5 A TTORNE y. July 13, 1965 B, D, EYTINGE 3,194,664 METHOD FOR CONTINUOUSLY PRODUCING NIXTAMAL BRUCE D. EYTINGE. Speed INVENTOR. (33. O ld O 3.

|

|

|

- Alban Flynn

- 5 years ago

- Views:

Transcription

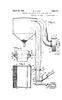

1 July 13, 196 B, D, EYTINGE 3,194,664 METHOD FOR CONTINUOUSLY PRODUCING NIXTAMAL Filed May 19, 1960 O ld 3. Sheets-Sheet Variable Speed Mofor O 3. BY (33 INVENTOR. BRUCE D. EYTINGE A TTORNE y

2 July 13, 196 B, D, EYTINGE 3,194,664 METHOD FOR CONTINUOUSLY PRODUCING NIXTAMAL Filed May 19, Sheets-Sheet 2 S. ED e ser SEW N INVENTOR, Bruce D. EYTINGE 242. ATTORNEY

3 July 13, 196 Filed May 19, 1960 B, D, EYTINGE METHOD FOR CONTINUOUSLY PRODUCING NIXTAMAL 3,194, Sheets-Sheet 3 Water F. G. 2 BY INVENTOR. BRUCE D. EYTINGE ATTORNEY

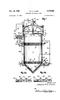

4 United States Patent Office -- 3,194,664 Paterated July 3, 196 3,94,664 METHOD FOR CONTINUGOUSLY PRODUCING NXTAMAL is rice D. Eytinge, near San Antonio, Tex., assiglei to The Frito Company, Daas, Tex., a corporation of Texas Fied May 19, 1960, Ser. No. 30, Claims. (C ) The invention relates to an improved method and ap paratus for processing continuously whole corn kernels as distinguished from batch processing-in preparing nix tamal which is useful in the making of masa (a cornmeal dough) for either corn-chips or tortillas or in the making of tortilla four. Nixtamal is a word derived from the Mexican language and designates corn kernels which have been processed, by cooking and/or soaking before milling, in a manner that imparts the proper characteristics to the masa for the par ticular food product to be prepared from or with it. In the production of finished nixtamal, which is ready for grinding-particularly for corn-chip masa-it is most desirable that the nixtamal should have a moisture content of between 0 to 2% (by weight), being devoid of all its outer hulls except for a very small quantity (in the order of less than % by weight) to give the end product the desired flavor, and the remaining constituents of the ker nels being soaked so that there are no white centers of starch as they appear as white specks in the finished corn chip and are undesirable. Because of the hard and tough characteristic of dried corn-kernels and their outer hulls and aleuronic layer, there have been generally two ways of preparing mixtamal heretofore, which may be briefly stated as: pue LeeA ug sieurex LIIoo Jo Auerb e. gunee (I) lime, as a batch, to approximately 80 degrees centigrade (176 F.), then discontinuing the heating and allowing the entire batch to cool slowly for a period of approximately 18 hours, then removing the corn kernels to a washer, the action of which removes the outer hull or hash of the kernels, the kernels then being ready to be milled into masa upon being discharged or conveyed from the washer. By controlling the amount of water added during the milling, a tortilla masa or corn-chip masa may be pro duced. However, this manner of producing mixtamal is not too suitable or readily adaptable for making the best corn-chip type of masa because the amount of absorption cannot be controlled very closely for the reason that as the temperature of the batch falls slowly, during the cool ing step, to that approaching room temperature, three things take place: (a) the outer hulls of the kernels are loosened, (b) water is absorbed unevenly through the kernels and (c) the constituents in the kernels are only partially hydrolyzed as this hydrolyzing occurs only in the initial stage of heating to 80 C. It is very difficult to con trol the total amount of moisture absorption and its total amount is quite important, controlling the characteristic of the resulting masa. And: (2) A batch of corn kernels is first heated in an agitated steam-jacketed kettle, containing an aqueous solution of calcium hydroxide, and boiled from to minutes, de pending upon the degree of agitation, the size of the kettle, and the type of corn used; then, when the proper gelatin ization has been formed through moisture absorption by the constituents of the kernels, the contents of the kettle are discharged into a large open tank or vat; and water, at its normal temperature, is stirred into the batch in the Vat to reduce its temperature to approximately 70 C. (or about 160 F.); and then the batch is allowed to stand and cool for a period from 8 to 12 hours. During this cooling period little moisture absorption occurs and the gelatiniza tion was established by close control during the cooking in the kettle. However, during this standing and cooling period, the outer hulls of the kernels are loosened further, the aleuronic layer of the kernels is softened, and Water is absorbed slowly and more evenly throughout the remain ing starch in the kernels than in said first example above stated. While this manner of preparing nixtamal is more suitable for the production of corn-chip masa because of its closer control of the amount of hydrolyzation of the constituents of the kernels in a two-stage system, it is slow and costly in labor and equipment and in the manipulation of mobile equipment and requires a large floor area for maneuvering and storing of said equipment, particularly of said soaking vats, in a production system and the mobile equipment becomes quickly damaged resulting in frequent replacement. Also, heretofore, some of the above mentioned steps have been mechanized to some degree and the moisture content of the nixtamal at or from the grinding mills has been substantially reduced to provide a normally dry flour, but this mechanization still, so far as have knowledge, processes the corn kernels in batches rather than in a con tinuous step or flow. Among the difficulties encountered, when processing corn kernels and the like in batches, are those of controlling the quality of the nixtamal produced therefrom because (1) of the uneven distribution of temperature from batch to batch, (2) of the uneven solid content of the Solution employed resulting in variations of its ph number and (3) the difficulties of handling large individual batches required to maintain a constant production with its at tendant high labor costs, greater space area requirement for equipment and for maneuvering the same. The main object or aim of the present invention is to overcome the above mentioned, as well as other, draw backs and to process corn kernels, and the like, for the preparation of nixtamal in a greatly reduced period of time with greater control of the moisture content and with a greater percentage and more uniform hydrolyzation of the constituents of the resulting nixtamal so that the end product-i.e. corn-chips, tortillas or tortilla four-will have the desired properties and uniform characteristics for that product. Briefly, this is accomplished by continuously feeding a measured amount of cleaned corn kernels into the upper end of a stationary tank containing a heated processing water solution of a ph higher than ten while this solution is being introduced, under pressure and at the proper temperature, into the bottom portion of the tank and flows upwardly in the tank through the kernels, which have collected by gravitation therein, and, after a period of time from the commencement of the process, continually and gradually discharging said kernels from the bottom of the tank at a controlled rate-in relation to the feeding of kernels into said tank-and in a condition whereby the husks may be removed from said kernels by an aqueous washing step. Thereafter the corn kernel is then ready for milling into masa, which may be then shaped and cooked in the conventional manner. Other objects and advantages of the present invention will be apparent as the following detailed description of the same proceeds. To practice the present invention, use of certain instru mentalities may be employed, of which several are shown in the accompanying drawings and form part of this in vention and wherein: FIGURE 1 is a schematic illustration of one arrange ment of instrumentalities that inay be employed to pro duce nixtamal according to this invention; FIGURE 2 is an enlarged fragmentary end elevational view of the lower end of the corn treating tank illustrating the discharge gate-valve;

5 s 3. FIGURE 3 is a transverse sectional view taken substan tially on line 3-3 of FIGURE 2; FIGURE 4 is an elevational view of the gate-valve and looking from the left of FIGURE 2 and shown partly in section; FIGURE is an end elevational view of the gate-valve looking from the left of FIGURE 4; and FIGURE 6 is a schematic illustration of another or modified arrangement of instrumentalities for producing nixtanal according to this invention. in carrying out this invention, the corn kernes are pre pared preliminarily, in the usual manner of processing nixtamal, by cleaning the kernels to eliminate foreign mat ter and to remove broken or cracked kernels-the less the better. After cleaning and at some time before using the kernels, they are stored in a storage elevator to equalize their moisture content; and, in the preparation of kernels for corn-chips, a blend of about 3/3 yellow corn and about 2% white corn is stored in said elevator. When the production of nixtainal is to begin, the stored corn kernels are fed from the elevator to a hopper is equipped with an adjustable gate it at its discharge end through which the kernels are fed onto an endless con veyor 22, this being adjustably controiled by means of the handle Elia. The conveyor 2 is driven by a variable speed drive 13 so that a continuous and controllable quantity of kerneis may be fed into the processing tank 1, which is, preferably, a vertical elongated cylinder hav ing a diameter about 2% of its length with its upper end open and the lower /3 of its length forming an inverted hollow frusto-cone Ea, at the open bottom end of which is a discharge gate or valve. The configuration of the conical portion 1a of the tank has been chosen in order to effect uniform downward movement of the kernels in the tank toward the valve or gate 6 and, froin experimentation, the length of the conical portion 3.a should be equal to the diameter of the tank 2 in order to effect the desired novement of the kernels. Initially, the tank is filed with the treating solution 17 at the proper treating temperature and ph, which is in troduced therein at its top end through a branch 13b of a supply pipe E8. The supply pipe 8 extends from a nake up tank 23 and is connected into the bottom of the treat ing tank directly above the valve or gate 6; and, when filled, the valve 88c in said branch i3 is closed and the valve 3a in the supply pipe 3 is open to deliver the treating solution, under pressure, to the bottom of the treating tank i. The processing commences by continu ously feeding the kernels from the conveyor A2 into the top of the tank while the processing solution continues to be supplied, at a temperature about 80 C. and under pres sure, to the treating tank 1 and flows upwardly through or around the mass of corn kernels that have accumulated within the tank. The solution overflows the tank and is collected and passed through a filtering, a heating, and a ph control means (24-2-2) and then returned to the supply pipe E8 by a pump 22 for reuse. This treating solution flows in the treating tank in a direction op posite to the movement of the kernels within said tank in order to keep the kernels from packing tightly therein, as they expand during the time their mcisture content is in creasing, and further provides a continuing flow of fresh solution (at the proper temperature, at the proper ph and proper solid content) moving upwardly into contact with the kernels to effect a more even and progressive proc essing of ail the kernes.. - s Under these conditions, the hulls of the corn kernels are hydrolyzed and loosened from the next contiguous or aleuronic layer of the kernels, thus allowing the water to soften the aleuronic layer and to more readily penetrate in the starch cells or sacks. At the completion of this action, the distribution of the moisture within each kernel, at the bottom of the tank adjacent the discharge valve or gate 6, is uniferina throughout the kernel-i.e., there are no white centers in the kernels-and their moisture m 3,194, A. content is between about 0 to 2%. This is achieved by bringing the corn kernels into contact with the treating solution moving relative to the kerneis and maintained at a substantially uniform elevated temperature of about 80 C. (i.e. 176 F.) and at a controlled ph of above 10, preferably, at 11 to 12.4 as an optimum. When the kernels at the bottom portion of the tanks are in the condition, just stated, the gate valve A6 is op erated to discharge the kernels upon a foraminous endless conveyor a 9 which allows the treating solution to drain from the kernels and which delivers the kerneis to a conventional corn washer 26, the action of which removes the aiready loosened hulls from the kernels, to produce the nixtamal. Since the kernels are being continuously fed into the tank 1 from conveyor 2, the action of the solution on the kernels continues while the accumulated mass. within the tank-1 traverses the length of the tanks, and that portion of the mass near or at the bottom of the tank i is ready to be controllabiy and continuously dis charged by the gate valve : With corn kernels having an initial moisture content. of approximately 13% and relatively soft characteristics, the processing of the kernels to a condition, just stated, may be accomplished in aproximately five hours, as against eight to ten hours with the prior process (b) stated in the forepart of this specification, and with less equipment, with less ficor-area and with less labor and, at the same time, producing a better nixtamal. The mixtamal, so produced, has a moisture content of about. 0.2, after washing and removing the outer hulls, and the amount of gelatin fortined, uinder the conditions of this process, is correct for extruding the masa, made for this mixtanal, into corn-chips. The flavor and color of the corn-chips is good and the oil content, after frying in the conventional manner, is about 36%. If the corn kernels are of a hard variety, such as grown in Texas, but with the same moisture content, then to obtain the desired condition of the kernels, just stated, the processing may require as long as seven hours to properly soften the horny portion of the kernel and obtain proper moisture content of the entire kernel, as against 10 to 12 hours by prior process (b) mentioned above... I have found that, if the ph of the treating aqueous solution 17, is less than 10, it takes too long to loosen the outer hulls of the kernels and the speed of water penetra tion into the kernels is reduced. The optimum ph of 11 to 12.4 can be easily obtained if calcium hydroxide is used because it is not very soluble in hot water, and the hot water will dissolve only a sufficient quantity of the calcium hydroxide at the processing temperature of 80 C. as to readily maintain the optimum ph. Most of the calciu in hydroxide is absorbed in the hulls as they are loosened from the kernel but, after the hulls have been washed from the treated corn kernels in the washer 28 and the kernels have been milled into masa, the result ing ph may be less than seven. Calcium hydroxide is not the only chemical that can be used in this process. Sodium hydroxide or potassium hydroxide will serve as well; however, since they are more soluble in water than calcium hydroxide, they do not lend themselves to as easy preparation of a solution having the desired ph. Sodium bicarbonate, trisodium phosphate, sodium carbonate, sodium sesquicarbonate, tetrasodium pyrophosphate, sodium tripolyphosphate, and many other chemicals may be used to raise the ph sufi sciently to loosen the outer hulls to increase water pene tration, but considerable care must be taken in the prepa ration of the proper strength of such solutions; and, also, a difficulty is sometimes encountered in washing the nix tamal so as to remove these other chemicals that might have an effect on the flavor of the finished product. The processing solution 7 is supplied to the pipe 18 from a main makeup tank 21 by means of a pump 22 interposed in the pipe-line 18. The overflow from the top of the tank is taken off by drain pipes 23 which

6 3,194,664 6 discharge in a primary settling sump 24. The sump 24 of the processing solution 27 may be maintained to the may also be, and preferably is, positioned to receive the treating tank 1, which should be about to 30 gallons solution drained by the treated kernels on the conveyor per minute for 1000 pounds of corn kernels per hour. belt 9 by means of a trough 19a, or the like, disposed It is preferred to provide the upper end of the treating under the said conveyor and discharging into the Sump tank with a lateral outwardly offset annular collection 24. A tank 2, containing a supersaturated aqueous solu drain b rimming said tank, into the side wall of tion of calcium hydroxide 2a, is positioned to constantly which the drain pipe 23 is connected at one or more discharge a metered quantity of said solution through spaced points to drain the overflow from tank 1 and valve 26 into the settling sump 24. The sump 24 has an maintain a constant liquid in said tank. outlet 27 on the discharge side of a filtering screen 28 in Since some of the corn kernels do not sink immedi O the sump 24 and discharges in one end of the makeup tank ately in the treating tank 1 until sufficiently wetted with 21 remote from the inlet end of solution Supply pipe i8, the treating solution 17, when they will sink slowly and which extends into the opposite end of the makeup tank rest upon the top of the kernels in process within the tank, 21. it is provided with a cylindrical sleeve baffle 4, of ap A series of contiguously disposed settling tanks 29, 30 proximately one-half the diameter of the tank, dis and 31 are removably fitted into the end of the makeup tank 21 adjacent the discharge 27 from the sump 24 so that the latter discharges into the out-board settling tank 31, from which it overflows into the adjacent tank 30, which overflows into the next tank 29, which in turn over flows into the main makeup tank 2. The velocity of flow in these settling tanks 29, 39 and 31 is low, and, therefore, allows additional solid particles, that may be in the solu tion drained from the sump 24, to settle out in the bottom of tanks 29, 30 and 31, which may be replaced quickly for cleaning purposes. The makeup tank 21 is equipped with a drain pipe 32 having a valve 33 therein by which the entire apparatus may be drained and which is to be adjusted to continu ously drain a small amount of the solution in the makeup tank 21, which amount is replenished by fresh water from a service water-line 34. The liquid level in the makeup tank 2, is maintained by a float valve 3 in the tank 22 and controls a supply valve 36 in the service water-line 34. The treating solution in the makeup tank 21 is heated to maintain its proper processing temperature of 80 C. in the treating tank and is accomplished by disposing a pipe 37 in the bottom portion of the makeup tank 21 and provided with a spaced series of orifices or jet nozzles 37a. One end of the pipe 37 is connected to a source of steam supply 39 through a manually controlled valve 38 thus permitting steam to eject through the nozzles 37a to heat the solution and to agitate the solution in the makeup tank 2. The valve 36 is set so as to allow steam to continuously enter the tank 21, but not quite enough in volume to maintain the desired temperature of the solution therein. An automatic temperature regulator is positioned adjacent to tank 2A and has its temperature responsive part 46a disposed in said tank to control a valve 41 in a shunt pipe 37b in the pipe 37 for by-passing the valve 38. Hence, the regulator actuates the valve 4 to override the valve 38 and nicely control and main tain a desired predetermined temperature of the solution in tank 22 so that the solution will be 80 C., more or less, when delivered to the treating tank 1. In practice this temperature has been maintained pius or minus about 2 degrees. As the corn kernels move or gravitate downwardly through the treating tank 1, the processing temperature is measured by a suitable thermometer 42, which may be a bulb-type measuring instrument or a remote reading thermocouple device to indicate to an attendant that the steam Supply should be increased or decreased by opera tion of the manual valve 33 in order to maintain the proper treating temperature of about 80 C.; or the ther mometer means 42 may be connected, as by a thermo couple means not shown, to the actuator 4e of the auto matic Steam control valve 4 to accomplish the same purpose.. A valve 22a in the supply pipe-line 18 acts as a throttling valve to control the fiow from the pump 22, which pump may be shunted by by-pass pipe 18p in pipe-line 18, which by-pass has a manual control valve 43 therein. A flow meter 44 is interposed in the supply pipe E8 down stream with respect to the valve 42 so that a proper flow posed at the top of the treating tank 1 and supported in position thereon, by radial arms 4a, so as to extend above the liquid level in said tank and below said level for a substantial distance as shown. The feeding con veyor 12 discharges into the sleeve-like baffle 4 so that dry corn kernels, which do not sink immediately, cannot float over to the circular drain rim 1b and be drained off. The corn kernels, settling downwardly from the sleeve baffle 4, spread out quite evenly in the treating tank i due to the circulation of the treating solution within said tank. As indicated above, after the treating tank 1 is filled With treating solution 7 from the makeup tank 21 by means of the pump 22, the processing may be started by closing valve 18c, opening valve sa, opening the gate 11 of hopper 8 and starting the feeding conveyor 2. The extent the gate 11 is opened is related to the speed of the conveyor (driven by the variable speed motor 13) So as to feed the kernels to the treating tank at the re quired rate that will deliver properly treated kernels to the discharge valve gate 16 of the treating tank at a predetermined amount, or pounds per hour. The maxi nun capacity of the system is limited according to the capacity of the treating tank. Also, as previously stated, the treating solution 17 from the makeup tank 21 is forced, under pressure from pump 22, lipwardly through the mass of kernels which acci. mulates in the tank 1. After the kernels in the bottom or conical portion 1a of the treating tank 1 have been sub jected to the treatment of the treating solution for a proper time-say, between to 7 hours depending upon the character or type of corn kernels being treated-the gate Valve 16 is then continuously operated to discharge prop erly treated kernels from the treating tank, onto the foram Inous conveyor 22, at a rate coordinated with the feeding of untreated kernels by the conveyor 12, so that a con. tinuous flow of properly treated kernels will be progres sively presented at the discharge gate valve 6 as the mass of accumulated kernels gravitates slowly thereto. This requires Special attention in retaining the solution in the treating tank and in avoiding turbulence by the admission of the treating solution into said tank that would destroy the Stratae or layers of the kernels in their progressive treatment. In other words the kernels gravitating en mass in the tank should not be Subjected to agitation that Would cause kernels in various levels in the treating tank to be mixed as this will destroy the effectiveness of the process. in order to accomplish the last stated result, the frusto end of the lower conical portion 1a of the treating tank is provided with a relatively short downwardly projecting cylindrical Wall 1c having an outwardly extending lateral flange f to which is removably secured a corresponding flange f' of the housing h of the gate valve 16. This wall 1c forms a turbulence reducing chamber a. This cylin drical wall 1c is provided with a plurality of circumfer ntially spaced tangentially disposed nozzles or orifices in each connected by branch pipes 18f to the supply pipe 18 and arranged to discharge into the chamber a circum ferentially thereof (see FIGS. 2 and 3); and each orifice

7 3,194,664 7 n has the same cross-sectional area as the supply pipe 18 continuous uninterrupted treating of the corn kernels to thereby reduce the velocity of the treating solution en in the tank 1, means are available and known by which tering the chamber a. By arranging the orifices in so that their operation may be coordinated and which may be the treating solution enters tangentially, the solution as employed in this apparatus. -. cends in the treating tank 1 somewhat spirally and any The washer 2 is of a conventional type used to remove stirring of the kernels in process within the tank i will the hulls of corn kernels that have been softened and tend to be circular and at the same level and since level loosened during the treatment: in treating tank.. It throughout the treating tank represents processing in serves also to wash away any of the treating solution ad time and a different condition of the kernels in that level, a hering to the kernels and to reduce the temperature of change of position of the kernels from one level to another l 0 the nixtamal below 100 degrees...f. so that it may be is to be avoided-hence, kernels once started through the readily milled into masa. The washer has a hopper 0 process must not mix. which receives the nixtamal from the stainless steel wire The gate valve 6 comprises, as shown in FIGS. 2, 4, conveyor 19 and is connected to a service water main : and, a housingh having a horizontally extending cylin by branch pipe 2 each having a flow adjusting valve 3 drical chamber c closed at each end by end plate phaving I therein and arranged to wash the mixtamal into the hop axially aligned openings otherein through which a shafts rotatably extends and is journalled in bearings i mounted in spider brackets b carried on the outer faces of the end plates p. A sealing gland g is carried at or in the openings o to prevent leakage of the treating solution therethrough. A rotor r completely fills the chamber c in the housing h and is fast upon the shaft. s. The rotor is formed with a plurality of cavities e (preferably about six in number) equally spaced around its periphery and extending axially of the rotor. The housing h has a flanged inlet passage i and an outlet passage d disposed at its opposite sides, re spectively, and opposing the periphery of the rotor r, the flange f' at the passage i underlying the chamber a and being connected with the rim flange f at the lower end of the cylindrical wall c. The shafts has a pulley wheel w keyed thereon driven from a variable speed motor 46 by belt t. Thus, the motor 46 continuously rotates the valving rotor r to suc cessively present one, or possibly two, of its cavities e under the chamber a (FIGS. 4 and ) which cavities be come filled with the kernels, gravitating from the treating tank 1 into the inlet passage i of the gate housing h, and are then carried by the rotor to the outlet passage d and discharged by gravity onto the foraminous conveyor beit 9. - Since the rotary gate valve 16, due to its design and construction, allows a small leakage of the treating solu tion continually between the rotor r and the housing h, this liquid helps to wash said internal cavities e clean of treated kernels, when they are aligned with the discharge. passage d: and, since air displaces the treating solution. in the discharging cavities e, as they continue to rotate up toward the inlet passage i, it is important to this process to prevent air from entering the treating tank 1 as bub bling air will mix the corn kernels under treatment, which, as stated above, is to be avoided particularly in that por tion of the treating tank above its conical bottom a. This is accomplished, as shown in FGS. 1, 2 and 4, by providing a branch pipe 18d controlled by valve 18e. and connected with supply pipe 18 at one of its ends and at its other end to rotor chamber within the housing h by means to extension pipes 47 and 48 each having a valve 49, respectively, therein. These extension pipes 47 and 48 communicate with the interior of the housingh through the end plates p, respectively, and are arranged to dis charge treating solution into the ends of cavities e of the. rotor after they have moved upwardly from the kernel discharge passage toward the kernel inlet passage i of the housing, thus replacing the air in said cavities before they reach the inlet passage i-hence, preventing air bubblings in the tank 1. The valves. 49 may be adjusted to allow just sufficient flow of the treating solution into the cavities e to accomplish this requirement so that no turbulence is caused that will mix the kernels, in process, in the tank i. The volume of corn kernels in the discharging cavities e and the speed of rotation of the rotor r determines the rate of discharge of the treated kernels from the tank 1. While the speed of the feeding motor 13 and the discharge motor 46 may be nicely adjusted manually to coordinate the feeding with the discharge of the kernels to produce a O per 9 and to jet spray the nixtamal in a cylindrical tum ble-screen 4 supported on rollers and rotated by a motor 6. An auger 7 is connected to the front end of the screen 4 and the water jets cause the hulls to be removed from the kernel. The spent wash water, the hulls and other waste material are collected in a tank 8 underlying the screen 4 and drained off by waste-pipe'9. - In FIGURE 6, the same apparatus is shown as in FIGURE 1, except that a modified makeup tank 60 is il lustrated which may be employed instead of the make up tank 21, and the same reference characters are em ployed except for the modified parts. Since the makeup tank 60 is a vertical enclosed, tank, it takes less floor space, is more sanitary and operates as a more efficient separator for solid material in the treating solution; how ever, it performs the same function as the horizontal makeup tank 2 in FIGURE 1. The bottom portion of the makeup tank 68 is connected to the sump 24 by a pipe-line 61 (the equivalent of pipe 27 in FIG. 1), which pipe has a pump 62 interposed therein and controlled by a float actuated switch 63 disposed at the top of tank 60 to maintain the level of the treating solution in said tank. A check valve 64 is disposed in the pipe line 61 on the discharge side of the pump 62 to prevent the treating solution from draining through the pump back into the sump 24. The discharge end of pipe line, 61 enters the tank 60 tangentially above a lower inverted conical portion 60a to cause the solution in the tank to circulate with a velocity which is highest adjacent the side wall of the tank and diminishing to zero at the cen ter, resulting in any solid particles dropping out of the solution near the vertical center of the tank 60 and settling to its conical bottom portion 69a to be drained out periodi cally through valved-drain pipe 6. The solution and Solid materials, so drained, may be dewatered, yielding a recovery from the waste products which has a value. The treatment solution from the makeup tank 60 is conveyed from the upper portion of said tank, below the liquid level therein, to the treating tank 1 by the sup ply E8 in the same manner as described and shown in connection with FIG.1. Additional water may be sup plied to the makeup tank 662 by introducing it from a Service pipe-line 66, through valve 67, into the pipe line 6, at a point downstream with respect to the pump 62 so as to enter the tank 68 in the manner described above. As in connection with the makeup tank 21 in FIG. 1, the treating solution in makeup tank 60 (in FIG. 6) is heated to the required degree so as to be delivered. to the treating tank 1 at about 80 C.; and substantially the same means is employed as in FIG. 1 and is shown as bearing the same reference numerals, except that the perforated steam pipe 37x may be centrally and vertically disposed in the tank 60 substantially as shown in FIG URE 6. Also, in this form of the makeup tank 60, a by-pass pipe 68, having a manual control valve 69 there in, is connected to supply pipe line 18b on the discharge side of pump 22 and discharges into the top of makeup tank. 66. By processing corn kernels according to the above described system, a better mixtamal is produced in a

8 3. continuous flow for mass production in much less time than heretofore and with the proper moisture content and with all the characteristics desired for tortillas, tortilla four and more especially for corn-chips; yet avoid ing ail the disadvantages of prior practices, as the corin kernels and the aqueous treating solution are held at a constant temperature by the constant inflow of fresh treat ing solution for a sufficient annount of time to allow the hulls to become loosened to allow the proper amount of gelatinization to be formed by hydrolyzation of their constituent materials and to allow the correct annount of water to be evenly absorbed in the remaining starch of the kernels. Having described the invention and the manner of per forming the same, it is to be understood that changes and modifications may be made in the exact steps herein recited as well as in details of construction and arrange ment of the parts of the apparatus described and shown and that such changes as fall within the scope of the appended claims are within the purview of the present invention and contemplated thereby. That which is claimed, as new and to be secured by Letters Patent, is:. A continuous method of producing mixtamal com prising: feeding corn kernels at a controlled rate into an aqueous treating bath having an alkalinity of at least 10 ph and a temperature of about 80 C., forming an accumulated mass of corn kernels in said bath which gravitates through the bath; causing said alkaline bath to pass through said mass and progressively subjecting said gravitating corn kernels to the action of said bath; and progressively discharging from said alkaline bath corn kernels which have been exposed to the bath for at least about five hours. 2. A method of producing nixtamal as defined in claim 1 wherein said alkaline solution contains calcium hy droxide in sufficient quantity to provide a ph of A method of producing nixtamal as defined in claim further comprising: discharging the liquid of said treating bath and reconstructing said liquid by adding alkaline material so that the ph thereof is in excess of 10, and heating said treating bath to about 80 C., plus or minus about 2 C.; and recirculating said recon structed and reheated treating liquid through said mass of corn kernels. 4. A continuous method of producing mixtannai as de fined in claim wherein said corn kernels are discharged from said bath with an absorbed moisture content of at least about 0%.. A continuous method of producing nixtamal as de fined in claim 1 wherein said bath is passed through said mass of corn kernels at the rate of about -30 gallons per minute per 1000 pounds of corn kernels per hour gravitating through said bath. 6. A continuous method of producing mixtamal as de fined in claim comprising: washing with water corn kernels discharged from said bath to remove outer hulls and excess alkaline solution so that the ph of the corn is reduced to about A continuous method of producing mixtamal as de fined in claim wherein the corn kernels progressively discharged from the bath have been exposed to said alkaline bath for about -7 hours according to the char acteristics of the corn kernels being treated. 8. A method of producing nixtamal comprising: feed ing corn kernels at a controlled rate into a receptacle con taining an aqueous solution having an alkalinity of at least 10 ph and a temperature of at least about 80 C., forming an accumulated mass of corn kernels in strata 3,194, a which progressively gravitate through said alkaline solu tion in substantially vertical direction along the recep tacie's vertical axis; causing said alkaline solution to move upwardly through said mass of corn kernels without agita tion and progressively subjecting strata of said gravitat ing corn kerneis to the action of said alkaline solution; progressively discharging from said alkaline solution low er strata of corn kernels which have been exposed to said alkaline solution a sufficient time so that the discharged kernels have an absorbed moisture content of at least about 0%; and feeding said alkaline solution of at least 10 ph into said receptacle adjacent the bottom thereof in a plane substantially perpendicular to the vertical axis of the receptacle thereby minimizing change of position of corin kernels in said strata as said alkaline solution is passed upwardly through said gravitating mass of corn kerneis. 9. A method of producing mixtamal comprising: feed ing corn kernels at a controlled rate into a receptacle containing an aqueous solution having an alkalinity of at least 10 ph and a temperature of at least about 80 C., forming an accumulated mass of corn kernels in strata which progressively gravitate through said alkaline solu tion; causing said alkaline solution to move upwardly through said mass of corn kernels without agitation and progressively subjecting strata of said gravitating corn kernels to the action of said alkaline solution lower Strata of corn kernels which have been exposed to said alkaiine solution a sufficient time so that the discharged kernels have an absorbed moisture content of at least about 0%; and feeding said aikaline solution of at least 16 ph into the lower portion of said receptacle as corn kernels are discharged therefrom to avoid entry of air into said receptacle and mixing of air with said mass of gravitating corn kernels. A. A method of producing nixtamal comprising: feed ing corn kernels at a controlled rate into an aqueous solution having an alkalinity of at least 10 ph and a temperature of at least about 80 C., forming an ac cumulated mass of corn kernels in strata which progres sively gravitate through said alkaline solution; causing said alkaline solution to move upwardly through said Inass of corn kernels without agitation and progressively Subjecting strata of said gravitating corn kernels to the action of said alkaline solution lower strata of corn kernels which have been exposed to said alkaline solu tion a sufficient time so that the discharged kernels have an absorbed moisture content of at least about 0%; said alkaline Solution being passed through said mass of corn kernels at the rate of about -30 gallons per minute for 1,000 pounds of corn kernels per hour. - References Cited by the Exainier UNITED STATES PATENTS 2,498,73 2/0 Ozai-Durrani ,71, 10/1 Fernandes ,84,893 2/2 Floyd et al ,638,837 /3 Taimey et al ,704,27 3/ De Sollano et al ,909,114 10/9 Bok ,964,8 12/60 Gates OTHER REFERENCES "Food Engineering, April 191, pages A LOUIS MONACELL, Primary Examiner. ABRAHAM H. WINKELSTEIN, Examiner,

III. United States Patent (19) Binacchi. Attorney, Agent, or Firm-Bucknam and Archer 57 ABSTRACT. 6 Claims, 3 Drawing Sheets

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

United States Patent (19) Binacchi 54 APPARATUS FOR MAKING, STARTING FROM A CONTINUOUS FILM, COFFEE ROUND OR NOT ROUND COFFEE WAFERS, FOR ESPRESSO-COFFEE MAKING MACHINES 76 Inventor: Fabio Binacchi, Via

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

(19) United States US 20080063772A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0063772 A1 Kirschner et al. (43) Pub. Date: Mar. 13, 2008 (54) CONCENTRATED FRESH BREWED TEA (75) Inventors:

United States Patent (19) 11) 4,167,008 Blickenstaff 45) Sep. 4, 1979

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

United States Patent (19) 11) Blickenstaff 45) Sep. 4, 1979 54 FLUID BED CHAFF DESPENSER 75 Inventor: John E. Blickenstaff, North Tonawanda, N.Y. 73) Assignee: Calspan Corporation, Buffalo, N.Y. FOREIGN

May 12, ,282,708 T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE. Filed Sept. 26, Sheets-Sheet l. --No.zzzzzzzzzzae.

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

May 12, 1942. T. DANTZIG COFFEE ROASTING PRODUCT, METHOD, AND MACHINE Filed Sept. 26, 1940 2,282,708 2. Sheets-Sheet l --No.zzzzzzzzzzae zs ZzZ2 May 12, 1942. T. DANTZIG 2,282,708 COFFEE ROASTING PRODUCT,

JUICE EXTRACTION AND FILTRATION JUICE EXTRACTION METHOD AND EQUIPMENT

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

College of Agricultural Engineering and Technology Dept. of Agricultural Processing and Food Engineering Course : Dairy and Food Engineering Chapter 11 JUICE EXTRACTION AND FILTRATION (Juice extraction

(*) Notice: Subject to any disclaimer, the term of this E. E. E. E. O.C.

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

United States Patent US007021202B2 (12) (10) Patent No.: US 7,021.202 B2 Sizer (45) Date of Patent: Apr. 4, 2006 (54) DISPOSABLE FRYING PAN INSERT 4,828,134 A 5/1989 Ferlanti 5,323,693. A 6/1994 Collard

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

(19) United States US 20070023463A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0023463 A1 MacClarence (43) Pub. Date: Feb. 1, 2007 (54) REMOVABLE POUR SPOUT (52) U.S. Cl.... 222/567 (76)

Sept. 7, l.t. ward 2,092,596 SIPHON

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

Sept. 7, 1937. l.t. ward SIPHON Filed Aug., 1936 3 Sheets-Sheet 1 NVENOR 4 weawea 7 Aead. Sept. 7, 1937. Lt. WARD SIPHON Filed Aug., 1936 3. Sheets-Sheet 2 N.VENOR 44 pea Mca 7 A2aa. Sept. 7, 1937. L.

TORTILLA-TORTILLA CHIPS

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

TORTILLA-TORTILLA CHIPS Food and Agriculture Organization of the United Nations TORTILLA- TORTILLA CHIPS 1.- Tortilla - General Information Tortilla is the most important corn food in Mexico, Central America,

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

US 2011 O174658A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0174658 A1 Otsubo (43) Pub. Date: Jul. 21, 2011 (54) DOME LIDS AND CUPS FOR HOT (52) U.S. Cl.... 2O6/508

7 IANSNA. (12) Patent Application Publication (10) Pub. No.: US 2003/ A1. (19) United States 2//

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

(19) United States US 2003O217647A1 (12) Patent Application Publication (10) Pub. No.: US 2003/0217647 A1 Jones (43) Pub. Date: (54) PORTABLE COOKINGAPPARATUS PROVIDING BOTH DIRECT AND INDIRECT HEAT COOKING

United States Patent [11] 3,559,565

![United States Patent [11] 3,559,565 United States Patent [11] 3,559,565](/thumbs/93/114425987.jpg) United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

United States Patent [11] 3,559,565 172 21 22 (45) Inventor Clarence A. Getz Hot Springs, Mont. (P.O. Box316 Davenport, Wash. 99122) Appl. No. 810,879 Filed Dec. 24, 1968 Patented Feb.2, 1971 Substitute

Dec. 9, M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

Dec. 9, 1941. M. H. SMITH 2,265,550 STRAINER Filed July 3, 1940. 2 Sheets-Sheet l %rk --L-A- NYA 2 43 N yzes N S/2 Su2 S %zzzzzzzzzzzo Nventor MYRON -, SMITH Aftorneys Dec. 9, 1941.. M. H. SMITH 2,265,550

March 24, 1970 H. H. BRIDGFORD 3,502,488 COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER HUGH. BROGFORD / ATTORNEY

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

March 24, 1970 H. H. BRIDGFORD COMBINED FROZEN DOUGH PACKAGE AND BAKING CONTAINER Filed July 25, 1968 3. Sheets-Sheet HUGH. BROGFORD /4-4-6-4 ATTORNEY March 24, 1970 H. H. BRIDGFord COMBINED FROZEN DOUGH

United States Patent It 3,593,647

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

United States Patent It 3,593,647 72) inventor Walter C. Copeland, Jr. Madison, Fla. 32340 21 Appl. No. 788,369 22 Filed Jan. 2, 1969 45 Patented July 20, 1971 54 BROILER 5 Claims, 8 Drawing Figs. (52)

INTRODUCTION TO CUSTOM FABRICATED STRAINERS

INTRODUCTION TO CUSTOM FABRICATED STRAINERS Nothing Too Big, Too Small or Too Special When unwanted solid material has to be removed from flowing fluids in order to protect equipment, a HAYWARD Strainer

INTRODUCTION TO CUSTOM FABRICATED STRAINERS Nothing Too Big, Too Small or Too Special When unwanted solid material has to be removed from flowing fluids in order to protect equipment, a HAYWARD Strainer

(12) United States Patent

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

(12) United States Patent Mueller USOO6942888B2 (10) Patent No.: (45) Date of Patent: Sep. 13, 2005 (54) CHEESE EXTRUDING MACHINE AND PROCESS FOR PRODUCING PIECES OF CHEESE (75) Inventor: Adam P. Mueller,

United States Patent (19) Ludder

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

United States Patent (19) Ludder (54) CLOSE-NESTING, LIGHT-WEIGHT, ONE-PECE DRINKING CUP AND APPARATUS FOR THE MANUFACTURE THEREOF (75) Inventor: Rodney E. Ludder, Glen Head, N.Y. 73) Assignee: Owens-Illinois,

(a) Dead-end/conventional filtration fluid flow perpendicular to the filter medium. (b) Crossflow filtration fluid flow parallel to the filter

FILTRATION (a) Dead-end/conventional filtration fluid flow perpendicular to the filter medium. (b) Crossflow filtration fluid flow parallel to the filter medium. Filtration Generally carry out in the early

FILTRATION (a) Dead-end/conventional filtration fluid flow perpendicular to the filter medium. (b) Crossflow filtration fluid flow parallel to the filter medium. Filtration Generally carry out in the early

US A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

IIII US005607072A United States Patent 19 11) Patent Number: 5,607,072 Rigney et al. (45) Date of Patent: Mar. 4, 1997 (54) BEVERAGE CONTAINERS 3,759,373 9/1973 Werth et al.... 220/23.4 X 3,948,105 4/1976

SIMPLEX STRAINER MODEL 90

The Eaton Model 90 Fabricated Simplex Strainer has been designed for manufacturing flexibility. It can be made for pipeline sizes from 1 to 48 in carbon steel or stainless steel although other materials

The Eaton Model 90 Fabricated Simplex Strainer has been designed for manufacturing flexibility. It can be made for pipeline sizes from 1 to 48 in carbon steel or stainless steel although other materials

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1. Hurley et al. (43) Pub. Date: Aug. 28, PROCESS Publication Classification

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

US 200802064O9A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0206409 A1 Hurley et al. (43) Pub. Date: Aug. 28, 2008 (54) FILLED CONFECTIONARY PRODUCT AND PROCESS (22)

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

US 201202.01934A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0201934 A1 Youssefi et al. (43) Pub. Date: Aug. 9, 2012 (54) TOPICALLY SEASONEDTACO SHELLS Publication Classification

Installation & Parts Manual 2" & 3" High Capacity Strainers For Class 1, Petroleum Applications

Installation & Parts Manual 2" & 3" High Capacity Strainers For Class 1, Petroleum Applications Installation: M200-20 www.lcmeter.com Table of Contents Description Page Number Introduction... 2 What LC

Installation & Parts Manual 2" & 3" High Capacity Strainers For Class 1, Petroleum Applications Installation: M200-20 www.lcmeter.com Table of Contents Description Page Number Introduction... 2 What LC

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(19) United States US 200801 05137A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0105137 A1 Genslak et al. (43) Pub. Date: May 8, 2008 (54) REMOVABLE MOLD FOR A GRILL (76) Inventors: Kristina

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

(19) United States US 2005.0089318A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0089318A1 Lai et al. (43) Pub. Date: Apr. 28, 2005 (54) ELECTRIC GRILL (75) Inventors: Wai Hing Lai, Kowloon

United States Patent (19)

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

United States Patent (19) Hawley 54 METHOD OF FORMING A PACKAGED EGG PRODUCT 75 linventor: Robert Lyle Hawley, Webster Groves, Mo. 73) Assignee: Ralston Purina Company, St. Louis, Mo. 22 Filed: July 23,

Introduction. 12 CO H 2 O = C 12 H 22 O O 2 carbon dioxide + water = sucrose + oxygen

Sugar cane Introduction What we call sugar, the chemist knows as 'sucrose', one of the family of sugars otherwise known as saccharides in the grouping called carbohydrates Sucrose, C 12 H 22 O 11, is a

Sugar cane Introduction What we call sugar, the chemist knows as 'sucrose', one of the family of sugars otherwise known as saccharides in the grouping called carbohydrates Sucrose, C 12 H 22 O 11, is a

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0150827 A1 Bruno et al. US 2006O150827A1 (43) Pub. Date: Jul. 13, 2006 (54) (76) (21) (22) (60) GRILLING APPARATUS Inventors:

MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

A21C MACHINES OR EQUIPMENT FOR MAKING OR PROCESSING DOUGHS; HANDLING BAKED ARTICLES MADE FROM DOUGH Machines or Equipment, including e.g. hand tools or trays, for preparing, shaping and processing edible

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

(19) United States US 2013 O149423A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0149423 A1 Lix (43) Pub. Date: Jun. 13, 2013 (54) WHISKEY MAKING METHOD Publication Classification (75) Inventor:

Eaton Filtration, LLC

Eaton Filtration, LLC 44 Apple Street, Tinton Falsl NJ 07724 Phone: 732-212-4700 Fax: 952-906-3706 E-Mail: filtration@eaton.com Web: www.eaton.com/filtration Installation, Operation & Service Manual Model

Eaton Filtration, LLC 44 Apple Street, Tinton Falsl NJ 07724 Phone: 732-212-4700 Fax: 952-906-3706 E-Mail: filtration@eaton.com Web: www.eaton.com/filtration Installation, Operation & Service Manual Model

United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

III US00532.3693A United States Patent (19) 11 Patent Number: 5,323,693 Collard et al. (45) Date of Patent: Jun. 28, 1994 (54) COMBINATION FRYING PAN INSERT AND 3,469,524 9/1969 FRYING PAN 3,837,330 9/1974

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

(19) United States US 2005O260324A1 (12) Patent Application Publication (10) Pub. No.: US 2005/0260324 A1 BOrtolato (43) Pub. Date: (54) AROMATIZED WINE-BASED DRINK (75) Inventor: Massimo Bortolato, Pescantina

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0284884 A1 Roy-Wedderburn US 2005O284884A1 (43) Pub. Date: (54) (76) (21) (22) (60) WINE KIT AND METHOD FOR MAKING WINE Inventor:

EFFECT OF TOMATO GENETIC VARIATION ON LYE PEELING EFFICACY TOMATO SOLUTIONS JIM AND ADAM DICK SUMMARY

EFFECT OF TOMATO GENETIC VARIATION ON LYE PEELING EFFICACY TOMATO SOLUTIONS JIM AND ADAM DICK 2013 SUMMARY Several breeding lines and hybrids were peeled in an 18% lye solution using an exposure time of

EFFECT OF TOMATO GENETIC VARIATION ON LYE PEELING EFFICACY TOMATO SOLUTIONS JIM AND ADAM DICK 2013 SUMMARY Several breeding lines and hybrids were peeled in an 18% lye solution using an exposure time of

Aaawaw A. M1axsom. - A 474/2/sr.przezz' SecY72/7. April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES.

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

April 9, 1963 D. B. MAXSON 3,084,613 MACHINE FOR BREWING AND DISPENSING HOT BEVERAGES Filed Aug. 10, 199 4 Sheets-Sheet l 1622.Éry Aer Aea/ 77%erzas/af 23 Arew sérez2/4 - A 474/2/sr.przezz' SecY72/7 -

United States Patent (19)

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

United States Patent (19) Traeger et al. (54) (76) (21) 22 (51) (52) (58 (56) PELLET-FIRED BARBEGUE Inventors: Joseph P. Traeger, 250 S. Oak St.; Randolph J. Traeger, 530 Alder St.; Mark A. Traeger, 540

YEDENT AGRO GROUP OF COMPANIES PROCESSING OF SOY BASED PRODUCTS FOR HUMAN FOODS AND POULTRY FEEDS

YEDENT AGRO GROUP OF COMPANIES PROCESSING OF SOY BASED PRODUCTS FOR HUMAN FOODS AND POULTRY FEEDS 1. SOYA EXTRUSION AND PRESSING PROCESS EQUIPMENT 1. The Pre Cleaner 2. The Course Mill 3. The Extruder

YEDENT AGRO GROUP OF COMPANIES PROCESSING OF SOY BASED PRODUCTS FOR HUMAN FOODS AND POULTRY FEEDS 1. SOYA EXTRUSION AND PRESSING PROCESS EQUIPMENT 1. The Pre Cleaner 2. The Course Mill 3. The Extruder

(12) United States Patent (10) Patent No.: US 6,419,120 B1

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

USOO641912OB1 (12) United States Patent (10) Patent No.: BertOne (45) Date of Patent: Jul. 16, 2002 (54) MULTI-FLAVORED HOT BEVERAGE 6,202,894 B1 * 3/2001 Struminski et al.... 222/129.3 DSPENSER * cited

United States Patent (19)

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

United States Patent (19) Hayashi (54) BIOCHEMICAL REACTION ANALYZING APPARATUS 75 Inventor: Hidechika Hayashi, Yokohama, Japan 73 Assignee: Tosoh Corporation, Shinnanyo, Japan (21) Appl. No.: 503,109

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0187694 A1 Cai US 2004O187694A1 (43) Pub. Date: (54) (76) (21) (22) (63) HOLDER FOR PRESSURE-BREWING COFFEE DRINK Inventor:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0187694 A1 Cai US 2004O187694A1 (43) Pub. Date: (54) (76) (21) (22) (63) HOLDER FOR PRESSURE-BREWING COFFEE DRINK Inventor:

United States Patent (19) Kovacevich, Jr.

United States Patent (19) Kovacevich, Jr. 11 Patent Number: Date of Patent: Jun. 9, 1987 54) 76 21 22 63 (51) 52 58 56) WNE DISTRIBUTION METHOD Inventor: Appl. No.: Filed: Sam Kovacevich, Jr., R.R. 1,

United States Patent (19) Kovacevich, Jr. 11 Patent Number: Date of Patent: Jun. 9, 1987 54) 76 21 22 63 (51) 52 58 56) WNE DISTRIBUTION METHOD Inventor: Appl. No.: Filed: Sam Kovacevich, Jr., R.R. 1,

A33. AORNEY. March 22, G. C. HERZ, 1,850,719. APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC. Filed Dec, l6, l Sheets-Sheet l NVENTOR

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

March 22, 1932. G. C. HERZ, 1,0,719 APPARATUS FOR CLEANING COFFEE, COCoA BEANS, ETC Filed Dec, l6, l929 2. Sheets-Sheet l rece? assess asses casessers Ssssss sts W NVENTOR A33. AORNEY March 22, 1932. G.

For Beer with Character

Yeast technology For Beer with Character Yeast technology Fresh yeast for Beer with Character The raw material yeast plays a crucial role in breweries. A wide range of flavors can be produced in beer using

Yeast technology For Beer with Character Yeast technology Fresh yeast for Beer with Character The raw material yeast plays a crucial role in breweries. A wide range of flavors can be produced in beer using

(12) United States Patent (10) Patent No.: US 6,813,994 B2

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

USOO6813994B2 (12) United States Patent (10) Patent No.: Williams () Date of Patent: Nov. 9, 2004 (54) MULTI-COMPARTMENTED GRIDDLE IRON 3,994.211 11/1976 Stanek 4,3,516 A 8/1982 Sinclair... 99/426 (76)

SOFTDOUGH & COOKIES cat_softdough_rev12gea.indd 1 22/07/

SOFTDOUGH & COOKIES The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given them our

SOFTDOUGH & COOKIES The basic ingredient. We know how. Ever since we first started, in 1962, we have always felt ourselves to be part of our customers recipies. This is why we have always given them our

Beer Hardware, Systems and Delivery

Beer Hardware, Systems and Delivery An Industry Standard Beer is the number one dispensed beverage in the foodservice industry. Commonly, draft beer is preferred by a wide margin for taste and product

Beer Hardware, Systems and Delivery An Industry Standard Beer is the number one dispensed beverage in the foodservice industry. Commonly, draft beer is preferred by a wide margin for taste and product

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. Lange (43) Pub. Date: Nov. 22, 2012

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

US 20120294997 A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0294997 A1 Lange (43) Pub. Date: Nov. 22, 2012 (54) EDIBLE BAKING LINER Publication Classification (51) Int.

BAKING SCIENCE AND TECHNOLOGY

BAKING SCIENCE AND TECHNOLOGY Learning Objectives Describe the purpose of mixing List common types of bread mixers Explain what mixing does to the dough and flour components Explain delayed mixing method

BAKING SCIENCE AND TECHNOLOGY Learning Objectives Describe the purpose of mixing List common types of bread mixers Explain what mixing does to the dough and flour components Explain delayed mixing method

ta-v, 9-1-N Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS EDWARD E ANDERSON ATORNEYS JACK D.

Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May 10, 1965 5 Sheets-Sheet INVENTORS EDWARD E ANDERSON JACK D. BROWN ta-v, 9-1-N-11-4. ATORNEYS Oct. 11,

Oct. 11, 1966 J. D., BROWN ETAL 3,278,311 METHOD OF MANUFACTURING CORN DOUGH AND CORN CHIPS Filed May 10, 1965 5 Sheets-Sheet INVENTORS EDWARD E ANDERSON JACK D. BROWN ta-v, 9-1-N-11-4. ATORNEYS Oct. 11,

3,702,608 11/1972 Tibbs. states by bying O st plunger T.

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

US006048334A United States Patent (19) 11 Patent Number: Hirschman et al. (45) Date of Patent: Apr. 11, 2000 54 SYRINGE, INJECTOR AND INJECTOR FOREIGN PATENT DOCUMENTS SYSTEM 0064858 A1 11/1982 European

R. 36. azzo 1/2-Za-Yas. Nov. 18, 1969 J. P. H. LANES 3,478,669 APPARATUS FOR MAKING WINE Z2/27/7212. E. y N AA A. as SS f.

Nov. 18, 1969 J. P. H. LANES APPARATUS FOR MAKING WINE Filed Sept. 16, 1966 2. Sheets-Sheet l R. 36. re-war Nanuma - measuresheat s, a. AA A. E. y N as SS f M Z2/27/7212 azzo 1/2-Za-Yas Nov. 18, 1969 J.

Nov. 18, 1969 J. P. H. LANES APPARATUS FOR MAKING WINE Filed Sept. 16, 1966 2. Sheets-Sheet l R. 36. re-war Nanuma - measuresheat s, a. AA A. E. y N as SS f M Z2/27/7212 azzo 1/2-Za-Yas Nov. 18, 1969 J.

United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993

USOO5230281A United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993 (54) APPARATUS FOR ROASTING COFFEE 4,924.765 5/1990 Pera... 99/470 BEANS OR THE LIKE

USOO5230281A United States Patent (19) 11) Patent Number: 5,230,281 Wireman et al. (45. Date of Patent: Jul. 27, 1993 (54) APPARATUS FOR ROASTING COFFEE 4,924.765 5/1990 Pera... 99/470 BEANS OR THE LIKE

ACME Fluid Systems. Strainer Selection Guidelines Web:

ACME Fluid Systems Strainer Selection Guidelines E-mail: info@strainersindia.com Web: www.strainersindia.com Introduction This document provides a general introduction to the parameters to be kept in mind

ACME Fluid Systems Strainer Selection Guidelines E-mail: info@strainersindia.com Web: www.strainersindia.com Introduction This document provides a general introduction to the parameters to be kept in mind

ZPM Mixer. Continuous mixing system

Mixer Continuous mixing system MIXER Continuous mixing system The continuous mixing system consists of several elements: Basic frame, drive support and pull-out frame with levelling legs for fastening

Mixer Continuous mixing system MIXER Continuous mixing system The continuous mixing system consists of several elements: Basic frame, drive support and pull-out frame with levelling legs for fastening

United States Patent (19) D'Alessandro

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

United States Patent (19) D'Alessandro 54 (76) 21) 22 (51) 52 (58) (56) WOOD BURNINGSTOVE AND OVEN Inventor: Sebastiano D'Alessandro, 74 Knockbolt Crescent, Scarborough, Ontario M1S2P6, Canada Appl. No.:

HONEY. Food and Agriculture Organization of the United Nations

HONEY Food and Agriculture Organization of the United Nations HONEY 1.- Honey General Information Honey has a fluid, crystallized (total or partially) consistence. Present a high viscosity and density

HONEY Food and Agriculture Organization of the United Nations HONEY 1.- Honey General Information Honey has a fluid, crystallized (total or partially) consistence. Present a high viscosity and density

PATENT ATTORNEYS EXAMINATION

2014 PATENT ATTORNEYS EXAMINATION PAPER E The New Zealand Law and Practice relating to Interpretation and Criticism of Patent Specifications Regulation 158 (1) (e) Duration: 4 hours (plus 10 minutes for

2014 PATENT ATTORNEYS EXAMINATION PAPER E The New Zealand Law and Practice relating to Interpretation and Criticism of Patent Specifications Regulation 158 (1) (e) Duration: 4 hours (plus 10 minutes for

PART III. THE HULLING OF PADDY

PART III. THE HULLING OF PADDY The objective of a hulling machine is to remove the husk from the paddy grain with a minimum of damage to the bran layer and, if possible, without breaking the brown rice

PART III. THE HULLING OF PADDY The objective of a hulling machine is to remove the husk from the paddy grain with a minimum of damage to the bran layer and, if possible, without breaking the brown rice

---- ÆØerá Z3zzegzée. Vzerzega2ZY.Zazee. June 16, Zee/ErzezØrzs 2,286, Sheets-Sheet 2 D G O D D D OD

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

June 16, 1942. M. PRINGLE ET AL METHOD AND APPARATUS FOR PROCESSING POTATOES Filed March 5, 1937 2 Sheets-Sheet 2 D G O D D D OD 0 0 0 0 C Q 0 ] O O G B C D E DO O D C D O G 0 0 0 0 0 0 0 0 0 0 D G D D

CHEM Experiment 4 Introduction to Separation Techniques I. Objectives

1 CHEM 0011 Experiment 4 Introduction to Separation Techniques I Objectives 1. To learn the gravity filtration technique 2. To learn the suction filtration technique 3. To learn about solvent extraction

1 CHEM 0011 Experiment 4 Introduction to Separation Techniques I Objectives 1. To learn the gravity filtration technique 2. To learn the suction filtration technique 3. To learn about solvent extraction

Peanut Cleaner. Frank s Designs for Peanuts, LLC Peanut Meds & Foods for Kids Haiti

Peanut Cleaner Frank s Designs for Peanuts, LLC Peanut cleaner @ Meds & Foods for Kids Haiti This cleaner is designed to clean peanuts prior to storage or shelling. Clean peanuts will store better with

Peanut Cleaner Frank s Designs for Peanuts, LLC Peanut cleaner @ Meds & Foods for Kids Haiti This cleaner is designed to clean peanuts prior to storage or shelling. Clean peanuts will store better with

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

US 2004OO16772A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0016772 A1 Rupp (43) Pub. Date: Jan. 29, 2004 (54) FLAVOR DISPENSING DEVICE Publication Classification (76)

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

(19) United States US 2013025 1877A1 (12) Patent Application Publication (10) Pub. No.: US 2013/0251877 A1 Levin et al. (43) Pub. Date: Sep. 26, 2013 (54) SNACKPRODUCTS AND METHOD FOR A2.3L I/27 (2006.01)

GE Active Containment Sump Strainer for PWR Applications

GE Active Containment Sump Strainer for PWR Applications IEEE/NPEC/SC2 MEETING 05-1 Ed Mohtashemi Principal Engineer APRIL 20-21, 2005 San Diego, CA. Agenda Summary/Background Active Strainer Overview

GE Active Containment Sump Strainer for PWR Applications IEEE/NPEC/SC2 MEETING 05-1 Ed Mohtashemi Principal Engineer APRIL 20-21, 2005 San Diego, CA. Agenda Summary/Background Active Strainer Overview

Product Consistency Comparison Study: Continuous Mixing & Batch Mixing

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

July 2015 Product Consistency Comparison Study: Continuous Mixing & Batch Mixing By: Jim G. Warren Vice President, Exact Mixing Baked snack production lines require mixing systems that can match the throughput

Dough Expert. Member of the

Dough Expert Dividing Rounding Proofing Moulding Member of the Dough Expert General The Dough Expert has a universal application and industrial design which is suitable for a wide range of dough processes.

Dough Expert Dividing Rounding Proofing Moulding Member of the Dough Expert General The Dough Expert has a universal application and industrial design which is suitable for a wide range of dough processes.

Notes on pressure fermentation

Notes on pressure fermentation Geoff Dye During World War II the fermenting room at Coopers Brewery, Southampton, received a direct hit which put it completely out of action, but left the brewhouse (wort

Notes on pressure fermentation Geoff Dye During World War II the fermenting room at Coopers Brewery, Southampton, received a direct hit which put it completely out of action, but left the brewhouse (wort

TILT-HEAD STAND MIXER FEATURES

ENGLISH TILT-HEAD STAND MIXER FEATURES Speed Control Knob Motor Head Attachment Hub Attachment Knob Motor Head Locking Lever (not shown) Beater Shaft Flat Beater Beater Height Adjustment Screw Wire Whip

ENGLISH TILT-HEAD STAND MIXER FEATURES Speed Control Knob Motor Head Attachment Hub Attachment Knob Motor Head Locking Lever (not shown) Beater Shaft Flat Beater Beater Height Adjustment Screw Wire Whip

(12) United States Patent

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

USOO945 1844B2 (12) United States Patent Olucha Soler et al. (10) Patent No.: (45) Date of Patent: US 9.451,844 B2 Sep. 27, 2016 (54) DEVICE FOR DIRECTLY OBTAINING JUICE FROM FRUIT (75) Inventors: Jordi

Section 3 Dough Management

Section 3 Dough Management Dough is the foundation of our pizza. Dough is the least expensive part of the pizza. Never use dough that is not perfect. If the dough is not perfect, throw it out. Without

Section 3 Dough Management Dough is the foundation of our pizza. Dough is the least expensive part of the pizza. Never use dough that is not perfect. If the dough is not perfect, throw it out. Without

(51) Int Cl.: A47J 31/18 ( ) A47J 31/46 ( )

(19) TEPZZ 7_ 95B_T (11) EP 2 712 295 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention of the grant of the patent: 31.08.16 Bulletin 16/35 (21) Application number: 12712780.1

(19) TEPZZ 7_ 95B_T (11) EP 2 712 295 B1 (12) EUROPEAN PATENT SPECIFICATION (45) Date of publication and mention of the grant of the patent: 31.08.16 Bulletin 16/35 (21) Application number: 12712780.1

MDD. High Speed Mixer. Member of the

MDD High Speed Mixer Mixing Dividing Rounding Proofing Moulding Member of the Mixing Dividing Rounding Proofing Moulding MDD High Speed Mixer Mechanical Dough Developers Benier Nederland BV manufactures

MDD High Speed Mixer Mixing Dividing Rounding Proofing Moulding Member of the Mixing Dividing Rounding Proofing Moulding MDD High Speed Mixer Mechanical Dough Developers Benier Nederland BV manufactures

89 Sugar and starch production

The German Patent Classification, Class 89 Page 1 89 Sugar and starch production 89a Washing, conveying and storage devices for beets and potatoes Comminution of sugar beets and sugar cane; treatment of

The German Patent Classification, Class 89 Page 1 89 Sugar and starch production 89a Washing, conveying and storage devices for beets and potatoes Comminution of sugar beets and sugar cane; treatment of

Commercial Ovens. trimarkusa.com

Commercial Ovens When purchasing the ideal oven to fit your needs, focus on features that will efficiently and consistently produce the quality food your guests will enjoy. trimarkusa.com info@trimarkusa.com

Commercial Ovens When purchasing the ideal oven to fit your needs, focus on features that will efficiently and consistently produce the quality food your guests will enjoy. trimarkusa.com info@trimarkusa.com

5 Litre Party Keg Manual

5 Litre Party Keg Manual These compact party kegs let you keg your beer and serve it on tap without the need for gas bottles, pressure regulators, cooler plates with ice and a mess of hose pipes and couplers.

5 Litre Party Keg Manual These compact party kegs let you keg your beer and serve it on tap without the need for gas bottles, pressure regulators, cooler plates with ice and a mess of hose pipes and couplers.

COALHO CHEESE. Food and Agriculture Organization of the United Nations

COALHO CHEESE Food and Agriculture Organization of the United Nations COALHO CHEESE 1.- Coalho Cheese - General Information The Coalho-type cheese is widely produced in under developed Brazilian states,

COALHO CHEESE Food and Agriculture Organization of the United Nations COALHO CHEESE 1.- Coalho Cheese - General Information The Coalho-type cheese is widely produced in under developed Brazilian states,

United States Patent (19) Adams et al.

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

United States Patent (19) Adams et al. (11 Patent Number: (45) Date of Patent: Mar. 19, 1991 54 PROCESS FOR ENZYME PEELING OF FRESH CITRUS FRUIT 75) Inventors: Bruce Adams, Pomona; William Kirk, Alta Loma,

300 Kilogram Coffee Roaster

300 Kilogram Coffee Roaster Brian Biggerstaff Jeff Biggerstaff Justin Ludwig Jess Webb 1 US Roaster Corp Owner Dan Joliff Serving the roasting industry for 33 years Located in Oklahoma City, Oklahoma Provide

300 Kilogram Coffee Roaster Brian Biggerstaff Jeff Biggerstaff Justin Ludwig Jess Webb 1 US Roaster Corp Owner Dan Joliff Serving the roasting industry for 33 years Located in Oklahoma City, Oklahoma Provide

Paper 7: Technology of Milk and Milk Products. Module no. 6: Cream Separation in Dairy Industry

Paper 7: Technology of Milk and Milk Products Module no. 6: Cream Separation in Dairy Industry Introduction Milk from the cattle contains a number of large and small butter-fat particles held in suspension.

Paper 7: Technology of Milk and Milk Products Module no. 6: Cream Separation in Dairy Industry Introduction Milk from the cattle contains a number of large and small butter-fat particles held in suspension.

CAUTIONS FOR ALL DEEP FAT FRYERS NEVER LEAVE AN OPERATING FRYER UNATTENDED REMEMBER HOT OIL IS DANGEROUS RESPECT IT! WARNING INSTALLATION Locate your

CAUTIONS FOR ALL DEEP FAT FRYERS NEVER LEAVE AN OPERATING FRYER UNATTENDED REMEMBER HOT OIL IS DANGEROUS RESPECT IT! WARNING INSTALLATION Locate your fryer in a protected place so that it cannot be tipped

CAUTIONS FOR ALL DEEP FAT FRYERS NEVER LEAVE AN OPERATING FRYER UNATTENDED REMEMBER HOT OIL IS DANGEROUS RESPECT IT! WARNING INSTALLATION Locate your fryer in a protected place so that it cannot be tipped

EQUIPMENT FOR MAKING BABCOCK TEST FOR FAT IN MILK

}L~c ~ ~Babcock Test T HE for Fat in Mi~k By J. ~ JJ R Professor of Dairy Chemistry Research....,) ~ '( li: )..-djg's BABCOCK TEST is the most satisfactory and practical method for determining the percentage