ZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZ-->

|

|

|

- Hubert Hancock

- 5 years ago

- Views:

Transcription

1 Jan. 7, C. A. THOMAS ET AL METHOD OF ARTIFICIALLY AGING WHISKY Filed Sept. 12, E= autuavaaaaaaaaaaava V E22 V R % [+] YA.!zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz!}}}}}}}####zzzz kzzzzzzzz! Pºzzzzzº ZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZZ--> SAAA CarasA/Zama *Czro/A/7mm/

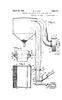

2 Patented Jan. 7, ,129 UNITED STATEs 2027,129 METO O OF ARTIFICIALLY AGING VVSK PATENT office Charles A. Thomas and Carroll A. Hochwatt, Dayton, Ohio, assignors, bymesne assignments, to Nelson S. Talbott, Dayton, Ohio Application September 12, 1934, Seria No. 43,72 This invention relatesto a method of treating green Whisky, such as Bourbon orrye, and is an improvement of the process disclosed in our co pending application Serial No. 703,14, filed December 19, An object of the invention isto provide anim proved process of treating whisky for the effec tive removal of undesirable taste and'odors com monly known in the industry as ºslopº or 10 greenº odor. Another object of the invention is to provide a process which removes such slopº orºgreen odors and which imparts an increased aromato the whisky. V 1 More specifically, an object of the invention resides in the provision of a process for hydro -genating whisky in the vaporphase in the pres ence of a catalyst. In the preferred embodi ment, green whisky in vapor form is mixed With 20 hydrogen and brought into intimate contact with a catalyst capable of promoting thereaction of º the hydrogen with the constituents of the whisky to effect the elimination of deleterious odors and - taste and improve the aroma. This step of º hydrogenation may be followed by treatment of the resulting product in charred. kegs or with the activated chars disclosed in our copending application above referred to in order tolend i color to the whisky and still further increase the 0 aromathereof. - Y --- Other objects and advantages of the invention. will appear in the following. description of the preferred embodiment of the invention illus trated by the accompanying drawing, of which: º Figure 1 is avertical sectional view of one modification i form of apparatus; and I Figure 2 is a simidar view of a Referring more particularly to the drawing, º in Figurei. I O indicates a condenser for lique fying the weak whisky from the primary still i (not shown). The weak whisky from the con densero is conducted by the pipe in and droppedinto heated Water in a doubler still i 2. 4º The water in the doubler still 12 may be heated in any known or convenient manner but is pref erably heated by steam passed through the coils. of thecatalytic treating chamber. * -- 6 Caims. (C ) 3 positioned in the doubler still. The green. whisky vapors from the doubler stil 2 are º passed through a pipe 4, blower 1, and pipe i6 into a catalytic treating chamber i 7. The treating chamber T isparty filled with a body : of water i 8 heated by any convenient means, such as a steam coil 19. The Water contains a sº finely divided catalyst such as powdered nickel in suspension. The pipe 6 extends below the surface of the water and terminates adiacent the bottom of the chamber 17 in vapor dis tributing member 20 provided with a plurality of Small apertures.2. Prior to passing the green whisky vapors into i the treating chamber 17, hydrogen is injected into and mixed with the vapors in the pipe 4 by means of a pipe 22 connected to a source of hydrogen (not shown). The blower i forces 10 the mixed vapors and hydrogen through the pipe 6 and apertures 2 sothat the mixture bubbles up through the heated water i 8 in contact with º the suspended catalyst. The resultanti agitation of the wateraids in keeping the catalyst in sus 1 pension and insures intimate contact thereof with the mixture of vapors and hydrogen. The temperature of the water is preferaby main tained above the condensation temperature of the Whisky vapors so that hydrogenation takes 20 place in the vapor phase. The treated vapors and any excess hydrogen collect above the sur face of the Water 8 in the treating chamber I 17 and are conducted by a pipe 23 to a con denser 24 Where the whisky vapors are liquefied. 2 From the condenser 24, the excess hydrogen and liquefied whisky are conducted by pipe 2to a hydrogen separating chamber 26 in which the hydrogen collects above the liquid Whisky. The excess hydrogen is returned to the process by, a 30 pipe 27 from the upper portion of the separat ing chamber 26, a blower 28 and pipe 29 con necting with pipe 4 on the low pressure side of blower. The liquid whisky in the separating chamber 26 may be conducted by a pipe 80, a 3 pump 3, and a pipe 32 to storage means (not shown), which may be in charredi kegs in order tolend, color to the whisky and further increase its aroma, or the whisky from the separating chamber 26 may be subjected to treatment byan 40. activated char as disclosed in applicants' above mentioned. co-pending application. The green whisky vapors. may be hydrogen ated at temperatures ranging from the border line between liquid and vaporphase hydrogen-4 ation, which is 90 to 9 C., up to the boiling point of the water, which is approximately. 100 C. The temperature of hydrogenation, hovever, influences.the aroma and flavor of the resulting whisky. The preferred temperature is approxi- 0 mately 100 C. Attemperatures of 90 to 9 C. the resulting product has a somewhat spicytaste and is not quite as aromatic as with the higher temperatures. At. 100º C, however, this spicy taste disappears entirely and the aromatic quale M

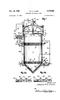

3 S30 S s i 2 ity of the Whisky is increased The ester con that a single treating chamber may be provided tent, goes up approximately 2 parts per One if it has sufficient capacity to treat the VaporS hundred thousand, Whereas the Original green coming from the still or, if necessary, a larger whisky has only around 10 to 11 parts per one number of treating chambers may be employed. hundred thousand. The treating chambers 33 are preferably Sur- It is to be noted that the pressure in the Sys rounded by heating jackets 34 so as to enable tem, orat least that in the catalytic chamber, the treating chambers to be kept at any desired may be increased in order to enable the tem temperature and steam is the heating medium perature in the catalytic chamber to be raised preferably employed. The treating chambers 33 to increase the rate of reaction. This, however, contain a catalyst capable of promoting hydro- 10 introduces operating difficulties not present genation of the green whisky vapor, preferably When substantially atmospheric pressure is used in finely divided form and supported by an inert in the cataltyic chamber. Also, at temperatures material 3. above 120 C., the ester content increases to an. After passing through the treating chambers undesirable extent. 33, the treated vapor and excess hydrogen are 1 As a specific example of the process, the green conducted through the pipe 23 to the hydrogen whisky vapors from the doubler still i 2 may be separating chamber 24 of Figure 1. From the under a pressure of approximately three pounds separating chamber, the hydrogen is returned per square inch. The head of catalytic Suspen to the process as described with respect to Fig sion above the distributing member 20 in the ure 1. The hydrogenated whisky may then be 20 treating chamber i may be approximately ten further treated in charred. kegs or with activated feet. An excess of hydrogen is admitted into char, as also described with respect to the modi the pipe f 4 by the pipe 22 so as to form a mix fication shown in Figure 1. ture With the green Whisky Vapors, and the pres The catalyst also, preferably used in this mod Sure of the mixture is raised to approxinately ification of the process is finely divided nickel. 2 eight pounds per square inch by the blower i The finely divided catalyst is packed with a po in order to Overcome the head of catalyst Sus rous body of inert material such as asbestos, pension in the treating chamber l'7. The green charcoal, coke, pumice stone, orany other porous Whisky vapors in the pipe I 4 may have a tem inert material. This packing acts as a support perature of 80 to 90 C., and the water 8 in the for the finely divided nickel, which is preferably 30 treating chamber is preferably heated to a tem a two hundred mesh active nickel, and the ca perature of approximately 100 C. so as to be at talyst is thoroughly distributed over the inert or near the boiling point thereof. Under these carrier and rests on the Surface and in the poges conditions the Whisky vapors remain in the vapor of the material. Besides this supporting func phase while contacting the catalyst suspended in tion, the carrier also acts to baffile and agitate 3 the Water. The mixture of Whisky vapors and the vapors, thus affording repeated and intimate hydrogen leaves the apertures 2 of the dis contact with the catalyst while in the treating tributing member 20 in the form of small bubbles chamber. and intimately contacts the suspended catalyst. While finely divided nickel is preferably used. The catalyst preferably employed is finely di vided nickel having a particle size sufficiently as the catalyst in this modification, the other 4o catalytic materials Such as the platinum, iron, Small to remain in suspension during the treat chrominum, or copper oxide before mentioned, ing operation and is preferably 200 mesh active or any other catalyst which has the capability nickel. While finely divided nickel is preferably of effecting hydrogenation, may be andare con templated by our process. As hereinbefore 4 used, other catalytic materials such as platinum, iron, chromium, copper oxide, or any other cat alyst which is capable of effecting hydrogena tion and being Suspended in Water, may be used and are contemplated by our process. Such catalysts apparently carry a Small amount of adsorbed oxygen since slight oxidation resulting in the formation of aldehydes also occurs during the hydrogenation process. The time of reac tion during which the Whisky vapor and hydro gen are subjected to contact With the catalyst Will vary with the catalyst and cannot be def initely stated. It Will be apparent, however, to those skilled in the art that the vapors must be. maintained in contact with the catalyst a suf fficientlength of time to remove the deleterious Odors and taste and increase the aroma of the Whisky to the desired extent. In Figure 2 is shown a different form of cat alytic treating device for effecting vapor phase hydrogenation of green Whistky in Which the Same reference characters are used for portions of the apparatus which are identical With those of the modification shown in Figure 1. In this modification the pipe A from the doubler still has connected thereto the hydrogen inlet pipe 22 and hydrogen return pipe 29 and leads di rectly to a plurality of treating chambers 33. i The treating chambers 33 are shown in dupli cate in order to increase the amount of vapor which may be treated, but it is to be understood stated, such catalysts carry a small amount of adsorbed oxygen. Also in this modification of the process the time of reaction during Which the Whisky vapor and hydrogen are subjected to contact with the catalyst cannot be definitely 60 stated since it will vary with the catalyst used and the temperature of the treating zone. For the same reasons as in the first described modi ffication of the process, the necessary time of re action will be apparent to those skilled in the 6 art. In this modification of the process, the green Whisky vapors may be hydrogenated at tempera tures ranging from the borderline between liquidi and vapor phase hydrogenation, that is, 90 to 00 9º C. up to 10 C. The preferred temperature is, however, approximately 120 C. At tempera tures of 90 to 9º C., the resulting product has a somewhat spicy taste and is not quite as aro matic as with higher temperatures. With tem-º peratures between 100 and 120 C., however, this spicy taste disappears and the aromatic quality of the Whisky is increased. As stated with refer ence to the modification of Figure 1, the ester content goes up to approximately 2 parts per 70 one hundred from the I0 to i parts per one thousand in the original green Whisky. Because of greater speed of reaction, the upper limit of this range (approximately 120 C.) is preferred.

4 At temperatures above 120 C. the ester contentº increases quite rapidly, and at hydrogenation temperatures of 10 to 160º C. the resultant productis full of esters and resembles a brandy more than a whisky. Also at these temperatures the aldehydes develop to a point where they be come objectional. Ashereinbefore stated, the present invention is an improvement over the liquid. phase process Of our above mentioned copending application, and the vaporphase hydrogenation product is better in every way than the liquidi phase product. The i ester content is raised considerably, and the spicy taste which always occurs With liquid phase hydrogenation is absent when the green whisky vapors are hydrogenated in the vapor phase. The product has amore whisky-like odor and taste so that when followed by the secondi step eitherby treatment with the activated char dis closed in our copending application above re ferred to, or by aging in a charred barrel, the product represents a very potable whisky. By the vaporphase treatment of the present inven tion the aldehydes are increased slightly, Which is a desirable feature as they help to increase the aroma and taste of the whisky. This is probably caused by a Small percentage of ad sorbed oxygen on the nickel catalyst, and even though the reaction is carried on in a reduction atmosphere of hydrogen, nevertheless some oxi dation occurs, causing formation of aldehydes. By maintaining the temperature of hydrogena tion between approximately 100 and 120 C., the quantities of aldehydes formed are not objec tionable-to the whisky although if the tempera ture of hydrogenation is too high, too large a quantity of them forms, which makes the whisky objectionable. Furthermore, the vapor phase process of hydrogenating green Whisky does not interfere in any Way with the regular distiling operations but is carried on as a continuous step in such distilling operations. If desired a por tion only of the green whisky vapors from the doubler still may be diverted to the hydrogena tion process and the remaining portion sub jected to the conventional processes. While We have described our process of vapor phase 'hydrogenation in connection With a dis tilling operation, it is to be understood that the improved results from vapor phase hydrogena tion may be accomplished by injecting liquid green whisky not taken directly from a still into heated Water and the resultant vapors passed through the vapor phase, hydrogenation step. The process mayalso be performed by directly heating liquidi green whisky and passing the evolved vapors through the hydrogenation step. This last mentioned modification, however, has the disadvantage that the first vapors evolved consist mainly of alcohol and the last vapors are principally water and that Some of the solids present in the green whisky remain in the heat ing chamber. fall the condensate from the last mentioned is collected in the same receiver, how ever, the resulting product represents substanti ally all of the whisky. while we have described the preferred embodi ment of our invention, it is understood that the details of the invention may be varied within the scope of the following claims. We claim as our invention: 1. The method of artificially aging Whisky to improve its odor and taste, which comprises, the step of passing said whisky in vapor phase with hydrogen over al hydrogenating catalyst, and maintaining said whisky in vapor phase during the treatment thereof with said hydrogen and catalyst. 2. The method of artificialy aging Whisky to improve its odor and taste, which comprises, treating the same in vaporphase with hydrogen in the presence of a hydrogenating catalyst, and maintaining said whisky in vapor phase during the treatment thereof with said hydrogen and catalyst. 3. The method of artificially aging whisky to improve its odor and taste, Which comprises, the steps of introducing it to a zone containing boilingwater, leading the vapors thus generated to a hydrogenating zone Where they are treated in the presence of hydrogen, anda hydrogenat ing catalyst and in finally condensing the thus treated product. 4. The method of artificially aging green whisky to improve its odor. and taste, which 20 comprises, treating the same in vaporphase with hydrogen in the presence of the hydrogenating catalyst at a temperature of from about 9º C. to about 10 C., and maintaining said whisky in vapor phase during the treatment thereof 2 with said hydrogen and catalyst. : 4. The method of artificially aging green whisky to improve its odor and taste, which comprises, passing the whisky in vapor phase and in admixture with hydrogen over a hy-3) drogenating catalyst maintained at a tempera ture of approximately 120 C.. 6. A process for artificially aging green whisky to improve its odor and taste, which comprises, converting the whisky into a vapor 3 of uniform composition by continuousy depos iting the liquor onto a body of water maintained at the distillation temperature of the whisky, adding hydrogen to the resultant vapors and passing the vaporous mixture thus formed into 40 contact with a hydrogenating catalyst main tained at a temperature adequate toreact the hydrogen with constituents of the 2 vaporized whisky, subsequenty condensing the thustreat ed whisky vapors, and separating the resultant 4 condensate from excess hydrogen. 7. In a process of artificially. aging whisky to improve its odor and taste, the step which comprises, contacting whisky vapors with finely divided nickel in the presence of hydrogen, and 0 maintaining the alcohol of said whisky in vapor phase while in contact with said nickel. 8. In a process of artificially aging whisky to improve its odor and taste, the step Which com prises, contacting a mixture of whisky vapor and hydrogen with finely divided catalyst capable of promoting a hydrogentzing reaction while said catalyst is supported by an inert porous material, and maintaining said whisky in vapor phase while in contact with said catalyst. 9. In a process of artificially aging whisky to improve its odorandi taste, the steps which com prise, passing green whisky vapors and hydro gen through a treating zone containing finely di vided nickel supported by an inert porous ma terial and maintaining said zone at a tempera ture of substantially 120º C, and maintaining said whisky in vaporphase while in said treat 10. In' a process of manufacturing Whisky O Wherein said whisky is artificially aged to im prove its odor and taste, the steps which com prise, distilling said whisky, mixing hydrogen with the evolved whisky vapors to forma mix-7 3 O

5 2 0 I S 30 4 ture of hydrogen and whisky vapors, continuous ly passing Said mixture through a treating zone maintained at a temperature above the lique fication point of Said vapors and containing a catalyst capable of promoting a hydrogenating reaction, and condensing said vapors. 11. In a process of manufacturing Whisky Wherein Said Whisky is artificially aged to im prove its odor and taste, the steps which com prise, distilling said Whisky, mixing hydrogen With the evolved Whisky vapors to form a mix ture of hydrogen and Whisky vapors, passing said mixture through a treating zone main tained at a temperature above the liquefication point of the vapors and containing a catalyst capable of promoting a hydrogenating reaction, condensing said vapors, and subjecting the thus deoderized Whisky to treatment with charred Wood containing alcohol solubles and continu ing Such treatment until the Whisky has been sufficiently aged by said solubles. 12. The method of artificially aging green Whisky to improve its odor and taste, Which comprises, the steps of treating the green Whis ky with a finely divided hydrogenating catalyst, in deodorizing the green Whisky by reacting the odoriferous constituents of the Whisky in the vapor phase With hydrogen in the presence of the hydrogenating catalyst while maintaining the same under pressure sufficient to maintain chemical hydrogenation of the odoriferous con stituents in a substantially non-oxidizing atmos phere, continuing the hydrogenation reaction under said substantially non-oxidizing atmos phere until the green Whisky has been Substan tially deodorized, maintaining said Whisky in vapor phase while in the presence of said cata lyst, and subjecting the thus deodorized whisky to treatment with charred Wood containing al cohol solubles and continuing such treatment until the whisky has been sufficiently aged by said solubles. 13. The method of artificially aging whisky by hydrogenating said whisky to improve its odor and taste, which comprises, bubbling a mixture of Whisky vapors and hydrogen through a body of Water having a finey divided catalyst Suspended therein, and maintaining the tem perature of the Water sufficiently high to keep the alcohol of the whisky in vapor phase during Said hydrogenating. 14. The method of artificially aging whisky by hydrogenating said whisky to improve its odor and taste, Which comprises, contacting a mix ture of Whisky vapors and hydrogen with a cata lyst in the presence of Water at a temperature above the condensation, point of the vapors so as to maintain the alcohol of the whisky in * vapor phase during Said hydrogenating. 1. The method of artificially aging Whisky by hydrogenating said whisky to improve its odor and taste, which comprises, introducing a mixture of Whisky vapors and hydrogen into a treating zone and bubbling Said mixture through a body of Water containing a finely divided cat alyst, and maintaining said water at the boil ing temperature of the water at the pressure in said zone so as to maintain the alcohol of the whisky in vapor phase during said hydrogenat ing 16. The method of artificially aging whisky by hydrogenating said whisky to improve its odor and taste, Which comprises, contacting a rnix ture of Whisky vapors and hydrogen With a cat 0 3O alyst in the presence of water at a temperature 3 of approximatey 100º C, and maintaining the alcohol of said whisky in vapor phase during said hydrogenating. M O 2 CHLARILES A. THOMAS. CARROLL A. HOCEVALT. 40

May 12, ,282,708 T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE. Filed Sept. 26, Sheets-Sheet l. --No.zzzzzzzzzzae.

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

(*) Notice: Subject to any disclaimer, the term of this E. E. E. E. O.C.

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

United States Patent (19) Forino

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

United States Patent (19) Forino (54) 76) 21 22 (51) (52) (58) 56) METHOD FOR MAKING FERMENTED BEVERAGES Inventor: Vincent Forino, 2922 E. Main St., Waterbury, Conn. 06705 Appl. No.: 204,888 Filed: Jun

III. United States Patent (19) Binacchi. Attorney, Agent, or Firm-Bucknam and Archer 57 ABSTRACT. 6 Claims, 3 Drawing Sheets

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

US 20030003199A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0003199 A1 Perez (43) Pub. Date: Jan. 2, 2003 (54) METHOD AND APPARATUS FOR Publication Classification UTILIZING

United States Patent (19) 11 4,094,997 Aishima et al. 45 June 13, 1978

United States Patent (19) 11 Aishima et al. 45 June 13, 1978 (54) BEEF FLAVORSUBSTANCE, PROCESS FOR 56) References Cited PRODUCING SAME AND BEEFFLAVORNGAGENT U.S. PATENT DOCUMENTS 3,394,0 7/1968 Giacino...

United States Patent (19) 11 Aishima et al. 45 June 13, 1978 (54) BEEF FLAVORSUBSTANCE, PROCESS FOR 56) References Cited PRODUCING SAME AND BEEFFLAVORNGAGENT U.S. PATENT DOCUMENTS 3,394,0 7/1968 Giacino...

United States Patent (19)

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

(19) United States US 201101 17255A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0117255A1 BrOWn et al. (43) Pub. Date: (54) ALCOHOLIC BEVERAGE FORMULATION (52) U.S. Cl.... 426/330.4; 426/592

(19) United States US 201101 17255A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0117255A1 BrOWn et al. (43) Pub. Date: (54) ALCOHOLIC BEVERAGE FORMULATION (52) U.S. Cl.... 426/330.4; 426/592

7 IANSNA. (12) Patent Application Publication (10) Pub. No.: US 2003/ A1. (19) United States 2//

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

Sept. 7, l.t. ward 2,092,596 SIPHON

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

---- ÆØerá Z3zzegzée. Vzerzega2ZY.Zazee. June 16, Zee/ErzezØrzs 2,286, Sheets-Sheet 2 D G O D D D OD

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(2-12. Zazza72M4 Aarzanez. Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS. Zaza/adar. aeo/ae/ -- e

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

Nov. 24, 1953 L. M. BERTRAND 2,660,134 PROCESS FOR MANUFACTURING BREAD STICKS Filed July 4, 1948-2 Sheets-Sheet l -- e i Zaza/adar Zazza72M4 Aarzanez (2-12 Z3 aeo/ae/ X cºsss!=================================

(12) United States Patent

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

(12) United States Patent Song-Bodenstab et al. USOO654.1056B1 (10) Patent No.: (45) Date of Patent: Apr. 1, 2003 (54) MALTED BEVERAGE POWDER AND PROCESS (75) Inventors: Xiaomei Song-Bodenstab, Mannens

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

A33. AORNEY. March 22, G. C. HERZ, 1,850,719. APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC. Filed Dec, l6, l Sheets-Sheet l NVENTOR

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

United States Patent (19) 11) 4,167,008 Blickenstaff 45) Sep. 4, 1979

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

Coffee Filter Chromatography

Here is a summary of what you will learn in this section: Solutions can be separated by filtration, paper chromatography, evaporation, or distillation. Mechanical mixtures can be separated by sorting,

Here is a summary of what you will learn in this section: Solutions can be separated by filtration, paper chromatography, evaporation, or distillation. Mechanical mixtures can be separated by sorting,

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States US 2004O147769A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0147769 A1 Davis (43) Pub. Date: Jul. 29, 2004 (54) OIL EXTRACTION PROCESS AND Publication Classification

(19) United States US 2004O147769A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0147769 A1 Davis (43) Pub. Date: Jul. 29, 2004 (54) OIL EXTRACTION PROCESS AND Publication Classification

Center et al. (45. Date of Patent: Aug. 29, 1995

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

United States Patent (19) 11 USOO5445287A Patent Number: 5,445,287 Center et al. (45. Date of Patent: Aug. 29, 1995 54 CO-DISPENSING SNACK FOOD PRODUCTS 5,176,287 1/1993 Suris AND BEVERAGES FROM A VENDING

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. Lange (43) Pub. Date: Nov. 22, 2012

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

US 2004O241299A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0241299 A1 Zhang (43) Pub. Date: (54) FUNCTIONAL WATER Publication Classification (75) Inventor: Shi Qiu Zhang,

(12) United States Patent (10) Patent No.: US 8,601,937 B2

USOO8601937B2 (12) United States Patent () Patent No.: Campetella et al. (45) Date of Patent: Dec., 2013 (54) APPARATUS FOR MAKING COFFEE 5,605,091 A * 2/1997 Garber... 99,330 5,650,186 A * 7/1997 Annoni

USOO8601937B2 (12) United States Patent () Patent No.: Campetella et al. (45) Date of Patent: Dec., 2013 (54) APPARATUS FOR MAKING COFFEE 5,605,091 A * 2/1997 Garber... 99,330 5,650,186 A * 7/1997 Annoni

United States Patent (19) Peterson

United States Patent (19) Peterson 54) YOGURT FLAVORED CONFECTIONERIES 75 Inventor: Marvin A. Peterson, Park Ridge, Ill. 73) Assignee: Beatrice Foods Co., Chicago, Ill. 21) Appl. No.: 851,8 (22 Filed:

United States Patent (19) Peterson 54) YOGURT FLAVORED CONFECTIONERIES 75 Inventor: Marvin A. Peterson, Park Ridge, Ill. 73) Assignee: Beatrice Foods Co., Chicago, Ill. 21) Appl. No.: 851,8 (22 Filed:

United States Patent (19)

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States US 201602896.19A1 (12) Patent Application Publication (10) Pub. No.: US 2016/02896.19 A1 Mancosky (43) Pub. Date: (54) AGING OF ALCOHOLIC BEVERAGES CI2G 3/07 (2006.01) USING CONTROLLED

(19) United States US 201602896.19A1 (12) Patent Application Publication (10) Pub. No.: US 2016/02896.19 A1 Mancosky (43) Pub. Date: (54) AGING OF ALCOHOLIC BEVERAGES CI2G 3/07 (2006.01) USING CONTROLLED

United States Patent (19) Morrison, Jr. et al. (54)

United States Patent (19) Morrison, Jr. et al. (54) (75) (73) 21 22 (51) 52) (58) (56) DESOLVENTIZNG PROCESS Inventors: Lowen R. Morrison, Jr., Hamilton; John H. Phillips, Fairfield, both of Ohio Assignee:

United States Patent (19) Morrison, Jr. et al. (54) (75) (73) 21 22 (51) 52) (58) (56) DESOLVENTIZNG PROCESS Inventors: Lowen R. Morrison, Jr., Hamilton; John H. Phillips, Fairfield, both of Ohio Assignee:

March 24, 1970 H. H. BRIDGFORD 3,502,488 COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER HUGH. BROGFORD / ATTORNEY

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

United States Patent (19)

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

(12) United States Patent (10) Patent No.: US 6,813,994 B2

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

United States Patent (19) Bowen et al.

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

United States Patent (19) Bowen et al. 11) Patent Number: 5,004,617 45 Date of Patent: Apr. 2, 1991 54 (75) (73) 21 22) 62 (51) 52) (58) METHOD OF HEATING FOOD Inventors: Assignee: Appl. No.: 448,408 Robert

W. A. HEYMAN 2,432,759. Dec. 16, PROCESS OF MAKING COFFEE CONCENTRATES. Filed Jan., l94l. it. Attorney

Dec. 16, 1947. W. A. HEYMAN 2,432,759 PRCESS F MAKING CFFEE CNCENTRATES Filed Jan., l94l S it. Attorney Patented Dec. 16, 1947 UNITED STATE s PATENT FFICE 2,432,759. PRCESS F MANG CFFEE concentrates 1

Dec. 16, 1947. W. A. HEYMAN 2,432,759 PRCESS F MAKING CFFEE CNCENTRATES Filed Jan., l94l S it. Attorney Patented Dec. 16, 1947 UNITED STATE s PATENT FFICE 2,432,759. PRCESS F MANG CFFEE concentrates 1

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1. Hurley et al. (43) Pub. Date: Aug. 28, PROCESS Publication Classification

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

JUICE EXTRACTION AND FILTRATION JUICE EXTRACTION METHOD AND EQUIPMENT

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

United States Patent (19) Denier et al.

United States Patent (19) Denier et al. 11 Patent Number: 4,744,37 4 Date of Patent: May 17, 1988 (4) 7 73) (21) 22) 1 (2) (8) PROCESS FOR FORMING FLAVOR COMPOUNDS IN TOBACCO Inventors: Robert F. Denier;

United States Patent (19) Denier et al. 11 Patent Number: 4,744,37 4 Date of Patent: May 17, 1988 (4) 7 73) (21) 22) 1 (2) (8) PROCESS FOR FORMING FLAVOR COMPOUNDS IN TOBACCO Inventors: Robert F. Denier;

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

(19) United States US 20120286O78A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0286078 A1 Bresciani (43) Pub. Date: Nov. 15, 2012 (54) (76) (21) (22) (60) THERMALLY CONTROLLED COFFEE GRINDER

United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0017300 A1 Avila et al. US 2013 001.7300A1 (43) Pub. Date: (54) (75) (73) (21) (22) (60) METHOD OF PREPARING AN OATCONTAINING

US A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(19) United States US 20020023912A1 (12) Patent Application Publication (10) Pub. No.: US 2002/0023912 A1 McGee et al. (43) Pub. Date: Feb. 28, 2002 (54) (76) Inventors: Roy McGee, Little Rock, AR (US);

(12) United States Patent (10) Patent No.: US 6,514,552 B1

USOO6514552B1 (12) United States Patent (10) Patent No.: Sivetz (45) Date of Patent: Feb. 4, 2003 (54) METHOD FOR KEEPING ROAST COFFEE JP 8-OOO175 9/1996 BEAN FRESHINESS WO WO985.7862 * 12/1998 (76) Inventor:

USOO6514552B1 (12) United States Patent (10) Patent No.: Sivetz (45) Date of Patent: Feb. 4, 2003 (54) METHOD FOR KEEPING ROAST COFFEE JP 8-OOO175 9/1996 BEAN FRESHINESS WO WO985.7862 * 12/1998 (76) Inventor:

United States Patent (19) Adams et al.

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

(12) United States Patent

US007582325B2 (12) United States Patent Giori () Patent No.: (45) Date of Patent: Sep. 1, 2009 (54) PROCESS FOR THE PREPARATION OF TOMATO EXTRACTS WITH HIGH CONTENT IN LYCOPENE (75) Inventor: Andrea Giori,

US007582325B2 (12) United States Patent Giori () Patent No.: (45) Date of Patent: Sep. 1, 2009 (54) PROCESS FOR THE PREPARATION OF TOMATO EXTRACTS WITH HIGH CONTENT IN LYCOPENE (75) Inventor: Andrea Giori,

III IIIHIII. United States Patent (19) Momiyama

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

United States Patent (19) Momiyama 54 METHOD OF MANUFACTURING INSTANT NOODLESTRP HAVING GOOD RECONSTITUTING PROPERTY 75) Inventor: Yasuo Momiyama. Kashiwa, Japan 73) Assignee: Sanyo Shokuhin Co., Ltd.,

(12) United States Patent (10) Patent No.: US 6,419,120 B1

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

HYDROGEN-ION CONCENTRATION OF PROTOZOAN CULTURES.

HYDROGEN-ION CONCENTRATION OF PROTOZOAN CULTURES. JOSEPH HALL BODINE, ZOOLoGICAL LABORATORY, UNIVERSITY OF PENNSYLVANIA. The chemical changes taking place in ordinary hay infusions used for protozoan cultures

HYDROGEN-ION CONCENTRATION OF PROTOZOAN CULTURES. JOSEPH HALL BODINE, ZOOLoGICAL LABORATORY, UNIVERSITY OF PENNSYLVANIA. The chemical changes taking place in ordinary hay infusions used for protozoan cultures

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

United States Patent (19)

United States Patent (19) Farkye et al. 4 (7) 73) 21) 22 1 (2) 8 6) CHEESE MAKING PROCESS Inventors: Nana Y. Farkye, Atascadero; B. Bhanu Prasad, San Luis Obispo, both of Calif. Assignee: California Polytechnic

United States Patent (19) Farkye et al. 4 (7) 73) 21) 22 1 (2) 8 6) CHEESE MAKING PROCESS Inventors: Nana Y. Farkye, Atascadero; B. Bhanu Prasad, San Luis Obispo, both of Calif. Assignee: California Polytechnic

United States Patent (19) 11, 3,979,527 Laws et al. (45) Sept. 7, 1976

United States Patent (19) 11, 3,979,527 Laws et al. () Sept. 7, 1976 54 PREPARATION OF HOP OIL OTHER PUBLICATIONS 75 Inventors: Derek Roy James Laws; John - a Anthony Pickett, both of Nutfield, Howard

United States Patent (19) 11, 3,979,527 Laws et al. () Sept. 7, 1976 54 PREPARATION OF HOP OIL OTHER PUBLICATIONS 75 Inventors: Derek Roy James Laws; John - a Anthony Pickett, both of Nutfield, Howard

United States Patent (113,607,299

United States Patent (113,7,299 72 21 22 ) 73 54) (52) (51) Inventor Gregory L. Bolt Cincinnati, Ohio Appl. No. 8,364 Fied Sept. 4, 1969 Patented Sept. 21, 1971 Assignee The Procter & Gamble Company Cincinnati,

United States Patent (113,7,299 72 21 22 ) 73 54) (52) (51) Inventor Gregory L. Bolt Cincinnati, Ohio Appl. No. 8,364 Fied Sept. 4, 1969 Patented Sept. 21, 1971 Assignee The Procter & Gamble Company Cincinnati,

United States Patent (19) D'Alessandro

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

US 2007003 1551A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0031551A1 Samson et al. (43) Pub. Date: (54) METHOD FOR CONTINUOUSLY Publication Classification PROCESSING

US 2007003 1551A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0031551A1 Samson et al. (43) Pub. Date: (54) METHOD FOR CONTINUOUSLY Publication Classification PROCESSING

Dec. 9, M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

INFLUENCE OF ENVIRONMENT - Wine evaporation from barrels By Richard M. Blazer, Enologist Sterling Vineyards Calistoga, CA

INFLUENCE OF ENVIRONMENT - Wine evaporation from barrels By Richard M. Blazer, Enologist Sterling Vineyards Calistoga, CA Sterling Vineyards stores barrels of wine in both an air-conditioned, unheated,

INFLUENCE OF ENVIRONMENT - Wine evaporation from barrels By Richard M. Blazer, Enologist Sterling Vineyards Calistoga, CA Sterling Vineyards stores barrels of wine in both an air-conditioned, unheated,

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

US 20070178190A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0178190 A1 Vatelot (43) Pub. Date: Aug. 2, 2007 (54) GRAPE TREATMENT METHOD FOR WINE (30) Foreign Application

US 20070178190A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0178190 A1 Vatelot (43) Pub. Date: Aug. 2, 2007 (54) GRAPE TREATMENT METHOD FOR WINE (30) Foreign Application

United States Patent It 3,593,647

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

Comparative determination of glycosides in senna by using different methods of extraction (Soxhlet, maceration and ultrasonic bath)

1 Experiment 1, 2 and 3 Comparative determination of glycosides in senna by using different methods of extraction (Soxhlet, maceration and ultrasonic bath) Aim: determine the yield among different extraction

1 Experiment 1, 2 and 3 Comparative determination of glycosides in senna by using different methods of extraction (Soxhlet, maceration and ultrasonic bath) Aim: determine the yield among different extraction

52 U.S. Cl... 99/295; 99/299; 99/305; 99/ / ) References Cited U.S. PATENT DOCUMENTS 1,778,792 10/1930 Cameron...

United States Patent (19) Glucksman (54) APPARATUS FOR BREWING COFFEE 76) Inventor: Dov Z. Glucksman, 137 Larch Row, Wenham, Mass. 01984 21 Appl. No.: 636,137 22 Filed: Dec. 31, 1990 51 Int. Cl.5......

United States Patent (19) Glucksman (54) APPARATUS FOR BREWING COFFEE 76) Inventor: Dov Z. Glucksman, 137 Larch Row, Wenham, Mass. 01984 21 Appl. No.: 636,137 22 Filed: Dec. 31, 1990 51 Int. Cl.5......

May 16, 1961 L. TALALAY ETAL 2,984,631 METHOD FOR MAKING LATEX FOAM RUBBER. Filed May 1, 1959 INVENTORS LEON TALALAY. By GEORGE F.

May 16, 1961 L. TALALAY ETAL 2,984,631 METHOD FOR MAKING LATEX FOAM RUBBER Filed May 1, 199 INVENTORS LEON TALALAY By GEORGE F. WATERS 3-7-, United States Patent Office 2,984,631 Patenied May 16, 1961

May 16, 1961 L. TALALAY ETAL 2,984,631 METHOD FOR MAKING LATEX FOAM RUBBER Filed May 1, 199 INVENTORS LEON TALALAY By GEORGE F. WATERS 3-7-, United States Patent Office 2,984,631 Patenied May 16, 1961

(12) United States Patent (10) Patent No.: US 6,550,552 B1

USOO6550552B1 (12) United States Patent (10) Patent No.: Pappa et al. (45) Date of Patent: Apr. 22, 2003 (54) METHOD FOR THE REMOVAL AND 4,434,028 A * 2/1984 Eppig et al.... 196/14.52 RECOVERY OF THE OL

USOO6550552B1 (12) United States Patent (10) Patent No.: Pappa et al. (45) Date of Patent: Apr. 22, 2003 (54) METHOD FOR THE REMOVAL AND 4,434,028 A * 2/1984 Eppig et al.... 196/14.52 RECOVERY OF THE OL

United States Patent (19) Aldrich

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

United States Patent (19) Aldrich 54 CO-DEPOSITED TWO-COMPONENT HARD CANDY 75 Inventor: Deborah G. Aldrich, Stamford, Conn. 73) Assignee: Nabisco Brands, Inc., Parsippany, 21 Appl. No.: 455,162 (22 Filed:

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080216664A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0216664 A1 K00n et al. (43) Pub. Date: Sep. 11, 2008 (54) ELECTRONICTEATHERMOMETER AND TIMER DEVICE (75) Inventors:

(19) United States US 20080216664A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0216664 A1 K00n et al. (43) Pub. Date: Sep. 11, 2008 (54) ELECTRONICTEATHERMOMETER AND TIMER DEVICE (75) Inventors:

(12) United States Patent (10) Patent No.: US 6,814,997 B2

USOO6814997B2 (12) United States Patent (10) Patent No.: Maier et al. () Date of Patent: Nov. 9, 2004 (54) SOLUBLE POWDER FOR ESPRESSOTYPE 5,620,733 A 4/1997 Chaveron et al.... 426/580 BEVERAGE 5,882,716

USOO6814997B2 (12) United States Patent (10) Patent No.: Maier et al. () Date of Patent: Nov. 9, 2004 (54) SOLUBLE POWDER FOR ESPRESSOTYPE 5,620,733 A 4/1997 Chaveron et al.... 426/580 BEVERAGE 5,882,716

United States Patent [11] 3,559,565

![United States Patent [11] 3,559,565 United States Patent [11] 3,559,565](/thumbs/93/114425987.jpg) United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

22 Filed: Jun. 6, 1995 (51) Int. Cl... A22C 9/ U.S. Cl /141; 426/56; 426/63 58) Field of Search /141, 142, Canner/Cutter

United States Patent (19) Teran IIII US0055120A 11 Patent Number: 45) Date of Patent: Apr., 1996 54 MEATTENDERIZATION PROCESS FOR A MICROWAVABLE MEAT PRODUCT 76 Inventor: James Teran, 932 E. Thames St.,

United States Patent (19) Teran IIII US0055120A 11 Patent Number: 45) Date of Patent: Apr., 1996 54 MEATTENDERIZATION PROCESS FOR A MICROWAVABLE MEAT PRODUCT 76 Inventor: James Teran, 932 E. Thames St.,

United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993

USOO5230281A United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993 (54) APPARATUS FOR ROASTING COFFEE 4,924.765 5/1990 Pera... 99/470 BEANS OR THE LIKE

USOO5230281A United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993 (54) APPARATUS FOR ROASTING COFFEE 4,924.765 5/1990 Pera... 99/470 BEANS OR THE LIKE

Effects of Preharvest Sprays of Maleic Hydrazide on Sugar Beets

Effects of Preharvest Sprays of Maleic Hydrazide on Sugar Beets F. H. PETO 1 W. G. SMITH 2 AND F. R. LOW 3 A study of 20 years results from the Canadian Sugar Factories at Raymond, Alberta, (l) 4 shows

Effects of Preharvest Sprays of Maleic Hydrazide on Sugar Beets F. H. PETO 1 W. G. SMITH 2 AND F. R. LOW 3 A study of 20 years results from the Canadian Sugar Factories at Raymond, Alberta, (l) 4 shows

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

US 2013 0337146A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0337146 A1 Katagiri et al. (43) Pub. Date: (54) BAKED CONFECTIONERY (30) Foreign Application Priority Data

US 2013 0337146A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2013/0337146 A1 Katagiri et al. (43) Pub. Date: (54) BAKED CONFECTIONERY (30) Foreign Application Priority Data

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

3,702,608 11/1972 Tibbs. states by bying O st plunger T.

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

US 2016.0338383A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0338383 A1 Daru (43) Pub. Date: (54) WET PET FOOD FORMULATED TO BE (52) U.S. Cl. SERVED IN A FORM SELECTED

US 2016.0338383A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0338383 A1 Daru (43) Pub. Date: (54) WET PET FOOD FORMULATED TO BE (52) U.S. Cl. SERVED IN A FORM SELECTED

CITRUS & ALLIED GLOSSARY OF INDUSTRY TERMS

Flavorings are used to augment the innate flavor of food and beverage products and, in some cases, are used to provide the entire flavor of the product. Some examples of foods and beverages that use flavors

Flavorings are used to augment the innate flavor of food and beverage products and, in some cases, are used to provide the entire flavor of the product. Some examples of foods and beverages that use flavors

Section 3 Dough Management

Section 3 Dough Management Dough is the foundation of our pizza. Dough is the least expensive part of the pizza. Never use dough that is not perfect. If the dough is not perfect, throw it out. Without

Section 3 Dough Management Dough is the foundation of our pizza. Dough is the least expensive part of the pizza. Never use dough that is not perfect. If the dough is not perfect, throw it out. Without

III. United States Patent (19) 5,590,586 Jan. 7, % 4. Ulfig et al. (75) Inventors: Kimberly A. Ulfig, Glen Ellyn;

United States Patent (19) Ulfig et al. 54 KITCHEN LAYOUT, SYSTEM (75) Inventors: Kimberly A. Ulfig, Glen Ellyn; Patricia A. Venetucci, Hawthorn Woods, both of Ill. (73) Assignee: Restaurant Technology,

United States Patent (19) Ulfig et al. 54 KITCHEN LAYOUT, SYSTEM (75) Inventors: Kimberly A. Ulfig, Glen Ellyn; Patricia A. Venetucci, Hawthorn Woods, both of Ill. (73) Assignee: Restaurant Technology,

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070184157A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0184157 A1 Stegmaier (43) Pub. Date: (54) HOT FILL AND QUICK CHILL PROCESS FOR PREMIUM QUALITY JUICE (75)

(19) United States US 20070184157A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0184157 A1 Stegmaier (43) Pub. Date: (54) HOT FILL AND QUICK CHILL PROCESS FOR PREMIUM QUALITY JUICE (75)

brewing device, and particularly an espresso machine. 4,871,555 10/1989 Schwartz et al /82

USOO5895672A United States Patent 19 11) Patent Number: Cooper ) Date of Patent: Apr. 20, 1999 54) PRODUCT AND PROCESS FOR PREPARING 5,072,661 12/1991 Kondo... 99/296 A TEA EXTRACT 5,104,666 4/1992 Sanvitale...

USOO5895672A United States Patent 19 11) Patent Number: Cooper ) Date of Patent: Apr. 20, 1999 54) PRODUCT AND PROCESS FOR PREPARING 5,072,661 12/1991 Kondo... 99/296 A TEA EXTRACT 5,104,666 4/1992 Sanvitale...

USOO A United States Patent (19) 11 Patent Number: 5,956,151 Zajac et al. (45) Date of Patent: Sep. 21, 1999

USOO59.56151A United States Patent (19) 11 Patent Number: 5,956,151 Zajac et al. (45) Date of Patent: Sep. 21, 1999 54) BEVERAGE FRESHNESS MONITOR 3,606,829 9/1971 Alwood... 99/285 3,974,758 8/1976 Stone,

USOO59.56151A United States Patent (19) 11 Patent Number: 5,956,151 Zajac et al. (45) Date of Patent: Sep. 21, 1999 54) BEVERAGE FRESHNESS MONITOR 3,606,829 9/1971 Alwood... 99/285 3,974,758 8/1976 Stone,

(12) Patent Application Publication (10) Pub. No.: US 2015/ A1

(19) United States US 20150237893A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0237893 A1 Miyajima et al. (43) Pub. Date: (54) FROZEN COOKED NOODLE AND METHOD (30) Foreign Application Priority

(19) United States US 20150237893A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0237893 A1 Miyajima et al. (43) Pub. Date: (54) FROZEN COOKED NOODLE AND METHOD (30) Foreign Application Priority

United States Patent (19) Ludder

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

(51) Int Cl.: C12G 3/06 ( ) C12H 1/16 ( )

(19) TEPZZ_4 498B_T (11) EP 1 423 498 B1 (12) EUROPEAN PATENT SPECIFICATION (4) Date of publication and mention of the grant of the patent: 07.11.12 Bulletin 12/4 (21) Application number: 0277821.0 (22)

(19) TEPZZ_4 498B_T (11) EP 1 423 498 B1 (12) EUROPEAN PATENT SPECIFICATION (4) Date of publication and mention of the grant of the patent: 07.11.12 Bulletin 12/4 (21) Application number: 0277821.0 (22)

52 U.S. Cl... 70s/ , 235,381 mitted from the automatic vending machine 1 to the center

US006021394A United States Patent (19) 11 Patent Number: 6,021,394 Takahashi (45) Date of Patent: Feb. 1, 2000 54) SALES MANAGEMENT METHOD IN 5,844,808 12/1998 Konsmo et al.... 364/479.14 AUTOMATIC VENDING

US006021394A United States Patent (19) 11 Patent Number: 6,021,394 Takahashi (45) Date of Patent: Feb. 1, 2000 54) SALES MANAGEMENT METHOD IN 5,844,808 12/1998 Konsmo et al.... 364/479.14 AUTOMATIC VENDING

Improving the Quality of Ghanaian Parboiled Rice. Training Manual

Improving the Quality of Ghanaian Parboiled Rice Training Manual The Role of Parboilers This publication is an output from the Crop Post-harvest Research Programme of the UK Department for International

Improving the Quality of Ghanaian Parboiled Rice Training Manual The Role of Parboilers This publication is an output from the Crop Post-harvest Research Programme of the UK Department for International

R. 36. azzo 1/2-Za-Yas. Nov. 18, 1969 J. P. H. LANES 3,478,669 APPARATUS FOR MAKING WINE Z2/27/7212. E. y N AA A. as SS f.

Nov. 18, 1969 J. P. H. LANES APPARATUS FOR MAKING WINE Filed Sept. 16, 1966 2. Sheets-Sheet l R. 36. re-war Nanuma - measuresheat s, a. AA A. E. y N as SS f M Z2/27/7212 azzo 1/2-Za-Yas Nov. 18, 1969 J.

Nov. 18, 1969 J. P. H. LANES APPARATUS FOR MAKING WINE Filed Sept. 16, 1966 2. Sheets-Sheet l R. 36. re-war Nanuma - measuresheat s, a. AA A. E. y N as SS f M Z2/27/7212 azzo 1/2-Za-Yas Nov. 18, 1969 J.

ta-v, 9-1-N Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS EDWARD E ANDERSON ATORNEYS JACK D.

Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May 10, 1965 5 Sheets-Sheet INVENTORS EDWARD E ANDERSON JACK D. BROWN ta-v, 9-1-N-11-4. ATORNEYS Oct. 11,

Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May 10, 1965 5 Sheets-Sheet INVENTORS EDWARD E ANDERSON JACK D. BROWN ta-v, 9-1-N-11-4. ATORNEYS Oct. 11,

3. : 12- C) {X C> C) () {X -K) --KX-KX-KX-K)--C-2 --C)-- (12) Patent Application Publication (10) Pub. No.: US 2012/ A1 4 - (19) United States

(19) United States US 2012O138603A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0138603 A1 McGuinness et al. (43) Pub. Date: Jun. 7, 2012 (54) VARIABLE GEOMETRY TORTILLA COOKINGAPPARATUS

(19) United States US 2012O138603A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0138603 A1 McGuinness et al. (43) Pub. Date: Jun. 7, 2012 (54) VARIABLE GEOMETRY TORTILLA COOKINGAPPARATUS

United States Patent Office 3,505,077

United States Patent ffice 3,0,077 Patented Apr. 7, 1970 1. 3,0,077 PRDUCTIN F RECMBINED CREAM Arthur Bratland, Bergen, Norway, assignor to GAF Cor poration, New York, N.Y., a corporation of Delaware No

United States Patent ffice 3,0,077 Patented Apr. 7, 1970 1. 3,0,077 PRDUCTIN F RECMBINED CREAM Arthur Bratland, Bergen, Norway, assignor to GAF Cor poration, New York, N.Y., a corporation of Delaware No

Aaawaw A. M1axsom. - A 474/2/sr.przezz' SecY72/7. April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES.

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

Dr.Nibras Nazar. Microbial Biomass Production: Bakers yeast

Microbial biomass In a few instances the cells i.e. biomass of microbes, has industrial application as listed in Table 3. The prime example is the production of single cell proteins (SCP) which are in

Microbial biomass In a few instances the cells i.e. biomass of microbes, has industrial application as listed in Table 3. The prime example is the production of single cell proteins (SCP) which are in

75 Inventors: Xiaoping Fu, Epalinges, Switzerland;. s1. Hist t al... 3.

USOO58275A United States Patent (19) 11 Patent Number: Fu et al. () Date of Patent: Oct. 27, 1998 54 PROCESS FOR PRODUCING COLD WATER 3,992,983 11/1976 Gasser et al.... 99/287 SOLUBLE TEA EXTRACT 4,6,024

USOO58275A United States Patent (19) 11 Patent Number: Fu et al. () Date of Patent: Oct. 27, 1998 54 PROCESS FOR PRODUCING COLD WATER 3,992,983 11/1976 Gasser et al.... 99/287 SOLUBLE TEA EXTRACT 4,6,024

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0262440 A1 Wettlaufer et al. US 2016O262440A1 (43) Pub. Date: Sep. 15, 2016 (54) (71) (72) (21) (22) (60) (51) APPARATUS AND

United States Patent (19) Aunsholt

United States Patent (19) Aunsholt 11. Patent Number: ) Date of Patent: May 20, 1986 54 FUEL BRIQUETTES AND METHD F MAKENG 75 Inventor: Knud E. H. Aunsholt, Roskilde, Denmark 73 Assignee: Kryolitselskabet

United States Patent (19) Aunsholt 11. Patent Number: ) Date of Patent: May 20, 1986 54 FUEL BRIQUETTES AND METHD F MAKENG 75 Inventor: Knud E. H. Aunsholt, Roskilde, Denmark 73 Assignee: Kryolitselskabet

(12) United States Patent

(12) United States Patent L0 et al. USOO963B1 (10) Patent No.: US 6,596,3 B1 () Date of Patent: Jul. 22, 2003 (54) REFRIGERATED READY TO EAT (75) (73) (*) (21) (22) (51) (52) (58) (56) ASEPTICALLY PRODUCED

(12) United States Patent L0 et al. USOO963B1 (10) Patent No.: US 6,596,3 B1 () Date of Patent: Jul. 22, 2003 (54) REFRIGERATED READY TO EAT (75) (73) (*) (21) (22) (51) (52) (58) (56) ASEPTICALLY PRODUCED