R. 36. azzo 1/2-Za-Yas. Nov. 18, 1969 J. P. H. LANES 3,478,669 APPARATUS FOR MAKING WINE Z2/27/7212. E. y N AA A. as SS f.

|

|

|

- Helen Ramsey

- 5 years ago

- Views:

Transcription

1 Nov. 18, 1969 J. P. H. LANES APPARATUS FOR MAKING WINE Filed Sept. 16, Sheets-Sheet l R. 36. re-war Nanuma - measuresheat s, a. AA A. E. y N as SS f M Z2/27/7212 azzo 1/2-Za-Yas

2 Nov. 18, 1969 J. P. H. LANES APPARATUS FOR MAKING WINE Filed Sept. 16, Sheets-Sheet 2 E. 2 E. É w^2-e earaz's 12 ZaMas 21 eatest 2á. 2a

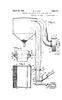

3 United States Patent Office Patented Nov. 18, APPARATUS FOR MAKING WINE Jacques P. H. Lanes, 12 Rue du Palais, Carcassonne, Aude, France Filed Sept. 16, 1966, Ser. No. 580,007 Claims priority, application France, Sept. 17, 1965, 31,873; Feb. 9, 1966, 49,020 Int, C, C12b 1/10 U.S. C Claims ABSTRACT OF THE DISCLOSURE Apparatus for the fermentation of crushed grapes.com prising a vertically positioned fermentation tank, hav ing a top portion, closed body and a cylindrical portion intermediate said top and bottom. A conduit for intro ducing crushed grapes into the tank is provided at the lower portion thereof. The apparatus also includes means for washing the cap formed at the top portion of the tank and a conduit in the cylindrical portion of the tank for withdrawing wine therefrom. This conduit also in cludes a recycle conduit which communicates with the upper portion of the tank. The apparatus also includes injector means adapted to be vertically reciprocated with in the upper portion of the tank. The present invention relates to an apparatus for mak ing wine of regular quality, under excellent economic conditions. The invention is particularly related to ap paratus for the continuous fermentation in a single tank of the vintage of a geographic region during the harvest. It is known that, to effect substantial savings in the economy and labor relating to fermentation processes, wine making techniques have already been proposed whereby wine from the vintage of a given region can be prepared in a single tank as the harvest proceeds. How ever, these processes have generally been unsatisfactory because of incomplete fermentation and because of the nonuniform quality of the grapes utilized which often de pends upon meteorological and geographic factors. Generally, in making wine, grapes are pressed to provide a suspension of heavy parts (chiefly seeds) and light parts (stems, pulp, skins) in a fresh must. There after, the fresh must be introduced into a fermentation tank so that conversion of the sugar contained in the must to alcohol can occur naturally, under the effect of the yeasts that bloom in maturity on the skin portion of the fresh must. It has been found that approximately 125 kilos of grapes, containing, e.g., 15.7 kilos sugar, furnish one hectoliter wine at ten degrees Gay Lussac which corre sponds to an alcohol content of 8 kilos. During such a process, it has been observed 3.9 m.3 carbon dioxide are produced with a release of 2880 calories which provides a downward separation of the heavy products and upward separation of the light products, the light products form ing a cap in the top of the fermentation vessel. This cap contains products that are necessary for good wine quality, and it has been found that their recovery can be effected if the cap is subjected to an alcohol extrac tion process. Consequently, the cap has heretofore been meticu lously washed to remove their advantageous constituents with the fermenting wine produced in the tank. But the known processes of washing by lateral injection of fer menting wine toward the core of the cap have turned out to be ineffective. Extractive washing of part of the cap with reinjection after stirring with the fermenting must upset the regular cycle required in fermenting the must. Consequently, the production of the good quality wine in the tank is generally significantly impaired. 5 O Moreover, it has been observed that the heat generated in the fermentation process raises the temperature of the must and the cap, which, in turn, advantageously ac celerates the yeast activity. However, it is advisable not to exceed a temperature limit that appears to be a func tion of the quality of the grapes, because beyond this limit and in any case at about 40 C. the yeasts become inactive and fermentation ceases. The cooling processes thus far proposed to increase the daily production of the tanks while insuring the most favorable temperatures for yeast activity have proved to be ineffective because trickling or spraying of the vats with cool water, or cooling of the wine by circulation in a heat exchanger and reinjection into the tank have prac tically no effect in the mass of the cap which not only contains components that are especially resistant to heat exchange but is also the hottest part of the tank. Further, in known wine making processes and ap paratus difficulties are encountered in removing developed wine and washing the wine due to the strainers used in conventional apparatus. The strainers often are obstruct ed by the light materials suspended in the tank. Furthermore, various component parts are often mounted inside conventional fermenting tanks and their presence constitutes serious obstacles to the upward move ment of the cap. A blocking of the cap often involves not only stopping the operation of the fermenter but also a deterioration of the must charge because of the combined stresses of hydrostatic thrust of the cap and the pressures due to irregular escape of the carbon dioxide. Finally, disruption of the operation of known wine making ap paratus is often caused by irregularities of the amounts of cap produced by a given source of grapes which can depend on the quality of the vines, the geographic region from which they originate, as well as the year. It has thus been found that conventional apparatus for making wine does not permit simultaneous washing and extraction of the cap and wine in amounts appropri ate to the delivery of must. Further, these imperfections lead to large proportions of lees being deposited in the Storage tanks. Further, conventional fermentation tanks make it difficult during the harvest to provide a separation of the wines as required by the differences in quality of the batches of grapes from which these wines are made. It is therefore a principal object of the present inven tion to overcome the disadvantages of known fermenting apparatus in making wine. It is a further object to provide a fermenting appara tus which insures the preparation of a wine, in a single tank, as the harvest of a vintage in a particular geo graphic region progresses. The invention concerns a wine making aparatus which is particularly efficient for making wine and which is re markable in that it permits a washing and simultaneous extractions of Wine and cap according to desired propor tions, especially according to the proportions in which they are present in a vintage. Other characteristics and advantages of the invention are evident from the description that follows with refer ence to the attached drawings which are only presented as nonlimitative examples. FIGURE 1 is an elevational view, in section, through the apparatus; FIGURE 2a is a fragmentary cross-sectional view along the line A-A of FIGURE 1; FIGURE 2b is a fragmentary cross-sectional view along the line B-B of FIGURE 1; FIGURE 3 is a fragmentary elevational view, in sec tion, through apparatus of another embodiment of the in stant invention;

4 3 FIGURES 4a and 4b are fragmentary top plan views of the basket and cleaning comb mechanism associated with the fermentation vessel of this invention; and FIGURE 5 is a fragmentary enlarged elevational view of the control mechanism employed with the cap washing means and the cleaning comb mechanism of the invention. Referring to the drawings, the novel apparatus ac cording to the embodiment shown in FIGURE 1 com prises a tank 1, preferably of reinforced concrete, having a conical bottom 2 directly supported on a foundation 4. The conical bottom mergers into a cylindrical portion of the tank provided with inlet means 15 opening into the lower third of the tank. The cylindrical portion of the tank in turn is provided with a dome-like top portion 11. Intermediate the cylindrical portion of the tank there is provided an annular chamber 5, rectangular in Section, in communication with the interior of the tank by means of a basket mechanism 17 comprising a plurality of ver tically disposed spacedly removed bars 162a fixedly at tached to circumferentially extending vertically spaced retainer bars 163. Bars 162a, as best seen in FIGURE 4a, comprise substantially dish-shaped members, the sides of which are directed inwardly with the sides of adja cent bars being spaced removed from each other to pro vide passageway 164 from the interior of the tank to the annular chamber 5. Intermediate proximate sides of ad jacent bars 162a and within each passageway i64 there is provided for vertical reciprocal movement the teeth of cleaning comb mechanism. 19 which extends circumfer entially around the tank E. The vertical reciprocal move ment of the comb mechanism is limited by the upper and lower retainer bars 163. The comb mechanism 19 is op eratively connected to vertically extending rod 20 housed within a vertically extending bore in the wall of the tank 1 and operatively connected at one end to reciprocating means such as cam means 27 and motor 167. A similar annular chamber 5a is provided between the lower part of the cylindrical portion of the tank and the conical bottom 2 to provide communication with the interior of the tank therewith by means of a basket mech anism 17a essentially of the same construction as basket mechanism 17, described above. A comb mechanism sub stantially the same as comb mechanism 19, above, is also employed with basket mechanism 17a and is also opera tively connected to rod 20 for vertical reciprocation of the teeth thereof between the passageways provided by the space between proximate sides of adjacent dish-shaped vertically extending bars which comprise basket mech anism 17a. Annular chamber 5 communicates with the bottom of reservoir 107 via conduit 105 and with the bottom of res ervoir 107a via conduit 165, three-way valve 166 and con duit 151. Annular chamber 5a communicates with the bot tom of reservoir 07a via conduit 165a, three-way valve 166 and conduit 161. Reservoirs 107 and 107a are sepa rated by a common longitudinally extending wall and are in communication with each other via annular chamber 5. Housed within reservoir 107 is articulated decanting elbow 112 in fluid-tight communication with conduit means leading from the bottom of the reservoir to a wine storage tank or vessel (not shown). Reservoir 07 is also provided with float valve means A to control the liquid level within the reservoir. Housed within reservoir 107a is float valve means B to control the liquid level therein. Additionally, reservoir 107a is in communication with the inlet side of pump means 17, the discharge side of which communicates with a conduit 152 leading to an assembly of tubes 87 immersed in a circumferentially extending trough 14 on the outer surface of dome-like top 11 of the tank 1. Also in communication with the tube assem bly 87 is flexible conduit means 85 in communication with one end of injector means 84 extending downwardly into the vessel 1 through the central opening 12 of the dome top 1 which is supported by annular walls 6 and 7 having a diameter greater than the wall of the cylin O drical portion of the tank. The lip 8 of the wall of the cylindrical portion of the tank extends above the an nular wall 6 to form with annular wall 7 circular chan nel 9. Injector means 84 is arranged to reciprocate vertical ly in hollow shaft 58 to which is connected a radially extending rotary sweep device 58a. A cam 27 keyed on the shaft of a reduction motor 167 controls the vertical movement of the injector means 84 within the vessel, said injector means being provided with vertical aligning guide means 32. The shaped discharge end of injector means 84 is provided with radially disposed apertures to produce a jet-like spray discharge therefrom. Rotary sweep device 58a is driven by motor 57 and has depending from the extremities thereof brushes 52 engag ing the circular channel 9 which is provided with dis charge trap 10 for removal of the waste light portions of the charge to the vessel. A radially extending conveyor 36 provided with scrapers and driven by motor 48 is ro tatably mounted beneath the rotary sweep device and above the rim of the tank 1. The conveyor 36 extends outwardly a distance sufficient to skim the waste at the top of the tank into the channel 9. Within the conical bottom 2 of the tank 1 there is pro vided pomace removal means 80, preferably, a screw con veyor. Any wine pressed from the pomace can be led to a storage vessel via conduit means controlled by valve 83. Additionally, conduit 172, in communication with the lower part of the cylindrical portion of the tank 1 leads to a storage vessel (not shown) for conveyance thereto of wine located within the tank above conduit 172. Leading from the storage tank into which the wine pressed from the pomace has previously been led via conduit means controlled by valve 83 is conduit 171 which, in turn, is in communication with the interior of the tank adjacent the conical bottom 2. Also in communi cation with the same storage tank via a three-way valve is conduit 173 which is in communication with the in terior of the tank 1 above the basket mechanism 17 and adjacent thermostat means 120. In operation, tank 1 is charged with grapes using stand ard must pumps through conduit 15 leading to the lower third of the tank and the fermentation process is begun The light parts of the crushed grape charge separate from the fermenting must to form the cap, the upper level of which is in contact with the rim 8. The free surface of the wine a, b is established at a level at which the decanter elbow 112 is adjusted. To enrich the fermenting wine with the valuable con stituents of the cap, the following procedures are effected. Pump 117 is activated with valve 166 being positioned to deliver wine from chamber 5 via conduit 165 and 151 to reservoir 107a and thence to heat exchange coil 87 lo cated in trough 4. From coil 87 the wine is introduced in a jet spray from the injector 84 via flexible conduit 85, as shown by the directional arrow f2. The tip of injector 84 can be arranged at a predetermined level in the body of the cap, as indicated by arrow fa by means of the con trol mechanism shown in FIGURE 5. This control mech anism comprises a cam 27 keyed on the shaft of a reduc tion motor 162 to cause vertical reciprocation of the in jector 84 in the injector guides 32. It is also possible to cool or heat the cap and thus in Sure the desired rate of fermentation by controlling the temperature of the washing wine as a function of the heat exchange medium surrounding the heat exchange coil 87 in the trough 88 and of the cap temperature. Additional ly, if desired, valve or by-pass devices can be utilized, as well as means associated with pump 117 to control the flow and pressure of the cap washing medium. Under pressure of radial jets of washing wine, which pressure can be appropriate for the flow resistance of the emergent part of the cap, it is possible to methodically wash the body of the cap at a specific temperature. This

5 5 cap washing can also be effected continuously by contin uous operation of cam 27. Also, in case of inadequate reach of the jets from in jector 84 for rapid washing of the whole cap, taking into account the delivery cycle of must to the tank, a plurality of injectors 168 can be utilized, as best seen in FIGURE 2. These injectors can be retracted upwards in the course of operation of rotary sweep device 58a, and synchro nized therewith. Because of the axial position of the injector and/or the means for upward retraction of the injectors, extractor 36 can be set into operation and driven by rotary sweep de vice 58a to sweep the entire cap surface and remove dur ing the washing the parts of the cap that are exhausted by the said washing. It is to be noted that these operations insure a very efficient filtration because the washing downward at va rious levels makes it possible to reduce to 2% the pro portion of less in the storage tanks, whereas the most favorable percentage afforded by known apparatus is about 6 to 8%. Moreover, the washed wine is below free surface a-b and the zone of separation of the washed wine and the freshly fermented must is lowered a little at a time, until it reaches the level of pipe 105 and then, if there is no charging, to the level of pipe 165. Accordingly, it is possible to effect a recycling of the washing wine as a function of the quality of the treated vintage. Thus, the washing cycle can be stopped when a charge at 15 provides a wine which it is desired to remove via conduit 105 and decanting elbow 112 to the storage tanks (not shown). The arrangement of two adequately spaced levels of pipes 105 and 165 facilitates washing of the cap and the cooling thereof by the fermenting wine, as well as supply ing the storage tanks with washed wine. In addition, the washing process makes possible the detection of any clog ging of basket mechanism 17. The operation of pump 117 effects the lowering of level c-d of reservoir 107a with reference to level a-b of the tank 1, until the charge of tank 1 on the reservoir corre sponds to resistance due principally to the clogging of baskets 17. When chamber 5 is inadequately supplied be cause of clogging, level c-d is lowered until a float B in said reservoir 107a acts on its lower stop t which is pro vided to control by a signal (an electric eye, for example) the halting of pump 117 and the automatic starting of the cleaning combs 19. Moreover, to avoid a sudden and excessive rise of level a-b of the tank, reservoir 107 is equipped with a float A which, by means of a stop, is able to trigger the opening of an electric valve 104 to accelerate discharge of the wine toward the storage tanks. It can be seen that reservoirs 107 and 107a comprise an arrangement of vessels that communicate with each other via chamber 5. In order to avoid adjustment of the position of floats A-B for every level a-b, the movements of elbow 112 and balances GA-GB are synchronized by means of a double-armed support 153, which supports the balances as best seen in FIGURES 1 and 3. The upright of this support is engaged in a vertical slide 153c so that its foot, furnished with a roller 154, can be applied against the horizontal bar 155 whose han dles 156a and 156b are of a length equal to that of elbow 112 associated with bar 156a whose direction of move ment is represented by arrows f1 and f1, as seen in FIG URE 3. It can thus be seen that the apparatus of this invention permits removal from the tank 1, simultaneously as re quired, even in the course of a washing or in the course of must charging, of quantities of cap and wine, specifi cally quantities according to the proportions presented by the grapes being treated. It is to be noted that in tank 1 there is no element to O impair formation and upward movement of the cap. It is also to be observed that the drawing off of washing wine and developed wine is effected in chamber 5, below the Cap. Also, because of its peripheral arrangement, the col lecting surface of chamber 5 is obviously as large as the dimensions of the tank permit, taking into account the separation to be maintained between pipes 105 and 165 to effect desired separation of the wines. As a consequence, the rate of removal will be low and thus clogging of the baskets will be avoided. Baskets 17 and 17a, as best seen in FIGURES 4a and 4b, are advantageously constructed of bars simply fixed on the flat bars that can be adapted to the curvature of the frame of tank 5. The said bars are conveniently con structed to provide profiled sections 162a, 162b, whose ends form open V-shaped apertures 164 which have proved to be very efficient for pulp retention outside chamber 5 and for pulp disengagement by the upward movement of the stems toward the cap. Finally, this apparatus readily allows successive fer mentations of batches of grapes of different qualities and the separation of the wines produced from these different qualities of grapes. In such operations, after the final charge at 15 of a batch of must to fill the tank, the fer mentation in the tank is accelerated as much as the wash ing of the cap will allow. In accordance with such proce dures, valve 166 is positioned to communicate chamber 5a with conduit 165a and reservoir 107a. Pump 117 is activated, the cold must delivered to coil 87 in trough 88 is heated by maintaining a hot water bath in trough 88, so that the most favorable temperature for activity of the yeast is rapidly reached. As soon as the fermentation gen erates sufficient heat, the heating of the water in trough 88 is halted. The water will then be cooled, as soon as the cap reaches the desired temperature. These bath heating and cooling operations can be controlled automatically by thermostat 120. When the fermentation in the tank has advanced suffi ciently, the cap washing procedure is stopped and wine taken from a storage tank is injected into tank 1 via pas sage 171, thereby lifting the cap so that it can be com pletely removed by conveyor 36. Then screw 80 will be manually operated to extract the pomace collected on the tank bottom. Finally, racking to the storage tanks can be effected by opening conduit 172 to deliver thereto all the wine above the said conduit. The wine below conduit 172 can be re served to initiate the fermentation of the freshly charged grapes. Of course, the wine that contains the cap and the pomace can be extracted in a press, and the "press wine' can be charged into the tank via conduit 15 or conduit 173. In accordance with another embodiment of the instant invention especially designed for small-scale apparatus, as best seen in FIGURE 3, the charge to the tank 1 can be effected manually, and a cap extractor can comprise sim ply a small trough equipped with a conveyor screw 158. The trough can be articulated by bars to a support rod 160 provided to slide and turn in a sleeve 151 which, in turn, can be enclosed in the curb at the top of the vat. Finally, the Washing circuit of this wine making appara tus may comprise a heat exchanger and, in this connec tion, coil 87 could be replaced by an exchanger associated with a refrigerating machine and a boiler. Obviously, the present invention is not limited to the above terms but comprises, on the contrary, all modifica tions within the ability of those skilled in the art. I claim: 1. Apparatus for the fermentation of crushed grapes comprising a vertically positioned fermentation tank, hav ing a top portion, closed body and a cylindrical portion intermediate said top and bottom, a conduit for intro ducing crushed grapes into the lower portion of said tank, means for Washing the cap formed at the top portion of

6 7 said tank thereby extracting wine soluble constituents thereof to enhance the quality of said wine, first conduit means in the cylindrical portion of said tank for with drawing wine therefrom, said conduit means including a recycle conduit in communication with the upper portion of said tank and injector means adaptable to be vertically reciprocated within the upper portion of said tank at a predetermined level in said cap formed therein. 2. The apparatus of claim 1 wherein said injector means comprises at least a tube having a plurality of radially extending holes adjacent the discharge end thereof. 3. The apparatus of claim including a first annular chamber in communication with the interior of said tank in the cylindrical portion thereof, said conduit leading from said annular chamber and being in communication with the upper portion of said tank. 4. The apparatus of claim 3 including open basket means in the cylindrical portion of said tank for com munication from the interior of said tank to said annular chamber, said open basket means comprising a plurality of dish-shaped vertically extending members, the edges of said dish-shaped members being directed inwardly of said tank, the edges of each dish-shaped member being laterally spaced from the next adjacent dish-shaped men ber and cleaning means disposed within the spaces between edges of adjacent dish-shaped members and adaptable to be vertically reciprocated therein. 5. The apparatus of claim 3 including a second annular chamber in communication with the interior of said tank in the cylindrical portion thereof, said second annular chamber being spacedly removed from said first annular chamber and positioned adjacent the lower part of said cylindrical portion, conduit means leading from said sec 8 ond annular chamber and in communication with the upper portion of said tank and second open basket means in said lower part of said cylindrical portion of said tank for communication from the interior of said tank to said Second annular chamber, said second open basket means comprising a plurality of dish-shaped vertically extending members, the edges of said dish-shaped members being directed inwardly of said tank, the edges of each dish shaped member being laterally spaced from the next adja cent dish-shaped member and cleaning means disposed within the spaces between adjacent dish-shaped members and adaptable to be vertically reciprocated therein. 6. The apparatus of claim 5 including reservoir means in communication with said conduit means from said first and second annular chamber and with said recycle con duit means, said reservoir provided with means for regulat ing the liquid level in said tank and pump means for Withdrawing wine from said annular chambers and for recycling wine to the top portion of said tank. 7. The apparatus of claim 3 including third conduit means leading from said first annular chamber and in communication with the interior of said tank at a level below said first conduit means. 8. The apparatus of claim 7 including means for regu lating the temperature of the wine in said recycle conduit. References Cited UNITED STATES PATENTS 2,034,468 3/1936 Heuser X 2,536,994 1/1951 Cremaschi ,758,0 8/1956 Metz ROBERT W. JENKINS, Primary Examiner

(*) Notice: Subject to any disclaimer, the term of this E. E. E. E. O.C.

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

III. United States Patent (19) Binacchi. Attorney, Agent, or Firm-Bucknam and Archer 57 ABSTRACT. 6 Claims, 3 Drawing Sheets

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

JUICE EXTRACTION AND FILTRATION JUICE EXTRACTION METHOD AND EQUIPMENT

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

Sept. 7, l.t. ward 2,092,596 SIPHON

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

United States Patent (19) 11) 4,167,008 Blickenstaff 45) Sep. 4, 1979

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

Dec. 9, M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

7 IANSNA. (12) Patent Application Publication (10) Pub. No.: US 2003/ A1. (19) United States 2//

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

May 12, ,282,708 T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE. Filed Sept. 26, Sheets-Sheet l. --No.zzzzzzzzzzae.

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

United States Patent It 3,593,647

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0187694 A1 Cai US 2004O187694A1 (43) Pub. Date: (54) (76) (21) (22) (63) HOLDER FOR PRESSURE-BREWING COFFEE DRINK Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0187694 A1 Cai US 2004O187694A1 (43) Pub. Date: (54) (76) (21) (22) (63) HOLDER FOR PRESSURE-BREWING COFFEE DRINK Inventor:

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

United States Patent (19) Kovacevich, Jr.

United States Patent (19) Kovacevich, Jr. 11 Patent Number: Date of Patent: Jun. 9, 1987 54) 76 21 22 63 (51) 52 58 56) WNE DISTRIBUTION METHOD Inventor: Appl. No.: Filed: Sam Kovacevich, Jr., R.R. 1,

United States Patent (19) Kovacevich, Jr. 11 Patent Number: Date of Patent: Jun. 9, 1987 54) 76 21 22 63 (51) 52 58 56) WNE DISTRIBUTION METHOD Inventor: Appl. No.: Filed: Sam Kovacevich, Jr., R.R. 1,

3,702,608 11/1972 Tibbs. states by bying O st plunger T.

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

United States Patent (19)

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

March 24, 1970 H. H. BRIDGFORD 3,502,488 COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER HUGH. BROGFORD / ATTORNEY

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

United States Patent (19) Forino

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

United States Patent [11] 3,559,565

![United States Patent [11] 3,559,565 United States Patent [11] 3,559,565](/thumbs/93/114425987.jpg) United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

PATENT ATTORNEYS EXAMINATION

2014 PATENT ATTORNEYS EXAMINATION PAPER E The New Zealand Law and Practice relating to Interpretation and Criticism of Patent Specifications Regulation 158 (1) (e) Duration: 4 hours (plus 10 minutes for

2014 PATENT ATTORNEYS EXAMINATION PAPER E The New Zealand Law and Practice relating to Interpretation and Criticism of Patent Specifications Regulation 158 (1) (e) Duration: 4 hours (plus 10 minutes for

(12) United States Patent (10) Patent No.: US 6,419,120 B1

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

AWRI Refrigeration Demand Calculator

AWRI Refrigeration Demand Calculator Resources and expertise are readily available to wine producers to manage efficient refrigeration supply and plant capacity. However, efficient management of winery

AWRI Refrigeration Demand Calculator Resources and expertise are readily available to wine producers to manage efficient refrigeration supply and plant capacity. However, efficient management of winery

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. Lange (43) Pub. Date: Nov. 22, 2012

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

United States Patent (19) D'Alessandro

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

SIMPLEX STRAINER MODEL 90

The Eaton Model 90 Fabricated Simplex Strainer has been designed for manufacturing flexibility. It can be made for pipeline sizes from 1 to 48 in carbon steel or stainless steel although other materials

The Eaton Model 90 Fabricated Simplex Strainer has been designed for manufacturing flexibility. It can be made for pipeline sizes from 1 to 48 in carbon steel or stainless steel although other materials

(51) Int Cl.: A47J 31/18 ( ) A47J 31/46 ( )

(19) TEPZZ 7_ 95B_T (11) EP 2 712 295 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention of the grant of the patent: 31.08.16 Bulletin 16/35 (21) Application number: 12712780.1

(19) TEPZZ 7_ 95B_T (11) EP 2 712 295 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention of the grant of the patent: 31.08.16 Bulletin 16/35 (21) Application number: 12712780.1

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

INTRODUCTION TO CUSTOM FABRICATED STRAINERS

INTRODUCTION TO CUSTOM FABRICATED STRAINERS Nothing Too Big, Too Small or Too Special When unwanted solid material has to be removed from flowing fluids in order to protect equipment, a HAYWARD Strainer

INTRODUCTION TO CUSTOM FABRICATED STRAINERS Nothing Too Big, Too Small or Too Special When unwanted solid material has to be removed from flowing fluids in order to protect equipment, a HAYWARD Strainer

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

United States Patent (19) Bowen et al.

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

(12) United States Patent

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

United States Patent (19) Ludder

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

Notes on pressure fermentation

Notes on pressure fermentation Geoff Dye During World War II the fermenting room at Coopers Brewery, Southampton, received a direct hit which put it completely out of action, but left the brewhouse (wort

Notes on pressure fermentation Geoff Dye During World War II the fermenting room at Coopers Brewery, Southampton, received a direct hit which put it completely out of action, but left the brewhouse (wort

Aaawaw A. M1axsom. - A 474/2/sr.przezz' SecY72/7. April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES.

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

MODELS 1315 & 1315-S La Pavoni CLUB COMBO

IMPORTANT WARNINGS MODELS 1315 & 1315-S La Pavoni CLUB COMBO DUET Never operate your espresso machine without water in the tank. This may cause premature pump failure. Do not allow the power cord to come

IMPORTANT WARNINGS MODELS 1315 & 1315-S La Pavoni CLUB COMBO DUET Never operate your espresso machine without water in the tank. This may cause premature pump failure. Do not allow the power cord to come

(12) United States Patent (10) Patent No.: US 6,813,994 B2

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

US 20140123859A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0123859 A1 Verbeek (43) Pub. Date: May 8, 2014 (54) PREPARATION OF AN ARABIC COFFEE (52) U.S. Cl. BEVERAGE

US 20140123859A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0123859 A1 Verbeek (43) Pub. Date: May 8, 2014 (54) PREPARATION OF AN ARABIC COFFEE (52) U.S. Cl. BEVERAGE

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

For Beer with Character

Yeast technology For Beer with Character Yeast technology Fresh yeast for Beer with Character The raw material yeast plays a crucial role in breweries. A wide range of flavors can be produced in beer using

Yeast technology For Beer with Character Yeast technology Fresh yeast for Beer with Character The raw material yeast plays a crucial role in breweries. A wide range of flavors can be produced in beer using

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

A33. AORNEY. March 22, G. C. HERZ, 1,850,719. APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC. Filed Dec, l6, l Sheets-Sheet l NVENTOR

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

United States Patent (19)

United States Patent (19) Brooke 54 METHOD AND APPARATUS FOR MANUFACTURING TEA BAGS AND THE LIKE 75 (73) Inventor: Assignee: Arthur A. Brooke, Toronto, Canada Delamere & Williams Company, Limited, Toronto,

United States Patent (19) Brooke 54 METHOD AND APPARATUS FOR MANUFACTURING TEA BAGS AND THE LIKE 75 (73) Inventor: Assignee: Arthur A. Brooke, Toronto, Canada Delamere & Williams Company, Limited, Toronto,

United States Patent (19)

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993

USOO5230281A United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993 (54) APPARATUS FOR ROASTING COFFEE 4,924.765 5/1990 Pera... 99/470 BEANS OR THE LIKE

USOO5230281A United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993 (54) APPARATUS FOR ROASTING COFFEE 4,924.765 5/1990 Pera... 99/470 BEANS OR THE LIKE

Feb. 20, 1968 S. L, BLACK 3,369,478 SINGLE CUP, DRY WASTE COFFEE BREWING AND DISPENSING MECHANISM

Feb. 20, 1968 S. L, BLACK SINGLE CUP, DRY WASTE COFFEE BREWING AND DISPENSING MECHANISM Filed April 22, 1966 4. Sheets-Sheet Feb. 20, 1968 S. l. BLACK SINGLE CUP, DRY WASTE COFFEE BREWING AND DISPENSING

Feb. 20, 1968 S. L, BLACK SINGLE CUP, DRY WASTE COFFEE BREWING AND DISPENSING MECHANISM Filed April 22, 1966 4. Sheets-Sheet Feb. 20, 1968 S. l. BLACK SINGLE CUP, DRY WASTE COFFEE BREWING AND DISPENSING

52 U.S. Cl... 99/295; 99/299; 99/305; 99/ / ) References Cited U.S. PATENT DOCUMENTS 1,778,792 10/1930 Cameron...

United States Patent (19) Glucksman (54) APPARATUS FOR BREWING COFFEE 76) Inventor: Dov Z. Glucksman, 137 Larch Row, Wenham, Mass. 01984 21 Appl. No.: 636,137 22 Filed: Dec. 31, 1990 51 Int. Cl.5......

United States Patent (19) Glucksman (54) APPARATUS FOR BREWING COFFEE 76) Inventor: Dov Z. Glucksman, 137 Larch Row, Wenham, Mass. 01984 21 Appl. No.: 636,137 22 Filed: Dec. 31, 1990 51 Int. Cl.5......

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

Center et al. (45. Date of Patent: Aug. 29, 1995

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

US 20070178190A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0178190 A1 Vatelot (43) Pub. Date: Aug. 2, 2007 (54) GRAPE TREATMENT METHOD FOR WINE (30) Foreign Application

US 20070178190A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0178190 A1 Vatelot (43) Pub. Date: Aug. 2, 2007 (54) GRAPE TREATMENT METHOD FOR WINE (30) Foreign Application

United States Patent (19)

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

Grooving Tool: used to cut the soil in the liquid limit device cup and conforming to the critical dimensions shown in AASHTO T 89 Figure 1.

DETERMINING THE LIQUID LIMIT OF SOILS FOP FOR AASHTO T 89 Scope This procedure covers the determination of the liquid limit of a soil in accordance with AASHTO T 89-13. It is used in conjunction with the

DETERMINING THE LIQUID LIMIT OF SOILS FOP FOR AASHTO T 89 Scope This procedure covers the determination of the liquid limit of a soil in accordance with AASHTO T 89-13. It is used in conjunction with the

White Paper. Dry Ingredient Chilling for Bakery Manufacturers.

White Paper. Dry Ingredient Chilling for Bakery Manufacturers. 02 Dry Ingredient Chilling for Bakery Manufacturers. Abstract Bakery manufacturers know that controlling dough temperature in the mixer is

White Paper. Dry Ingredient Chilling for Bakery Manufacturers. 02 Dry Ingredient Chilling for Bakery Manufacturers. Abstract Bakery manufacturers know that controlling dough temperature in the mixer is

» Red wine mash flooder FD-MÜ

» Red wine mash flooder FD-MÜ Speidel s FD-MÜ is an upright standing red wine mash fermentation tank with a simple but efficient technology. After the fermentation has started and a marc cake has formed

» Red wine mash flooder FD-MÜ Speidel s FD-MÜ is an upright standing red wine mash fermentation tank with a simple but efficient technology. After the fermentation has started and a marc cake has formed

US A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

(12) United States Patent

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States US 2004O147769A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0147769 A1 Davis (43) Pub. Date: Jul. 29, 2004 (54) OIL EXTRACTION PROCESS AND Publication Classification

(19) United States US 2004O147769A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0147769 A1 Davis (43) Pub. Date: Jul. 29, 2004 (54) OIL EXTRACTION PROCESS AND Publication Classification

(12) Patent Application Publication (10) Pub. No.: US 2015/ A1

(19) United States US 20150238.045A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0238.045 A1 Hansen et al. (43) Pub. Date: Aug. 27, 2015 (54) BEVERAGE PREPARATION MACHINES (71) Applicant:

(19) United States US 20150238.045A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0238.045 A1 Hansen et al. (43) Pub. Date: Aug. 27, 2015 (54) BEVERAGE PREPARATION MACHINES (71) Applicant:

SERVICE MANUAL ESPRESSO COFFEE BREWER UNITS

AFTER-SALES SERVICE SERVICE MANUAL ESPRESSO COFFEE BREWER UNITS Z 3000V (with variable brewing chamber) Z-3000 var 13/10/2005 page 1 / 11 ESPRESSO COFFEE BREWER UNITS Z 3000 V ESPRESSO The espresso coffee

AFTER-SALES SERVICE SERVICE MANUAL ESPRESSO COFFEE BREWER UNITS Z 3000V (with variable brewing chamber) Z-3000 var 13/10/2005 page 1 / 11 ESPRESSO COFFEE BREWER UNITS Z 3000 V ESPRESSO The espresso coffee

WINE; OTHER ALCOHOLIC BEVERAGES; PREPARATION THEREOF (beer

CPC - C12G - 2017.08 C12G WINE; OTHER ALCOHOLIC BEVERAGES; PREPARATION THEREOF (beer C12C) Relationships with other classification places C12H deals only with pasteurisation, sterilisation, preservation,

CPC - C12G - 2017.08 C12G WINE; OTHER ALCOHOLIC BEVERAGES; PREPARATION THEREOF (beer C12C) Relationships with other classification places C12H deals only with pasteurisation, sterilisation, preservation,

SIGMA It s the result that counts

The future since 1918 SIGMA It s the result that counts Advantage comes in the form of the patented SIGMA pressing principle: hermetically sealed, pressing in the filling position, vertical juice extraction,

The future since 1918 SIGMA It s the result that counts Advantage comes in the form of the patented SIGMA pressing principle: hermetically sealed, pressing in the filling position, vertical juice extraction,

SIGMA The results count

SIGMA The results count Designing the future since 1918 Operating efficiently producing quality SIGMA Purchasing a wine press is one of the most important decisions for your business to make. You are going

SIGMA The results count Designing the future since 1918 Operating efficiently producing quality SIGMA Purchasing a wine press is one of the most important decisions for your business to make. You are going

Module 6: Overview of bakery machinery: mixers, forming machines and ovens.

Paper No. 09 Paper Title: Bakery and Confectionery Technology Module 6: Overview of bakery machinery: mixers, forming machines and ovens. Introduction Bakery units can be classified as manual, semi-automatic

Paper No. 09 Paper Title: Bakery and Confectionery Technology Module 6: Overview of bakery machinery: mixers, forming machines and ovens. Introduction Bakery units can be classified as manual, semi-automatic

III. United States Patent (19) 5,590,586 Jan. 7, % 4. Ulfig et al. (75) Inventors: Kimberly A. Ulfig, Glen Ellyn;

United States Patent (19) Ulfig et al. 54 KITCHEN LAYOUT, SYSTEM (75) Inventors: Kimberly A. Ulfig, Glen Ellyn; Patricia A. Venetucci, Hawthorn Woods, both of Ill. (73) Assignee: Restaurant Technology,

United States Patent (19) Ulfig et al. 54 KITCHEN LAYOUT, SYSTEM (75) Inventors: Kimberly A. Ulfig, Glen Ellyn; Patricia A. Venetucci, Hawthorn Woods, both of Ill. (73) Assignee: Restaurant Technology,

LINEAR GUIDES. Aluminum Roller Guides

LINEAR GUIDES Aluminum Roller Guides Table of Contents Page The Guideline Concept........................................................ 2 The Guideline System.........................................................

LINEAR GUIDES Aluminum Roller Guides Table of Contents Page The Guideline Concept........................................................ 2 The Guideline System.........................................................

Table of Contents. Foundation and Preparation 2 Hearth Base Dimensions 2. Laying the Inner Hearth 3 Inner Hearth Dimensions 4

Table of Contents Foundation and Preparation 2 Hearth Base Dimensions 2 Laying the Inner Hearth 3 Inner Hearth Dimensions 4 Constructing the Firebox 5 Face Opening Dimensions 5 Setting the Rumford Throat

Table of Contents Foundation and Preparation 2 Hearth Base Dimensions 2 Laying the Inner Hearth 3 Inner Hearth Dimensions 4 Constructing the Firebox 5 Face Opening Dimensions 5 Setting the Rumford Throat

United States Patent (19) Aldrich

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

(a) Dead-end/conventional filtration fluid flow perpendicular to the filter medium. (b) Crossflow filtration fluid flow parallel to the filter

FILTRATION (a) Dead-end/conventional filtration fluid flow perpendicular to the filter medium. (b) Crossflow filtration fluid flow parallel to the filter medium. Filtration Generally carry out in the early

FILTRATION (a) Dead-end/conventional filtration fluid flow perpendicular to the filter medium. (b) Crossflow filtration fluid flow parallel to the filter medium. Filtration Generally carry out in the early

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120279416A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0279416A1 Nishimura et al. (43) Pub. Date: Nov. 8, 2012 (54) RAILCAR BOGIE (52) U.S. Cl.... 105/218.1 (75)

(19) United States US 20120279416A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0279416A1 Nishimura et al. (43) Pub. Date: Nov. 8, 2012 (54) RAILCAR BOGIE (52) U.S. Cl.... 105/218.1 (75)

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

US 2006O141114A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0141114A1 Lang et al. (43) Pub. Date: Jun. 29, 2006 (54) JUICE RECOVERY PROCESS Publication Classification

US 2006O141114A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0141114A1 Lang et al. (43) Pub. Date: Jun. 29, 2006 (54) JUICE RECOVERY PROCESS Publication Classification

United States Patent (19) Weller et al.

United States Patent (19) Weller et al. 54 BEVERAGE BREWING MACHINE 75 Inventors: Albrecht Weller, Steinbach; Georges Driesen, Niederhöchstadt, Andreas Peter, Kronberg; Peter Herber; Gerhard Schäfer, both

United States Patent (19) Weller et al. 54 BEVERAGE BREWING MACHINE 75 Inventors: Albrecht Weller, Steinbach; Georges Driesen, Niederhöchstadt, Andreas Peter, Kronberg; Peter Herber; Gerhard Schäfer, both

(12) Patent Application Publication (10) Pub. No.: US 2015/ A1

(19) United States US 20150282662A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0282662 A1 Levine et al. (43) Pub. Date: (54) STOP VALVE FOR COFFEE MAKER (52) U.S. Cl. CPC... A47J 31/106

(19) United States US 20150282662A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0282662 A1 Levine et al. (43) Pub. Date: (54) STOP VALVE FOR COFFEE MAKER (52) U.S. Cl. CPC... A47J 31/106

(12) Patent Application Publication (10) Pub. No.: US 2017/ A1

US 201700 13866A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2017/0013866A1 Tanaka et al. (43) Pub. Date: (54) EXTRUDED NOODLE AND DIE PIECE FOR (30) Foreign Application Priority

US 201700 13866A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2017/0013866A1 Tanaka et al. (43) Pub. Date: (54) EXTRUDED NOODLE AND DIE PIECE FOR (30) Foreign Application Priority

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1. Hurley et al. (43) Pub. Date: Aug. 28, PROCESS Publication Classification

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

III IIIHIII. United States Patent (19) Momiyama

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

Beer Hardware, Systems and Delivery

Beer Hardware, Systems and Delivery An Industry Standard Beer is the number one dispensed beverage in the foodservice industry. Commonly, draft beer is preferred by a wide margin for taste and product

Beer Hardware, Systems and Delivery An Industry Standard Beer is the number one dispensed beverage in the foodservice industry. Commonly, draft beer is preferred by a wide margin for taste and product

(2-12. Zazza72M4 Aarzanez. Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS. Zaza/adar. aeo/ae/ -- e

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

For Jura parts, repairs & tech support, contact: Services Unlimited, Inc./ Parts Guru

For Jura parts, repairs & tech support, contact: Services Unlimited, Inc./ Parts Guru 209 Walnut street, Lansdale, PA 19446 Phone: 215-362-7000 Fax: 215-361-7434 email: sales@partsguru.com Online store

For Jura parts, repairs & tech support, contact: Services Unlimited, Inc./ Parts Guru 209 Walnut street, Lansdale, PA 19446 Phone: 215-362-7000 Fax: 215-361-7434 email: sales@partsguru.com Online store

Smart Plunger TM by PCS

Smart Plunger TM by PCS What they are Highly accurate downhole pressure & temperature gauges Contained inside a variety of high quality plunger styles Utilized in a traveling mode or stationary position

Smart Plunger TM by PCS What they are Highly accurate downhole pressure & temperature gauges Contained inside a variety of high quality plunger styles Utilized in a traveling mode or stationary position

THE PERFECT SOLUTION FOR EVERY MIXING TASK

THE PERFECT SOLUTION FOR EVERY MIXING TASK Food Processing Plants www.zeppelin-systems.com ENGINEERING YOUR SUCCESS Every Zeppelin plant is developed according to the clients specific requirements, and

THE PERFECT SOLUTION FOR EVERY MIXING TASK Food Processing Plants www.zeppelin-systems.com ENGINEERING YOUR SUCCESS Every Zeppelin plant is developed according to the clients specific requirements, and

EXTRACTION. Extraction is a very common laboratory procedure used when isolating or purifying a product.

EXTRACTION Extraction is a very common laboratory procedure used when isolating or purifying a product. Extraction is the drawing or pulling out of something from something else. By far the most universal

EXTRACTION Extraction is a very common laboratory procedure used when isolating or purifying a product. Extraction is the drawing or pulling out of something from something else. By far the most universal

EXTRACTION PRESSURES UP TO 1000 BAR: EXPERIMENTS FOR THE EXTRACTION/DECAFFEINATION OF COCOA

CO 2 -EXTRACTION TEST FACILITY FOR EXTRACTION PRESSURES UP TO 1000 BAR: EXPERIMENTS FOR THE EXTRACTION/DECAFFEINATION OF COCOA Josef Schulmeyr NATECO 2 GmbH & Co.KG Auenstraße 18-20 85283 Wolnzach, Germany

CO 2 -EXTRACTION TEST FACILITY FOR EXTRACTION PRESSURES UP TO 1000 BAR: EXPERIMENTS FOR THE EXTRACTION/DECAFFEINATION OF COCOA Josef Schulmeyr NATECO 2 GmbH & Co.KG Auenstraße 18-20 85283 Wolnzach, Germany

Electric round boil.pan+stirrer-tilting

The Electrolux THERMETIC line is designed for the very heavy duty requirements of hotels, institutions, hospitals, central kitchens and in-flight kitchens. The range consists of a wide choice of elements

The Electrolux THERMETIC line is designed for the very heavy duty requirements of hotels, institutions, hospitals, central kitchens and in-flight kitchens. The range consists of a wide choice of elements

Thermal Hydraulic Analysis of 49-2 Swimming Pool Reactor with a. Passive Siphon Breaker

Thermal Hydraulic Analysis of 49-2 Swimming Pool Reactor with a Passive Siphon Breaker Zhiting Yue 1, Songtao Ji 1 1) China Institute of Atomic Energy(CIAE), Beijing 102413, China Corresponding author:

Thermal Hydraulic Analysis of 49-2 Swimming Pool Reactor with a Passive Siphon Breaker Zhiting Yue 1, Songtao Ji 1 1) China Institute of Atomic Energy(CIAE), Beijing 102413, China Corresponding author:

Eaton Filtration, LLC

Eaton Filtration, LLC 44 Apple Street, Tinton Falsl NJ 07724 Phone: 732-212-4700 Fax: 952-906-3706 E-Mail: filtration@eaton.com Web: www.eaton.com/filtration Installation, Operation & Service Manual Model

Eaton Filtration, LLC 44 Apple Street, Tinton Falsl NJ 07724 Phone: 732-212-4700 Fax: 952-906-3706 E-Mail: filtration@eaton.com Web: www.eaton.com/filtration Installation, Operation & Service Manual Model

Product Consistency Comparison Study: Continuous Mixing & Batch Mixing

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

EQUIPMENT FOR MAKING BABCOCK TEST FOR FAT IN MILK

}L~c ~ ~Babcock Test T HE for Fat in Mi~k By J. ~ JJ R Professor of Dairy Chemistry Research....,) ~ '( li: )..-djg's BABCOCK TEST is the most satisfactory and practical method for determining the percentage

}L~c ~ ~Babcock Test T HE for Fat in Mi~k By J. ~ JJ R Professor of Dairy Chemistry Research....,) ~ '( li: )..-djg's BABCOCK TEST is the most satisfactory and practical method for determining the percentage

1. IMPORTANT SAFEGUARDS When using electrical appliances, basic safety precautions should always be followed to reduce the risk of fire, electric

1. IMPORTANT SAFEGUARDS When using electrical appliances, basic safety precautions should always be followed to reduce the risk of fire, electric shock, and/pr injury to persons including the following:

1. IMPORTANT SAFEGUARDS When using electrical appliances, basic safety precautions should always be followed to reduce the risk of fire, electric shock, and/pr injury to persons including the following:

(12) Patent Application Publication (10) Pub. No.: US 2010/ A1

(19) United States US 2010.0005979A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0005979 A1 Baccetti (43) Pub. Date: Jan. 14, 2010 (54) DISPOSABLE BEVERAGE PRESS Publication Classification

(19) United States US 2010.0005979A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0005979 A1 Baccetti (43) Pub. Date: Jan. 14, 2010 (54) DISPOSABLE BEVERAGE PRESS Publication Classification

Electric round boiling pan -tilting

Thermetic boiling pans - wall The Electrolux THERMETIC line is designed for the very heavy duty requirements of hotels, institutions, hospitals, central kitchens and in-flight kitchens. The range consists

Thermetic boiling pans - wall The Electrolux THERMETIC line is designed for the very heavy duty requirements of hotels, institutions, hospitals, central kitchens and in-flight kitchens. The range consists

(12) United States Patent (10) Patent No.: US 7,325,807 B1. Eason (45) Date of Patent: Feb. 5, 2008

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

IMPORTANT SAFEGUARDS. 3. To protect against fire, electric shock and injury to persons do not immerse cord, plug or unit in water or other liquid.

IMPORTANT SAFEGUARDS When using electrical appliances, basic precautions should always be followed, including the following: 1. Read all instructions. 2. Make sure that your outlet voltage corresponds

IMPORTANT SAFEGUARDS When using electrical appliances, basic precautions should always be followed, including the following: 1. Read all instructions. 2. Make sure that your outlet voltage corresponds