3,024,112. PRODUCTION OF BISCUITS Filed July 10, Sheets-Sheet? INZENTOR. pr Hovey M Burgess

|

|

|

- Jayson Murphy

- 5 years ago

- Views:

Transcription

1 March 6?1962 H M. BURGESS 3,024,112 PRODUCTION OF BISCUITS Filed July 10, Sheets-Sheet? N N INZENTOR. pr Hovey M Burgess

2 March 6?1962 H. M. BURGESS 3,024,112 FRODUCTION OF BISCUITS Filed July 10, Sheets-Sheet 2 -? 1NVENTOR Hovey M.Burgess BY 27????????? ATT?RNEY

3

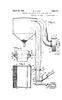

4 3 inspection of the accompanying drawing and the follow ing description. According to certain aspects of this inventionitis pos sible to prepare kibbled biscuits characterized by rough unglazed edges which permit increased adsorption of aqueous liquids by the process which comprises forming a workable dough of Sufficient moisture content to yield acceptable liquid adsorption characteristics when the dough is baked and broken forming said dough into a biscuit sheet?forming a plurality of separated preferably frusto-pyramidal biscuits in said sheetinterconnected by distinct Sections of dough of a thickness Such that on baking saidinterconnecting sections dry out more rapidly than said biscuits and form when broken biscuitedges of Substantial cross-section the sides of Said biscuits being so disposed with respect to Said Sections that the latter are exposed directly to heat during baking baking said sheetto reduce the moisture content thereof and to lower the moisture content of Said Sections below that of Said biscuits to the point that upon cooling Said sections are brittle and said biscuits are thermoplastic cooling Said sheet and breaking said sheet into individual biscuits at Said brittle interconnecting SectionS. Accordingto a preferred embodiment of thisinvention, biscuits may be produced by blending parts by weight of aqueous liquid into about 100 parts by weight of dry ingredients containing predominantly wheat flour, thereby forming a wheat dough forming the dough into a biscuit sheet; forming a plurality of Spaced separated biscuits insaid sheetinterconnected by orseparated from each other by sections of dough of thickness of about %?50% of thickness of the biscuits the interconnect ing or separating sections being thin enough so that on baking?they will dry out more rapidly than the thicker biscuits and being of a width above that at which after baking and cooling the sheet will breakfaithfully across said sections instead of across said biscuits but being below that width at which uneven broken edges of Said sections resultwhen said sheetis broken; bakingthe sheet whereby the moisture content of the biscuits is reduced to 17%-% and the moisture content of the intercon necting or Separating dough sections is reduced to 7%? 12%; cooling Said sheet to a temperature preferably 150 F-165 F. at which the interconnecting or sepa rating sections are brittle and may be Snapped; and break ing or snapping said sheet through the Said interconnect ing or separating dough sections into individual biscuits. In the preparation of the biscuits according to the presentinvention itis preferred to employ wheat flour and preferably hard wheat flour Preferably the solid content of the dough will be predominantly (i.e at least one-half) wheat flour and under preferred conditions itwill be as high as about 73% hard wheat flour The remaining components of the solid portion of the biscuit dough may include a leavening agent Such as baking powder preferably atthe optimum level of about1% by weight of the dry ingredients. The use of leavening provides a more porous product and aids in achieving the desired high rate of liquid adsorption Other in gredients which may be included within the solid portion of the dough stock include Soy bean meal meat and meat derivatives bone meal fish meal fat as well as desiredvitamin and mineral supplements to provide in the ultimate product the propertaste and nutritional balance. Under preferred conditions the solid portion of the dough stock is mixed with aqueous liquid which will be water ormilk It has been found that acceptable results are obtained when about bs of aqueous liquid are employed per 1001bs of dryingredients. The preferred range corresponds to an aqueous liquid concentration of about 35%?% in the final dough If the aqueous 1iquid content of the dough be Substantially above or below this preferred range it may not be possible to fully realize the highly advantageous features of this invention as herein expressed More Specifically use of liquid in 3,024,112 4 amounts Substantially in excess of about % provides a dough which is too wet to work conveniently which rendersitsubstantially impossible to conduct the process hereinafter set forth If the liquid level be substantially 1ess thant33%-34%?itis found thatthe product biscuit possesses an undesirably low liquid adsorption, and an unsatisfactory density Preferably the aqueous liquid should be at a temperature of about100 F-160 F., depending to some extent whetheritiswater or milk the lower temperatures providing more eficient leavening action prior to baking but the higher temperatures fa cilitating the actual dough preparation All things con sidered, a temperature of about 160 F is preferred wherever possible. Formation of the dough sheet from a mass of dough and subsequent treatmentin accordance with this inven tion to produce the novel product herein described may be most conveniently understood by reference to applica tion Serial No.582,562?filed May 3?1956, for Biscuit Making Apparatus inventors Hovey M. Burgess and Harvey H. Grice (now U.S.P. 2,837,043) and by refer ence to the accompanying drawing wherein FIG 1 is a side view partly in section diagrammatically illustrating a die and associated apparatus useful in practicing this invention; FIGS.2 and 3 are perspective views partly in section?illustrating two different dies which may be used in connection with this invention; FIGS 4 and 5 are respectively sectionalviews on radial planes of the dies illustrated in FIGS.2 and 3 respectively; and FIG.6 is a considerably enlarged view of a portion of the dough sheet. The apparatus shown in the drawings is adapted to carry out continuously the process of the invention A 70 mass 1 of doughis containedin a hopper 2 to whichit may be supplied continuously Rotating in the hopper 2 is a pressure roll3 preferably a smooth roll which opposes a rotating die roll 4 of the type described in detail hereinafter The outer surface of the die roll com prises a plurality of suitably arranged rib-like projections defining pockets or molds which receive the dough and shape the biscuits To this end the die roll projects into the hopper 2 through an opening in its wall and the dough mass1 isfed between the rolls 3 and 4 by their rotation andis pressed into the pockets in the die roll surface Excess dough is scraped from the Surface of the die rolland returned to the hopper 2 by a Suitable doctor blade or scraper 5 located below the point of closest approach of the two rolls 3?4 and conveniently forming a part of the wall of the hopperitself Beyond the doctor blade S and outside the hopper a molded sheet orstrip of dough 6 is stripped from the bottom of the rotating dieroll4 and carried of by any Suitable con veying means here shown as a belt7 passing around a drive roll 8. It will be understood from the foregoing description that the conveyor 7 carries the strip to_a baking oven asindicated diagrammatically at9 in FIG URES 2 and 3, and thence to a breaking mechanism where the stripis broken up into individual biscuits 10 asindicatedin these figures. FIGURES 2-5 inclusive illustrate in greater detail the construction and operation of the die roll and its operat ing doctor blade The die roll comprises a generally?ylindrical structure mounted to rotate The die Surface can be made up of preformed die members of desired number size and shape which may be connected and supportedforrotation Forsimplicity the drawings show a cylindrical die roll of one-piece hollow construction, butit will be understood that any other convenient con struction can be employed. Generally described the die roll 4 has circumferential ribs in parallel planes which define between them a bis cuit-forming space having the width of the continuous strip 6 mentioned above which width may be that of any desired number of biscuits as hereinafter explained The space between these ribs is traversed by rib-like projec

5 3,024,112 5?ons which form a plurality of dough-receiving pockets or biscuit molds. The doctor blade 5 has scraping en gagementwith the circumferential ribs and extends across the space therebetween preferably in a substantially straight line but the rib-like projections between the circumferential ribs are of less height than the ribs so that their outer edges are spaced from the doctor blade. Thus the rotating roll and blade cooperate to form be tween the circumferential ribs a continuous strip 6 which is removedfromthe bottom ofthe rollas describedabove, the upper surface of this strip having thereon a plurality of raised biscuit shapes. It will be understood that the strip may be thus subdivided into any desired number of frusto-pyramidal biscuits In any case however the base of the stripis a continuous layer having a thickness equal to the diference in height between the outer edges of the rib-like projections and the outer edges of the cir cumferential ribs?this layer providingthe thin dough sec tions which interconnect the individual biscuits. The thickness of these sections should be about one quarter to one half the height of the biscuits The width of said Sections (i.e.?the space between the feet of biscuitsides) being determined by the width of said rib-like projec tions and being above that at which after baking and cooling the sheet can be broken faithfully across said Sections;the width of Said Sectionsis below thatat which uneven Section edges resultwhen said sections are broken. The rib-like projections have blunt orflat outer edges and increase in thickness toward their bottoms?i.e.?toward the axis of the roll the degree of taper being Such that the breakage. Strip pulls free from the roll without undue risk of FIGURES2 and4 show a roll forforming astrip hav ing the width of four biscuits. The roll 4 is shown as a hollow one-piece cylindrical body having a suitabletrun nion or shaft l1 whereby itis mounted for rotation in any suitable manner The roll4 is provided ateachend with a circumferential rib 12 projecting outwardly from the Surface of the roll by a distance equal to the thick ness of the biscuits to be made The doctor blade 5 has Scrapingengagement with the spaced circumferential ribs 12 and extends across the space therebetweeninastraight line asillustratedin FIGURE4. The space between the ribs 12istraversed by a plu rality ofintersecting circumferential and axially extending rib-like projections 13 which intersect one another to form dough-receiving pockets or biscuit molds 14. As Shown the biscuitshapes are rectangularin cross-section and the strip has the width of four biscuits. AS Shown in FIGURE 2 and in greater detailin FIG URE 4 the height of the rib-like projections 13 is less than that of the ribs 12 so that the outer edges of the projections 13 are spaced from the edge of the doctor blade 5 The result is that the projections 13 form grooves extending only partway through the thickness of the mass of dough confined between the ribs 12 and the blade 5 When the continuous strip is removed from the bottom of the rollasillustratedin FIGURE2 there fore the strip comprises a continuous bottom layer 15 and a plurality of superposed molded biscuit shapes 16 thereon It will be seen that after baking when the strip is broken up into individual biscuits?there will be rough freshlybroken edges around the individual biscuits that are the Same in width as the thickness of the con tinuous bottom layer 15 These broken edges facilitate adsorption of aqueous liquid as described above while at the same time excessive breakup of the material into finesis avoided. The continuous biscuit strip 5 may have any desired widthand FIGS.3 and 5 illustratestrips having the width of a single biscuit only Preferably however the roll is arranged to form a series of Such narrow strips side by-side These results areaccomplished bythe rollstruc ture shown in FIGS 3 and 5 which comprises an end circumferential rib 17 and a plurality of similar circum I ferential ribs 13 all of the Same height Said ribs arranged in parallel planes and Spaced axially by the width of the narrow strips to be formed orin other words by the width of one biscuit Inthis case the rib-like projections 19 which traverse the space between each pair of cir cumferential ribs extend in axial direction between and interconnect the ribsto provide dough pockets these projections 19 being of less height than the ribs as indi cated by the dotted line in FIG 5. It will be understood, of course that the frusto-pyramidal dough-receiving pockets 14 and may be given any desired cross-sec tional shape by suitably arranging the rib-like projections such as those shown at 13 and 19 Also diferent cross sectional shapes can be provided in side-by-side strips, either as parts of a plural-row strip 6 as shown in FIG. 2 or asseparate side-by-side strips 6 as shown in FIG.3. Adough sheet containing the ingredients hereinbefore noted and preferably prepared by the apparatus herein before described will under preferred conditions have a total biscuit (ie?a sheet) thickness or height of about approximately %2 inch Because of the technique em ployed in its preparation the dough sheet will contain a plurality of separated frusto-pyramidal biscuits each having a thickness or heightthe Same as the dough Sheet, i.e.?preferably %2inch interconnected or separated by sections of dough of a thickness of about %?50% of the thickness of the biscuit?preferably about %2 inch. The interconnecting sections of dough which connect the separated biscuits or (alternatively expressed) which separate discrete biscuits from each other are a char acteristic feature which contributes Substantially to the invention preferably the width of the interconnecting sectionis ofthe order of %2inch Because ofthe frusto pyramidal configuration of the biscuits and the presence of these interconnecting or separating Sections itis pos Sible to obtain different properties in the biscuit and in the interconnecting sections after baking as hereinbefore noted Morespecifically the biscuitsheetis formedunder conditions such that the interconnecting or Separating sections are sufficiently thin so that when subjected to baking they dry out more rapidly than the thicker bis cuits wherebythe brittlesection may bebroken orsnapped withoutinjury to the biscuits The die which forms the individual biscuits from the sheet is So constructed that the interconnecting sections are exposed to the heat of the Oven, The oven in which the biscuit Sheetis baked i.e the standard type baking oven is So designed that a large portion of the heat Supplied to the biscuit sheetis in the form of radiant heat?asis well known to those skilled in-the-art radiantheatactsuponthoseportions ofaheated mass whichit can see." Because of the particular con figuration of the biscuit sheet of the instant application, andin particularbecause ofthe combination ofthe frusto pyramidal shape ofthe discrete biscuitand the Separating or interconnecting dough Sections between discrete bis? cuits the heatis readily able to reach the interconnecting dough portions and to provide therein the degree of heat ing necessarytoreducethe moisture content to the desired levelas hereinafter noted. It may be noted that prior art attempts typified by the hereinbefore mentioned patent to Rastrick to efect the results obtained by practice of this invention fail to Show either the frusto-pyramidal biscuit configuration or the presence of discrete Separating orinterconnecting por tions of a biscuit sheet Rather do they show a plurality of biscuits in a Sheet wherein a Series of slits has been made the resulting configuration being essentially a plu rality of biscuits which are immediately coterminous at the lower portions thereof and which approach ortouch each other at upper portions On heating the prior art biscuits expand somewhat because of the action of the leavening agent and the plasticity of the dough to sub Stantially close the Slits. No radiant heat could possibly see"(nor could any convection heat contact) any sub

6 3,024, Stantial portion of the sheet between the touching Sub siderably below thoseusedin baking?i.e at lower tem stantially cube-shaped biscuits Because the entire Sheet peratures at which the brittle interconnecting Sections may be snapped or broken Optimum temperatures for has been baked to a homogeneous final moisture content and the heating has in factundone the advantages which the breaking have been determined to be of the order of were sought by Splitting the sheet?it has been found that 150 F-165 F. with sections of %2-%2 inch thick al though temperatures appreciably above and below this the biscuits become re-secured together during the heat ing and the resulting sheet is substantially dificult to range may also be employed with Success and optimum temperatures vary with dough composition thickness of impossible to breakintoseparate biscuits withoutfracture of a large portion of the biscuits and production offines. the section and other factors. Attemperatures appreci ably above this range an increasingly high percentage of In the preferred embodiment of this invention the 10 biscuits pass through the mechanical breaking equipment biscuitsheetis preferably baked at a baking temperature of the order of450 F-475 F. The optimum duration without being separated into the individual biscuits be cause of the higher plasticity of the sheet and more ofbakingis ofthe orderof minutes. Under the preferred conditions of baking including particularly of the interconnecting Sections On the other hand attemperatures appreciably below this range an in the biscuit sheet thickness the interconnecting section thickness and the time and temperature conditions noted, the moisture content of the thicker section of the biscuit sheet is reduced from about the preferred 35%-% range to approximately 17%-%; simultaneously the moisture content ofthe interconnecting Sectionsis reduced to about 7%-12%. The Structure of the biscuit sheet may be mostreadily observed by inspection of FIGURE 6 of the drawing, which is a considerably enlarged view of a cross-section of a dough Sheet Biscuits and 26 are shown as ad joining biscuits in the biscuit sheet These separate dis tinct discrete biscuits are separated from and intercon nected to each other by interconnecting dough section27, which is defined essentially by the two dotted lines 28 and 29. It is apparent that the dough section 27 is not a portion ofeither biscuit26, butratherthatitis a sepa rate Section which connects the two spaced biscuits and 26 Biscuit (and also of course biscuit26 whichis its duplicate) has agenerally frusto-pyramidal configura tion In this embodimentit has a bottom, a top 31? both of which areflat and preferablygenerally fallingin the horizontal plane Fourslant faces?typified by faces 32 essentially complete the frusto-pyramidal biscuit as it occurs in the biscuit sheet All of these faces?31 and 32 under normal conditions of operation occurring during baking will be baked to a point at which they have a glazed finish the baking conditions in the pre ferred embodiment being Such that the moisture content in the biscuit has been reduced from about35%?% to about 17%-%?The interconnectingsection27 has been Subjected to a greater degree of heating because of the openness of the configuration?ie the slantsurfaces 32 of the biscuit provide no obstacle to radiant or con vection heat reaching the surface 33 of the connecting Section27 Since the section27is%-50% ofthethick ness of the biscuit, any radiant heat which hits face?33(aswellas the lowersurface of the connectionsection) will be Such as to provide higher volumetric heatfluxes into the mass of section 27?i.e.?although the heat will fall on the surface 33 at the same rate (when expressed in terms of B.t.u per Square inch) asit does on surface 31; Since there is a Smaller depth under surface 33 than thereis under Surface 31?the degree of heatinginsection 27 (expressedinterms e.g of B.t.u. per cubicinch) will be much greater than the degree of heating in biscuit Thus althoughthe interconnecting section will have beensubjected tothe Sametemperatureforthesame length oftime?itwill be heated to a greater degree of Severity? preferably Sufficient to reduce its moisture content to about 7%-12%? The Sheet which has been baked to a biscuit moisture content of 17%?% and interconnecting section mois ture content of about 7%?12% may then be passed to the breaking operation, While moisture content of the interconnecting sections atthe time of breakingto provide the individual biscuits is a factorto be carefully controlled the temperature of such sections is also a factor to be considered The baked doughisto some extent thermoplastic and forthat reason a better breakingis obtained attemperatures con creasing number of breaksin the biscuititselfresults, not being limited to the interconnecting sections because the biscuits themselves have lost their thermoplasticity. The breaking operation discussed above may typically be carried outin a horizontally mounted revolving roll on which is mounted a plurality offingers, say about 6 inches long and %?1 inch thick the roll revolving at about 0 rp.m. The separate biscuits are conveyed away from the breaker by a screening device which serves to Separate the fines from the biscuits and later the indi vidual biscuits from ones not separated. Generally the 50 properly formed and completely separated biscuits are obtained in a yield of about 97% with only about3% fines which must be reworked. The usual so-called kibbling"processin which a uniformlythick dough sheet is broken up usually yields no more than % of the kibbled"biscuits Much of the materialis unacceptable 5 5 because it needs to be Subjected to further breakage but a very large percentage is fines which must be reworked completely. 60 An example of the process of the presentinventionis Set forth in deail below, 100 pounds of dry ingredients of the following com position are prepared: Percent Hard wheatfour Soybean ol meal ,0 Meat and bone meal Fishmeal Wh" germ Prewers yeast * Vitamin and mineral supplements?????????????? 1.0 A"f* "ening???????????????????????????? Certified food coloring To these ingredients areadded 55pounds ofskim milk atatemperature ofabout160 F The doughis prepared by mixingin a dough mixer and then fed to a biscuit die which forms a dough sheet of individual biscuits about %2 inch thick in which said biscuits are interconnected by relatively thin dough sections about%2inch thick and wide This dough or biscuitsheetis conveyed to an oven operating at a temperature of about 450 F-475 F? Said dough sheet remaining therein for 7%-8% minutes. Upon being removed the interconnecting sections have a moisture content of about 7%?12%?the biscuits having about 17%-% moisture and afterthe dough sheet has been cooled to a point where saidinterconnectingsections are ata temperature of about150 F-165 F. the baked sheet is put through a mechanical breaker to separate the baked Sheet into the individual biscuits the breaker comprising a horizontally mounted roll on which are mounted a plurality offingers of 6 inches long and 1inch thick revolving at about 0rp.m. The separated bis Cuits are conveyed from the breaker and Screened to re move fines and unseparated biscuits. The biscuits ob tainedin 97% yield are further cooled packaged and are

7 3,024,112 ready for distribution through regular commercial "10 channels. mogeneous kibbled biscuits characterized by rough un The individual biscuits produced in accordance with glazededges which permitincreasedadsorption ofaqueous this invention contain predominantly wheat flour and liquids which comprises forming a workable dough of are characterized by a configuration which results from suficient moisture content to yield acceptable liquid their novel method of preparation and whichimparts to adsorption characteristics when the dough is baked and them particularly Superior properties Whileitis obvi broken formingsaid doughinto a biscuit sheet?forming ous that the biscuits may be of any size under the pre a plurality of Separated frusto-pyramidal biscuits in said ferred conditions of operation the total thickness from Sheet interconnected by distinct sections of dough of a top to bottom Will be as hereinbefore noted about%2 thickness Such that on baking Said interconnecting sec 10 inch The biscuits will be frusto-pyramidal shape and the tions dry out more rapidly than said biscuits and form preferred embodiment will have a substantialtrapezoidal when broken biscuitedges ofsubstantialcross-section said cross-section when viewed through a vertical plane The bottom Will be substantially flat and the surface generally will be glazed for the most part Adjacent to the bot tom of the biscuit will be a rough unglazed area which includes the portion of the dough sheet containing the separating or connecting portions thereof This unglazed area Will have a height and width of %?50% of the thickness of the biscuit and may typically be?2 inch high Each biscuitis characterized by a very high re sistance to fracture and powdering and by its regularand attractive configuration. Because of the presence of the large amount of un glazed area (which may beas much as 50% ofthe slant Surfaces of the frusto-pyramidal biscuit the rate of ad Sorption of aqueous liquidis high. While individual dough sheets may be prepared de pending upon the apparatus available itis preferred to produce a continuous sheet whichis fed to a continuous oven, the rate at which the sheet progresses through the oven or the length of the oven being So regulated as to provide the desired baking period Also?in addition to the type of breaker described above itis possible to use Several pairs of oppositely rotating rubber rolls mounted above and below a horizontally moving belt which con veys the dough sheet through the oven and the breaker rolls. While the present invention has been described with particular reference to the above specific example and in terms of specific Operating conditions procedures and apparatus itis notto be construed as limited thereby but reference is to be had to the appended claims for a definition of the scope of the invention. This application is a continuation-in-part of application Serial No.565,537 filed February 15?1956, by Hovey M. Burgess for Product and ProcessTherefor abandoned July 12?1958?and of application Serial No.582,562?filed May 3?1956 for Biscuit Die for Bits by Hovey M. Burgess and Harvey H. Grice issued June 3?1958 as U.S.P Whatis claimedis: 1. A process for producing substantially internally ho Sections having a width substantially equal to said thick ness at which Said sections will break faithfully there across when Said sheetis broken?the sides of said biscuits being so disposed with respect to said sections that the latter are exposed directly to heat during baking baking Said Sheet to reduce the moisture content thereof and to lower the moisture content of said sections below that of Said biscuits to the point that upon cooling said Sections are brittle and Said biscuits are thermoplastic coolingsaid sheet to breaking temperature and breaking said sheet into individual biscuits at Said brittle interconnecting sections. 2. A process for producing Substantiallyinternally ho mogeneous kibbled biscuits characterized by rough un glazed edges which permitincreasedadsorption ofaqueous liquids which comprises adding about parts by weight of aqueous liquid to about100 parts by weight of dry ingredients containing about 50%-73% wheat flour thereby forming a wheat dough forming Said dough into a biscuit sheet?forming a plurality of separated frusto pyramidal biscuits in said sheetinterconnected by distinct Sections of dough of thickness of about%?50% ofthe thickness of said biscuits said sections being of a width substantially equaltosaid thickness atwhich said sections will break faithfully thereacross and when Said sheet is broken, baking Said dough sheet whereby the moisture content ofthe biscuitsis reduced to about17%-% and the moisture content of the interconnecting dough sec tionsis reduced to about 7%?12%?cooling said sheetto a breaking temperature at which the interconnecting sec tions are brittle and the biscuits are thermo-plastic and breaking Said sheet into individual biscuits at said temperature. References Citedin the file ofthis patent UNITED STATES PATENTS 2.075,157 Alberti Mar.? , Eshbaugh Sept?18?1945 FOREIGN PATENTS 3,341 Great Britain Mar.14, 1885

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

III. United States Patent (19) Binacchi. Attorney, Agent, or Firm-Bucknam and Archer 57 ABSTRACT. 6 Claims, 3 Drawing Sheets

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(*) Notice: Subject to any disclaimer, the term of this E. E. E. E. O.C.

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

May 12, ,282,708 T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE. Filed Sept. 26, Sheets-Sheet l. --No.zzzzzzzzzzae.

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

7 IANSNA. (12) Patent Application Publication (10) Pub. No.: US 2003/ A1. (19) United States 2//

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

United States Patent (19)

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

United States Patent [11] 3,559,565

![United States Patent [11] 3,559,565 United States Patent [11] 3,559,565](/thumbs/93/114425987.jpg) United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

III IIIHIII. United States Patent (19) Momiyama

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

United States Patent (19) Ludder

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. Lange (43) Pub. Date: Nov. 22, 2012

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

3,702,608 11/1972 Tibbs. states by bying O st plunger T.

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

(12) United States Patent (10) Patent No.: US 6,813,994 B2

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

United States Patent (19) 11) 4,167,008 Blickenstaff 45) Sep. 4, 1979

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

March 24, 1970 H. H. BRIDGFORD 3,502,488 COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER HUGH. BROGFORD / ATTORNEY

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

---- ÆØerá Z3zzegzée. Vzerzega2ZY.Zazee. June 16, Zee/ErzezØrzs 2,286, Sheets-Sheet 2 D G O D D D OD

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

US A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

Sept. 7, l.t. ward 2,092,596 SIPHON

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

United States Patent (19) Forino

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

United States Patent (19) Aldrich

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1. Hurley et al. (43) Pub. Date: Aug. 28, PROCESS Publication Classification

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

(12) United States Patent (10) Patent No.: US 7,325,807 B1. Eason (45) Date of Patent: Feb. 5, 2008

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

USOO7325807B1 (12) United States Patent (10) Patent No.: US 7,325,807 B1 Eason (45) Date of Patent: Feb. 5, 2008 (54) BEER PONG TABLE 3,001,791 A 9, 1961 Atwood... 473/470 3,372,934. A * 3/1968 Heil......

3. : 12- C) {X C> C) () {X -K) --KX-KX-KX-K)--C-2 --C)-- (12) Patent Application Publication (10) Pub. No.: US 2012/ A1 4 - (19) United States

(19) United States US 2012O138603A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0138603 A1 McGuinness et al. (43) Pub. Date: Jun. 7, 2012 (54) VARIABLE GEOMETRY TORTILLA COOKINGAPPARATUS

(19) United States US 2012O138603A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0138603 A1 McGuinness et al. (43) Pub. Date: Jun. 7, 2012 (54) VARIABLE GEOMETRY TORTILLA COOKINGAPPARATUS

United States Patent (19) Bowen et al.

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(12) United States Patent

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

United States Patent (19) D'Alessandro

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States US 20040O866O1A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0086601A1 ROSS et al. (43) Pub. Date: (54) SCORED SAVORY DOUGH WITH TOPPINGS OR FILLINGS (76) Inventors: Robert

(19) United States US 20040O866O1A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0086601A1 ROSS et al. (43) Pub. Date: (54) SCORED SAVORY DOUGH WITH TOPPINGS OR FILLINGS (76) Inventors: Robert

(2-12. Zazza72M4 Aarzanez. Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS. Zaza/adar. aeo/ae/ -- e

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

A33. AORNEY. March 22, G. C. HERZ, 1,850,719. APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC. Filed Dec, l6, l Sheets-Sheet l NVENTOR

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

Dec. 9, M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

CODEX STANDARD FOR CANNED APRICOTS CODEX STAN

CODEX STAN 129 Page 1 of 9 CODEX STANDARD FOR CANNED APRICOTS CODEX STAN 129-1981 1. DESCRIPTION 1.1 Product Definition Canned apricots is the product (a) prepared from stemmed, fresh or frozen or previously

CODEX STAN 129 Page 1 of 9 CODEX STANDARD FOR CANNED APRICOTS CODEX STAN 129-1981 1. DESCRIPTION 1.1 Product Definition Canned apricots is the product (a) prepared from stemmed, fresh or frozen or previously

Module 6: Overview of bakery machinery: mixers, forming machines and ovens.

Paper No. 09 Paper Title: Bakery and Confectionery Technology Module 6: Overview of bakery machinery: mixers, forming machines and ovens. Introduction Bakery units can be classified as manual, semi-automatic

Paper No. 09 Paper Title: Bakery and Confectionery Technology Module 6: Overview of bakery machinery: mixers, forming machines and ovens. Introduction Bakery units can be classified as manual, semi-automatic

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

Grooving Tool: used to cut the soil in the liquid limit device cup and conforming to the critical dimensions shown in AASHTO T 89 Figure 1.

DETERMINING THE LIQUID LIMIT OF SOILS FOP FOR AASHTO T 89 Scope This procedure covers the determination of the liquid limit of a soil in accordance with AASHTO T 89-13. It is used in conjunction with the

DETERMINING THE LIQUID LIMIT OF SOILS FOP FOR AASHTO T 89 Scope This procedure covers the determination of the liquid limit of a soil in accordance with AASHTO T 89-13. It is used in conjunction with the

Sugar maple tree named Legacy

( 1 of 1 ) United States Patent PP4,979 Wandell February 1, 1983 Sugar maple tree named Legacy Abstract This disclosure concerns a new and distinct variety of Acer saccharum (commonly known as sugar maple

( 1 of 1 ) United States Patent PP4,979 Wandell February 1, 1983 Sugar maple tree named Legacy Abstract This disclosure concerns a new and distinct variety of Acer saccharum (commonly known as sugar maple

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

United States Patent (19) Adams et al.

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

United States Patent (19)

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

United States Patent (19)

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

(12) Patent Application Publication (10) Pub. No.: US 2017/ A1

US 201700 13866A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2017/0013866A1 Tanaka et al. (43) Pub. Date: (54) EXTRUDED NOODLE AND DIE PIECE FOR (30) Foreign Application Priority

US 201700 13866A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2017/0013866A1 Tanaka et al. (43) Pub. Date: (54) EXTRUDED NOODLE AND DIE PIECE FOR (30) Foreign Application Priority

PATENT ATTORNEYS EXAMINATION

2014 PATENT ATTORNEYS EXAMINATION PAPER E The New Zealand Law and Practice relating to Interpretation and Criticism of Patent Specifications Regulation 158 (1) (e) Duration: 4 hours (plus 10 minutes for

2014 PATENT ATTORNEYS EXAMINATION PAPER E The New Zealand Law and Practice relating to Interpretation and Criticism of Patent Specifications Regulation 158 (1) (e) Duration: 4 hours (plus 10 minutes for

JUICE EXTRACTION AND FILTRATION JUICE EXTRACTION METHOD AND EQUIPMENT

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

Center et al. (45. Date of Patent: Aug. 29, 1995

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

(12) United States Patent

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

United States Patent It 3,593,647

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

(12) United States Patent

(12) United States Patent Chapman et al. USOO6539842B1 (10) Patent No.: (45) Date of Patent: US 6,539,842 B1 Apr. 1, 2003 (54) (75) (73) (21) (22) (51) (52) (58) (56) ROTISSERIE SYSTEM HAVING AREMOTE TEMPERATURE

(12) United States Patent Chapman et al. USOO6539842B1 (10) Patent No.: (45) Date of Patent: US 6,539,842 B1 Apr. 1, 2003 (54) (75) (73) (21) (22) (51) (52) (58) (56) ROTISSERIE SYSTEM HAVING AREMOTE TEMPERATURE

EQUIPMENT FOR MAKING BABCOCK TEST FOR FAT IN MILK

}L~c ~ ~Babcock Test T HE for Fat in Mi~k By J. ~ JJ R Professor of Dairy Chemistry Research....,) ~ '( li: )..-djg's BABCOCK TEST is the most satisfactory and practical method for determining the percentage

}L~c ~ ~Babcock Test T HE for Fat in Mi~k By J. ~ JJ R Professor of Dairy Chemistry Research....,) ~ '( li: )..-djg's BABCOCK TEST is the most satisfactory and practical method for determining the percentage

TORTILLA-TORTILLA CHIPS

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

Artisan Pastry Dough and Butter Croissant. Proof

Artisan Pastry Dough and Butter Croissant PACKAGE STORAGE SHELF LIFE FROZEN SHELF LIFE THAWED CHEESE PASTRY PRODUCT SPECIFICATION AND INFORMATION SHEET 192 PER CASE RAW WEIGHT NO TOPPING 3.0 oz (+/-.25

Artisan Pastry Dough and Butter Croissant PACKAGE STORAGE SHELF LIFE FROZEN SHELF LIFE THAWED CHEESE PASTRY PRODUCT SPECIFICATION AND INFORMATION SHEET 192 PER CASE RAW WEIGHT NO TOPPING 3.0 oz (+/-.25

TURBOMIXERS AND PREMIXERS. VERTIMIX TURBOMIXER GTM SERIES TURBOMIXER GTM TANK-LESS SERIES TURBOMIXER GMG SERIES PREMIXER PCG SERIES

TURBOMIXER GTM SERIES TURBOMIXERS AND PREMIXERS TURBOMIXER GTM TANK-LESS SERIES TURBOMIXER GMG SERIES VERTIMIX TECHNOLOGY PREMIXER PCG SERIES www.gorreri.com TECHNOLOGIES FOR CONTINUOUS MIXING SPEED RELIABILITY

TURBOMIXER GTM SERIES TURBOMIXERS AND PREMIXERS TURBOMIXER GTM TANK-LESS SERIES TURBOMIXER GMG SERIES VERTIMIX TECHNOLOGY PREMIXER PCG SERIES www.gorreri.com TECHNOLOGIES FOR CONTINUOUS MIXING SPEED RELIABILITY

22 Filed: Jun. 6, 1995 (51) Int. Cl... A22C 9/ U.S. Cl /141; 426/56; 426/63 58) Field of Search /141, 142, Canner/Cutter

United States Patent (19) Teran IIII US0055120A 11 Patent Number: 45) Date of Patent: Apr., 1996 54 MEATTENDERIZATION PROCESS FOR A MICROWAVABLE MEAT PRODUCT 76 Inventor: James Teran, 932 E. Thames St.,

United States Patent (19) Teran IIII US0055120A 11 Patent Number: 45) Date of Patent: Apr., 1996 54 MEATTENDERIZATION PROCESS FOR A MICROWAVABLE MEAT PRODUCT 76 Inventor: James Teran, 932 E. Thames St.,

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

Separations. Objective. Background. Date Lab Time Name

Objective Separations Techniques of separating mixtures will be illustrated using chromatographic methods. The natural pigments found in spinach leaves, β-carotene and chlorophyll, will be separated using

Objective Separations Techniques of separating mixtures will be illustrated using chromatographic methods. The natural pigments found in spinach leaves, β-carotene and chlorophyll, will be separated using

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120279416A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0279416A1 Nishimura et al. (43) Pub. Date: Nov. 8, 2012 (54) RAILCAR BOGIE (52) U.S. Cl.... 105/218.1 (75)

(19) United States US 20120279416A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0279416A1 Nishimura et al. (43) Pub. Date: Nov. 8, 2012 (54) RAILCAR BOGIE (52) U.S. Cl.... 105/218.1 (75)

Chapter 3 Dough Ingredients

For your review, this is the first five pages of Chapter 3 of The Original Encyclopizza. To return to prior page, use your Back button. ~ To get more info on this book, go to: http://correllconcepts.com/encyclopizza/_home_encyclopizza.htm

For your review, this is the first five pages of Chapter 3 of The Original Encyclopizza. To return to prior page, use your Back button. ~ To get more info on this book, go to: http://correllconcepts.com/encyclopizza/_home_encyclopizza.htm

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

Sorghum Yield Loss Due to Hail Damage, G A

1 of 8 6/11/2009 9:27 AM G86-812-A Sorghum Yield Loss Due to Hail Damage* This NebGuide discusses the methods used by the hail insurance industry to assess yield loss due to hail damage in grain sorghum.

1 of 8 6/11/2009 9:27 AM G86-812-A Sorghum Yield Loss Due to Hail Damage* This NebGuide discusses the methods used by the hail insurance industry to assess yield loss due to hail damage in grain sorghum.

CODEX STANDARD FOR CANNED PINEAPPLE 1 CODEX STAN

CODEX STAN 42 Page 1 of 9 CODEX STANDARD FOR CANNED PINEAPPLE 1 CODEX STAN 42-1981 1. DESCRIPTION 1.1 Product Definition Canned pineapple is the product (a) prepared from fresh, frozen, or previously canned,

CODEX STAN 42 Page 1 of 9 CODEX STANDARD FOR CANNED PINEAPPLE 1 CODEX STAN 42-1981 1. DESCRIPTION 1.1 Product Definition Canned pineapple is the product (a) prepared from fresh, frozen, or previously canned,

Appendices. Section. Food Buying Guide for Child Nu tri tion Pro grams A P P E N D I C E S

Section 6 Food Buying Guide for Child Nu tri tion Pro grams Appendices A P P E N D I C E S Appendix A: Recipe Analysis Appendix B: Using Column 6 for Recipe Analysis Appendix C: The USDA Child Nutrition

Section 6 Food Buying Guide for Child Nu tri tion Pro grams Appendices A P P E N D I C E S Appendix A: Recipe Analysis Appendix B: Using Column 6 for Recipe Analysis Appendix C: The USDA Child Nutrition

Application of Microwave Technology to Bakery Products

Application of Microwave Technology to Bakery Products Roy Lee Mast Good morning and greetings from America. First I should apologise early on for possibly the English that I may use. I find it's a little

Application of Microwave Technology to Bakery Products Roy Lee Mast Good morning and greetings from America. First I should apologise early on for possibly the English that I may use. I find it's a little

EFFECT OF TOMATO GENETIC VARIATION ON LYE PEELING EFFICACY TOMATO SOLUTIONS JIM AND ADAM DICK SUMMARY

EFFECT OF TOMATO GENETIC VARIATION ON LYE PEELING EFFICACY TOMATO SOLUTIONS JIM AND ADAM DICK 2013 SUMMARY Several breeding lines and hybrids were peeled in an 18% lye solution using an exposure time of

EFFECT OF TOMATO GENETIC VARIATION ON LYE PEELING EFFICACY TOMATO SOLUTIONS JIM AND ADAM DICK 2013 SUMMARY Several breeding lines and hybrids were peeled in an 18% lye solution using an exposure time of

Notes on pressure fermentation

Notes on pressure fermentation Geoff Dye During World War II the fermenting room at Coopers Brewery, Southampton, received a direct hit which put it completely out of action, but left the brewhouse (wort

Notes on pressure fermentation Geoff Dye During World War II the fermenting room at Coopers Brewery, Southampton, received a direct hit which put it completely out of action, but left the brewhouse (wort

Use of Lecithin in Sweet Goods: Cookies

Use of Lecithin in Sweet Goods: Cookies Version 1 E - Page 1 of 9 This information corresponds to our knowledge at this date and does not substitute for testing to determine the suitability of this product

Use of Lecithin in Sweet Goods: Cookies Version 1 E - Page 1 of 9 This information corresponds to our knowledge at this date and does not substitute for testing to determine the suitability of this product

(12) Plant Patent Application Publication

(19) United States (12) Plant Patent Application Publication Martin US 20100 199395P1 (10) Pub. No.: (43) Pub. Date: Aug. 5, 2010 (54) BRUGMANSIA ANGELS SUMMER DREAM (76) Inventor: Byron E. Martin, Danielson,

(19) United States (12) Plant Patent Application Publication Martin US 20100 199395P1 (10) Pub. No.: (43) Pub. Date: Aug. 5, 2010 (54) BRUGMANSIA ANGELS SUMMER DREAM (76) Inventor: Byron E. Martin, Danielson,

Bunker Silo and Drive- Over Silage Pile Management

Bunker Silo and Drive- Over Silage Pile Management By: Donna M. Amaral-Phillips Management of a bunker silo or drive-over silage pile during harvest, storage and feedout directly impacts the quantity and

Bunker Silo and Drive- Over Silage Pile Management By: Donna M. Amaral-Phillips Management of a bunker silo or drive-over silage pile during harvest, storage and feedout directly impacts the quantity and

(12) United States Patent

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

CODEX STANDARD FOR CANNED PEACHES 1 CODEX STAN

CODEX STAN 14 Page 1 of 8 1. DESCRIPTION 1.1 Product Definition 2 CODEX STANDARD FOR CANNED PEACHES 1 CODEX STAN 14-1981 Canned peaches is the product (a) prepared from peeled, stemmed, fresh or frozen

CODEX STAN 14 Page 1 of 8 1. DESCRIPTION 1.1 Product Definition 2 CODEX STANDARD FOR CANNED PEACHES 1 CODEX STAN 14-1981 Canned peaches is the product (a) prepared from peeled, stemmed, fresh or frozen

SOFTDOUGH & COOKIES cat_softdough_rev12gea.indd 1 22/07/

SOFTDOUGH & COOKIES The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given them our

SOFTDOUGH & COOKIES The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given them our

contents 165 Custards and Puddings 8 Introduction 193 Frozen Desserts 35 Yeast Breads 215 Pastries 67 Quick Breads 239 Chocolates and Confections

contents 8 Introduction 10 ABOUT BAKING 12 INGREDIENTS AND THEIR ROLES 21 TYPES OF EQUIPMENT 29 SAFETY 29 MIXING METHODS 35 Yeast Breads 38 TECHNIQUES 44 RECIPES 67 Quick Breads 69 TECHNIQUES 72 RECIPES

contents 8 Introduction 10 ABOUT BAKING 12 INGREDIENTS AND THEIR ROLES 21 TYPES OF EQUIPMENT 29 SAFETY 29 MIXING METHODS 35 Yeast Breads 38 TECHNIQUES 44 RECIPES 67 Quick Breads 69 TECHNIQUES 72 RECIPES

United States Patent (19) Peterson

United States Patent (19) Peterson 54) YOGURT FLAVORED CONFECTIONERIES 75 Inventor: Marvin A. Peterson, Park Ridge, Ill. 73) Assignee: Beatrice Foods Co., Chicago, Ill. 21) Appl. No.: 851,8 (22 Filed:

United States Patent (19) Peterson 54) YOGURT FLAVORED CONFECTIONERIES 75 Inventor: Marvin A. Peterson, Park Ridge, Ill. 73) Assignee: Beatrice Foods Co., Chicago, Ill. 21) Appl. No.: 851,8 (22 Filed:

Unsere aktuellste Innovation:

Pipe-Vent 2 02.01-02.02 Pipe-Vent 02.03-02.05 Siphons with Pipe-Vent 02.06-02.06 Disposal Pipes with Pipe-Vent 02.07-02.07 Accessoiries 02.08-02.08 Ventilations-Pipes Unsere aktuellste Innovation: OHA-Pipe-Vent

Pipe-Vent 2 02.01-02.02 Pipe-Vent 02.03-02.05 Siphons with Pipe-Vent 02.06-02.06 Disposal Pipes with Pipe-Vent 02.07-02.07 Accessoiries 02.08-02.08 Ventilations-Pipes Unsere aktuellste Innovation: OHA-Pipe-Vent

! MXING-LIQUID. United States Patent (19) Khalsa 2-"22 18 INSPECTION. 11 Patent Number: 5,298,274 45) Date of Patent: Mar.

United States Patent (19) Khalsa (54) METHODS FOR MAKING TORTILLACHIPS AND TORTELLA CHIPS PRODUCED THEREBY 76 Inventor: Nirbhao S. Khalsa, 3141 NW. Greenbriar Ter, Portland, Oreg. 97.210 21 22) (51) (52)

United States Patent (19) Khalsa (54) METHODS FOR MAKING TORTILLACHIPS AND TORTELLA CHIPS PRODUCED THEREBY 76 Inventor: Nirbhao S. Khalsa, 3141 NW. Greenbriar Ter, Portland, Oreg. 97.210 21 22) (51) (52)

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004O1371.15A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0137115 A1 Leshik et al. (43) Pub. Date: (54) STABLE, MULTI-TEXTURE, READY-TO-EAT (22) Filed: Jan. 15, 2003

US 2004O1371.15A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0137115 A1 Leshik et al. (43) Pub. Date: (54) STABLE, MULTI-TEXTURE, READY-TO-EAT (22) Filed: Jan. 15, 2003

brewing device, and particularly an espresso machine. 4,871,555 10/1989 Schwartz et al /82

USOO5895672A United States Patent 19 11) Patent Number: Cooper ) Date of Patent: Apr. 20, 1999 54) PRODUCT AND PROCESS FOR PREPARING 5,072,661 12/1991 Kondo... 99/296 A TEA EXTRACT 5,104,666 4/1992 Sanvitale...

USOO5895672A United States Patent 19 11) Patent Number: Cooper ) Date of Patent: Apr. 20, 1999 54) PRODUCT AND PROCESS FOR PREPARING 5,072,661 12/1991 Kondo... 99/296 A TEA EXTRACT 5,104,666 4/1992 Sanvitale...

All in One Bakeshop. Sugar Art Training. Panorama Eggs. Supplies. Instructions

Panorama Eggs Supplies Glass or plastic bowl Small cake board, paper plate or styrofoam plate Royal Icing flowers (made in advance) Small fillers (commercially made or figure piped rabbits, ducks, baby

Panorama Eggs Supplies Glass or plastic bowl Small cake board, paper plate or styrofoam plate Royal Icing flowers (made in advance) Small fillers (commercially made or figure piped rabbits, ducks, baby

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States US 20140O37829A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0037829 A1 Lobel (43) Pub. Date: (54) DRY AGING PROCESSES FOR MEAT Publication Classification (71) Applicant:

(19) United States US 20140O37829A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0037829 A1 Lobel (43) Pub. Date: (54) DRY AGING PROCESSES FOR MEAT Publication Classification (71) Applicant:

PART III. THE HULLING OF PADDY

PART III. THE HULLING OF PADDY The objective of a hulling machine is to remove the husk from the paddy grain with a minimum of damage to the bran layer and, if possible, without breaking the brown rice

PART III. THE HULLING OF PADDY The objective of a hulling machine is to remove the husk from the paddy grain with a minimum of damage to the bran layer and, if possible, without breaking the brown rice

Product Consistency Comparison Study: Continuous Mixing & Batch Mixing

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

Table of Contents. Foundation and Preparation 2 Hearth Base Dimensions 2. Laying the Inner Hearth 3 Inner Hearth Dimensions 4

Table of Contents Foundation and Preparation 2 Hearth Base Dimensions 2 Laying the Inner Hearth 3 Inner Hearth Dimensions 4 Constructing the Firebox 5 Face Opening Dimensions 5 Setting the Rumford Throat

Table of Contents Foundation and Preparation 2 Hearth Base Dimensions 2 Laying the Inner Hearth 3 Inner Hearth Dimensions 4 Constructing the Firebox 5 Face Opening Dimensions 5 Setting the Rumford Throat

(12) United States Patent (10) Patent No.: US 6,419,120 B1

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

ta-v, 9-1-N Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS EDWARD E ANDERSON ATORNEYS JACK D.

Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May 10, 1965 5 Sheets-Sheet INVENTORS EDWARD E ANDERSON JACK D. BROWN ta-v, 9-1-N-11-4. ATORNEYS Oct. 11,

Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May 10, 1965 5 Sheets-Sheet INVENTORS EDWARD E ANDERSON JACK D. BROWN ta-v, 9-1-N-11-4. ATORNEYS Oct. 11,

The new improver time

The new improver time The Polish bakery goods manufacturer Inter Europol produces large volumes of starter doughs for wheat and rye bakery products using equipment supplied by Daxner An important success

The new improver time The Polish bakery goods manufacturer Inter Europol produces large volumes of starter doughs for wheat and rye bakery products using equipment supplied by Daxner An important success

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

Aaawaw A. M1axsom. - A 474/2/sr.przezz' SecY72/7. April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES.

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

(12) (10) Patent No.: US 7,763,302 B2. Hairsine et al. (45) Date of Patent: Jul. 27, 2010

United States Patent USOO7763302B2 (12) (10) Patent No.: Hairsine et al. (45) Date of Patent: Jul. 27, 2010 (54) METHODS FOR AUTOMATICALLY MAKING 4,137,838 A * 2/1979 Warren... 99.500 LARGE QUANTITIES

United States Patent USOO7763302B2 (12) (10) Patent No.: Hairsine et al. (45) Date of Patent: Jul. 27, 2010 (54) METHODS FOR AUTOMATICALLY MAKING 4,137,838 A * 2/1979 Warren... 99.500 LARGE QUANTITIES

COVERED PLUNGER. 1. Corrosive wear It caused by a chemical reaction comes from sulphr, water etc. in fuel oil.

COVERED PLUNGER We can repair and revive old used plungers under special methods of DAIWA DIESEL Co. Ltd. By using Ni-based self-flushing alloy, we can reduce following problems against plungers and as

COVERED PLUNGER We can repair and revive old used plungers under special methods of DAIWA DIESEL Co. Ltd. By using Ni-based self-flushing alloy, we can reduce following problems against plungers and as

Today for tomorrow. Tradition Reliability Quality TORNADO. Maize pickers. Maize pickers from a group of machines for gathering in maize

Today for tomorrow. Tradition Reliability Quality TORNADO Maize pickers Maize pickers from a group of machines for gathering in maize TORNADO Tornados are drawn maize pickers used for picking all sorts

Today for tomorrow. Tradition Reliability Quality TORNADO Maize pickers Maize pickers from a group of machines for gathering in maize TORNADO Tornados are drawn maize pickers used for picking all sorts