1933,158 PROCESS FOR PRODUCING A CEREA, PRODUCT IN A NEW FORM Ralph M. Bohn, Evanston, and Carl S. Miner, No Drawing. Application August 6, 1930

|

|

|

- Bennett Harvey

- 5 years ago

- Views:

Transcription

1 Patented Oct. 31, 1933 UNITED STATES 1933,18 PATENT OFFICE po 1933,18 PROCESS FOR PRODUCING A CEREA, PRODUCT IN A NEW FORM Ralph M. Bohn, Evanston, and Carl S. Miner, Company, Glencoe, III Chicago, assignors Ill. to The Quaker Oats No Drawing. Application August 6, 19 Serial No. 473,1 6 Claims. The present invention relates to a process of producing a cereal product in a new form, as well as a new cereal food product, Suitable for human consumption and readily prepared by the mere admixture of hot water or hot milk whereby a fully cooked palatable and nutritious food product is produced. It has special reference to a pre Cooked cereal and by this term, or its equivalent, We refer to a cereal product in which the starch has been so modified that no additional cooking is necessary to produce a hot cooked cereal food Of Satisfactory digestibility and edibility, i. e., the food may be prepared for consumption by the mere addition of hot water, hot milk or the like. One of the objects of the invention is to produce a food product thoroughly precooked and sub stantially instantaneously convertible into a hot Cooked cereal by the mere addition of hot water Or milk. Another object of the invention is to treat cereals or cereal products by an improvement in known methods of puffing in the presence of a pre determined percentage of moisture in which proc ess the cereal is cooked under pressure and after 6 Wards quickly discharged into an area of normal atmospheric pressure whereby the extraneous moisture will flash into steam thereby effecting the puffing of the cereal, following which, the re Sultant puffed product is milled to produce a pre cooked cereal product which is mixed with hot water or hot milk to produce a hot cooked cereal. It is understood that the term "milling' includes Such operations as rolling, flaking, or other mechanical methods of modifying the form or Size of the puffed or enlarged particles. As heretofore manufactured for human con Sumption, cereal products have been prepared in two forms: - (1) An uncooked form which is to be cooked usually at or near boiling temperatures with suff cient water to form a thick gelatinous mass (ex amples of this type are rolled Oats, corn-meal, farina, cracked wheat, etc.); and (2) A ready prepared form, i. e., ready to eat without further cooking, usually by adding cream and Sugar or mixing with fruit (examples of the ready prepared type are corn flakes, rice flakes, puffed rice, puffed wheat, etc.). The cereals which require cooking are prac tically always served hot, whereas the ready pre pared type are, as a rule, served cold. The preparation of cooked cereals, such as roiled Cats, requires a certain minimum amount of labor and time. For this reason it is not cus tomary to prepare individual portions of cooked (Cl ). cereal in restaurants and other public eating places so that each patron may have a freshly prepared portion, but rather a large quantity is cooked up at the beginning of the period during which the meal is served. Cooked cereals of this type lose their tastiness and desirable eating char acteristics upon standing even under the best con ditions for any considerable period of time, i. e., longer than thirty minutes or, at most, an hour. Moreover, any cereal which is not consumed dur ing the meal for which it is prepared must usually be thrown away. In household use, similar objections exist. The trouble and time required to prepare a cooked cereal preclude its use by one member of the fam ily who may prefer a different cereal than the other members, or who may prefer a cooked cereal while the others do not eat cereal at all. From the discussion just presented, it is obvious that a cereal which has characteristics some what similar to the present cooked cereals but which could be prepared instantly and economi cally in any quantity would have important ad vantages over any cereal known at present. This invention relates to the manufacture of a cereal from any of the well known cereal grains, as well as to the method of preparation of Said cereal in a new and novel manner to produce a hot cereal ready for consumption. Specifically it pertains to the manufacture of a cereal which is completely cooked and which merely requires thorough mixing with hot water to obtain a di gestible and palatable product ready for con Sumption. The preparation or cooking of a cereal grain to improve its digestibility and pala tability, i. e., to change it to a form ready for consumption, is chiefly a matter of subjecting the cereal to the influence of Sufficient heat and moisture to modify the starch and make it readily digestible and palatable. Heretofore with the cooked cereals, i. e., of the rolled oats type, the cooking of the cereal has always been per formed, either partially or completely, in the kitchen by the housewife or chef. With the cereals of Our invention, Sufficient "cooking', or treatment to make the product edible and readily digestible, is performed by the manufacturer of the cereal. The only step performed by the consumer is the addition of hot Water or hot milk Or the like to get the already cooked cereal in a form suitable for consumption. In the preparation of our new cereal products, at least three major operations are performed. These are (1) cooking of the cereal by puffing either the entire berry or a portion of the berry

2 ,18 from which more or less of the bran. Or germ exhaustion of the air from the cylinder and the or both have been removed. In this operation use of inert gas therein may not be necessary the starch is modified and made digestible and the to prevent burning but even then may be desir physical structure of the grain or grain particle able. The initial pressure may, if desired, in the is profoundly altered. (2) Milling the cereal So latter case, be obtained with compressed air, the that it more readily absorbs the hot water or hot remainder of the puffing operation being the milk or the like added in the final step. Grind same. The methods of puffing heretofore used ing or flaking is usually necessary to make all commercially may be utilized for the production parts of the cereal instantly accessible to the hot of a new cereal but such methods must be modi water. Some portion of the milling should take fied in accordance with our invention so as to place subsequent to the puffing. (3) Addition puff only to One and One-half to three times of hot water or hot milk or the like to the cereal the size of the raw grain particle, instead of Six prepared in operations (1) and (2), accompanied or ten times the original size, as is done in the by sufficient stirring and mixing to give a homo prior art methods. geneous mixture. During the puffing operation, the starch gran We shall now describe in detail the preferred ules are cooked by the influence of the heat and methods of preparation of our new cereal from moisture and then Swelled when the pressure in several of the cereal grains. The initial treat the cylinder is subsequently released instanta ment of the cereal varies with the particular neously and the grains puffed to an increased cereal used, as well as with the amount of bran size. In this condition the cereal is easily and or germ which has been removed from it. We have found that a desirable method of cooking the cereal is an improvement of the method here tofore used for puffing wheat and rice. When the cereal is one from which the bran or germ has not been removed and which consequently tends to burn very readily, the preferred method of puffing is as follows: The cereal is hermetically sealed in a pressure cylinder which is provided with means for ro tating the same slowly in a hot oven. One end of the cylinder is provided with a door or lid which may be opened to release the pressure with in the cylinder instantaneously if desired. This is essentially the apparatus used at present for producing puffed rice and puffed wheat. Means are also provided for withdrawing the air or other gas from the cylinder at any time and also for introducing air or other gas under pressure. After the cylinder is loaded to about half its capacity with the cereal, the air is almost com pletely removed from the cylinder as rapidly as possible by means of a vacuum pump. The ex hausted cylinder is then charged with a gas inert with respect to the cereal, such as nitrogen or carbon dioxide, to a super-atmospheric pres sure. We have found that satisfactory results can be obtained with pressures ranging from 10 lbs. to 0 lbs. per square inch, although the lower pressures (10- lbs.) are preferable. The cylinder is rotated while being heated until the pressure within the cylinder has substantially increased, whereupon the door on the cylinder is opened and the pressure thereby instantane ously released. The final pressure obtained just before the release should be high enough to cause the grains or grain particles to "puff' slightly on their discharge from the cylinder, preferably to not more than about three times their size before puffing. This pressure may be, for example, be tween 100 and 0 lbs., depending on the cereal used, the initial gas pressure, the rate of heating of the cylinder, the water content of the cereal, and the degree of puffing desired. The cereal ; before puffing may be treated with water to in crease the moisture content in a manner similar to that used in tempering wheat for flour milling, if desired. Whether Such tempering treatment is necessary or desirable depends on the original moisture content of the cereal. If it is desired to add salt or flavor to the cereal, the proper amount of Salt or favor may be dissolved in the water used for tempering. When cereals sub stantially free from bran or germ, such as milled rice or degerminated corn grits, are puffed, the quickly digestible and properly may be termed precooked. In addition, the swelling which oc curs during puffing helps make the starch and other parts of the berry readily accessible to the hot water which is added in the last opera tion. We shall now describe preferred methods for treating the various cereals to obtain our new precooked products, 1. Wheat (a) Whole aphedt. The wheat is tempered with water until the moisture content is between 1% and %, depending on the variety of wheat. It is puffed as follows: The wheat of 1% to % moisture content is placed in the cylinder. The air is exhausted by means of a vacuum pump and nitrogen gas is introduced to a pressure of 10 lbs. The cylinder is rotated while being heated until a pressure of 1 lbs. is obtained, preferably in eight to nine minutes, and the pressure Sub stantially instantaneously reduced to atmos pheric. An alternative puffing method: The wheat of 1% to % moisture content is placed in the cylinder which is rotated while heating until a pressure of lbs. is attained in four to five minutes. This pressure is blown off through a valve and steam is introduced to a pressure Of about 1 lbs. and held there for a half minute when the pressure is instantaneously reduced to atmospheric. The resulting slightly puffed berries are coarse ly ground. One cup of the ground cereal is mixed With approximately one and one-half cups of Water at or near the boiling point, adding Salt to taste. After a few seconds of stirring to get a uniform mixture, it is ready to eat, usually with Cream and Sugar as in the case of ordinary hot cereals. The hot cereal prepared from our new product as just described shows some im portant physical advantages over hot cereals made from wheat as prepared at present in that there is little or no sliminess. Alternatively, the slightly puffed wheat may be flaked instead of ground and the flakes mixed with hot water as described to form the ready-to-eat hot cereal. (b) Wheat of lou) brain content.--when wheat is pearled, more or less of the bran and germ are removed, depending on the degree of pearling. It is not possible to remove all of the bran because of the crease in the wheat berry. The partially de-branned wheat is treated substantially the same as is described above for whole wheat. The resulting cereal is of milder flavor, as would be expected, and is extremely palatable. (c) Another means for producing a wheat

3 10 4 O cereal of low bran content is available. If wheat (entire) is puffed slightly by the method de Scribed in (a) above and then given a milling treatment similar to that used in flour milling, portions of the wheat may be obtained which have a high bran content and other portions of low bran content. With proper milling procedure, products which make excellent hot cereals when mixed with hot water are obtained. (d) To produce a precooked cereal of the farna, (practically bran-free) type, a coarse semolina, (large flour middlings) is used. This is puffed as follows: middlings of 1% to % moisture content are introduced into the cylinder. Gas under pressure, such as air or nitrogen, is intro duced until a pressure of 1 lbs. is attained. The cylinder is rotated with heat until the pressure has risen to 110 in six to seven minutes when the pressure is instantaneously reduced to atmos pheric. The puffed particles are then faked. When these flakes are mixed with hot water a ready-to-eat hot cereal closely resembling farina cooked in the usual manner, i. e., boiling for minutes to one hour, is obtained. 2. Oats Oat groats are preferably tempered with % of water and lightly puffed as follows: The oat groats of 1% to % moisture content are loaded into the cylinder. The air is evacuated and nitro gen introduced to a pressure of 10 lbs. The cylin der is rotated with heat until a pressure of 160 lbs. is attained in six to seven minutes when the pressure is instantaneously reduced to atmos pheric. An alternative puffing method: the loaded cylinder is rotated until a pressure of lbs. is obtained. The pressure is reduced through a valve to atmospheric and steam is introduced to a pressure of 1 lbs. which is maintained for seconds. The pressure is then Suddenly reduced to atmospheric. The puffed groats may be either coarsely ground or flaked. The faked or ground oats are mixed with hot water (and salt if desired) to give a cereal por ridge ready for immediate consumption. 3. Barley Pearled barley is tempered and lightly puffed as follows: The barley of 1% to % moisture 0 content is loaded into the cylinder. Nitrogen gas is introduced into the cylinder until the pres sure rises to 10 lbs. The cylinder is rotated with heat until a pressure of 110 lbs. is attained, when the pressure is instantaneously reduced to at mospheric. The puffed product is ground or faked and mixed with hot water (and salt if de sired) to produce a hot cooked cereal. 4. Rice 60. (a) Whole rice. (Natural brown)-natural brown rice is handled exactly like whole wheat Or Oat groats. It is tempered, lightly puffed, and the puffed product milled. The addition of hot water (and salt if desired) to the ground or a flaked products gives a hot cooked cereal. (b) Milled rice. (White). Milled rice is tem pered and lightly puffed as follows: The moisture content of the rice is raised to 1% to % by exposure to humid air. A Suitable amount, say, half the capacity of the cylinder, is placed in the cylinder, which is sealed tightly. Compressed air is introduced until a pressure of 10 lbs. is ob tained. The cylinder is rotated and heated SO that the pressure rises to 1 lbs. in seven to eight minutes, when the pressure is instanta 1,938,18 3 neously reduced to atmospheric. The lightly puffed rice may be ground or faked. The ground or flaked product is mixed with hot water (and Salt if desired) to form a hot cooked cereal,. Yellou) corn Corn is best handled to produce our new cereal if it has received a preliminary. milling treat ment, although the whole grain may be used. We have found that the product known to the trade as coarse corn grits, containing little or no bran or germ, can be tempered and lightly puffed as follows: The corn grits of 1% to % mois ture content are introduced into the cylinder and the pressure in the cylinder raised to 10 to 1 lbs. with compressed air or nitrogen. The cylin der is rotated with heat until the pressure has risen to 110 lbs. in six to eight minutes, when the pressure is instantaneously released. The puffed product is then milled and mixed with hot water (and Salt if desired) to form a corn-meal mush that is very satisfactory as such or for the prep aration of fried mush. 6. White corn White corn grits, substantially free from bran and germ, are tempered and lightly puffed in a manner similar to that for yellow corn grits. If the puffed product is coarsely ground and mixed with hot water (and salt if desired), a corn-meal mush is obtained. If, however, the puffed grits are tempered with sufficient water to prevent shattering, and faked, a new type of food product is obtained. For making this prod uct, the preferred procedure is as follows: the preferred moisture content is 14% to %. The Coarse Corn grits, or pearl hominy, are intro duced into the cylinder followed by compressed air or nitrogen to raise the pressure to 10 lbs. The cylinder is rotated with heat until the pres Sure has risen to 110 lbs., preferably, in seven to nine minutes. The pressure is suddenly released. The puffed product is flaked quickly to prevent undue loss of moisture before flaking. The flakes are mixed with a minimum of hot water. In this case a loose, non-coherent mass of Swelled flakes, of good flavor and general palatability is produced. This ready-to-eat product is an ex cellent substitute for potatoes, macaroni, rice, hominy grits and foods of like character. It is excellent when eaten with melted butter, gravy, cheese and in similar type dishes. The essential features of the present, invention Will thus be seen to consist of the puffing of a cereal to a much lesser degree than has hereto fore been practiced in the art, said puffing caus ing thorough cooking of the starch of the cereal and being followed by milling and the addition of a hot aqueous liquid to the puffed milled prod uct to obtain a ready-to-eat hot cereal. In United States Patents Nos. 766,212 and 9,093, puffed products which may be mixed with water to form a gruel are mentioned. A careful examination of the products described in the above mentioned patents shows them to be essentially different from the products of our present invention. The specific differences be tween the products of the above mentioned pat ents and the products of our invention are as follows: I. Siee Patents Nos. 766,212 and 9,093 are described as "greatly enlarged' and "six to eight times' or 10)

4 O ,18 "eight to ten times' the size of the original grain. The puffed products which are manufactured for use in our ready-to-eat hot cereals are puffed to a much lesser degree, i. e., to only one and One half to three times the size of the Original ber ries or particles. We have found that a larger expansion than one and one-half to three times the size of the original berries or particles pro duces cereals, when mixed with the hot water, which have the following unsatisfactory charac teristics: (a) Pastiness.--When the puffed, milled prod uct is mixed with hot water, a pasty, structureless, very soft porridge is produced if the original berry (or milled berry particle) is puffed to much more than three times the original Size. (b) Flavor.--With cereals puffed to much more than three times the original size, the ready-to eat hot cereal normally has a decidedly burnt flavor, the degree of burning increasing with in crease in size of the puffed product. II. Degree of rupture of the starch granules In the puffed products made as described in United States Patents Nos. 766,212 and 9,093, the starch granules have been "obliterated Sub stantially' and disrupted substantially'. With our slightly puffed products this is by no means the case. The starch granules in the products of our present invention are rather swollen and are not generally disrupted' or shattered, as shown by microscopical examination. III (a) Un milled puffed products.-the puffed products made as described in United States Patents Nos. 766,212 and 9,093 produce a gruel when mixed with water (temperature not speci fied). This indicates a considerable degree of degradation of the starch. The unmilled puffed products made in accordance with our present invention do not produce a smooth gruel with water of any temperature, even at boiling ten peratures. (b) Milled puffed products. The milled puffed products produced as described in United States Patents Nos. 766,212 and 9,093 form a gruel when mixed with water (temperature not speci fled), presumably more readily than when un milled. The puffed products of our present in vention herewith do not make a Suitable ready to-eat cereal, even when milled, when mixed with cold water (or milk), but require admixture with hot, preferably boiling, water (or milk) to pro duce a porridge of proper eating characteristics. IV. Degree of rupture of the bran-degerminating Patents Nos. 766,612 and 9,093 are characterized by shattering of the bran and separation of the germ to the extent that both may be removed by blowing, sifting or other mechanical means. The puffed products of our present invention are puffed to such a slight degree that no shattering of the bran or separation of the germ occurs. Any bran or germ removal must be performed by entirely different means-usually by pearling Or milling prior to puffing. V. Water used in tempering Patents Nos. 766,612 and 9,093 are made by puffing "substantially air-dry' cereal grains. We have found that in our invention it is not only desirable but usually necessary to add more Or less water to the air-dry cereals before puffing, in order to produce the desired products. The characteristics vary rather markedly, depending on the moisture content of the grain at the time of puffing. A low-moisture grain when puffed pro duces a more spongy, finely divided starch struc ture, whereas the starch in a high-moisture grain is gelatinized more but is tougher. The differ ence is extremely noticeable on coarse grinding of the puffed products. The low-moisture puffed cereal gives off much flour during coarse grinding, whereas the high-moisture puffed cereal grinds to thin flakes with little flour. It is assumed, of course, that the moisture Content at the time of grinding is the same. VI. Water-soluble material The following table shows the water-soluble material (One hour shaking of the ground mate rial with water, room temperature, filtration, dry ing of the filtrate, weighing) of various puffed cereals of different degrees of puffing. Cereal Added Water water Comgara Total water pare Ea tempering tive to orig soluble" cereal Wheat (pearled) Untreated.-- 1.% 1. Wheat (pearled) % HO--- 2% Wheat (peared). % H.O.-- 6% Barley--- Untreated 1 4.8% Barley- 10% H2O.-- 2% Barley 10% EO.-- 6% Oats Untreated.-- i. 4.% Oats % H2O.--- 1% ats % H.O.-- %' White corn- Untreated % 1. White corn- - 8% EIO---- 2%. 3, 1.42 White corn % EO.--- % White corn % B.O.--- 7" Egree of puffing of cereals in accordance with our in WetO. ' Degree of puffing of cereals described in United States Patents Nos. 766,212 and 9,093. A Superficial inspection of the table shows such marked differences in water-soluble material be tween the puffed cereals of our present invention and the food products of the prior art patents that it is obvious that we are working with quite different puffed cereals than are described in the prior art patents. In the specific illustrative examples herein de Scribed we have specified certain moisture con tents for the cereals to be puffed. The optimum results, as far as the cooked cereals are con cerned, are probably obtained when the moisture contents are midway between those specified. However, We have determined that if the moisture contents of the cereals are kept within the limits described, very palatable cooked cereals result. But if the moisture contents are below those speci fied, the cooked cereals are not satisfactory as COOked foods and they become progressively un Satisfactory as the moisture contents decrease below those specified. If the moisture contents are above those specified, the mechanical dif ficulties of puffing are very great in that the cereal particles tend to stick to each other and to the cooking or pressure cylinder during puffing. It is to be understood that the puffed cereal that forms the subject matter of our invention contemplates that it is not puffed more than about three times the original size of the berry Or cereal particle. In some instances the original cereal material may be puffed to about one and one-quarter to two times its original size. In other instances it may be puffed to about

5 ,18 three and one-half times its original size. In all instances we have found that if the cereal material is puffed more than about four times its Original size, the final hot cereal is too mushy and possesses a burnt taste which renders it un palatable. The puffing increase to three times the original size is the limit to which the cereal can be puffed with the production of quick cook ing cereals of the highest quality. As the size of the puffed cereal is increased above three times that of the Original cereal particle, the hot quick cooking cereal becomes progressively poorer in quality, i. e., increasingly mushy, pasty, and burnt. When mention is made herein of in creasing the size of the cereal by puffing to three times the original size, we do not mean that each individual cereal particle is precisely three times its original size but that the volume of the en tire lot of the cereal puffed has been increased from for example, 1 cu. ft. to 3 cu. ft. Obvious modifications of the processes herein above described are, of course, to be considered as within the scope of the invention for which we claim and desire to protect by Letters Patent as follows: 1. A precooked cereal food comprising a milled non-toasted cereal product that has been puffed, previously to milling, to not more than three times its original size and in which the starch granules are swollen without complete disruption. 2. A hot precooked cereal food comprising hot aqueous liquid absorbed in a non-toasted milled cereal product that has been puffed previously to milling to not more than three times its original size, the starch granules in said puffed product, prior to mixture with the hot aqueous liquid be ing swollen without complete disruption. 3. A precooked non-toasted milled cereal of satisfactory digestibility, palatability and edi bility in which the starch, previously to milling, has been so modified that the size of the cereal S is not in excess of three times its Original size and that by adding a hot aqueous liquid thereto the same is immediately absorbed in said milled cereal and a hot cooked cereal food results. 4. The method of preparing a non-toasted cereal food which comprises subjecting moist cereal material to an elevated temperature and pressure, releasing said pressure substantially instantaneously thereby puffing said cereal ma terial, the moisture content of the cereal mate rial and the pressure and temperature being So controlled that the cereal is puffed to not more than three times its original volume, and then milling said cereal material.. The method of preparing a non-toasted cereal food which comprises subjecting cereal having a moisture content of not less than fif teen per cent to an elevated temperature and pressure, and releasing said pressure Substan tially instantaneously, thereby puffing said cereal without complete disruption of the starch gran ules to not more than three times its Original volume, and then milling the individual cereal particles. 6. The method of preparing a hot non-toasted 100 cooked cereal food of satisfactory digestibility and palatability which comprises subjecting ce real material having a moisture content of not less than fifteen per cent to an elevated temper ature and pressure which are so controlled that 10 on releasing said pressure Substantially instan taneously the said cereal material will be puffed to not more than three times its original volume, thereby enlarging the starch granules without complete disruption, milling the cereal, and add-110 ing thereto a hot aqueous liquid which becomes absorbed in said cereal. S. 8 RAPH. M. BOHN. CAR. S. MNER,

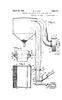

May 12, ,282,708 T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE. Filed Sept. 26, Sheets-Sheet l. --No.zzzzzzzzzzae.

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

Buying Filberts On a Sample Basis

E 55 m ^7q Buying Filberts On a Sample Basis Special Report 279 September 1969 Cooperative Extension Service c, 789/0 ite IP") 0, i mi 1910 S R e, `g,,ttsoliktill:torvti EARs srin ITQ, E,6

E 55 m ^7q Buying Filberts On a Sample Basis Special Report 279 September 1969 Cooperative Extension Service c, 789/0 ite IP") 0, i mi 1910 S R e, `g,,ttsoliktill:torvti EARs srin ITQ, E,6

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

Sept. 7, l.t. ward 2,092,596 SIPHON

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

HNU 145 Types and Uses of Cereals Grains & Pasta. Chapters 16 February 23, 2016

HNU 145 Types and Uses of Cereals Grains & Pasta. Chapters 16 February 23, 2016 Learning Objectives Know then composition of cereal grains. Know the different types of grains. Know the different uses of

HNU 145 Types and Uses of Cereals Grains & Pasta. Chapters 16 February 23, 2016 Learning Objectives Know then composition of cereal grains. Know the different types of grains. Know the different uses of

Appendices. Section. Food Buying Guide for Child Nu tri tion Pro grams A P P E N D I C E S

Section 6 Food Buying Guide for Child Nu tri tion Pro grams Appendices A P P E N D I C E S Appendix A: Recipe Analysis Appendix B: Using Column 6 for Recipe Analysis Appendix C: The USDA Child Nutrition

Section 6 Food Buying Guide for Child Nu tri tion Pro grams Appendices A P P E N D I C E S Appendix A: Recipe Analysis Appendix B: Using Column 6 for Recipe Analysis Appendix C: The USDA Child Nutrition

(12) United States Patent

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

THE UNIVERSITY OF ILLINOIS - Q3QT7 LIBRARY

no THE UNIVERSITY OF ILLINOIS - LIBRARY Q3QT7 r NON CIRCULATING CHECK FOR UNBOUND CIRCULA UNIVERSITY OF ILLINOIS. Agricultural Experiment Station, CHAMPAIGN, APRIL, 1894. BULLETIN NO. 32. AN ACID TEST

no THE UNIVERSITY OF ILLINOIS - LIBRARY Q3QT7 r NON CIRCULATING CHECK FOR UNBOUND CIRCULA UNIVERSITY OF ILLINOIS. Agricultural Experiment Station, CHAMPAIGN, APRIL, 1894. BULLETIN NO. 32. AN ACID TEST

United States Patent (19)

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

War Breads and Cakes

Extension Bulletin 217 October 1, 1917 Oregon Agricultural College Extension Service 0. D. CENTER Director School of Home Economics War Breads and Cakes CORVALLIS, OREGON Oregon State Agricultural College

Extension Bulletin 217 October 1, 1917 Oregon Agricultural College Extension Service 0. D. CENTER Director School of Home Economics War Breads and Cakes CORVALLIS, OREGON Oregon State Agricultural College

ISO 712 INTERNATIONAL STANDARD. Cereals and cereal products Determination of moisture content Reference method

INTERNATIONAL STANDARD ISO 712 Fourth edition 2009-11-15 Cereals and cereal products Determination of moisture content Reference method Céréales et produits céréaliers Détermination de la teneur en eau

INTERNATIONAL STANDARD ISO 712 Fourth edition 2009-11-15 Cereals and cereal products Determination of moisture content Reference method Céréales et produits céréaliers Détermination de la teneur en eau

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

Oregon Agricultural College

College Bulletin No. 83. Extension Series 3. No. 2 Issued Monthly Entered as second-class matter November 27. 1909, at the postoffice at Corvallis, Oregon, under Act of July 16, 1894 Oregon Agricultural

College Bulletin No. 83. Extension Series 3. No. 2 Issued Monthly Entered as second-class matter November 27. 1909, at the postoffice at Corvallis, Oregon, under Act of July 16, 1894 Oregon Agricultural

CHAMPION TOC INDEX. How To Make Barley Silage. Arvid Aasen. Take Home Message. The Ensiling Process

CHAMPION Feed Services Ltd. TOC How To Make Silage INDEX Arvid Aasen Take Home Message Making barley silage is the process of taking green wet whole plant barley and processing it in such a way that it

CHAMPION Feed Services Ltd. TOC How To Make Silage INDEX Arvid Aasen Take Home Message Making barley silage is the process of taking green wet whole plant barley and processing it in such a way that it

III. United States Patent (19) Binacchi. Attorney, Agent, or Firm-Bucknam and Archer 57 ABSTRACT. 6 Claims, 3 Drawing Sheets

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

(*) Notice: Subject to any disclaimer, the term of this E. E. E. E. O.C.

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

22 Filed: Jun. 6, 1995 (51) Int. Cl... A22C 9/ U.S. Cl /141; 426/56; 426/63 58) Field of Search /141, 142, Canner/Cutter

United States Patent (19) Teran IIII US0055120A 11 Patent Number: 45) Date of Patent: Apr., 1996 54 MEATTENDERIZATION PROCESS FOR A MICROWAVABLE MEAT PRODUCT 76 Inventor: James Teran, 932 E. Thames St.,

United States Patent (19) Teran IIII US0055120A 11 Patent Number: 45) Date of Patent: Apr., 1996 54 MEATTENDERIZATION PROCESS FOR A MICROWAVABLE MEAT PRODUCT 76 Inventor: James Teran, 932 E. Thames St.,

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

---- ÆØerá Z3zzegzée. Vzerzega2ZY.Zazee. June 16, Zee/ErzezØrzs 2,286, Sheets-Sheet 2 D G O D D D OD

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

United States Patent (19) Morrison, Jr. et al. (54)

United States Patent (19) Morrison, Jr. et al. (54) (75) (73) 21 22 (51) 52) (58) (56) DESOLVENTIZNG PROCESS Inventors: Lowen R. Morrison, Jr., Hamilton; John H. Phillips, Fairfield, both of Ohio Assignee:

United States Patent (19) Morrison, Jr. et al. (54) (75) (73) 21 22 (51) 52) (58) (56) DESOLVENTIZNG PROCESS Inventors: Lowen R. Morrison, Jr., Hamilton; John H. Phillips, Fairfield, both of Ohio Assignee:

Why are grains an important part of healthful eating?

Grains Why are grains an important part of healthful eating? They are an excellent sources of complex carbohydrates and fiber Combined with animal protein or legumes they provide highquality protein They

Grains Why are grains an important part of healthful eating? They are an excellent sources of complex carbohydrates and fiber Combined with animal protein or legumes they provide highquality protein They

CODEX STANDARD FOR RAISINS CODEX STAN

CODEX STAN 67-1981 Page 1 of 5 CODEX STANDARD FOR RAISINS CODEX STAN 67-1981 1. SCOPE This standard applies to dried grapes of varieties conforming to the characteristics of Vitis vinifera L. which have

CODEX STAN 67-1981 Page 1 of 5 CODEX STANDARD FOR RAISINS CODEX STAN 67-1981 1. SCOPE This standard applies to dried grapes of varieties conforming to the characteristics of Vitis vinifera L. which have

United States Patent (19) 11) 4,167,008 Blickenstaff 45) Sep. 4, 1979

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

Section 3 Dough Management

Section 3 Dough Management Dough is the foundation of our pizza. Dough is the least expensive part of the pizza. Never use dough that is not perfect. If the dough is not perfect, throw it out. Without

Section 3 Dough Management Dough is the foundation of our pizza. Dough is the least expensive part of the pizza. Never use dough that is not perfect. If the dough is not perfect, throw it out. Without

CODEX STANDARD FOR CANNED SWEET CORN 1 CODEX STAN For the purposes of this standard, canned sweet corn does not include corn-on-the-cob.

CODEX STAN 8 Page of 6. SCOPE CODEX STANDARD FOR CANNED SWEET CORN CODEX STAN 8-98 For the purposes of this standard, canned sweet corn does not include corn-on-the-cob. 2. DESCRIPTION 2. Product Definition

CODEX STAN 8 Page of 6. SCOPE CODEX STANDARD FOR CANNED SWEET CORN CODEX STAN 8-98 For the purposes of this standard, canned sweet corn does not include corn-on-the-cob. 2. DESCRIPTION 2. Product Definition

Lecture 4. Factors affecting ripening can be physiological, physical, or biotic. Fruit maturity. Temperature.

Lecture 4. Factors affecting ripening can be physiological, physical, or biotic. Physiological factors relate to fruit maturity or environmental factors, which affect the metabolism of fruit and banana.

Lecture 4. Factors affecting ripening can be physiological, physical, or biotic. Physiological factors relate to fruit maturity or environmental factors, which affect the metabolism of fruit and banana.

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. Lange (43) Pub. Date: Nov. 22, 2012

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

Grains/Breads. Section. Food Buying Guide for Child Nutrition Programs

Section 3 Food Buying Guide for Child Nutrition Programs Grains/Breads 3. Grains/Breads 3-1 3-1 3-2 3-3 3-3 3-7 3-8 3-13 3-15 3-17 3-17 3-18 Grains/Breads Component for the Child Nutrition Programs Definitions

Section 3 Food Buying Guide for Child Nutrition Programs Grains/Breads 3. Grains/Breads 3-1 3-1 3-2 3-3 3-3 3-7 3-8 3-13 3-15 3-17 3-17 3-18 Grains/Breads Component for the Child Nutrition Programs Definitions

Chapter 3 Dough Ingredients

For your review, this is the first five pages of Chapter 3 of The Original Encyclopizza. To return to prior page, use your Back button. ~ To get more info on this book, go to: http://correllconcepts.com/encyclopizza/_home_encyclopizza.htm

For your review, this is the first five pages of Chapter 3 of The Original Encyclopizza. To return to prior page, use your Back button. ~ To get more info on this book, go to: http://correllconcepts.com/encyclopizza/_home_encyclopizza.htm

A33. AORNEY. March 22, G. C. HERZ, 1,850,719. APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC. Filed Dec, l6, l Sheets-Sheet l NVENTOR

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

Whole Wheat Sourdough Bread With Linseed

Whole Wheat Sourdough Bread With Linseed The bread recipe described here owes much to two books: Peter Reinhard's Crust and Crumb and The Bread Builders by Daniel Wing and Alan Scott. I learned all my

Whole Wheat Sourdough Bread With Linseed The bread recipe described here owes much to two books: Peter Reinhard's Crust and Crumb and The Bread Builders by Daniel Wing and Alan Scott. I learned all my

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

GRAIN INSPECTION, PACKERS AND STOCKYARDS CHAPTER 3 ADMINISTRATION FEDERAL GRAIN INSPECTION SERVICE STOP 3630 WASHINGTON, D.C.

U.S. DEPARTMENT OF AGRICULTURE AFLATOXIN HANDBOOK GRAIN INSPECTION, PACKERS AND STOCKYARDS CHAPTER 3 ADMINISTRATION 3-17-03 FEDERAL GRAIN INSPECTION SERVICE STOP 3630 WASHINGTON, D.C. 20090-3630 CHAPTER

U.S. DEPARTMENT OF AGRICULTURE AFLATOXIN HANDBOOK GRAIN INSPECTION, PACKERS AND STOCKYARDS CHAPTER 3 ADMINISTRATION 3-17-03 FEDERAL GRAIN INSPECTION SERVICE STOP 3630 WASHINGTON, D.C. 20090-3630 CHAPTER

RESEARCH ON AVOCADO PROCESSING AT THE UNIVERSITY OF CALIFORNIA, DAVIS

California Avocado Society 1970-71 Yearbook 54: 79-84 RESEARCH ON AVOCADO PROCESSING AT THE UNIVERSITY OF CALIFORNIA, DAVIS Lloyd M. Smith Professor Food Science and Technology, U.C. Davis Frank H. Winter

California Avocado Society 1970-71 Yearbook 54: 79-84 RESEARCH ON AVOCADO PROCESSING AT THE UNIVERSITY OF CALIFORNIA, DAVIS Lloyd M. Smith Professor Food Science and Technology, U.C. Davis Frank H. Winter

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

CODEX STANDARD FOR CANNED APRICOTS CODEX STAN

CODEX STAN 129 Page 1 of 9 CODEX STANDARD FOR CANNED APRICOTS CODEX STAN 129-1981 1. DESCRIPTION 1.1 Product Definition Canned apricots is the product (a) prepared from stemmed, fresh or frozen or previously

CODEX STAN 129 Page 1 of 9 CODEX STANDARD FOR CANNED APRICOTS CODEX STAN 129-1981 1. DESCRIPTION 1.1 Product Definition Canned apricots is the product (a) prepared from stemmed, fresh or frozen or previously

ACIDITY OF BUTTER AND ITS BY-PRODUCTS F. W. BOUSKA

ACIDITY OF BUTTER AND ITS BY-PRODUCTS F. W. BOUSKA 8uperi~cndent of Manufacturing, Be~,trice Creamery Company, Chicago, Illinois Received for publication December 11, 1922 From the very be~nning of the

ACIDITY OF BUTTER AND ITS BY-PRODUCTS F. W. BOUSKA 8uperi~cndent of Manufacturing, Be~,trice Creamery Company, Chicago, Illinois Received for publication December 11, 1922 From the very be~nning of the

Variations in the Test of Separator Cream.

Variations in the Test of Separator Cream. One of the greatest problems that has presented itself to the creamery patrons and managers of the West-Central states for the past few years is that of the cause

Variations in the Test of Separator Cream. One of the greatest problems that has presented itself to the creamery patrons and managers of the West-Central states for the past few years is that of the cause

Pasteurization of Milk Booklet No.281 Dairy Management & Milk Products: DMMPS - 11

Contents Preface I. Introduction Pasteurization of Milk Booklet No.281 Dairy Management & Milk Products: DMMPS - 11 II. Advantages of Pasteurization III. Temperature & Time Combination IV. Methods of Pasteurization

Contents Preface I. Introduction Pasteurization of Milk Booklet No.281 Dairy Management & Milk Products: DMMPS - 11 II. Advantages of Pasteurization III. Temperature & Time Combination IV. Methods of Pasteurization

ISO 9852 INTERNATIONAL STANDARD

INTERNATIONAL STANDARD ISO 9852 Second edition 2007-05-01 Unplasticized poly(vinyl chloride) (PVC-U) pipes Dichloromethane resistance at specified temperature (DCMT) Test method Tubes en poly(chlorure

INTERNATIONAL STANDARD ISO 9852 Second edition 2007-05-01 Unplasticized poly(vinyl chloride) (PVC-U) pipes Dichloromethane resistance at specified temperature (DCMT) Test method Tubes en poly(chlorure

Functions of Raising Agents

Objective Functions of Raising Agents To investigate how different types of raising agent (baking powder, baking soda, yeast) work. Principles Raising agents, also known as leavening agents, cause baked

Objective Functions of Raising Agents To investigate how different types of raising agent (baking powder, baking soda, yeast) work. Principles Raising agents, also known as leavening agents, cause baked

THE ANTISCORBUTIC VALUE OF FRESH AND CANNED ENGLISH TOMATOES. XC. (Received May 1st, 1924.)

XC. THE ANTISCORBUTIC VALUE OF FRESH AND CANNED ENGLISH TOMATOES. BY ELLEN MARION DELF. (Received May 1st, 1924.) THE juice of raw tomatoes is known to be powerfully antiscorbutic, and according to American

XC. THE ANTISCORBUTIC VALUE OF FRESH AND CANNED ENGLISH TOMATOES. BY ELLEN MARION DELF. (Received May 1st, 1924.) THE juice of raw tomatoes is known to be powerfully antiscorbutic, and according to American

United States Patent (19) 11 4,094,997 Aishima et al. 45 June 13, 1978

United States Patent (19) 11 Aishima et al. 45 June 13, 1978 (54) BEEF FLAVORSUBSTANCE, PROCESS FOR 56) References Cited PRODUCING SAME AND BEEFFLAVORNGAGENT U.S. PATENT DOCUMENTS 3,394,0 7/1968 Giacino...

United States Patent (19) 11 Aishima et al. 45 June 13, 1978 (54) BEEF FLAVORSUBSTANCE, PROCESS FOR 56) References Cited PRODUCING SAME AND BEEFFLAVORNGAGENT U.S. PATENT DOCUMENTS 3,394,0 7/1968 Giacino...

OREGON AGRICULTURAL COLLEGE

OREGON AGRICULTURAL COLLEGE EXTENSION SERVICE BOYS' AND GIRLS' INDUSTRIAL CLUBS Oregon Agricultural College, United States Department of Agriculture, and State Department of Education, cooperating. Club

OREGON AGRICULTURAL COLLEGE EXTENSION SERVICE BOYS' AND GIRLS' INDUSTRIAL CLUBS Oregon Agricultural College, United States Department of Agriculture, and State Department of Education, cooperating. Club

TEMPERATURE CONDITIONS AND TOLERANCE OF AVOCADO FRUIT TISSUE

California Avocado Society 1961 Yearbook 45: 87-92 TEMPERATURE CONDITIONS AND TOLERANCE OF AVOCADO FRUIT TISSUE C. A. Schroeder and Ernest Kay Professor of Botany. University of California, Los Angeles;

California Avocado Society 1961 Yearbook 45: 87-92 TEMPERATURE CONDITIONS AND TOLERANCE OF AVOCADO FRUIT TISSUE C. A. Schroeder and Ernest Kay Professor of Botany. University of California, Los Angeles;

Life Skills: Cooking Name

Life Skills: Cooking Name Keep this form in the student portfolio for each child. It may take a few years before every item is checked. Define: Develop safe, sanitary, and practical skills for basic food

Life Skills: Cooking Name Keep this form in the student portfolio for each child. It may take a few years before every item is checked. Define: Develop safe, sanitary, and practical skills for basic food

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

FACTORS DETERMINING UNITED STATES IMPORTS OF COFFEE

12 November 1953 FACTORS DETERMINING UNITED STATES IMPORTS OF COFFEE The present paper is the first in a series which will offer analyses of the factors that account for the imports into the United States

12 November 1953 FACTORS DETERMINING UNITED STATES IMPORTS OF COFFEE The present paper is the first in a series which will offer analyses of the factors that account for the imports into the United States

(2-12. Zazza72M4 Aarzanez. Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS. Zaza/adar. aeo/ae/ -- e

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

A. GENERAL INFORMATION No. 2 (1) DEFINITION OF TERMS USED IN FOOD PREPARATION

A. GENERAL INFORMATION No. 2 (1) DEFINITION OF TERMS USED IN FOOD PREPARATION Bake... To cook by dry heat in an oven, either covered or uncovered. Barbecue... To roast or cook slowly, basting with a highly

A. GENERAL INFORMATION No. 2 (1) DEFINITION OF TERMS USED IN FOOD PREPARATION Bake... To cook by dry heat in an oven, either covered or uncovered. Barbecue... To roast or cook slowly, basting with a highly

EXTRACTION. Extraction is a very common laboratory procedure used when isolating or purifying a product.

EXTRACTION Extraction is a very common laboratory procedure used when isolating or purifying a product. Extraction is the drawing or pulling out of something from something else. By far the most universal

EXTRACTION Extraction is a very common laboratory procedure used when isolating or purifying a product. Extraction is the drawing or pulling out of something from something else. By far the most universal

Award Winning Canning. Brenda Hill, Ph.D. Family Consumer Science Educator Cleveland County Extension 2015

Award Winning Canning Brenda Hill, Ph.D. Family Consumer Science Educator Cleveland County Extension 2015 Fairs, Festivals and Special Events Objectives for conducting & judging competition events: To

Award Winning Canning Brenda Hill, Ph.D. Family Consumer Science Educator Cleveland County Extension 2015 Fairs, Festivals and Special Events Objectives for conducting & judging competition events: To

(12) United States Patent

(12) United States Patent US008778441B2 () Patent No.: Sky (45) Date of Patent: Jul. 15, 2014 (54) READY-TO-EAT OAT-BASED FOOD (56) References Cited PRODUCT U.S. PATENT DOCUMENTS (76) Inventor: Phillip

(12) United States Patent US008778441B2 () Patent No.: Sky (45) Date of Patent: Jul. 15, 2014 (54) READY-TO-EAT OAT-BASED FOOD (56) References Cited PRODUCT U.S. PATENT DOCUMENTS (76) Inventor: Phillip

BLBS015-Conforti August 11, :35 LABORATORY 1. Measuring Techniques COPYRIGHTED MATERIAL

LABORATORY 1 Measuring Techniques COPYRIGHTED MATERIAL 1 LABORATORY 1 Measuring Techniques Proper measuring techniques must be emphasized to ensure success in food preparation. There are differences when

LABORATORY 1 Measuring Techniques COPYRIGHTED MATERIAL 1 LABORATORY 1 Measuring Techniques Proper measuring techniques must be emphasized to ensure success in food preparation. There are differences when

TORTILLA-TORTILLA CHIPS

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

Peanut Meal as a Protein. Fattening Hogs in the Dry Lot. Supplement to Corn for AGRICULTURAL EXPERIMENT STATION ALABAMA POLYTECHNIC INSTITUTE

BULLETIN No. 224 AUGUST, 1924 Peanut Meal as a Protein Supplement to Corn for Fattening Hogs in the Dry Lot By J. C. GRIMES AND W. D. SALMON AGRICULTURAL EXPERIMENT STATION of the ALABAMA POLYTECHNIC INSTITUTE

BULLETIN No. 224 AUGUST, 1924 Peanut Meal as a Protein Supplement to Corn for Fattening Hogs in the Dry Lot By J. C. GRIMES AND W. D. SALMON AGRICULTURAL EXPERIMENT STATION of the ALABAMA POLYTECHNIC INSTITUTE

US A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

CODEX STANDARD FOR RICE CODEX STAN

CODEX STAN 198 Page 1 of 10 CODEX STANDARD FOR RICE CODEX STAN 198-1995 The Annex to this standard contains provisions which are not intended to be applied within the meaning of the acceptance provisions

CODEX STAN 198 Page 1 of 10 CODEX STANDARD FOR RICE CODEX STAN 198-1995 The Annex to this standard contains provisions which are not intended to be applied within the meaning of the acceptance provisions

YEDENT AGRO GROUP OF COMPANIES PROCESSING OF SOY BASED PRODUCTS FOR HUMAN FOODS AND POULTRY FEEDS

YEDENT AGRO GROUP OF COMPANIES PROCESSING OF SOY BASED PRODUCTS FOR HUMAN FOODS AND POULTRY FEEDS 1. SOYA EXTRUSION AND PRESSING PROCESS EQUIPMENT 1. The Pre Cleaner 2. The Course Mill 3. The Extruder

YEDENT AGRO GROUP OF COMPANIES PROCESSING OF SOY BASED PRODUCTS FOR HUMAN FOODS AND POULTRY FEEDS 1. SOYA EXTRUSION AND PRESSING PROCESS EQUIPMENT 1. The Pre Cleaner 2. The Course Mill 3. The Extruder

United States Patent (19) Adams et al.

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

Center et al. (45. Date of Patent: Aug. 29, 1995

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

PROTOCOLS FOR HCP LAB LIQUOR AND CHOCOLATE PREPARATION AND ANALYSIS

PROTOCOLS FOR HCP LAB LIQUOR AND CHOCOLATE PREPARATION AND ANALYSIS Processing of beans by the HCP has been standardized to ensure consistency for all submissions for Roasting, Liquor Milling, Chocolate

PROTOCOLS FOR HCP LAB LIQUOR AND CHOCOLATE PREPARATION AND ANALYSIS Processing of beans by the HCP has been standardized to ensure consistency for all submissions for Roasting, Liquor Milling, Chocolate

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

United States Patent (19) Aldrich

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

Proclamations Proklamasies

3 Agricultural Product Standards Act (119/1990): Regulations relating to the grading, packing and marking of maize products intended for sale in the Republic of South Africa 1130. STAATSKOERANT, 22 JANUARIE

3 Agricultural Product Standards Act (119/1990): Regulations relating to the grading, packing and marking of maize products intended for sale in the Republic of South Africa 1130. STAATSKOERANT, 22 JANUARIE

Let s Preserve. Tomatoes. Bulletin #4085. Recommended Varieties. Quantity. Table 1. Quantities of Fresh Tomatoes Needed for Tomato Products

Bulletin #4085 Let s Preserve Tomatoes Recommended Varieties Campbell 1327, Heinz 1350, Heinz 1370, Pik-Red, Supersonic, and late-season Ramapo are good choices for making juice, crushed, and whole tomato

Bulletin #4085 Let s Preserve Tomatoes Recommended Varieties Campbell 1327, Heinz 1350, Heinz 1370, Pik-Red, Supersonic, and late-season Ramapo are good choices for making juice, crushed, and whole tomato

Grooving Tool: used to cut the soil in the liquid limit device cup and conforming to the critical dimensions shown in AASHTO T 89 Figure 1.

DETERMINING THE LIQUID LIMIT OF SOILS FOP FOR AASHTO T 89 Scope This procedure covers the determination of the liquid limit of a soil in accordance with AASHTO T 89-13. It is used in conjunction with the

DETERMINING THE LIQUID LIMIT OF SOILS FOP FOR AASHTO T 89 Scope This procedure covers the determination of the liquid limit of a soil in accordance with AASHTO T 89-13. It is used in conjunction with the

Best Quality for the Best Wines

Best Quality for the Best Wines High-quality Raw Material Only exclusively selected healthy oak is used for supplied by longstanding partners that operate controlled, sustainable forestry. Computer-aided

Best Quality for the Best Wines High-quality Raw Material Only exclusively selected healthy oak is used for supplied by longstanding partners that operate controlled, sustainable forestry. Computer-aided

II. PROVISIONS CONCERNING QUALITY The purpose of the standard is to define the quality requirements for kiwifruit, after preparation and packaging.

ANNEX I to Commission Implementing Regulation (EC) No 543/2011 of 7 June 2011 laying down detailed rules for the application of Council Regulation (EC) No 1234/2007 in respect of the fruit and vegetables

ANNEX I to Commission Implementing Regulation (EC) No 543/2011 of 7 June 2011 laying down detailed rules for the application of Council Regulation (EC) No 1234/2007 in respect of the fruit and vegetables

Grains. Definition: single, hard seed Most common grains. Wheat Corn Rice

Grains Grains Definition: single, hard seed Most common grains Wheat Corn Rice The Anatomy of a Grain Bran The outer layer. It contains B-vitamins, Iron, Protein, and Fiber Endosperm Composed mostly of

Grains Grains Definition: single, hard seed Most common grains Wheat Corn Rice The Anatomy of a Grain Bran The outer layer. It contains B-vitamins, Iron, Protein, and Fiber Endosperm Composed mostly of

(12) Patent Application Publication (10) Pub. No.: US 2015/ A1

(19) United States US 20150237893A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0237893 A1 Miyajima et al. (43) Pub. Date: (54) FROZEN COOKED NOODLE AND METHOD (30) Foreign Application Priority

(19) United States US 20150237893A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0237893 A1 Miyajima et al. (43) Pub. Date: (54) FROZEN COOKED NOODLE AND METHOD (30) Foreign Application Priority

CODEX STANDARD FOR CANNED TOMATOES 1 CODEX STAN

CODEX STAN 13 Page 1 of 6 1. DESCRIPTION 1.1 Product Definition CODEX STANDARD FOR CANNED TOMATOES 1 Canned tomatoes is the product: CODEX STAN 13-1981 (a) prepared from washed, ripened tomatoes, conforming

CODEX STAN 13 Page 1 of 6 1. DESCRIPTION 1.1 Product Definition CODEX STANDARD FOR CANNED TOMATOES 1 Canned tomatoes is the product: CODEX STAN 13-1981 (a) prepared from washed, ripened tomatoes, conforming

Milk Treatments. Lecture 3 English Mustafa M. Kadhim

Milk Treatments Pasteurization Along with correct cooling, the pasteurization of milk is one of the most important processes in the treatment of milk. If carried out correctly, these processes will supply

Milk Treatments Pasteurization Along with correct cooling, the pasteurization of milk is one of the most important processes in the treatment of milk. If carried out correctly, these processes will supply

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

US 2007003 1551A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0031551A1 Samson et al. (43) Pub. Date: (54) METHOD FOR CONTINUOUSLY Publication Classification PROCESSING

US 2007003 1551A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0031551A1 Samson et al. (43) Pub. Date: (54) METHOD FOR CONTINUOUSLY Publication Classification PROCESSING

II. PROVISIONS CONCERNING QUALITY The purpose of the standard is to define the quality requirements for tomatoes, after preparation and packaging.

ANNEX I to Commission Implementing Regulation (EC) No 543/2011 of 7 June 2011 laying down detailed rules for the application of Council Regulation (EC) No 1234/2007 in respect of the fruit and vegetables

ANNEX I to Commission Implementing Regulation (EC) No 543/2011 of 7 June 2011 laying down detailed rules for the application of Council Regulation (EC) No 1234/2007 in respect of the fruit and vegetables

INSHELL MACADAMIA NUTS

Recommendation on trial through 2010 for STANDARD DDPconcerning the marketing and commercial quality control of INSHELL MACADAMIA NUTS The present recommendation for Inshell macadamia nuts is based on

Recommendation on trial through 2010 for STANDARD DDPconcerning the marketing and commercial quality control of INSHELL MACADAMIA NUTS The present recommendation for Inshell macadamia nuts is based on

GEORGIA DEPARTMENT OF CORRECTIONS Standard Operating Procedures. Policy Number: Effective Date: 1/16/2018 Page Number: 1 of 6

Policy Number: 409.04.03 Effective Date: 1/16/2018 Page Number: 1 of 6 I. Introduction and Summary: A. All Food Service Directors, Managers, and Supervisors of Georgia Department of Corrections (GDC) State

Policy Number: 409.04.03 Effective Date: 1/16/2018 Page Number: 1 of 6 I. Introduction and Summary: A. All Food Service Directors, Managers, and Supervisors of Georgia Department of Corrections (GDC) State

STANDARD FOR CANNED CHESTNUTS AND CANNED CHESTNUT PUREE CODEX STAN Adopted in Amendment: 2015.

STANDARD FOR CANNED CHESTNUTS AND CANNED CHESTNUT PUREE CODEX STAN 145-1985 Adopted in 1985. Amendment: 2015. CODEX STAN 145-1985 2 1. DESCRIPTION 1.1 Product Definition 1.1.1 Canned chestnuts is the product

STANDARD FOR CANNED CHESTNUTS AND CANNED CHESTNUT PUREE CODEX STAN 145-1985 Adopted in 1985. Amendment: 2015. CODEX STAN 145-1985 2 1. DESCRIPTION 1.1 Product Definition 1.1.1 Canned chestnuts is the product

GRAIN TRADE AUSTRALIA. Section 9 MILLING BY-PRODUCTS & FIBRE STANDARDS 2014/2015 SEASON

GRAIN TRADE AUSTRALIA Section 9 MILLING BY-PRODUCTS & FIBRE STANDARDS 2014/2015 SEASON TABLE OF CONTENTS COMMODITY STANDARD REFERENCE Molasses (Cane) CSBP 1 Millrun / Wheat Offal CSBP 2 Rice Pollard CSBP

GRAIN TRADE AUSTRALIA Section 9 MILLING BY-PRODUCTS & FIBRE STANDARDS 2014/2015 SEASON TABLE OF CONTENTS COMMODITY STANDARD REFERENCE Molasses (Cane) CSBP 1 Millrun / Wheat Offal CSBP 2 Rice Pollard CSBP

THE EFFECT OF ETHYLENE UPON RIPENING AND RESPIRATORY RATE OF AVOCADO FRUIT

California Avocado Society 1966 Yearbook 50: 128-133 THE EFFECT OF ETHYLENE UPON RIPENING AND RESPIRATORY RATE OF AVOCADO FRUIT Irving L. Eaks University of California, Riverside Avocado fruits will not

California Avocado Society 1966 Yearbook 50: 128-133 THE EFFECT OF ETHYLENE UPON RIPENING AND RESPIRATORY RATE OF AVOCADO FRUIT Irving L. Eaks University of California, Riverside Avocado fruits will not

ISO Wheat (Triticum aestivum L.) Specification. Blé tendre (Triticum aestivum L.) Spécifications. Third edition

Provläsningsexemplar / Preview INTERNATIONAL STANDARD ISO 7970 Third edition 2011-11-01 Wheat (Triticum aestivum L.) Specification Blé tendre (Triticum aestivum L.) Spécifications Reference number ISO

Provläsningsexemplar / Preview INTERNATIONAL STANDARD ISO 7970 Third edition 2011-11-01 Wheat (Triticum aestivum L.) Specification Blé tendre (Triticum aestivum L.) Spécifications Reference number ISO

INF.3 Proposal for a new UNECE Standard: Inshell Pecans

Proposal for a new UNECE Standard: Inshell Pecans Contribution from the United States of America Note by the secretariat: This text is a revised proposal for a new UNECE Standard for Inshell Pecans reproduced

Proposal for a new UNECE Standard: Inshell Pecans Contribution from the United States of America Note by the secretariat: This text is a revised proposal for a new UNECE Standard for Inshell Pecans reproduced

WINE; OTHER ALCOHOLIC BEVERAGES; PREPARATION THEREOF (beer

CPC - C12G - 2017.08 C12G WINE; OTHER ALCOHOLIC BEVERAGES; PREPARATION THEREOF (beer C12C) Relationships with other classification places C12H deals only with pasteurisation, sterilisation, preservation,

CPC - C12G - 2017.08 C12G WINE; OTHER ALCOHOLIC BEVERAGES; PREPARATION THEREOF (beer C12C) Relationships with other classification places C12H deals only with pasteurisation, sterilisation, preservation,

For your review, this is the first five pages of Chapter 7 of The Original Encyclopizza.

For your review, this is the first five pages of Chapter 7 of The Original Encyclopizza. To return to prior page, use your Back button. ~ To get more info on this book, go to: http://correllconcepts.com/encyclopizza/_home_encyclopizza.htm

For your review, this is the first five pages of Chapter 7 of The Original Encyclopizza. To return to prior page, use your Back button. ~ To get more info on this book, go to: http://correllconcepts.com/encyclopizza/_home_encyclopizza.htm

Honey Whole Wheat Bread Recipe. Blender Wheat Pancakes

Honey Whole Wheat Bread Recipe 2 cups all-purpose flour 1 tsp. salt 1 package quick rise yeast ¾ c. milk (can also use powdered milk) ¾ c. water 2 T. honey 2 T. vegetable oil 2 c. whole wheat flour Combine

Honey Whole Wheat Bread Recipe 2 cups all-purpose flour 1 tsp. salt 1 package quick rise yeast ¾ c. milk (can also use powdered milk) ¾ c. water 2 T. honey 2 T. vegetable oil 2 c. whole wheat flour Combine

Bulletin No. 42 May 1943 FREEZING VEGETABLES

Bulletin No. 42 May 1943 FREEZING FRUITS AND VEGETABLES Freezing Fruits and Vegetables w. E. PYKE and A. M. BINKLEy 1 Fruits for Freezing The fruits most commonly frozen and stored in frozen-food lockers

Bulletin No. 42 May 1943 FREEZING FRUITS AND VEGETABLES Freezing Fruits and Vegetables w. E. PYKE and A. M. BINKLEy 1 Fruits for Freezing The fruits most commonly frozen and stored in frozen-food lockers

1. Blender: Osterizer, 10-speed, or equivalent. 2. Separatory Funnel: Kilborn or equivalent (see figure 1) 2. HCl Solution: HCl/water (7:93 by volume)

EXTER.01-1 INFESTATION IN WHOLE CORN PRINCIPLE Whole corn is suspended in aqueous borax solution to float insects and insect fragments, which are collected on filter paper for microscopic identification

EXTER.01-1 INFESTATION IN WHOLE CORN PRINCIPLE Whole corn is suspended in aqueous borax solution to float insects and insect fragments, which are collected on filter paper for microscopic identification

United States Patent (19) Peterson

United States Patent (19) Peterson 54) YOGURT FLAVORED CONFECTIONERIES 75 Inventor: Marvin A. Peterson, Park Ridge, Ill. 73) Assignee: Beatrice Foods Co., Chicago, Ill. 21) Appl. No.: 851,8 (22 Filed:

United States Patent (19) Peterson 54) YOGURT FLAVORED CONFECTIONERIES 75 Inventor: Marvin A. Peterson, Park Ridge, Ill. 73) Assignee: Beatrice Foods Co., Chicago, Ill. 21) Appl. No.: 851,8 (22 Filed:

EDICT ± OF GOVERNMENT

EDICT ± OF GOVERNMENT Inordertopromotepubliceducationandpublicsafety,equal justiceforal,abeterinformedcitizenry,theruleoflaw,world tradeandworldpeace,thislegaldocumentisherebymade availableonanoncommercialbasis,asitistherightofal

EDICT ± OF GOVERNMENT Inordertopromotepubliceducationandpublicsafety,equal justiceforal,abeterinformedcitizenry,theruleoflaw,world tradeandworldpeace,thislegaldocumentisherebymade availableonanoncommercialbasis,asitistherightofal

Oregon Agricultural College Extension Service

Entered as second-class matter November 27, 1909. at the postoff ice at Corvallis, Oregon, under Act of July 16, 1894 Oregon Agricultural College Extension Service R. D. HETZEL Director The School Luncheon

Entered as second-class matter November 27, 1909. at the postoff ice at Corvallis, Oregon, under Act of July 16, 1894 Oregon Agricultural College Extension Service R. D. HETZEL Director The School Luncheon

United States Patent (113,607,299

United States Patent (113,7,299 72 21 22 ) 73 54) (52) (51) Inventor Gregory L. Bolt Cincinnati, Ohio Appl. No. 8,364 Fied Sept. 4, 1969 Patented Sept. 21, 1971 Assignee The Procter & Gamble Company Cincinnati,

United States Patent (113,7,299 72 21 22 ) 73 54) (52) (51) Inventor Gregory L. Bolt Cincinnati, Ohio Appl. No. 8,364 Fied Sept. 4, 1969 Patented Sept. 21, 1971 Assignee The Procter & Gamble Company Cincinnati,

Ancient Grains Cooking Table

Ancient Grains Cooking Table This table provides a quick, handy reference for cooking many different types of grains. The ratios given are for volumetric measuring. Grains are all measured as 1 (one) unit*

Ancient Grains Cooking Table This table provides a quick, handy reference for cooking many different types of grains. The ratios given are for volumetric measuring. Grains are all measured as 1 (one) unit*

Coffee Filter Chromatography

Here is a summary of what you will learn in this section: Solutions can be separated by filtration, paper chromatography, evaporation, or distillation. Mechanical mixtures can be separated by sorting,

Here is a summary of what you will learn in this section: Solutions can be separated by filtration, paper chromatography, evaporation, or distillation. Mechanical mixtures can be separated by sorting,

Factors affecting finished products

Factors affecting finished products See separate word document on factors affecting finished product as shown on next slide Too little Less moist Product become stale quicker Less flavour and colour TOO

Factors affecting finished products See separate word document on factors affecting finished product as shown on next slide Too little Less moist Product become stale quicker Less flavour and colour TOO

CODEX STANDARD FOR CANNED PEACHES 1 CODEX STAN

CODEX STAN 14 Page 1 of 8 1. DESCRIPTION 1.1 Product Definition 2 CODEX STANDARD FOR CANNED PEACHES 1 CODEX STAN 14-1981 Canned peaches is the product (a) prepared from peeled, stemmed, fresh or frozen

CODEX STAN 14 Page 1 of 8 1. DESCRIPTION 1.1 Product Definition 2 CODEX STANDARD FOR CANNED PEACHES 1 CODEX STAN 14-1981 Canned peaches is the product (a) prepared from peeled, stemmed, fresh or frozen

Judging Canned Fruits and Fruit Juices

Judging Canned Fruits and Fruit Juices Headspace for fruits should be ½ inch. Apple juice, grape juice and fruit purees use ¼ inch headspace. Canned fruit should meet all of the general characteristics

Judging Canned Fruits and Fruit Juices Headspace for fruits should be ½ inch. Apple juice, grape juice and fruit purees use ¼ inch headspace. Canned fruit should meet all of the general characteristics