 inches (30.48 cm) and includes a conical-shaped lower portion 42a which would, if extended to an apex, form an angle of about 90'. It is also desirable to have a closable opening and valve 42 at the bottom of about 5.5 inches ( cm) in diameter so that the 50 pounds (22.7 kilos) of beans can be dumped through the central pipe 46 and into the roasting chamber 3 within about 3 seconds. In essence, it is desirable to charge the roaster as fast as possible to minimize dead time in between roasting. A 65 roaster as described would, for example, have a capac ity of about 700 to 1,000 pounds (317.5 to kilos) of coffee per hour O 8 As illustrated in FIG. 2, the roasting chamber 3 in cludes a lower section 33 which contains a plurality of louvers 6' and a cylindrical upper section 10 which is the same diameter as a cylindrical portion of lower section 33. This cylindrical upper section 10 may also include a plurality of openings 6 and louvers 6' in a lower portion thereof and may include a viewing port (not shown). The chamber 3 also includes means for exhausting air and/or hot gasses and the normal chaff produced during the roasting of the coffee through an upper portion thereof. For example, the air, hot gasses and chaff rise up wardly toward the top of the chamber 3 and are di rected by the louvers 34 into the separator 30. The louvers 34 impart a rotational movement to the air, hot gasses and chaff as illustrated in FIG. 3. As the chaff moves outwardly against wall 12", it spirals upwardly through the separator 30 and a majority of the air and hot gasses are exhausted out of the separator 30 by passing through aperture 37. The chaff, together with a relatively small portion of the air and hot gasses, is concentrated at the outside of separator 30 against wall 12' and is removed from sepa rator 30 by means of opening 38 and pipe 40. The chaff is removed from the hot gasses in a small standard cy clone or similar device. The exhaust from this small cyclone is fed back into the system at a point where the system pressure is lower than aperture 38. The lower section 31 of chamber 3 is surrounded by an inlet scroll or manifold 41 which directs the air in a direction which is generally or mostly tangentially toward the louvers in the lower section. The paddles 26 are rotated in the direction of the louvers by means of shaft 37 and motor drive assembly 39 to aid in the initial rotation of the beans and heated air at a temperature between F. is pumped into the manifold 41 and is directed toward the louvers 6' and into the inte rior of chamber 3 to form and maintain a stable con trolled spinning bed of beans. The manifold 41 may also be connected to a centrifu gal blower or spiral impeller (not shown) and is con structed and arranged to direct a flow of heated air through the louvers 6 in the lower section in a mostly tangential direction to spin the coffee beans about a central and vertical axis. This tangentially directed air enters the chamber through, for example, 10 rows of 1 inch louvers with inch (1.9 cm) spacings and which are disposed with an upward angle of about 22. It is presently believed that the upward angle aids in sup porting the spinning bed without levitating the beans. The inlet Scroll or spiral distributor is, in essence, the reverse of a spiral diffuser and is constructed and ar. ranged so that the air is directed toward the louvers in a tangential direction and in a manner such that the inlet velocity is the same or approximately the same for each louver. The lower section and chamber 3 in an upper part thereof, or in a lower part of upper portion 10, may also include three circumferential rows of louvers of about 0.67 inches equally spaced and angled downwardly at about 7, 10 and 15, respectively, from bottom to top. These rows of louvers are shown as disposed in a right circular cylindrical section and are thought to aid in limiting the amount of climb by the beans up the wall 5 of the chamber 3. After roasting the beans for about 60 to 90 seconds, the conically-shaped base 4 is moved upwardly or downwardly in a manner which will be described in

11 more detail hereinafter and the airflow into the chamber may be stopped. The beans passing out of the roasting chamber 3 pass downwardly through a quench spray ring (not shown) and are preferably sprayed with cooling water to re duce their temperature, prevent further pyrolysis and increase the humidity within the coffee beans. The par tially cooled beans then drop into a second chamber 53 which is disposed coaxially with and below chamber 3. The details of a improved bean spill are disclosed in our co-pending application entitled "Improved Apparatus for Conditioning Particulate Material" filed on even date herewith and incorporated herein in its entirety by reference. Chamber 53, may be equally dimensioned and is gen erally similar to chamber 3. However, chamber 53 is a cooling chamber which uses air at ambient temperature for cooling the beans. Thus, the dumping means for the second chamber 53 is also generally similar to that used for chamber 3, but does not usually but may incorporate a quenching spray for further cooling of the beans. In designing an apparatus according to the present invention, there are a number of parameters to be con sidered which have been described in detail in our ear lier application. A presently preferred embodiment of the invention is illustrated in FIG. 3 wherein a roaster 2 including a generally upright chamber 3 having an upwardly ex tending divergent wall 5 as previously described. The cyclone separator 30 as shown in FIG. 3 is joined to the roaster 2 by means of a flange F. As illustrated, the separator 30 is formed as an extension of an upper por tion 10 or welded thereto. In the preferred embodiment of the invention, separator 30 includes an upwardly extending divergent wall 12' and conically shaped plate 32 at the bottom thereof with a plurality of louvers or openings 33 to provide rotational movement to the upwardly moving flow of hot gas. In the preferred embodiment, the conically shaped plate is made up of a plurality of overlapping plates which form relatively large tangential louvers. The divergent or conical wall 12' is preferred since less velocity is needed to move the chaff up to the top of the separator 30 and to concen trate the chaff at the top for removal by scoop 63. The separator 30 also includes a partial cover 36 around the top of wall 12' which defines a central open ing 37. An outlet duct 60 extends through opening 37 and downwardly for a short distance into the separator 30 for exhausting the flow of hot gas which is relatively free of chaff. An arrow 61 indicates the general flow of gas. A second relatively small cyclone separator 62 is disposed adjacent separator 30 and constructed and arranged to receive the concentrated chaff by means of scoop 63. The separator 62 is of conventional design and separates the concentrated chaff from the relatively small amount of gas which is removed therewith. The chaff then drops out of the bottom of second separator 62 while the clean gas is returned to the system by means of a pipe 64. FIG. 4 illustrates a further embodiment of the inven tion wherein a radial flame burner 65 is disposed imme diately above the separator 30. As illustrated, a flame 65' heats the clean air which is returned via volutes 66 to a circulation fan (not shown). In this case, the bean hopper 42 is shifted off axis and feeds the coffee beans into one side of the roaster 2. A further embodiment of the invention is illustrated in FIG. 5 which shows a roaster separator combination 5,230, wherein the chaff is removed from a lower portion of the separator 30. In this case, the wall 12" of separator 30 diverges outwardly from the top to bottom to form an inverted cone with its longest radius at the base of the separator 30. The chaff is then fed to the second separa tor 62 through an inlet 62' so that the chaff will be dropped out of the bottom of the second separator 62 while the hot gas will be exhausted through the top thereof. As illustrated, the volute 66 exhausts the gas in a horizontal direction rather than vertically. While the invention has been described in connection with several preferred embodiments, it should be under stood that numerous modifications and changes may be made without departing from the scope of the appended claims. What is claimed is: 1. Apparatus for roasting particulate vegetable mate rial comprising a generally vertically disposed chamber for receiving a charge of particulate vegetable material, means for generating a flow of heated fluid and for introducing the flow of heated fluid into said chamber for roasting the particulate vegetable material within said chamber and with relative movement of the partic ulate vegetable material with respect to said chamber, a centrifugal separator disposed above and abutting said chamber, said centrifugal separator defined by a gener ally cylindrical wall and having a vertical axis which is in general axial aligment with said chamber, means for rotating the heated fluid as it moves upwardly out of said chamber and into and through said separator and for removing any chaff or residue from the heated fluid and means for removing the roasted particulate vegeta ble material from said chamber. 2. Apparatus for roasting particulate vegetable mate rial according to claim 1, in which said centrifugal sepa rator is integral with said chamber. 3. Apparatus for roasting particulate vegetable mate rial according to claim 1, in which said separator in cludes upper and lower portions having a top and base with an opening therein respectively and in which said means for introducing a flow of heated fluid into said separator introduces the flow through said base and into said lower portion and in which said means for rotating the heated fluid mass comprises an element disposed in said opening in said base, said element having a plurality of fluid deflectors which are constructed and arranged to impart rotational movement to the fluid mass as it passes upwardly into and through said separator. 4. Apparatus for roasting particulate vegetable mate rial according to claim3, in which said element is a plate and said fluid deflectors are louvers within said plate. 5. Apparatus for roasting particulate vegetable mate rial according to claim3, which includes means defining a central opening in said top of said separator but re moved from the wall of said separator for removing a major portion of the heated fluid mass which is rela tively free of chaff and means defining a second opening in an upper portion of said separator for removing the chaff with a minor portion of the fluid mass. 6. Apparatus for roasting particulate vegetable mate rial comprising a roasting chamber for receiving the particulate vegetable material, said chamber having a generally circular base and an upwardly extending di vergent wall defining a segment of a cone with upper and lower portions, a central axis and a plurality of openings in said wall, means for heating a fluid mass, means for inducing the heated fluid mass generally tangentially into said chamber to rotate the vegetable

12 11 material about the axis with relative movement with respect to said chamber and for maintaining the rotating vegetable material in a relatively densely packed state during the heating thereof, exit means in said upper portion of said chamber for allowing the heated fluid mass and any chaff produced during heating of the particulate vegetable material to leave the chamber, a centrifugal separator disposed above and abutting said chamber, said separator having a conical wall and a base which defines an opening adjacent to and abutting said exit means of said chamber for receiving the heated fluid mass and any chaff entrained therein, means for rotating the heated fluid mass as it moves upwardly into and through said separator, and exit means in an upper portion of said separator for separately removing a major portion of the fluid mass which is relatively free of chaff and a smaller portion of the fluid mass with chaff entrained therein from said separator and means for removing the material from said chamber. 7. Apparatus for roasting particulate vegetable mate rial according to claim 6, in which means for rotating the heated fluid mass as it moves upwardly into and through said separator comprises a plate having a plu rality of openings and adjacent louvers therein which are disposed at the base of said separator and which is constructed and arranged to impart rotational move ment to the fluid mass as it passes therethrough. 8. Apparatus for roasting particulate vegetable mate rial according to claim 7 in which the cross-sectional area defined by the openings in said plate are greater than the cross-sectional area defined by the openings in said wall of said chamber so that the velocity of fluid 5,230,281 5 O flow in said separator is substantially less than the veloc ity of fluid flow in said chamber. 9. Apparatus for roasting particulate vegetable mate rial according to claim 8 in which said centrifugal sepa rator is axially aligned with said chamber. 10. Apparatus for roasting particulate vegetable ma terial according to claim 9 in which said centrifugal separator is formed as an integral part of said chamber. 11. Apparatus for roasting particulate vegetable ma terial according to claim 10, in which said exit means in said separator defines a central opening in the top of said separator inwardly from the wall thereof for re moving a majority of said heated fluid mass which is relatively free of chaff and a second opening in said upper portion of said separator for removing the chaff and a minor portion of the heated fluid mass. 12. Apparatus for roasting particulate vegetable ma terial according to claim 11 which includes a hopper for holding a charge of particulate vegetable material, said hopper disposed above said separator and pipe means passing through a center portion of said separator for delivering a charge of vegetable material to said roast ing chamber and valve means disposed between said hopper and said roasting chamber for opening and clos ing and said pipe means. 13. Apparatus for roasting particulate vegetable ma terial according to claim 6 in which said means for inducing the heated fluid mass generally tangentially into said chamber causes a first pressure drop and in which said means for rotating the heated fluid mass as it moves upwardly into and through said separator causes a second pressure drop which is less than the first pres sure drop so that any chaff entrained in the heated fluid mass is moved relatively gently through said separator. 3. k k s: k

III. United States Patent (19) Binacchi. Attorney, Agent, or Firm-Bucknam and Archer 57 ABSTRACT. 6 Claims, 3 Drawing Sheets

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19) 11) 4,167,008 Blickenstaff 45) Sep. 4, 1979

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

(*) Notice: Subject to any disclaimer, the term of this E. E. E. E. O.C.

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

7 IANSNA. (12) Patent Application Publication (10) Pub. No.: US 2003/ A1. (19) United States 2//

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

US A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

United States Patent It 3,593,647

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

United States Patent [11] 3,559,565

![United States Patent [11] 3,559,565 United States Patent [11] 3,559,565](/thumbs/93/114425987.jpg) United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

United States Patent (19) Ludder

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

United States Patent (19) D'Alessandro

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent (19)

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

SIMPLEX STRAINER MODEL 90

The Eaton Model 90 Fabricated Simplex Strainer has been designed for manufacturing flexibility. It can be made for pipeline sizes from 1 to 48 in carbon steel or stainless steel although other materials

The Eaton Model 90 Fabricated Simplex Strainer has been designed for manufacturing flexibility. It can be made for pipeline sizes from 1 to 48 in carbon steel or stainless steel although other materials

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

3,702,608 11/1972 Tibbs. states by bying O st plunger T.

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

JUICE EXTRACTION AND FILTRATION JUICE EXTRACTION METHOD AND EQUIPMENT

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

(12) United States Patent

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

United States Patent (19) Forino

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

INTRODUCTION TO CUSTOM FABRICATED STRAINERS

INTRODUCTION TO CUSTOM FABRICATED STRAINERS Nothing Too Big, Too Small or Too Special When unwanted solid material has to be removed from flowing fluids in order to protect equipment, a HAYWARD Strainer

INTRODUCTION TO CUSTOM FABRICATED STRAINERS Nothing Too Big, Too Small or Too Special When unwanted solid material has to be removed from flowing fluids in order to protect equipment, a HAYWARD Strainer

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

Dec. 9, M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

May 12, ,282,708 T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE. Filed Sept. 26, Sheets-Sheet l. --No.zzzzzzzzzzae.

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

ACME Fluid Systems. Strainer Selection Guidelines Web:

ACME Fluid Systems Strainer Selection Guidelines E-mail: info@strainersindia.com Web: www.strainersindia.com Introduction This document provides a general introduction to the parameters to be kept in mind

ACME Fluid Systems Strainer Selection Guidelines E-mail: info@strainersindia.com Web: www.strainersindia.com Introduction This document provides a general introduction to the parameters to be kept in mind

March 24, 1970 H. H. BRIDGFORD 3,502,488 COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER HUGH. BROGFORD / ATTORNEY

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. Lange (43) Pub. Date: Nov. 22, 2012

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

Center et al. (45. Date of Patent: Aug. 29, 1995

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

United States Patent (19)

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

(12) United States Patent (10) Patent No.: US 6,813,994 B2

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1. Hurley et al. (43) Pub. Date: Aug. 28, PROCESS Publication Classification

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

A33. AORNEY. March 22, G. C. HERZ, 1,850,719. APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC. Filed Dec, l6, l Sheets-Sheet l NVENTOR

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

Sept. 7, l.t. ward 2,092,596 SIPHON

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

United States Patent (19) Kovacevich, Jr.

United States Patent (19) Kovacevich, Jr. 11 Patent Number: Date of Patent: Jun. 9, 1987 54) 76 21 22 63 (51) 52 58 56) WNE DISTRIBUTION METHOD Inventor: Appl. No.: Filed: Sam Kovacevich, Jr., R.R. 1,

United States Patent (19) Kovacevich, Jr. 11 Patent Number: Date of Patent: Jun. 9, 1987 54) 76 21 22 63 (51) 52 58 56) WNE DISTRIBUTION METHOD Inventor: Appl. No.: Filed: Sam Kovacevich, Jr., R.R. 1,

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

United States Patent (19) Aldrich

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

Brewhouse technology

Brewhouse technology For Beer with Character Brewhouse technology The best quality wort for the best quality beer The brewhouse is the heart of every brewery and therefore crucial to the quality of the

Brewhouse technology For Beer with Character Brewhouse technology The best quality wort for the best quality beer The brewhouse is the heart of every brewery and therefore crucial to the quality of the

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0187694 A1 Cai US 2004O187694A1 (43) Pub. Date: (54) (76) (21) (22) (63) HOLDER FOR PRESSURE-BREWING COFFEE DRINK Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0187694 A1 Cai US 2004O187694A1 (43) Pub. Date: (54) (76) (21) (22) (63) HOLDER FOR PRESSURE-BREWING COFFEE DRINK Inventor:

United States Patent (19)

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

Beer Hardware, Systems and Delivery

Beer Hardware, Systems and Delivery An Industry Standard Beer is the number one dispensed beverage in the foodservice industry. Commonly, draft beer is preferred by a wide margin for taste and product

Beer Hardware, Systems and Delivery An Industry Standard Beer is the number one dispensed beverage in the foodservice industry. Commonly, draft beer is preferred by a wide margin for taste and product

2009 Australian & New Zealand Winemakers P/L

2009 Australian & New Zealand Winemakers P/L TECHNICAL ARTICLE Seital Centrifuge: Supreme Clarification For Today s Environment The Seital range of centrifuges represents over 20 years of development and

2009 Australian & New Zealand Winemakers P/L TECHNICAL ARTICLE Seital Centrifuge: Supreme Clarification For Today s Environment The Seital range of centrifuges represents over 20 years of development and

(12) United States Patent (10) Patent No.: US 6,419,120 B1

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

Installation & Parts Manual 2" & 3" High Capacity Strainers For Class 1, Petroleum Applications

Installation & Parts Manual 2" & 3" High Capacity Strainers For Class 1, Petroleum Applications Installation: M200-20 www.lcmeter.com Table of Contents Description Page Number Introduction... 2 What LC

Installation & Parts Manual 2" & 3" High Capacity Strainers For Class 1, Petroleum Applications Installation: M200-20 www.lcmeter.com Table of Contents Description Page Number Introduction... 2 What LC

(12) United States Patent

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

STEAM TUBES OVENS RANGE

STEAM TUBES OVENS RANGE 1 Steam tube deck oven PRIME KAPPA FOKUS MINI STAR STONE MINI STAR RING Multi deck steam tube oven TOWER 2 Steam tube ovens PRIME - KAPPA(Stone heating system) LoGiudice Forni is

STEAM TUBES OVENS RANGE 1 Steam tube deck oven PRIME KAPPA FOKUS MINI STAR STONE MINI STAR RING Multi deck steam tube oven TOWER 2 Steam tube ovens PRIME - KAPPA(Stone heating system) LoGiudice Forni is

(12) United States Patent (10) Patent No.: US 7,325,807 B1. Eason (45) Date of Patent: Feb. 5, 2008

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

TURBOMIXERS AND PREMIXERS. VERTIMIX TURBOMIXER GTM SERIES TURBOMIXER GTM TANK-LESS SERIES TURBOMIXER GMG SERIES PREMIXER PCG SERIES

TURBOMIXER GTM SERIES TURBOMIXERS AND PREMIXERS TURBOMIXER GTM TANK-LESS SERIES TURBOMIXER GMG SERIES VERTIMIX TECHNOLOGY PREMIXER PCG SERIES www.gorreri.com TECHNOLOGIES FOR CONTINUOUS MIXING SPEED RELIABILITY

TURBOMIXER GTM SERIES TURBOMIXERS AND PREMIXERS TURBOMIXER GTM TANK-LESS SERIES TURBOMIXER GMG SERIES VERTIMIX TECHNOLOGY PREMIXER PCG SERIES www.gorreri.com TECHNOLOGIES FOR CONTINUOUS MIXING SPEED RELIABILITY

R. 36. azzo 1/2-Za-Yas. Nov. 18, 1969 J. P. H. LANES 3,478,669 APPARATUS FOR MAKING WINE Z2/27/7212. E. y N AA A. as SS f.

Nov. 18, 1969 J. P. H. LANES APPARATUS FOR MAKING WINE Filed Sept. 16, 1966 2. Sheets-Sheet l R. 36. re-war Nanuma - measuresheat s, a. AA A. E. y N as SS f M Z2/27/7212 azzo 1/2-Za-Yas Nov. 18, 1969 J.

Nov. 18, 1969 J. P. H. LANES APPARATUS FOR MAKING WINE Filed Sept. 16, 1966 2. Sheets-Sheet l R. 36. re-war Nanuma - measuresheat s, a. AA A. E. y N as SS f M Z2/27/7212 azzo 1/2-Za-Yas Nov. 18, 1969 J.

OPERATING MANUAL. Sample PRO 100 Series. Electric Heating. Applies to Versions: SPE1*, SPE2, SPE4, SPE6

OPERATING MANUAL Sample PRO 100 Series Electric Heating Applies to Versions: SPE1*, SPE2, SPE4, SPE6 NOTE: All electrically heated roasters in the Sample PRO 100 Series are modular and this manual applies

OPERATING MANUAL Sample PRO 100 Series Electric Heating Applies to Versions: SPE1*, SPE2, SPE4, SPE6 NOTE: All electrically heated roasters in the Sample PRO 100 Series are modular and this manual applies

The Premium Benefits of Steam Infusion UHT Treatment

EDITORIAL October 2012 The Premium Benefits of Steam Infusion UHT Treatment UHT, or Ultra High Temperature, treatment uses high temperature for a short time to kill micro-organisms in a food or beverage

EDITORIAL October 2012 The Premium Benefits of Steam Infusion UHT Treatment UHT, or Ultra High Temperature, treatment uses high temperature for a short time to kill micro-organisms in a food or beverage

TORTILLA-TORTILLA CHIPS

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

United States Patent (19) Best

United States Patent (19) Best 54 INFRARED GAS GRILL 76 Inventor: Willie H. Best, 18C The Heritage, Columbia, S.C. 29201 (21) Appl. No.: 138,854 22 Filed: Apr. 8, 1980 51) Int. C.... A47J 37/04 52 U.S.C....

United States Patent (19) Best 54 INFRARED GAS GRILL 76 Inventor: Willie H. Best, 18C The Heritage, Columbia, S.C. 29201 (21) Appl. No.: 138,854 22 Filed: Apr. 8, 1980 51) Int. C.... A47J 37/04 52 U.S.C....

The Design and Marketing of a 300 Kilogram Coffee Roaster

The Design and Marketing of a 300 Kilogram Coffee Roaster Marketing: Karolyn Bolay Business: Kelsey Hubbard Team Leader/Engineer: Brittany Looke Engineer: Mark Marshall Engineer: Nathan Moyer US Roaster

The Design and Marketing of a 300 Kilogram Coffee Roaster Marketing: Karolyn Bolay Business: Kelsey Hubbard Team Leader/Engineer: Brittany Looke Engineer: Mark Marshall Engineer: Nathan Moyer US Roaster

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

United States Patent (19) Adams et al.

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

(a) Dead-end/conventional filtration fluid flow perpendicular to the filter medium. (b) Crossflow filtration fluid flow parallel to the filter

FILTRATION (a) Dead-end/conventional filtration fluid flow perpendicular to the filter medium. (b) Crossflow filtration fluid flow parallel to the filter medium. Filtration Generally carry out in the early

FILTRATION (a) Dead-end/conventional filtration fluid flow perpendicular to the filter medium. (b) Crossflow filtration fluid flow parallel to the filter medium. Filtration Generally carry out in the early

(12) United States Patent (10) Patent No.: US 8,601,937 B2

USOO8601937B2 (12) United States Patent () Patent No.: Campetella et al. (45) Date of Patent: Dec., 2013 (54) APPARATUS FOR MAKING COFFEE 5,605,091 A * 2/1997 Garber... 99,330 5,650,186 A * 7/1997 Annoni

USOO8601937B2 (12) United States Patent () Patent No.: Campetella et al. (45) Date of Patent: Dec., 2013 (54) APPARATUS FOR MAKING COFFEE 5,605,091 A * 2/1997 Garber... 99,330 5,650,186 A * 7/1997 Annoni

III. United States Patent (19) 5,590,586 Jan. 7, % 4. Ulfig et al. (75) Inventors: Kimberly A. Ulfig, Glen Ellyn;

United States Patent (19) Ulfig et al. 54 KITCHEN LAYOUT, SYSTEM (75) Inventors: Kimberly A. Ulfig, Glen Ellyn; Patricia A. Venetucci, Hawthorn Woods, both of Ill. (73) Assignee: Restaurant Technology,

United States Patent (19) Ulfig et al. 54 KITCHEN LAYOUT, SYSTEM (75) Inventors: Kimberly A. Ulfig, Glen Ellyn; Patricia A. Venetucci, Hawthorn Woods, both of Ill. (73) Assignee: Restaurant Technology,

brewing device, and particularly an espresso machine. 4,871,555 10/1989 Schwartz et al /82

USOO5895672A United States Patent 19 11) Patent Number: Cooper ) Date of Patent: Apr. 20, 1999 54) PRODUCT AND PROCESS FOR PREPARING 5,072,661 12/1991 Kondo... 99/296 A TEA EXTRACT 5,104,666 4/1992 Sanvitale...

USOO5895672A United States Patent 19 11) Patent Number: Cooper ) Date of Patent: Apr. 20, 1999 54) PRODUCT AND PROCESS FOR PREPARING 5,072,661 12/1991 Kondo... 99/296 A TEA EXTRACT 5,104,666 4/1992 Sanvitale...

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

Aaawaw A. M1axsom. - A 474/2/sr.przezz' SecY72/7. April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES.

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

SOFTDOUGH & COOKIES cat_softdough_rev12gea.indd 1 22/07/

SOFTDOUGH & COOKIES The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given them our

SOFTDOUGH & COOKIES The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given them our

HONEY. Food and Agriculture Organization of the United Nations

HONEY Food and Agriculture Organization of the United Nations HONEY 1.- Honey General Information Honey has a fluid, crystallized (total or partially) consistence. Present a high viscosity and density

HONEY Food and Agriculture Organization of the United Nations HONEY 1.- Honey General Information Honey has a fluid, crystallized (total or partially) consistence. Present a high viscosity and density

30 kg of peanuts takes 30 minutes to roast. Plus the peanuts are evenly roasted with fewer losses due to over roasting.

PEANUT ROASTER Background In urban and sub-urban areas, roadside peanut vendors are a common sight. This is because roasted peanuts are a popular snack and there is a good market. The street vendors use

PEANUT ROASTER Background In urban and sub-urban areas, roadside peanut vendors are a common sight. This is because roasted peanuts are a popular snack and there is a good market. The street vendors use

Paper 7: Technology of Milk and Milk Products. Module no. 6: Cream Separation in Dairy Industry

Paper 7: Technology of Milk and Milk Products Module no. 6: Cream Separation in Dairy Industry Introduction Milk from the cattle contains a number of large and small butter-fat particles held in suspension.

Paper 7: Technology of Milk and Milk Products Module no. 6: Cream Separation in Dairy Industry Introduction Milk from the cattle contains a number of large and small butter-fat particles held in suspension.

Table of Contents. Foundation and Preparation 2 Hearth Base Dimensions 2. Laying the Inner Hearth 3 Inner Hearth Dimensions 4

Table of Contents Foundation and Preparation 2 Hearth Base Dimensions 2 Laying the Inner Hearth 3 Inner Hearth Dimensions 4 Constructing the Firebox 5 Face Opening Dimensions 5 Setting the Rumford Throat

Table of Contents Foundation and Preparation 2 Hearth Base Dimensions 2 Laying the Inner Hearth 3 Inner Hearth Dimensions 4 Constructing the Firebox 5 Face Opening Dimensions 5 Setting the Rumford Throat

Sugar maple tree named Legacy

( 1 of 1 ) United States Patent PP4,979 Wandell February 1, 1983 Sugar maple tree named Legacy Abstract This disclosure concerns a new and distinct variety of Acer saccharum (commonly known as sugar maple

( 1 of 1 ) United States Patent PP4,979 Wandell February 1, 1983 Sugar maple tree named Legacy Abstract This disclosure concerns a new and distinct variety of Acer saccharum (commonly known as sugar maple

Thermal Hydraulic Analysis of 49-2 Swimming Pool Reactor with a. Passive Siphon Breaker